air filter RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Manual PDF

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 324 of 329

13B-324

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 9

CONTINUED 3

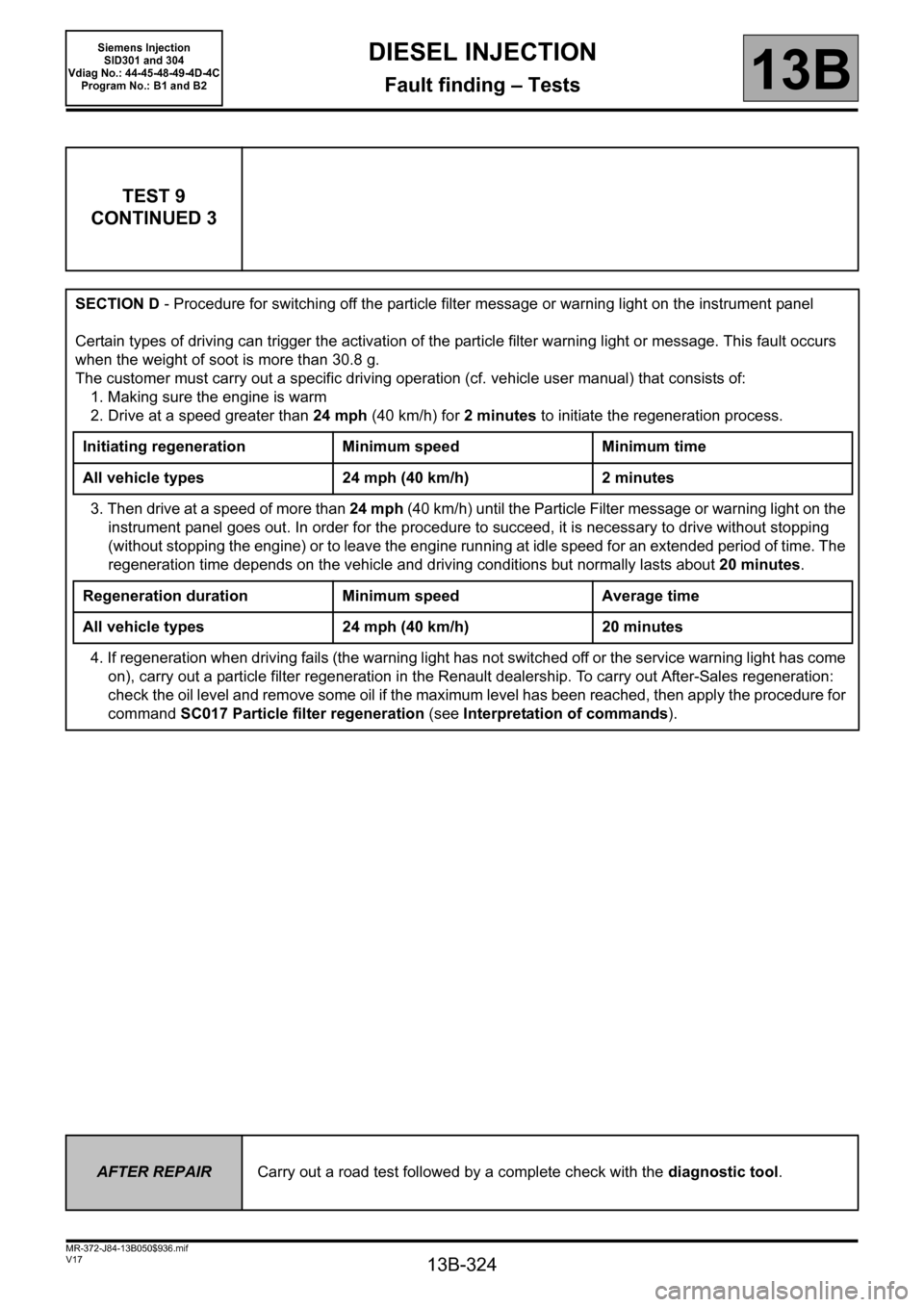

SECTION D - Procedure for switching off the particle filter message or warning light on the instrument panel

Certain types of driving can trigger the activation of the particle filter warning light or message. This fault occurs

when the weight of soot is more than 30.8 g.

The customer must carry out a specific driving operation (cf. vehicle user manual) that consists of:

1. Making sure the engine is warm

2. Drive at a speed greater than 24 mph (40 km/h) for 2 minutes to initiate the regeneration process.

Initiating regeneration Minimum speed Minimum time

All vehicle types 24 mph (40 km/h) 2 minutes

3. Then drive at a speed of more than 24 mph (40 km/h) until the Particle Filter message or warning light on the

instrument panel goes out. In order for the procedure to succeed, it is necessary to drive without stopping

(without stopping the engine) or to leave the engine running at idle speed for an extended period of time. The

regeneration time depends on the vehicle and driving conditions but normally lasts about 20 minutes.

Regeneration duration Minimum speed Average time

All vehicle types 24 mph (40 km/h) 20 minutes

4. If regeneration when driving fails (the warning light has not switched off or the service warning light has come

on), carry out a particle filter regeneration in the Renault dealership. To carry out After-Sales regeneration:

check the oil level and remove some oil if the maximum level has been reached, then apply the procedure for

command SC017 Particle filter regeneration (see Interpretation of commands).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 325 of 329

13B-325

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

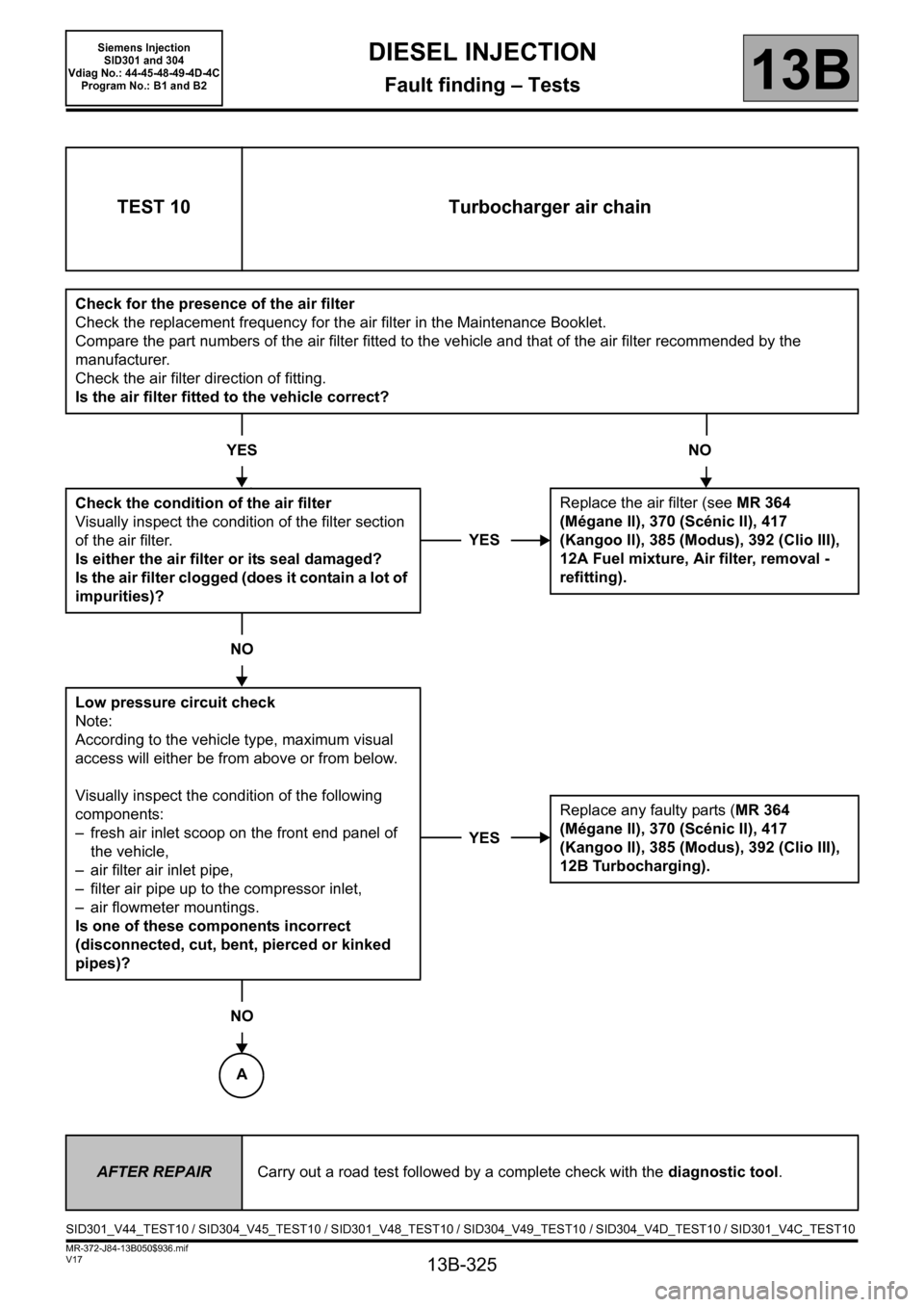

TEST 10 Turbocharger air chain

Check for the presence of the air filter

Check the replacement frequency for the air filter in the Maintenance Booklet.

Compare the part numbers of the air filter fitted to the vehicle and that of the air filter recommended by the

manufacturer.

Check the air filter direction of fitting.

Is the air filter fitted to the vehicle correct?

YES NO

Check the condition of the air filter

Visually inspect the condition of the filter section

of the air filter.

Is either the air filter or its seal damaged?

Is the air filter clogged (does it contain a lot of

impurities)?

NO

Low pressure circuit check

Note:

According to the vehicle type, maximum visual

access will either be from above or from below.

Visually inspect the condition of the following

components:

– fresh air inlet scoop on the front end panel of

the vehicle,

– air filter air inlet pipe,

– filter air pipe up to the compressor inlet,

– air flowmeter mountings.

Is one of these components incorrect

(disconnected, cut, bent, pierced or kinked

pipes)?

NO

YESReplace the air filter (see MR 364

(Mégane II), 370 (Scénic II), 417

(Kangoo II), 385 (Modus), 392 (Clio III),

12A Fuel mixture, Air filter, removal -

refitting).

YESReplace any faulty parts (MR 364

(Mégane II), 370 (Scénic II), 417

(Kangoo II), 385 (Modus), 392 (Clio III),

12B Turbocharging).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST10 / SID304_V45_TEST10 / SID301_V48_TEST10 / SID304_V49_TEST10 / SID304_V4D_TEST10 / SID301_V4C_TEST10

A

Page 327 of 329

13B-327

MR-372-J84-13B050$975.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

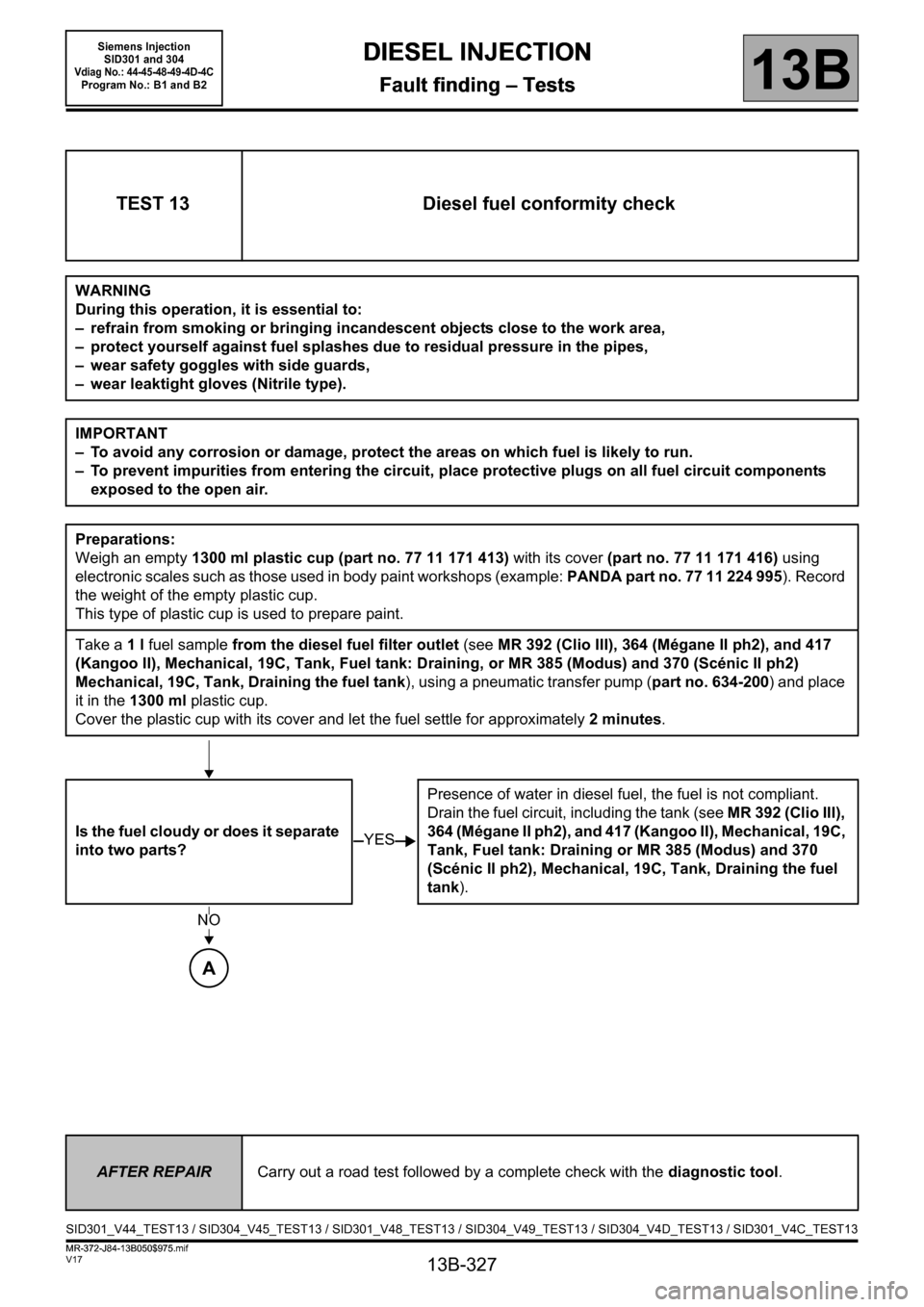

TEST 13 Diesel fuel conformity check

WARNING

During this operation, it is essential to:

– refrain from smoking or bringing incandescent objects close to the work area,

– protect yourself against fuel splashes due to residual pressure in the pipes,

– wear safety goggles with side guards,

– wear leaktight gloves (Nitrile type).

IMPORTANT

– To avoid any corrosion or damage, protect the areas on which fuel is likely to run.

– To prevent impurities from entering the circuit, place protective plugs on all fuel circuit components

exposed to the open air.

Preparations:

Weigh an empty 1300 ml plastic cup (part no. 77 11 171 413) with its cover (part no. 77 11 171 416) using

electronic scales such as those used in body paint workshops (example: PANDA part no. 77 11 224 995). Record

the weight of the empty plastic cup.

This type of plastic cup is used to prepare paint.

Take a 1 l fuel sample from the diesel fuel filter outlet (see MR 392 (Clio III), 364 (Mégane II ph2), and 417

(Kangoo II), Mechanical, 19C, Tank, Fuel tank: Draining, or MR 385 (Modus) and 370 (Scénic II ph2)

Mechanical, 19C, Tank, Draining the fuel tank), using a pneumatic transfer pump (part no. 634-200) and place

it in the 1300 ml plastic cup.

Cover the plastic cup with its cover and let the fuel settle for approximately 2 minutes.

Is the fuel cloudy or does it separate

into two parts?Presence of water in diesel fuel, the fuel is not compliant.

Drain the fuel circuit, including the tank (see MR 392 (Clio III),

364 (Mégane II ph2), and 417 (Kangoo II), Mechanical, 19C,

Tank, Fuel tank: Draining or MR 385 (Modus) and 370

(Scénic II ph2), Mechanical, 19C, Tank, Draining the fuel

tank).

YES

NO

A

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST13 / SID304_V45_TEST13 / SID301_V48_TEST13 / SID304_V49_TEST13 / SID304_V4D_TEST13 / SID301_V4C_TEST13

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4CProgram No.: B1 and B2

MR-372-J84-13B050$975.mif