air filter RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Siemens Injection Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 329, PDF Size: 1.71 MB

Page 300 of 329

13B-300

MR-372-J84-13B050$897.mif

V17

DIESEL INJECTION

Fault finding – Fault Finding Chart

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

ALP 21

CONTINUED 2

Check the air flow:

●The air flow must be approximately 250 mg/st.

Check the air flowmeter connector, component code 799 (corrosion, fouling, etc.).

If the connector is faulty and there is a repair method (see Technical Note 6015A, Repairing electrical wiring,

Wiring: Precautions for repair), repair the connector(s), otherwise replace the wiring.

Check the continuity, insulation and absence of interference resistance on the following connections:

●Code connection 3FB (3FB3 for Kangoo II) between components 799 and 1768.

●Connection code 3ABQ between components 799 and 120.

●Connection code 3DV between components 799 and 120.

●Connection code 3KJ between components 799 and 120.

●connection code 3DW between components 799 and 120.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A, Electrical

wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Check the particle filter injector supply system by running Test 8 Particle filter injector supply circuit check.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 301 of 329

13B-301

MR-372-J84-13B050$936.mif

V17

13B

DIESEL INJECTION

Fault finding – Tests

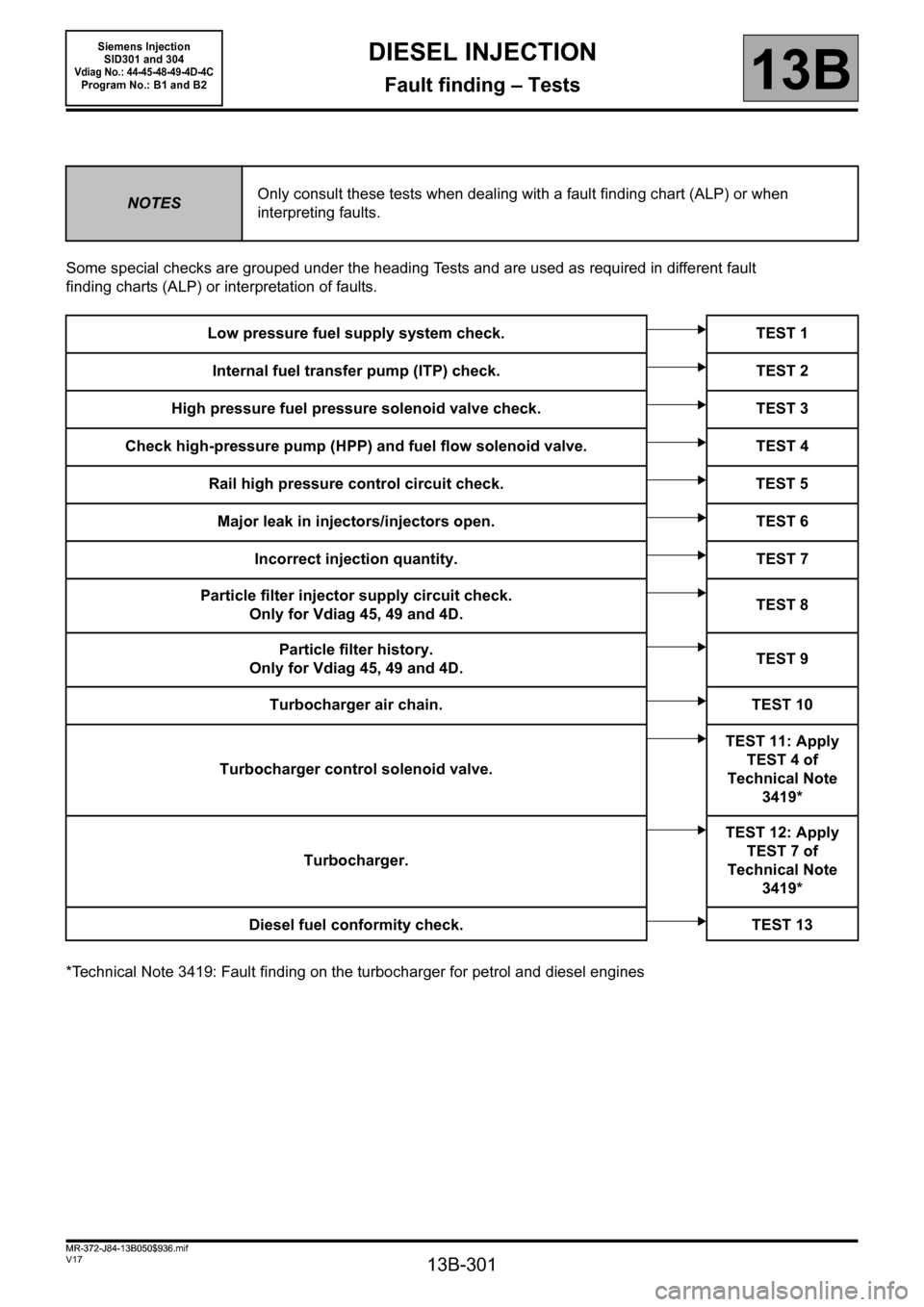

Some special checks are grouped under the heading Tests and are used as required in different fault

finding charts (ALP) or interpretation of faults.

*Technical Note 3419: Fault finding on the turbocharger for petrol and diesel engines

NOTESOnly consult these tests when dealing with a fault finding chart (ALP) or when

interpreting faults.

Low pressure fuel supply system check. TEST 1

Internal fuel transfer pump (ITP) check. TEST 2

High pressure fuel pressure solenoid valve check. TEST 3

Check high-pressure pump (HPP) and fuel flow solenoid valve. TEST 4

Rail high pressure control circuit check. TEST 5

Major leak in injectors/injectors open. TEST 6

Incorrect injection quantity. TEST 7

Particle filter injector supply circuit check.

Only for Vdiag 45, 49 and 4D.TEST 8

Particle filter history.

Only for Vdiag 45, 49 and 4D.TEST 9

Turbocharger air chain. TEST 10

Turbocharger control solenoid valve.TEST 11: Apply

TEST 4 of

Technical Note

3419*

Turbocharger.TEST 12: Apply

TEST 7 of

Technical Note

3419*

Diesel fuel conformity check. TEST 13

MR-372-J84-13B050$936.mif

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4CProgram No.: B1 and B2

Page 302 of 329

13B-302

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

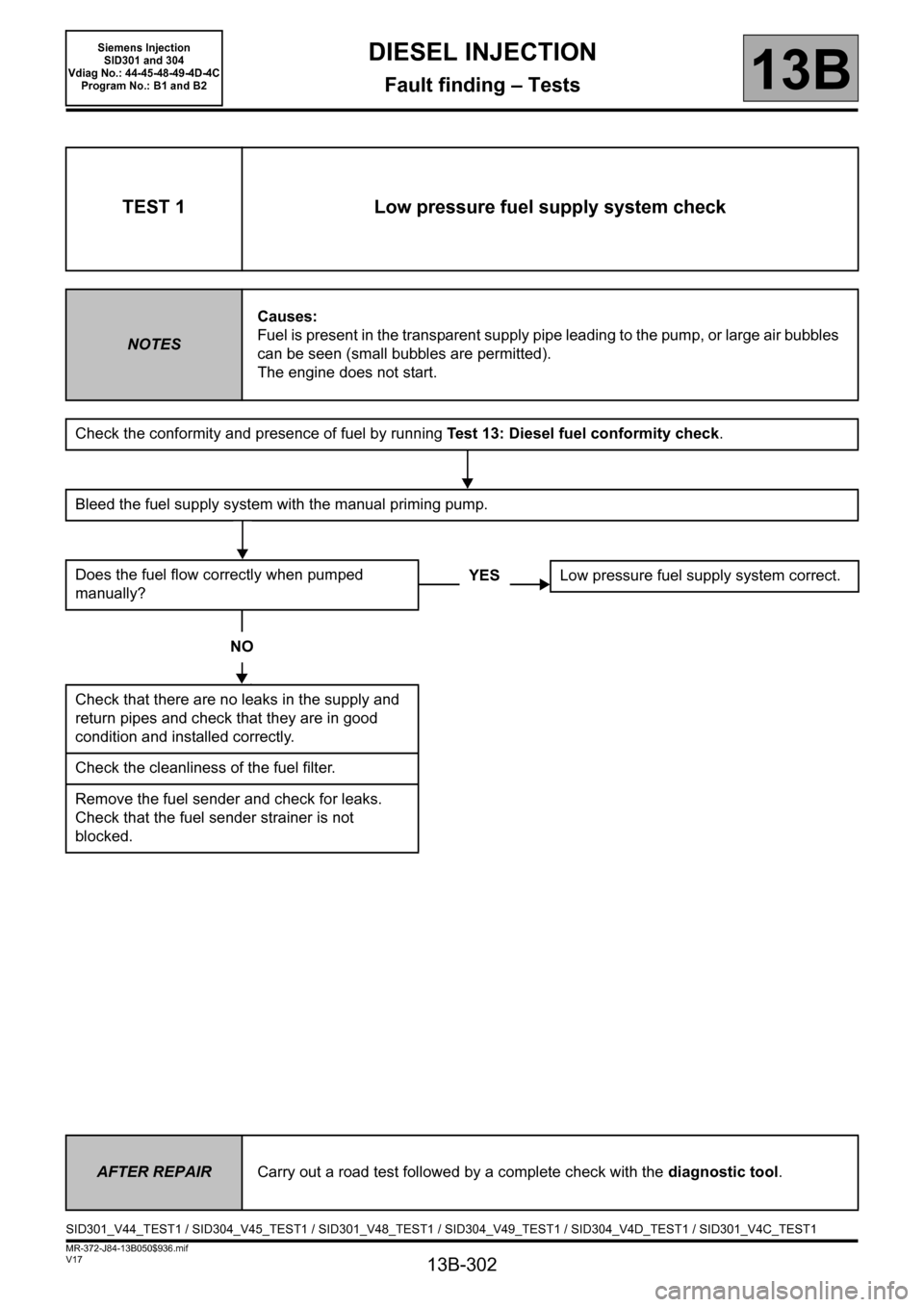

TEST 1 Low pressure fuel supply system check

NOTESCauses:

Fuel is present in the transparent supply pipe leading to the pump, or large air bubbles

can be seen (small bubbles are permitted).

The engine does not start.

Check the conformity and presence of fuel by running Test 13: Diesel fuel conformity check.

Bleed the fuel supply system with the manual priming pump.

Does the fuel flow correctly when pumped

manually?

NO

Check that there are no leaks in the supply and

return pipes and check that they are in good

condition and installed correctly.

Check the cleanliness of the fuel filter.

Remove the fuel sender and check for leaks.

Check that the fuel sender strainer is not

blocked.

YESLow pressure fuel supply system correct.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST1 / SID304_V45_TEST1 / SID301_V48_TEST1 / SID304_V49_TEST1 / SID304_V4D_TEST1 / SID301_V4C_TEST1

Page 308 of 329

13B-308

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

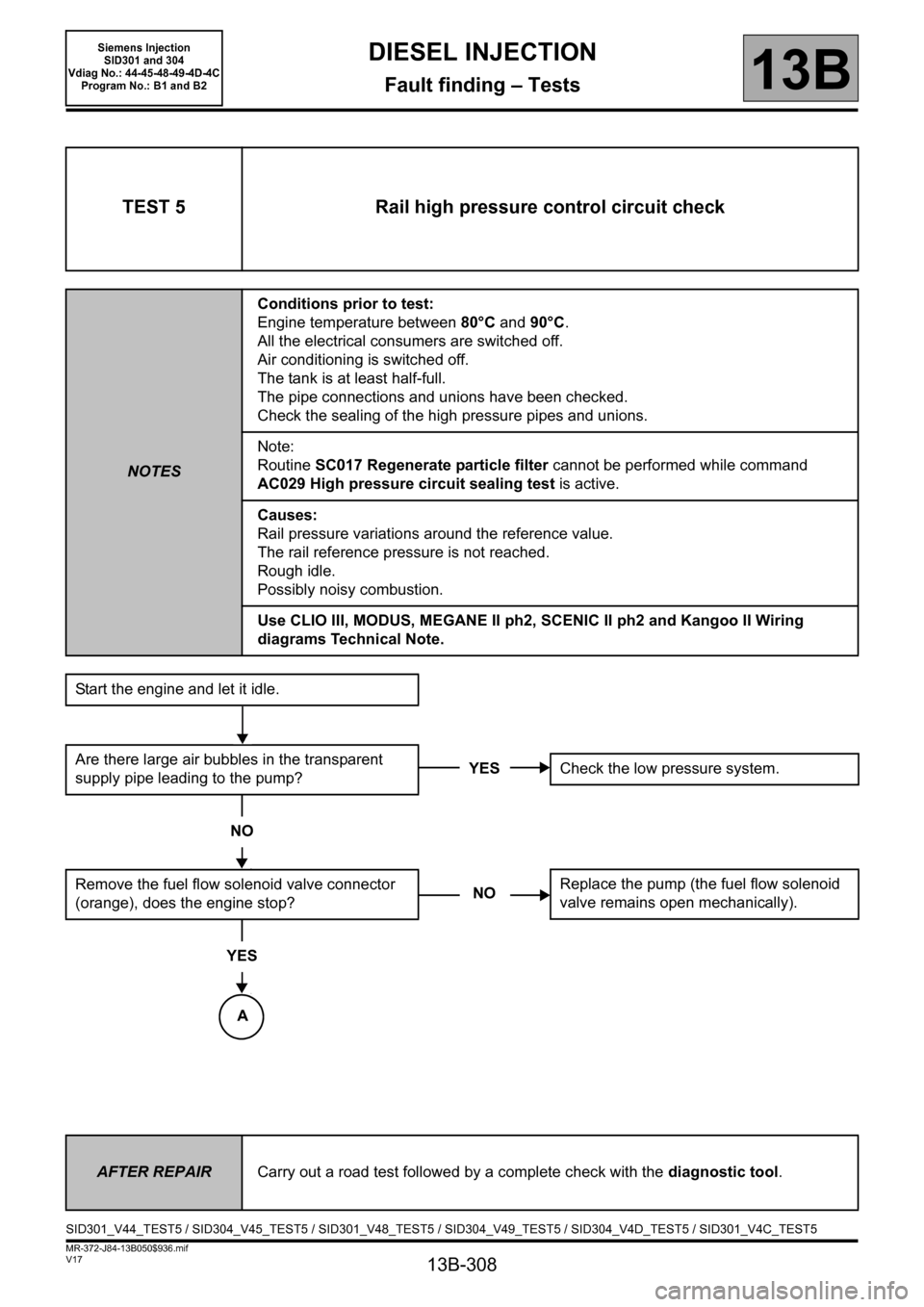

TEST 5 Rail high pressure control circuit check

NOTESConditions prior to test:

Engine temperature between 80°C and 90°C.

All the electrical consumers are switched off.

Air conditioning is switched off.

The tank is at least half-full.

The pipe connections and unions have been checked.

Check the sealing of the high pressure pipes and unions.

Note:

Routine SC017 Regenerate particle filter cannot be performed while command

AC029 High pressure circuit sealing test is active.

Causes:

Rail pressure variations around the reference value.

The rail reference pressure is not reached.

Rough idle.

Possibly noisy combustion.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Start the engine and let it idle.

Are there large air bubbles in the transparent

supply pipe leading to the pump?

NO

Remove the fuel flow solenoid valve connector

(orange), does the engine stop?

YES

YESCheck the low pressure system.

NOReplace the pump (the fuel flow solenoid

valve remains open mechanically).

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID301_V44_TEST5 / SID304_V45_TEST5 / SID301_V48_TEST5 / SID304_V49_TEST5 / SID304_V4D_TEST5 / SID301_V4C_TEST5

A

Page 318 of 329

13B-318

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests13B

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

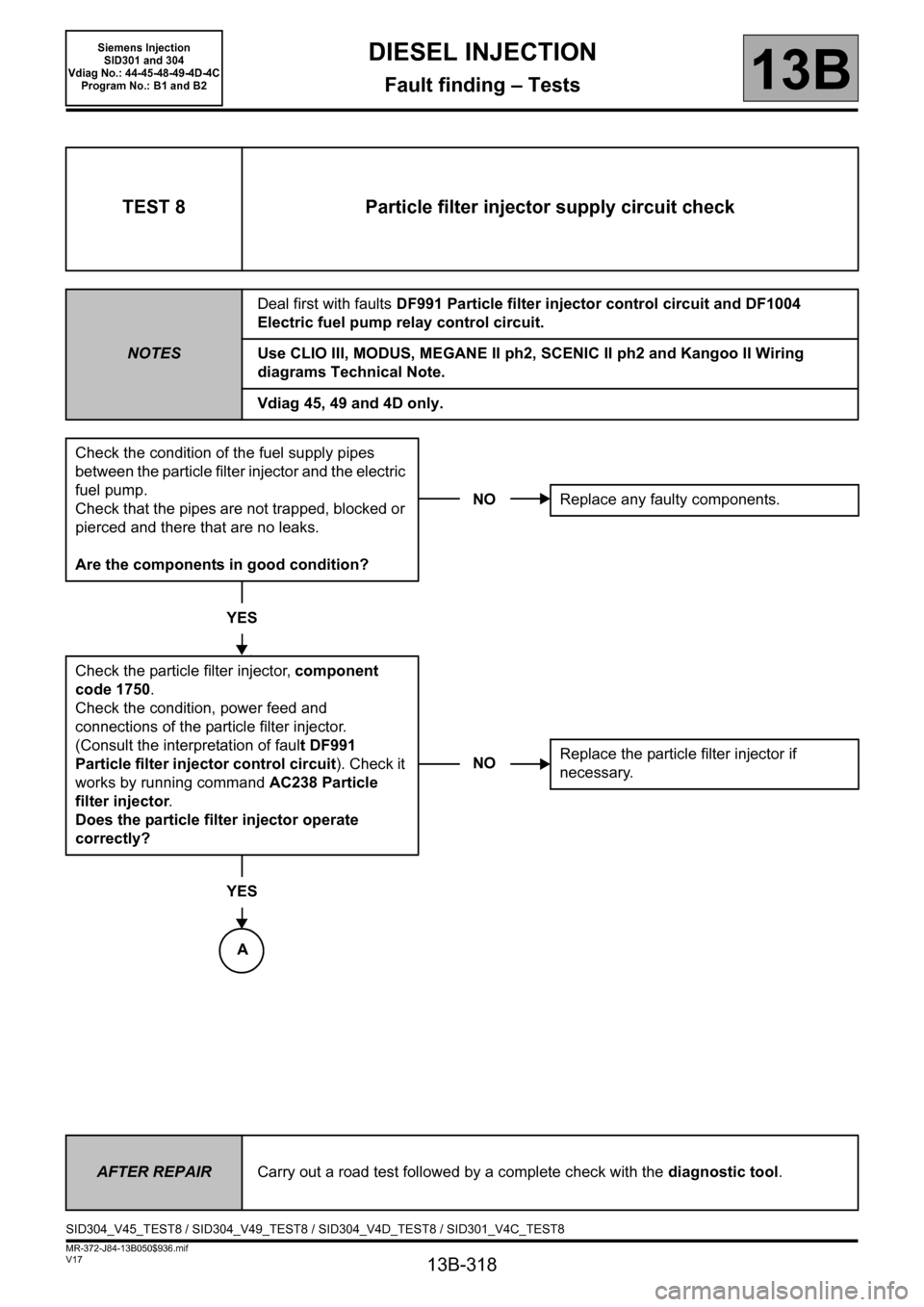

TEST 8 Particle filter injector supply circuit check

NOTESDeal first with faults DF991 Particle filter injector control circuit and DF1004

Electric fuel pump relay control circuit.

Use CLIO III, MODUS, MEGANE II ph2, SCENIC II ph2 and Kangoo II Wiring

diagrams Technical Note.

Vdiag 45, 49 and 4D only.

Check the condition of the fuel supply pipes

between the particle filter injector and the electric

fuel pump.

Check that the pipes are not trapped, blocked or

pierced and there that are no leaks.

Are the components in good condition?

YES

Check the particle filter injector, component

code 1750.

Check the condition, power feed and

connections of the particle filter injector.

(Consult the interpretation of fault DF991

Particle filter injector control circuit). Check it

works by running command AC238 Particle

filter injector.

Does the particle filter injector operate

correctly?

YES

NOReplace any faulty components.

NOReplace the particle filter injector if

necessary.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID304_V45_TEST8 / SID304_V49_TEST8 / SID304_V4D_TEST8 / SID301_V4C_TEST8

A

Page 319 of 329

13B-319

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 8

CONTINUED 1

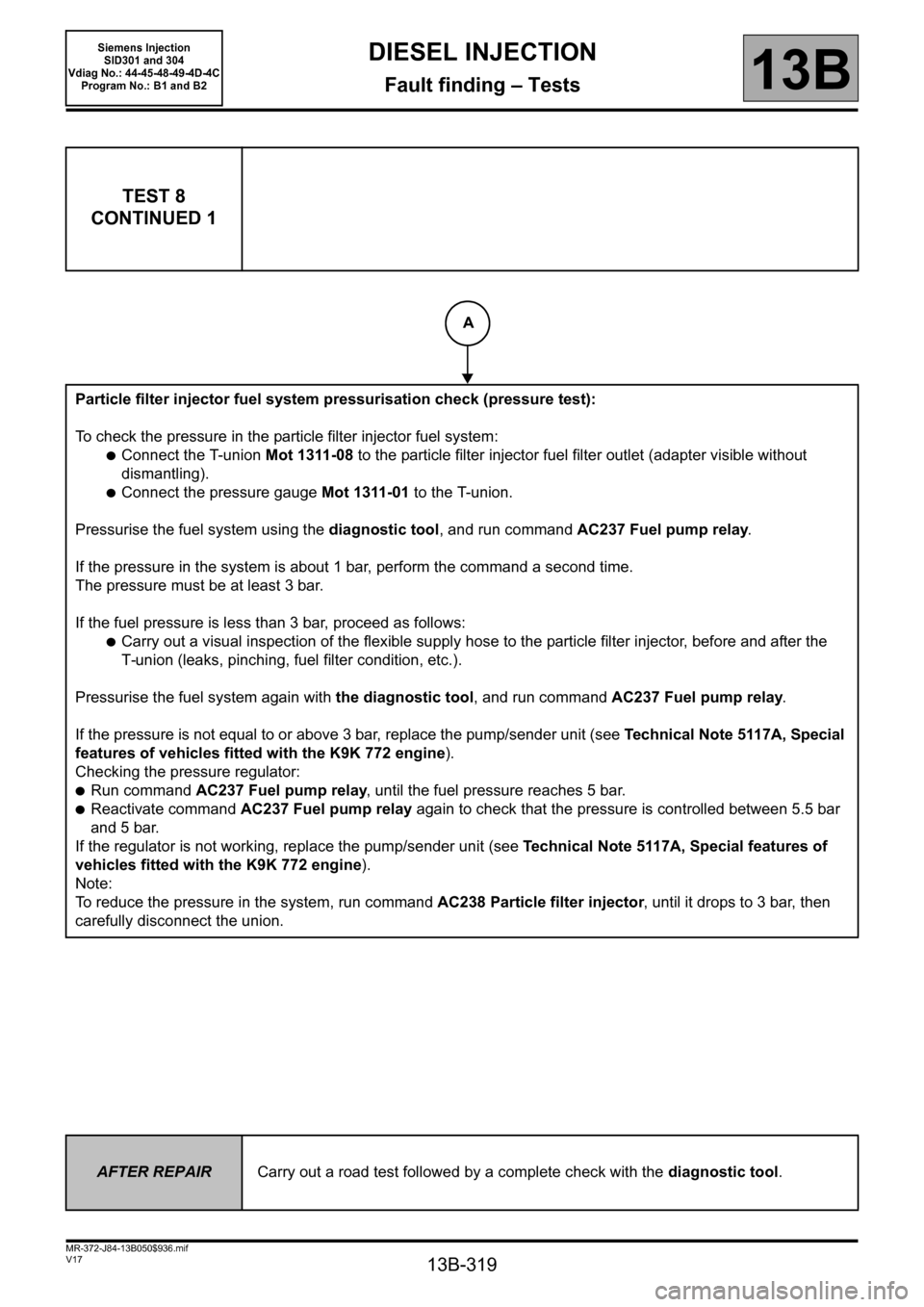

Particle filter injector fuel system pressurisation check (pressure test):

To check the pressure in the particle filter injector fuel system:

●Connect the T-union Mot 1311-08 to the particle filter injector fuel filter outlet (adapter visible without

dismantling).

●Connect the pressure gauge Mot 1311-01 to the T-union.

Pressurise the fuel system using the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure in the system is about 1 bar, perform the command a second time.

The pressure must be at least 3 bar.

If the fuel pressure is less than 3 bar, proceed as follows:

●Carry out a visual inspection of the flexible supply hose to the particle filter injector, before and after the

T-union (leaks, pinching, fuel filter condition, etc.).

Pressurise the fuel system again with the diagnostic tool, and run command AC237 Fuel pump relay.

If the pressure is not equal to or above 3 bar, replace the pump/sender unit (see Technical Note 5117A, Special

features of vehicles fitted with the K9K 772 engine).

Checking the pressure regulator:

●Run command AC237 Fuel pump relay, until the fuel pressure reaches 5 bar.

●Reactivate command AC237 Fuel pump relay again to check that the pressure is controlled between 5.5 bar

and 5 bar.

If the regulator is not working, replace the pump/sender unit (see Technical Note 5117A, Special features of

vehicles fitted with the K9K 772 engine).

Note:

To reduce the pressure in the system, run command AC238 Particle filter injector, until it drops to 3 bar, then

carefully disconnect the union.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 320 of 329

13B-320

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 8

CONTINUED 2

With + after ignition feed on, check for + 12 V feed between connection codes 3AHB and M at the electric pump

connector of the particle filter injector, component code 1767.

If there is no + 12 V feed to the sensor, check the continuity, insulation and absence of interference

resistance on the following connections:

●connection code 3AHB between components 1767 and 1768,

●Connection code M between component 1767 and the vehicle earth.

If the connection or connections are faulty and there is a repair procedure (see Technical Note 6015A,

Electrical wiring repair, Wiring: Precautions for repair), repair the wiring, otherwise replace it.

(Refer to the interpretation of faults DF1004 Electric fuel pump relay control and DF1001 Particle filter

upstream temperature regulation).

●Reconnect or replace the pipe.

Repeat the pressure test.

●Replace the fuel filter (see MR 392, 385, 364, 370 and 417 Mechanics, 13A, Fuel supply, Fuel filter:

Removal - Refitting).

Repeat the pressure test.

●Replace the particle filter injector electric pump.

Repeat the pressure test.

●Check that the particle filter injector is fitted correctly.

Check that the particle filter injector is correctly held in place. Repair or replace the particle filter injector mounting.

●"Only on Kangoo 2:

Check the integrity and correct fitting of the evaporator plate located under the particle filter injector, at the level of

the bracket.

If the blade of the evaporator plate has become detached, it may be located downstream from the line between its

original position and the oxidation catalytic converter inlet.

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

Page 321 of 329

13B-321

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

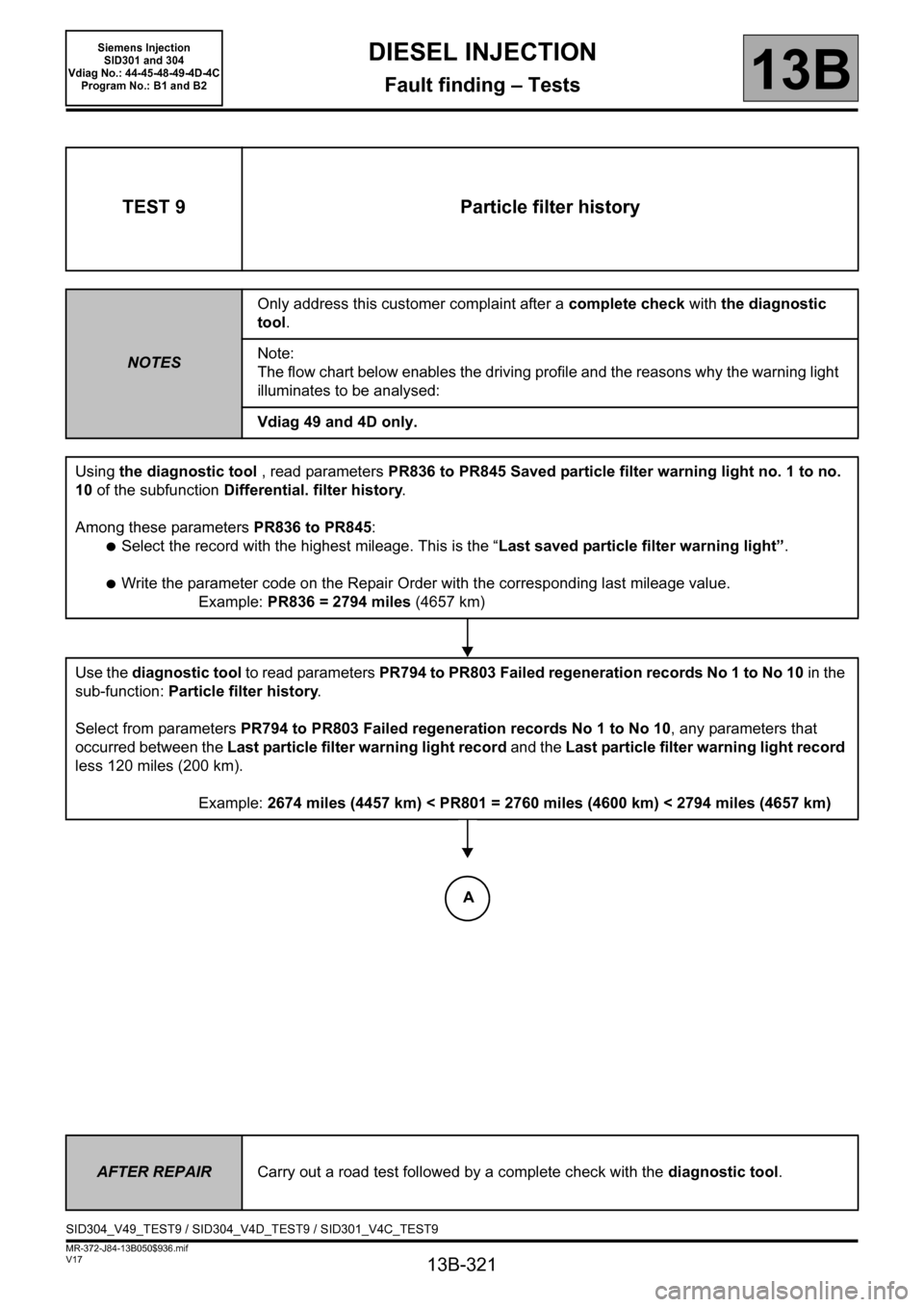

TEST 9 Particle filter history

NOTESOnly address this customer complaint after a complete check with the diagnostic

tool.

Note:

The flow chart below enables the driving profile and the reasons why the warning light

illuminates to be analysed:

Vdiag 49 and 4D only.

Using the diagnostic tool , read parameters PR836 to PR845 Saved particle filter warning light no. 1 to no.

10 of the subfunction Differential. filter history.

Among these parameters PR836 to PR845:

●Select the record with the highest mileage. This is the “Last saved particle filter warning light”.

●Write the parameter code on the Repair Order with the corresponding last mileage value.

Example: PR836 = 2794 miles (4657 km)

Use the diagnostic tool to read parameters PR794 to PR803 Failed regeneration records No 1 to No 10 in the

sub-function: Particle filter history.

Select from parameters PR794 to PR803 Failed regeneration records No 1 to No 10, any parameters that

occurred between the Last particle filter warning light record and the Last particle filter warning light record

less 120 miles (200 km).

Example: 2674 miles (4457 km) < PR801 = 2760 miles (4600 km) < 2794 miles (4657 km)

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

SID304_V49_TEST9 / SID304_V4D_TEST9 / SID301_V4C_TEST9

A

Page 322 of 329

13B-322

MR-372-J84-13B050$936.mif

V17

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2DIESEL INJECTION

Fault finding – Tests13B

TEST 9

CONTINUED 1

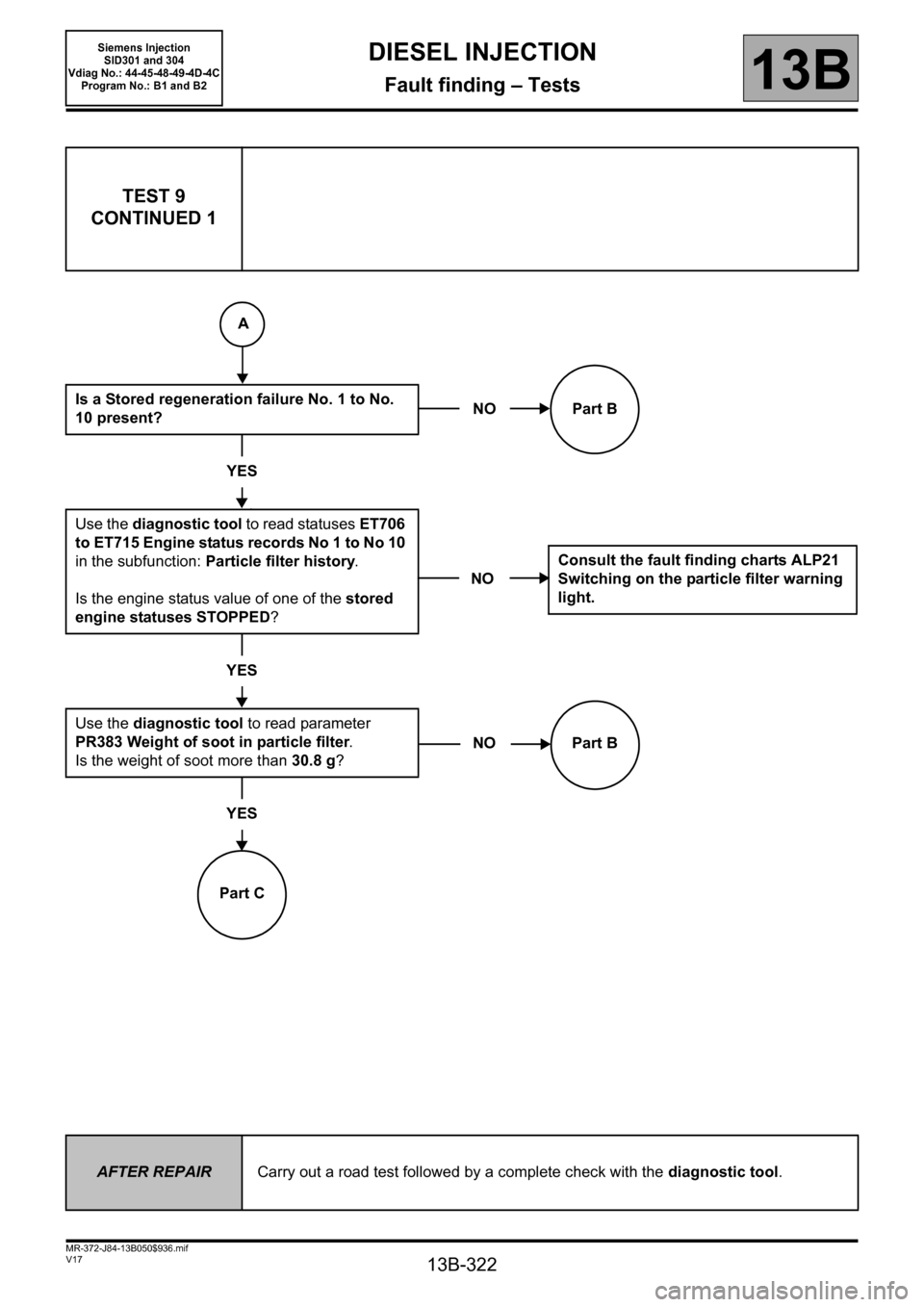

Is a Stored regeneration failure No. 1 to No.

10 present?

YES

Use the diagnostic tool to read statuses ET706

to ET715 Engine status records No 1 to No 10

in the subfunction: Particle filter history.

Is the engine status value of one of the stored

engine statuses STOPPED?

YES

Use the diagnostic tool to read parameter

PR383 Weight of soot in particle filter.

Is the weight of soot more than 30.8 g?

YES

Part CNO Part B

NOConsult the fault finding charts ALP21

Switching on the particle filter warning

light.

NO Part B

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.

A

Page 323 of 329

13B-323

MR-372-J84-13B050$936.mif

V17

DIESEL INJECTION

Fault finding – Tests

Siemens Injection

SID301 and 304

Vdiag No.: 44-45-48-49-4D-4C

Program No.: B1 and B2

13B

TEST 9

CONTINUED 2

PA R T B

1 - NO particle filter regeneration.

2 - Write on the repair order: the parameter and status relating to the last failure:

– Mileage of last Particle filter warning light record

– Mileage of last Failed regeneration records

– Engine statuses for last Engine status records

Example: PR837 = 2794 miles (4657 km); PR801 = 2760 miles (4600 km); engine status = STOPPED

3 - Interpretation of the values written on the repair order by the service advisor for the customer:

Before the last time the warning light or Particle Filter message came on (appeared at the mileage of the last

Stored particle filter warning light) the customer did not follow the driving instructions: the failure which

occurred at the Mileage of the last failure was due to the engine being switched off.

4 - Service advisor explains to the customer the procedure to turn off the warning light, backed up by the

parameters written in the repair order: see PA R T D.

PA R T C

1 - Carry out a regeneration in the Renault dealership with the approval of the Techline.

Follow the procedure for command SC017 Particle filter regeneration.

Note: Do not carry out an engine oil change following an After-Sales regeneration.

2 - Explain the procedure for regeneration while driving to the customer to reduce returns to the garage:

see SECTION D:

AFTER REPAIRCarry out a road test followed by a complete check with the diagnostic tool.