fuel pressure RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 307 of 329

13B-307

MR-372-J84-13B050$936.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Tests13B

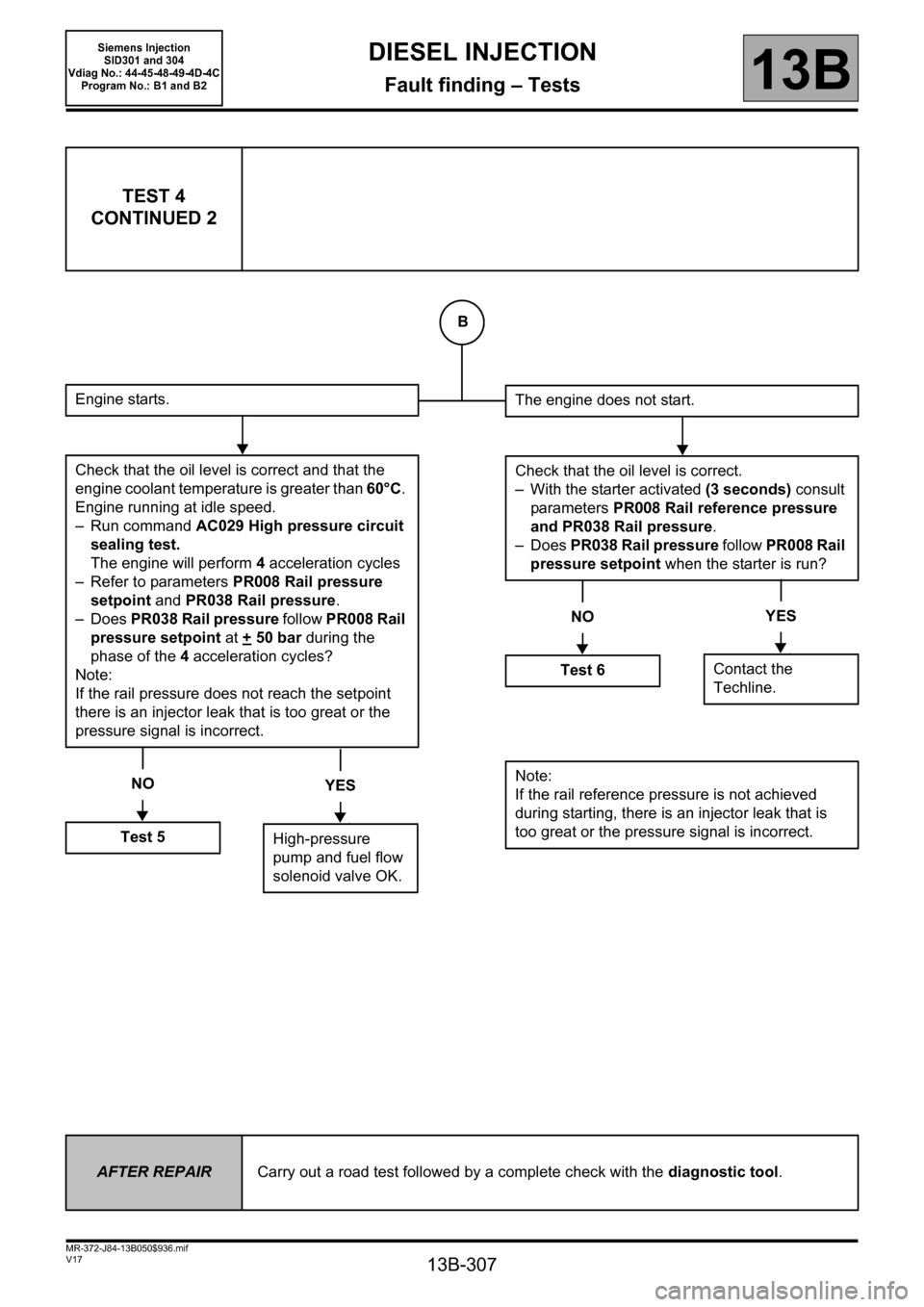

TEST 4

CONTINUED 2

Engine starts.

Check that the oil level is correct and that the

engine coolant temperature is greater than 60°C.

Engine running at idle speed.

– Run command AC029 High pressure circuit

sealing test.

The engine will perform 4acceleration cycles

– Refer to parameters PR008 Rail pressure

setpoint and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint at +

50 bar during the

phase of the 4 acceleration cycles?

Note:

If the rail pressure does not reach the setpoint

there is an injector leak that is too great or the

pressure signal is incorrect.

NO

Test 5

YES

High-pressure

pump and fuel flow

solenoid valve OK.

The engine does not start.

Check that the oil level is correct.

– With the starter activated (3 seconds) consult

parameters PR008 Rail reference pressure

and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint when the starter is run?

NO

Test 6

YES

Contact the

Techline.

Note:

If the rail reference pressure is not achieved

during starting, there is an injector leak that is

too great or the pressure signal is incorrect.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

Page 308 of 329

13B-308

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

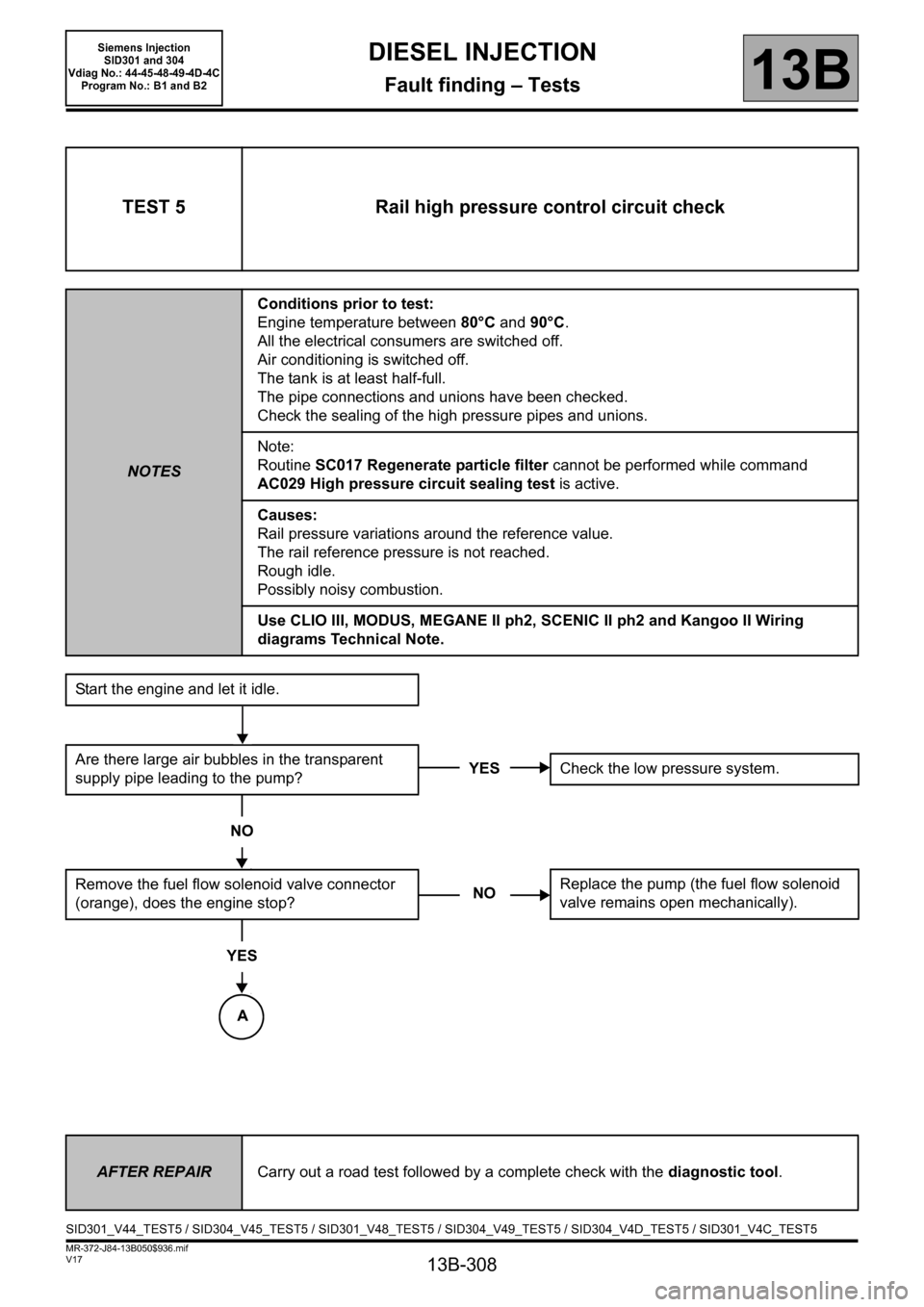

TEST 5 Rail high pressure control circuit check

NOTESConditions prior to test:

Engine temperature between 80°C and 90°C.

All the electrical consumers are switched off.

Air conditioning is switched off.

The tank is at least half-full.

The pipe connections and unions have been checked.

Check the sealing of the high pressure pipes and unions.

Note:

Routine SC017 Regenerate particle filter cannot be performed while command

AC029 High pressure circuit sealing test is active.

Causes:

Rail pressure variations around the reference value.

The rail reference pressure is not reached.

Rough idle.

Possibly noisy combustion.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Start the engine and let it idle.

Are there large air bubbles in the transparent

supply pipe leading to the pump?

NO

Remove the fuel flow solenoid valve connector

(orange), does the engine stop?

YES

YESCheck the low pressure system.

NOReplace the pump (the fuel flow solenoid

valve remains open mechanically).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST5 / SID304_V45_TEST5 / SID301_V48_TEST5 / SID304_V49_TEST5 / SID304_V4D_TEST5 / SID301_V4C_TEST5

A

Page 309 of 329

13B-309

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

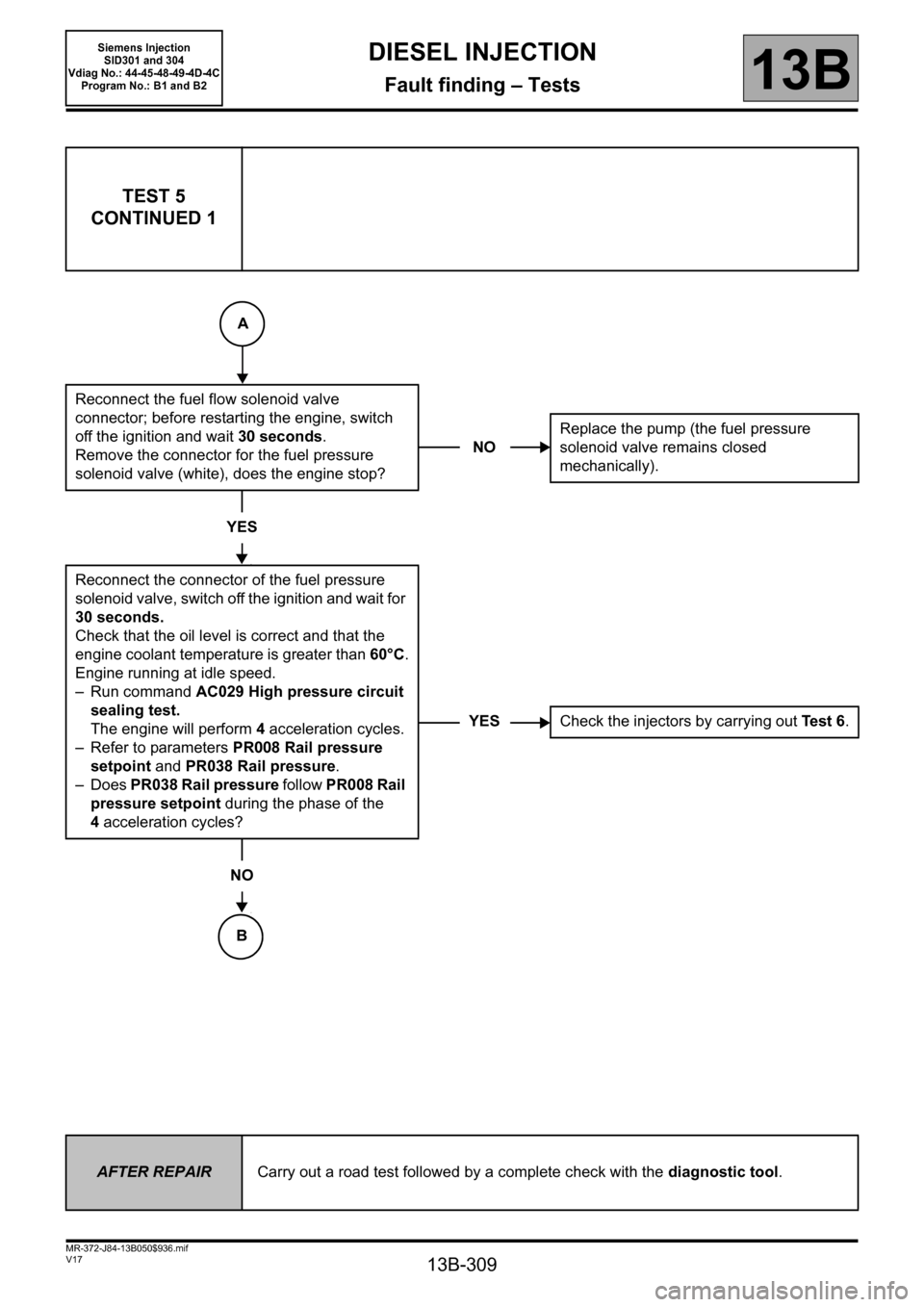

TEST 5

CONTINUED 1

Reconnect the fuel flow solenoid valve

connector; before restarting the engine, switch

off the ignition and wait 30 seconds.

Remove the connector for the fuel pressure

solenoid valve (white), does the engine stop?

YES

Reconnect the connector of the fuel pressure

solenoid valve, switch off the ignition and wait for

30 seconds.

Check that the oil level is correct and that the

engine coolant temperature is greater than 60°C.

Engine running at idle speed.

– Run command AC029 High pressure circuit

sealing test.

The engine will perform 4acceleration cycles.

– Refer to parameters PR008 Rail pressure

setpoint and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint during the phase of the

4acceleration cycles?

NO

NOReplace the pump (the fuel pressure

solenoid valve remains closed

mechanically).

YESCheck the injectors by carrying out Te s t 6.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

B

Page 310 of 329

13B-310

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

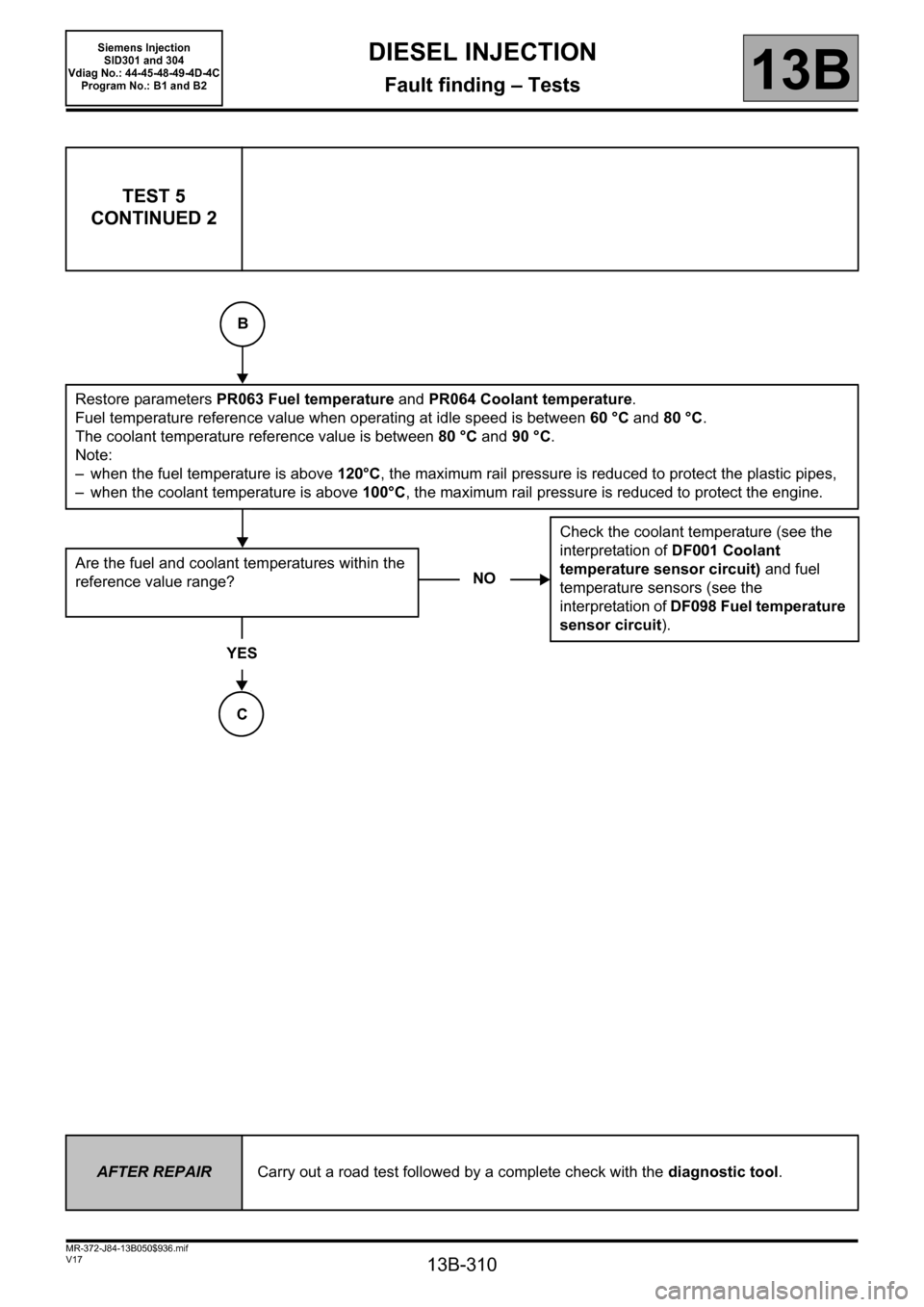

TEST 5

CONTINUED 2

Restore parameters PR063 Fuel temperature and PR064 Coolant temperature.

Fuel temperature reference value when operating at idle speed is between 60 °C and 80 °C.

The coolant temperature reference value is between 80 °C and 90 °C.

Note:

– when the fuel temperature is above 120°C, the maximum rail pressure is reduced to protect the plastic pipes,

– when the coolant temperature is above 100°C, the maximum rail pressure is reduced to protect the engine.

Are the fuel and coolant temperatures within the

reference value range?

YES

NOCheck the coolant temperature (see the

interpretation of DF001 Coolant

temperature sensor circuit) and fuel

temperature sensors (see the

interpretation of DF098 Fuel temperature

sensor circuit).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

C

Page 311 of 329

13B-311

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

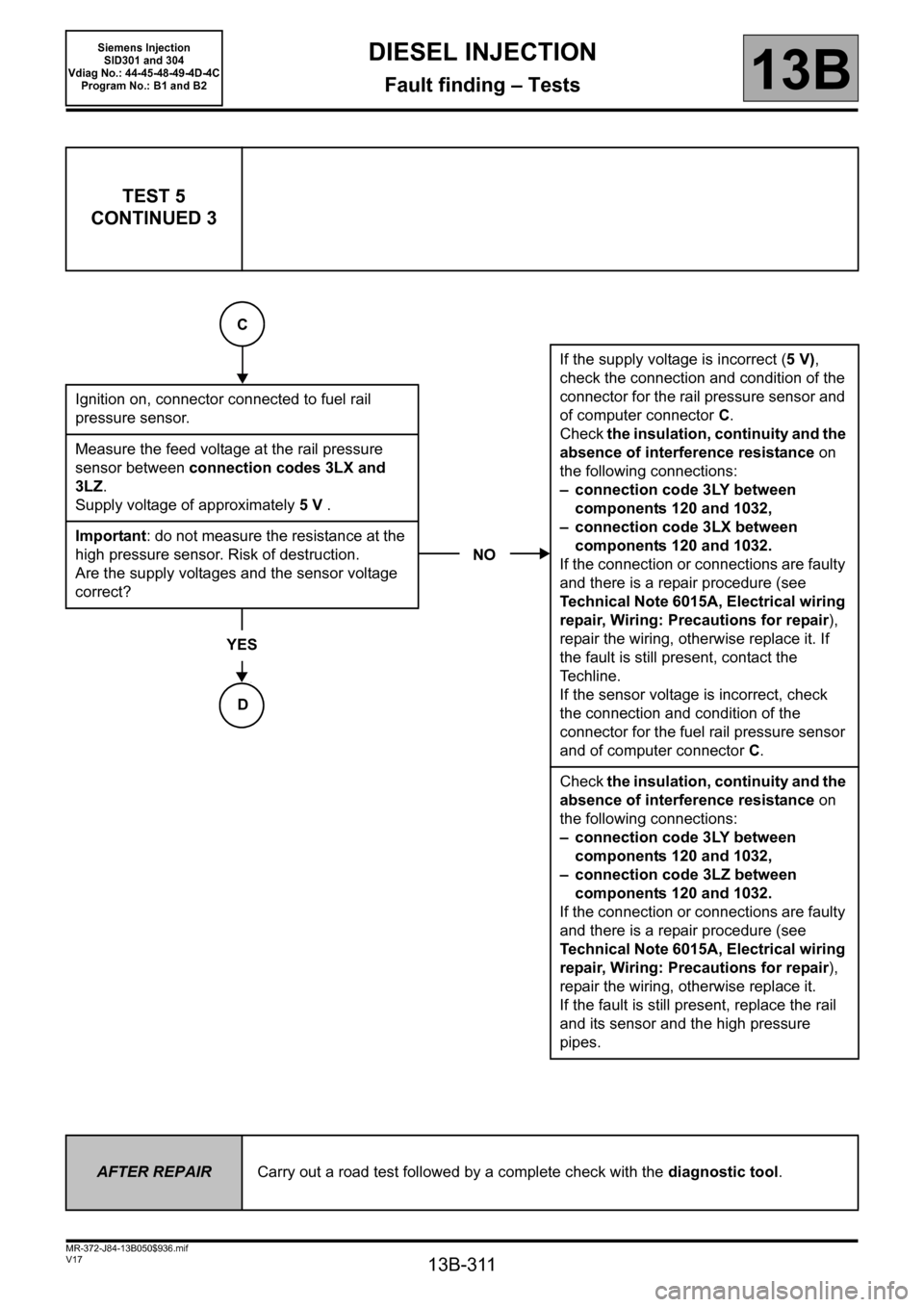

TEST 5

CONTINUED 3

Ignition on, connector connected to fuel rail

pressure sensor.

Measure the feed voltage at the rail pressure

sensor between connection codes 3LX and

3LZ.

Supply voltage of approximately 5V .

Important: do not measure the resistance at the

high pressure sensor. Risk of destruction.

Are the supply voltages and the sensor voltage

correct?

YES

NOIf the supply voltage is incorrect (5 V),

check the connection and condition of the

connector for the rail pressure sensor and

of computer connector C.

Check the insulation, continuity and the

absence of interference resistance on

the following connections:

– connection code 3LY between

components 120 and 1032,

– connection code 3LX between

components 120 and 1032.

If the connection or connections are faulty

and there is a repair procedure (see

Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace it. If

the fault is still present, contact the

Techline.

If the sensor voltage is incorrect, check

the connection and condition of the

connector for the fuel rail pressure sensor

and of computer connector C.

Check the insulation, continuity and the

absence of interference resistance on

the following connections:

– connection code 3LY between

components 120 and 1032,

– connection code 3LZ between

components 120 and 1032.

If the connection or connections are faulty

and there is a repair procedure (see

Technical Note 6015A, Electrical wiring

repair, Wiring: Precautions for repair),

repair the wiring, otherwise replace it.

If the fault is still present, replace the rail

and its sensor and the high pressure

pipes.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

C

D

Page 313 of 329

13B-313

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

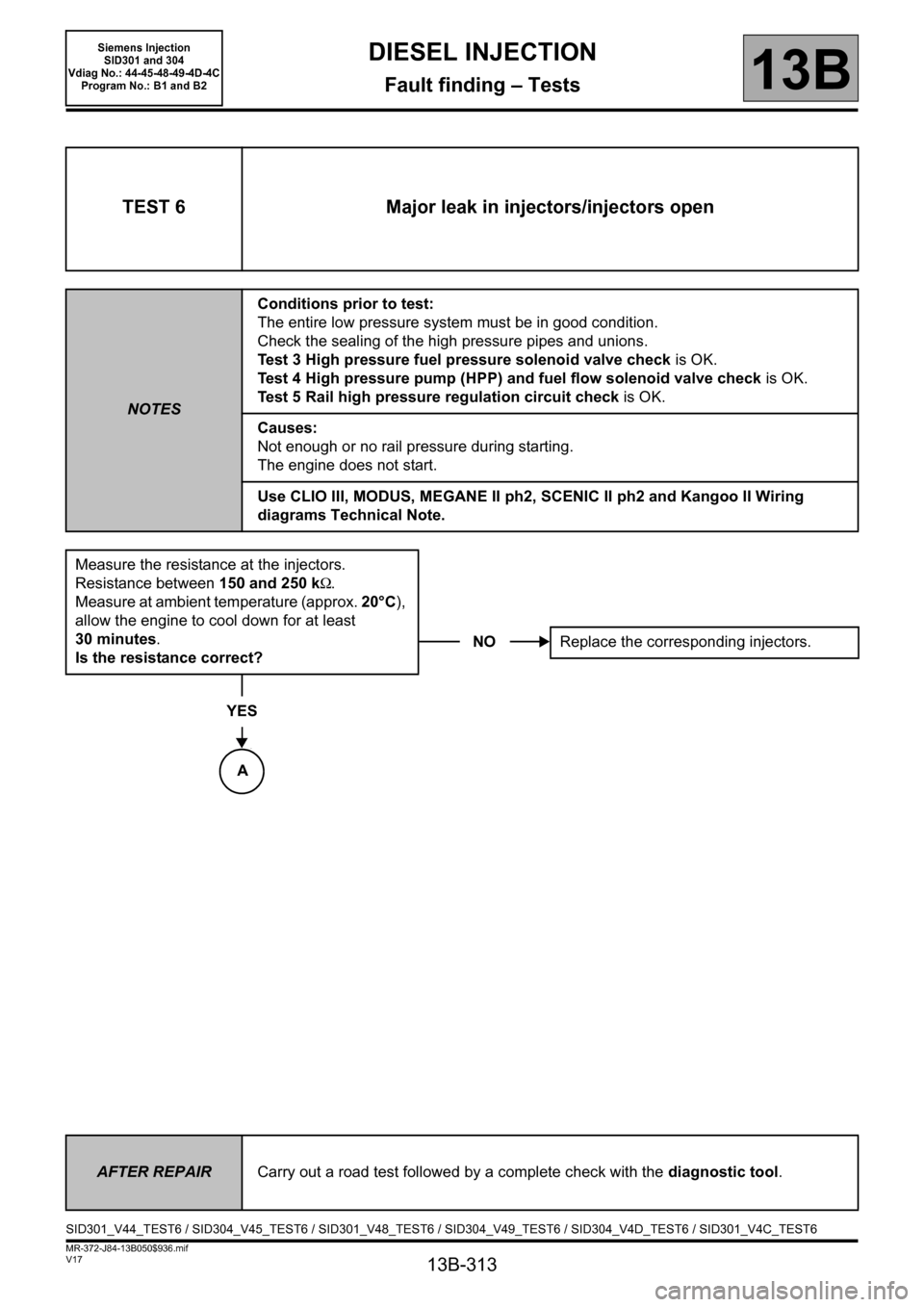

TEST 6 Major leak in injectors/injectors open

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

Causes:

Not enough or no rail pressure during starting.

The engine does not start.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Measure the resistance at the injectors.

Resistance between 150 and 250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Is the resistance correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST6 / SID304_V45_TEST6 / SID301_V48_TEST6 / SID304_V49_TEST6 / SID304_V4D_TEST6 / SID301_V4C_TEST6

A

Page 315 of 329

13B-315

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

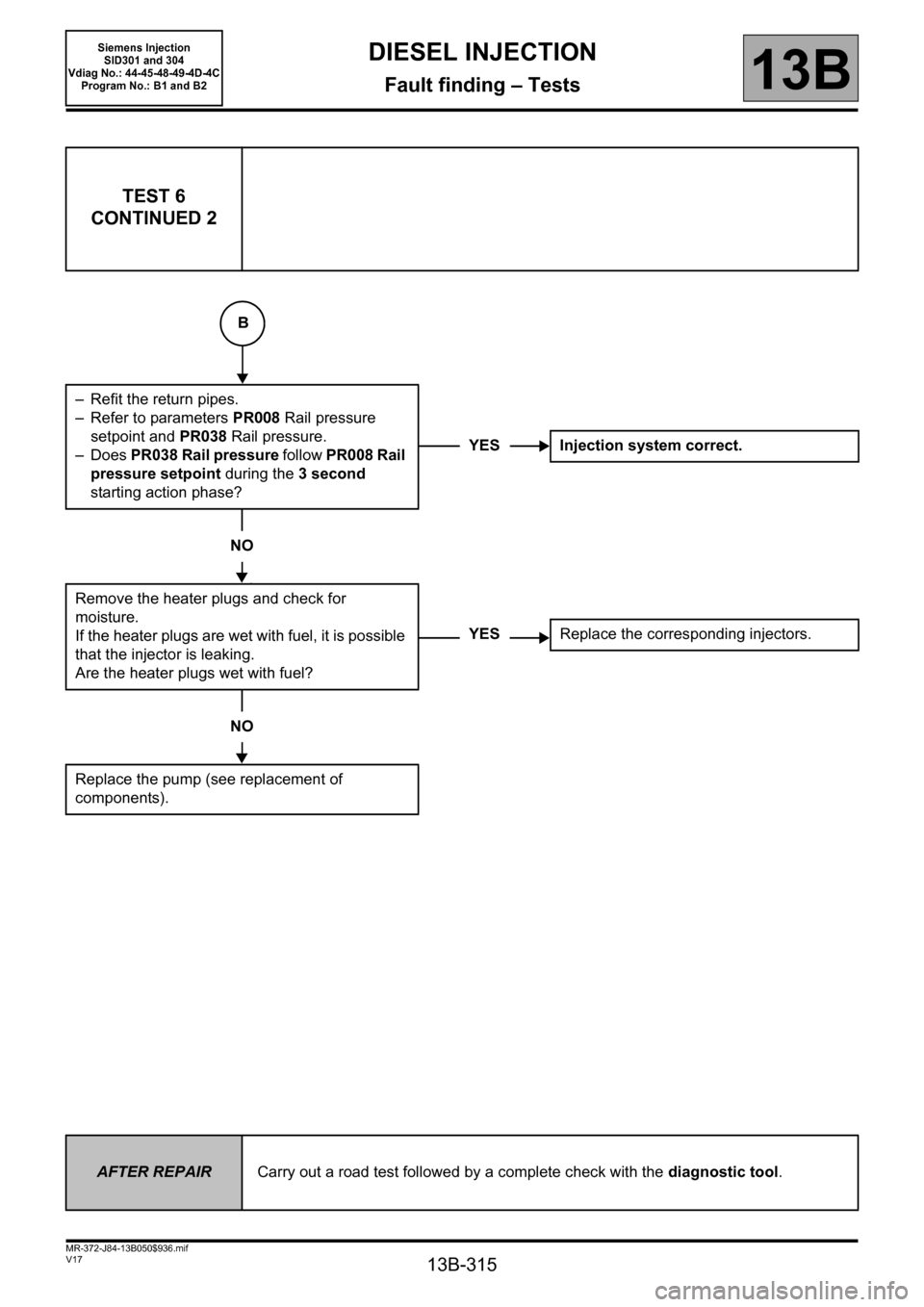

TEST 6

CONTINUED 2

– Refit the return pipes.

– Refer to parameters PR008 Rail pressure

setpoint and PR038 Rail pressure.

–Does PR038 Rail pressure follow PR008 Rail

pressure setpoint during the 3second

starting action phase?

NO

Remove the heater plugs and check for

moisture.

If the heater plugs are wet with fuel, it is possible

that the injector is leaking.

Are the heater plugs wet with fuel?

NO

Replace the pump (see replacement of

components).

YES Injection system correct.

YESReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

B

Page 316 of 329

13B-316

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

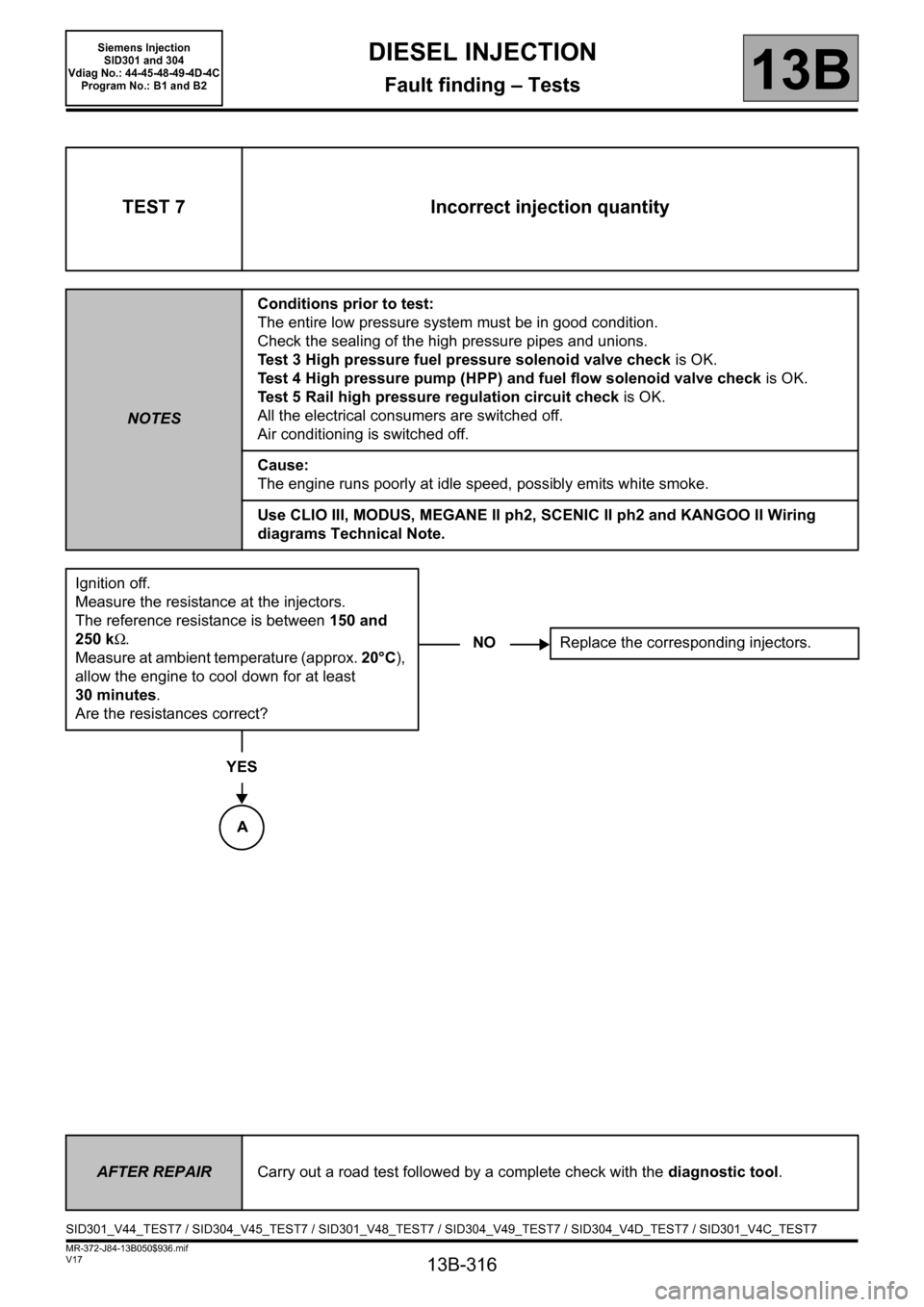

TEST 7 Incorrect injection quantity

NOTESConditions prior to test:

The entire low pressure system must be in good condition.

Check the sealing of the high pressure pipes and unions.

Te s t 3 High pressure fuel pressure solenoid valve check is OK.

Test 4 High pressure pump (HPP) and fuel flow solenoid valve check is OK.

Te s t 5 Rail high pressure regulation circuit check is OK.

All the electrical consumers are switched off.

Air conditioning is switched off.

Cause:

The engine runs poorly at idle speed, possibly emits white smoke.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and KANGOO II Wiring

diagrams Technical Note.

Ignition off.

Measure the resistance at the injectors.

The reference resistance is between 150 and

250 kΩ.

Measure at ambient temperature (approx. 20°C),

allow the engine to cool down for at least

30 minutes.

Are the resistances correct?

YES

NOReplace the corresponding injectors.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST7 / SID304_V45_TEST7 / SID301_V48_TEST7 / SID304_V49_TEST7 / SID304_V4D_TEST7 / SID301_V4C_TEST7

A

Page 319 of 329

13B-319

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 8

CONTINUED 1

Particle filter injector fuel system pressurisation check (pressure test):

To check the pressure in the particle filter injector fuel system:

●Connect the T-union Mot 1311-08 to the particle filter injector fuel filter outlet (adapter visible without

dismantling).

●Connect the pressure gauge Mot 1311-01 to the T-union.

Pressurise the fuel system using the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure in the system is about 1 bar, perform the command a second time.

The pressure must be at least 3 bar.

If the fuel pressure is less than 3 bar, proceed as follows:

●Carry out a visual inspection of the flexible supply hose to the particle filter injector, before and after the

T-union (leaks, pinching, fuel filter condition, etc.).

Pressurise the fuel system again with the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure is not equal to or above 3 bar, replace the pump/sender unit (see Technical Note 5117A, Special

features of vehicles fitted with the K9K 772 engine).

Checking the pressure regulator:

●Run command AC237 Fuel pump relay, until the fuel pressure reaches 5 bar.

●Reactivate command AC237 Fuel pump relay again to check that the pressure is controlled between 5.5 bar

and 5 bar.

If the regulator is not working, replace the pump/sender unit (see Technical Note 5117A, Special features of

vehicles fitted with the K9K 772 engine).

Note:

To reduce the pressure in the system, run command AC238 Particle filter injector, until it drops to 3 bar, then

carefully disconnect the union.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 320 of 329

13B-320

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 8

CONTINUED 2

With + after ignition feed on, check for + 12 V feed between connection codes 3AHB and M at the electric pump

connector of the particle filter injector, component code 1767.

If there is no + 12 V feed to the sensor, check the continuity, insulation and absence of interference

resistance on the following connections:

●connection code 3AHB between components 1767 and 1768,

●Connection code M between component 1767 and the vehicle earth.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A,

Electrical wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

(Refer to the interpretation of faults DF1004 Electric fuel pump relay control and DF1001 Particle filter

upstream temperature regulation).

●Reconnect or replace the pipe.

Repeat the pressure test.

●Replace the fuel filter (see MR 392, 385, 364, 370 and 417 Mechanics, 13A, Fuel supply, Fuel filter:

Removal - Refitting).

Repeat the pressure test.

●Replace the particle filter injector electric pump.

Repeat the pressure test.

●Check that the particle filter injector is fitted correctly.

Check that the particle filter injector is correctly held in place. Repair or replace the particle filter injector mounting.

●"Only on Kangoo 2:

Check the integrity and correct fitting of the evaporator plate located under the particle filter injector, at the level of

the bracket.

If the blade of the evaporator plate has become detached, it may be located downstream from the line between its

original position and the oxidation catalytic converter inlet.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.