charge circuit RENAULT SCENIC 2011 J95 / 3.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2011, Model line: SCENIC, Model: RENAULT SCENIC 2011 J95 / 3.GPages: 198, PDF Size: 0.85 MB

Page 8 of 198

13B-8V4 MR-372-J84-13B000$020.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

System outline

The DDCR injection system used on the K9 engine is an electronically managed high pressure injection system.

The fuel is compressed by a high pressure pump then stored in a rail that feeds the injectors. Injection occurs when

a current pulse is applied to the injector holders. The injected flow is proportional to the rail pressure and to

the applied pulse length, and the start of injection is phased with the start of the pulse.

The circuit comprises two subsystems, which are distinguished by the fuel pressure level.

– The low pressure system includes the tank, diesel fuel filter, transfer pump and injector holder return pipes.

– The high pressure circuit contains the high pressure pump, the rail, the injector holders and the high pressure tubes.

Finally, there are a certain number of sensors and regulating actuators for controlling and monitoring the entire

system.

Functions provided

Function: Fuel supply management (timing, flow and pressure).

Quantity of fuel injected and injection timing adjustment

The injection checking parameters are the quantities to be injected and their respective timing. These are calculated

by the computer using signals from the following sensors:

• Engine speed (Crankshaft + Cam for synchronisation)

• Accelerator pedal

• Turbocharging pressure and air temperature (Turbocharger pressure)

• Coolant temperature

• Air temperature

• Air load (Flow and Pressure)

• Rail pressure

• Flowmeter

• Turbocharging solenoid valve

The quantities to be injected and their respective timing are converted into:

• a reference tooth

• the time between this tooth and the start of the pulse

• the time for which the supply to the injector holder is on

An electrical current (pulse) is sent to each injector holder according to previously calculated data. The system

makes one or two injections (1 pilot injection, 1 main injection). The general principle is to calculate an overall

injected flow which will then be divided into a main injection flow and a pilot injection flow, to help the combustion

process work properly and to reduce pollutant emissions.

An accelerometer is used to monitor some of the fuel injection deviation. This has several roles:

• Protecting the engine by detecting injection leaks (disabled on the basic vehicle).

• Checking the pilot quantity by measuring deviation and dispersion

• By changing both the duration and timing of the injection, the quantity of fuel injected and the mixture ignition timing

can be adjusted.

DIESEL INJECTION

Fault finding – System operation

Page 9 of 198

13B-9V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

Rail pressure check

The quality of combustion is influenced by the size of the atomised droplets in the cylinder. In the combustion

chamber, smaller fuel droplets will have time to burn fully, and will not produce smoke or unburned particles. To

meet the pollution requirements, the droplet size, and therefore the size of the injection holes, must be reduced.

With smaller holes, less fuel will be able to be introduced at a given pressure, which limits the power. To handle this

drawback, the injected fuel flow has to be increased, which means a pressure increase (and more apertures on the

injector nozzles). For the DDCR injection system, the pressure reaches 1400 bar in the rail, and must be constantly

regulated. The measuring circuit consists of an active pressure sensor on the rail connected to an analogue port on

the computer.

The High Pressure pump is supplied at low pressure (5bar) by a built-in transfer pump. This pump supplies the rail.

The rail filling pressure is controlled by the filling valve (IMV) and the discharge pressure is controlled by the injector

valves. This compensates for pressure drops. The filling actuator enables the high pressure pump to supply just

the exact quantity of diesel fuel required to maintain the rail pressure. This mechanism minimises the heat

generated and improves engine output.

In order to discharge the rail using the injector valves, the valves are actuated by short electrical pulses which are:

– short enough not to open the injector (and pass through the return circuit from the injectors),

– long enough to open the valves and discharge the rail.

The fuel surplus is sent back to the fuel filter or the tank, according to its flow. If there is no IMV control, the rail

pressure is limited by a discharge valve fitted on the pump.

Idling speed regulation

The computer handles the calculation of idling speed. This has to take account of the instantaneous power level to

be supplied, according to the following factors:

– Engine coolant temperature

– Gear engaged

– Battery charging

– Electrical consumers (Heating elements, Air conditioning, Fan assembly, Heated windscreen, etc.) active or

inactive

Individual injector correction (C2I)

The DDCR system injectors must be calibrated with corrective values to adjust their flow precisely. Each injector is

calibrated for different pressures on a test bench, and its specifications are shown on a label attached to the body of

the injector holders. These individual correction values are then written to the computer EEPROM, which can then

actuate the injectors by taking into account their manufacturing dispersion.

Page 11 of 198

13B-11V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

WITH FLOWMETER (K9K 728)

The flow of fresh air entering the engine is given by a hot wire ratiometric sensor. This flow sensor is used to

manage the amount of exhaust gas to be recirculated to ensure optimum recirculation rates. A fresh air temperature

sensor is built into the flowmeter.

Air flow measurement allows closed-loop control via the EGR valve.

Besides electrical faults with the sensor, there is a consistency test between the measured air flow and an estimated

air flow without EGR.

This flow evaluates the amount of fresh inlet air, based on the values supplied by the surrounding systems:

– the inlet air temperature measured by a sensor located after the turbocharger and/or after the intercooler (if fitted),

– the turbocharging pressure,

– the engine speed.

Pre-postheating actuation

Pre-postheating actuation consists of controlling the heater plugs and preheating warning light on the instrument

panel. The heater plugs are activated by relays, and the power is supplied from the battery. After the ignition is

switched on. Preheating is activated for a period of time. The warning light is illuminated for an activation period that

depends on the battery voltage, the atmospheric pressure, and the coolant temperature. When the temperature is

below a certain threshold, a postheating function can be used to improve the combustion stability, and consequently

engine operation (reducing unburnt particles and pollutant emissions).

Turbocharger control solenoid valve actuation

The turbocharger system comprises a solenoid valve that is used to actuate the vanes (or wastegate) to create an

overpressure or a vacuum in the inlet circuit.

Page 12 of 198

13B-12V4 MR-372-J84-13B000$020.mif

DIESEL INJECTION

Fault finding – System operation13B

DDCR INJECTION

Vdiag No.: 44, 48

Functions included

Air conditioning management assistance

For vehicles with air conditioning, the DDCR system can switch off the air conditioning under certain engine

operating conditions:

– when requested by the driver,

– when starting the engine,

– if the engine overheats (in order to reduce the power the engine has to supply),

– when the engine speed is kept at a very high level (to protect the compressor),

– during transition phases (e.g. under heavy acceleration when overtaking, anti-stalling and moving off strategies).

These conditions are only taken into account when they do not occur repeatedly, in order to prevent system

instabilities (erratic deactivations),

– when certain faults appear.

Cold loop air conditioning management

The air conditioning is the cold loop type and its management shared between several computers. The injection

computer is responsible for:

– managing demand for cold air according to the passenger compartment commands and the pressure value,

– determining the power absorbed by the compressor from the pressure,

– determining the fan unit commands according to vehicle speed and pressure.

The driver requests the air conditioning to be switched on by means of the ventilation selector coupled to a switch.

The cold air request is authorised or denied depending on the pressure measured. If this pressure is outside

the operating limits, the cold loop program is not activated.

Thermal regulation of the passenger compartment heating circuit

In a direct injection engine, fuel is injected directly into the combustion chamber. This leads to heat being lost

through the upper part of the engine and consequently, the cylinder head cooling circuit is smaller in size.

The effect of this is that the temperature of the coolant flowing through this circuit rises more slowly. However, this

coolant is also used by the passenger compartment heating system. In very cold conditions, it is therefore difficult to

achieve a comfortable passenger compartment temperature quickly.

To limit the time taken to warm up the system, air heating resistors, called RCHs, are fitted into the passenger

compartment heating circuit. The UCH decides whether the RCH are required, the UPC physically actuates

the RCH, and the injection computer determines whether to limit the power supplied to the RCH depending on

alternator charge, and also whether to disable them according to engine speed, load and vehicle speed. NOTE:

Fan unit actuation requests can be made by the injection computer, but these are sent on the CAN. These requests

depend on the air conditioning but also on the coolant temperature and vehicle speed.

Page 52 of 198

13B-52

AFTER REPAIRDeal with any faults displayed by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$061.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF047

STOREDCOMPUTER SUPPLY VOLTAGE1.DEF: Above maximum threshold.

2.DEF: Below minimum threshold.

NOTESConditions for applying the fault finding procedure to a stored fault:

The fault is present with the engine running above 1000 rpm.

Measure the battery voltage when the ignition is switched on.

If the battery voltage < 10 V recharge the battery.

Check the condition and connection of the battery terminals.

Repair if necessary.

Check the vehicle's charging circuit.

Repair if necessary.

Check the connection and condition of the black 32-track computer connector A.

Repair if necessary.

Check the insulation, continuity and the absence of interference resistance on the following connections:

+ after ignition feed. Track D1 computer connector A

Chassis earth Tracks G4 and H4 computer connector A

Repair if necessary.

DDCR_V44_DF047M/DDCR_V48_DF039P

Page 60 of 198

13B-60

AFTER REPAIRDeal with any faults declared by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$062.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF054

STOREDTURBOCHARGING SOLENOID VALVE CONTROL CIRCUITCO.0: Open circuit or short circuit to earth

CC.1: Short circuit to +12 volts

1.DEF: At minimum limit

2.DEF: At maximum limit

NOTESSpecial notes:

If DF054, the performance of the vehicle is adversely affected and the level 1 warning

light illuminates along with the message Faulty injection.

Check the condition of the air filter, and replace it if necessary.

Check that the inlet manifold is not blocked (clogged).

Check that the turbocharger is working properly, and carry out any necessary repairs.

Check the connection and condition of the 2-track connector of the turbocharging solenoid valve.

Repair if necessary.

Check for +12 V on track 2 of the solenoid valve.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Check the continuity, insulation, and the absence of interference resistance on the following connections:

Solenoid valve connector track 2 + after ignition feed

Solenoid valve connector track 1 Track M2 computer connector B

Repair if necessary.

Run TEST 11 Air line at the turbocharger.

Run TEST 10 Turbocharger control solenoid valve check.

Run TEST 12 Turbocharger.

If the fault persists, replace the turbocharging solenoid valve.

DDCR_V44_DF054M/DDCR_V48_DF054M

Page 61 of 198

13B-61

AFTER REPAIRDeal with any faults declared by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$062.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF056

PRESENT

OR

STOREDAIR FLOW SENSOR CIRCUIT1.DEF: Permanent low level

2.DEF: Permanent high signal

3.DEF: Below minimum threshold

4.DEF: Above maximum threshold

5.DEF: At minimum limit

6.DEF: At maximum limit

NOTESPriority when dealing with a number of faults:

– DF054 Turbocharging solenoid valve control circuit.

– DF113 Sensor supply voltage.

Conditions for applying fault finding procedures to stored faults:

the fault reappears after the faults have been cleared followed by a road test.

Check the condition of the air filter, and replace it if necessary.

Check that the inlet manifold is not blocked (clogged).

Check that the turbocharger is working properly.

Run TEST 11 Air line at the turbocharger.

Run TEST 10 Turbocharger control solenoid valve check.

Run TEST 12 Turbocharger.

Carry out the necessary repairs.

Check the connection and condition of the 6-track connector of the air flow sensor.

Repair if necessary.

Check for +5 V after ignition feed on track 3 of the sensor connector.

Repair if necessary.

Check for +12 V on track 4 of the sensor connector.

Repair if necessary.

Check for earth on connector track 6.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

DDCR_V44_DF056/DDCR_V48_DF056

Page 69 of 198

13B-69

AFTER REPAIRDeal with any faults declared by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$062.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

DF089

CONTINUED 1

5.DEF-6.DEF

7.DEFNOTESNone.

Visually check the turbocharging circuit sealing.

Run TEST 11 Air line at the turbocharger.

Repair if necessary.

Remove the air supply ducts and check that they are not blocked.

Repair if necessary.

Check for consistency between the atmospheric pressure and the manifold pressure (PR035 = PR032).

With the engine stopped, the pressure should be approximately the same between the 2 sensors.

Replace the manifold pressure sensor if necessary.

Check the turbocharger,

Run TEST 10 Turbocharger control solenoid valve check.

Run TEST 12 Turbocharger.

Repair if necessary.

Page 70 of 198

13B-70

AFTER REPAIRDeal with any faults declared by the diagnostic tool. Clear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V4 MR-372-J84-13B000$062.mif

DIESEL INJECTION

Fault finding – Interpretation of faults13B

DDCR INJECTION

Vdiag No.: 44, 48

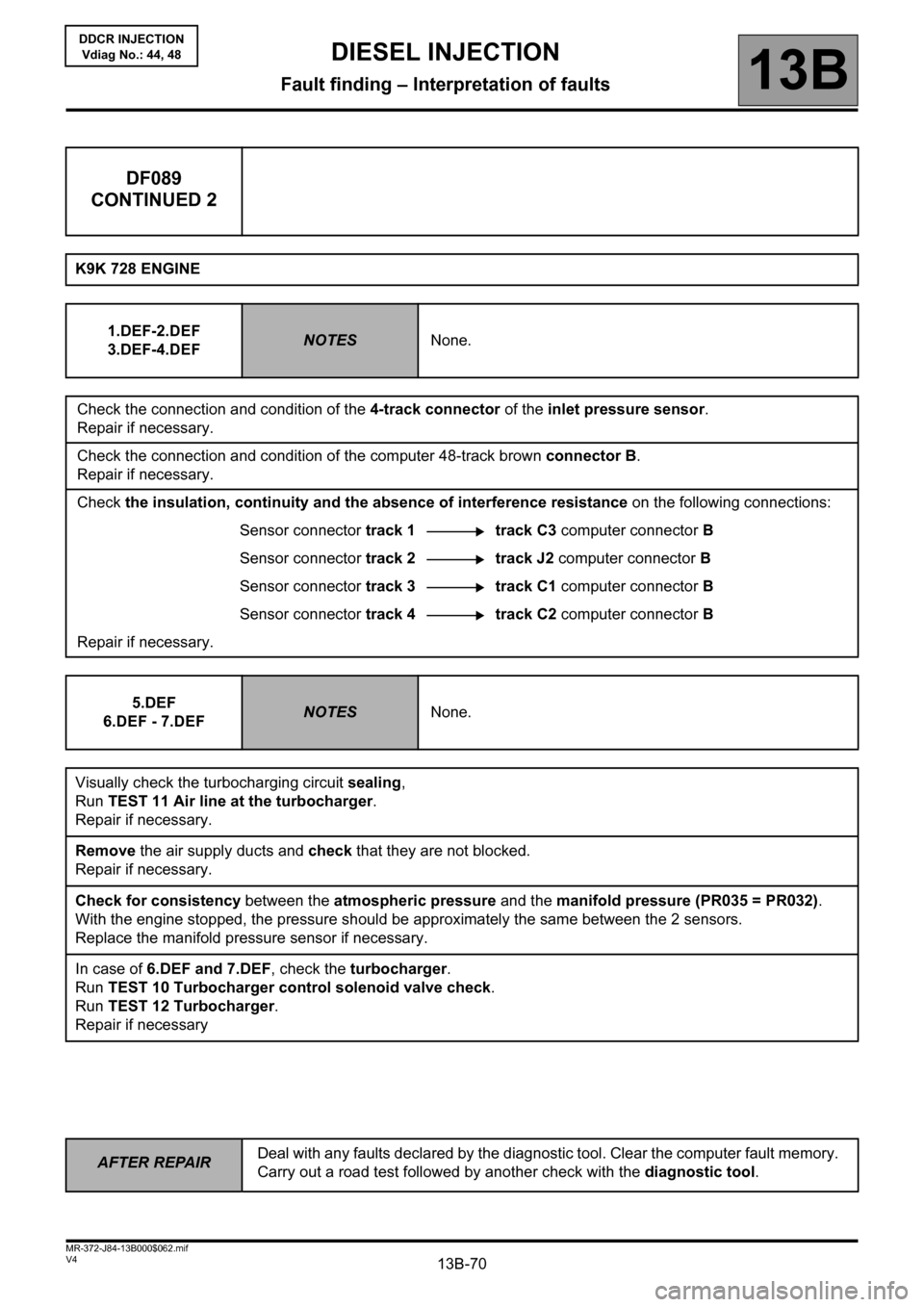

DF089

CONTINUED 2

K9K 728 ENGINE

1.DEF-2.DEF

3.DEF-4.DEF

NOTESNone.

Check the connection and condition of the 4-track connector of the inlet pressure sensor.

Repair if necessary.

Check the connection and condition of the computer 48-track brown connector B.

Repair if necessary.

Check the insulation, continuity and the absence of interference resistance on the following connections:

Sensor connector track 1 track C3 computer connector B

Sensor connector track 2 track J2 computer connector B

Sensor connector track 3 track C1 computer connector B

Sensor connector track 4 track C2 computer connector B

Repair if necessary.

5.DEF

6.DEF - 7.DEF

NOTESNone.

Visually check the turbocharging circuit sealing,

Run TEST 11 Air line at the turbocharger.

Repair if necessary.

Remove the air supply ducts and check that they are not blocked.

Repair if necessary.

Check for consistency between the atmospheric pressure and the manifold pressure (PR035 = PR032).

With the engine stopped, the pressure should be approximately the same between the 2 sensors.

Replace the manifold pressure sensor if necessary.

In case of 6.DEF and 7.DEF, check the turbocharger.

Run TEST 10 Turbocharger control solenoid valve check.

Run TEST 12 Turbocharger.

Repair if necessary

Page 83 of 198

13B-83V4 MR-372-J84-13B000$070.mif

13B

DDCR INJECTION

Vdiag No.: 44, 48

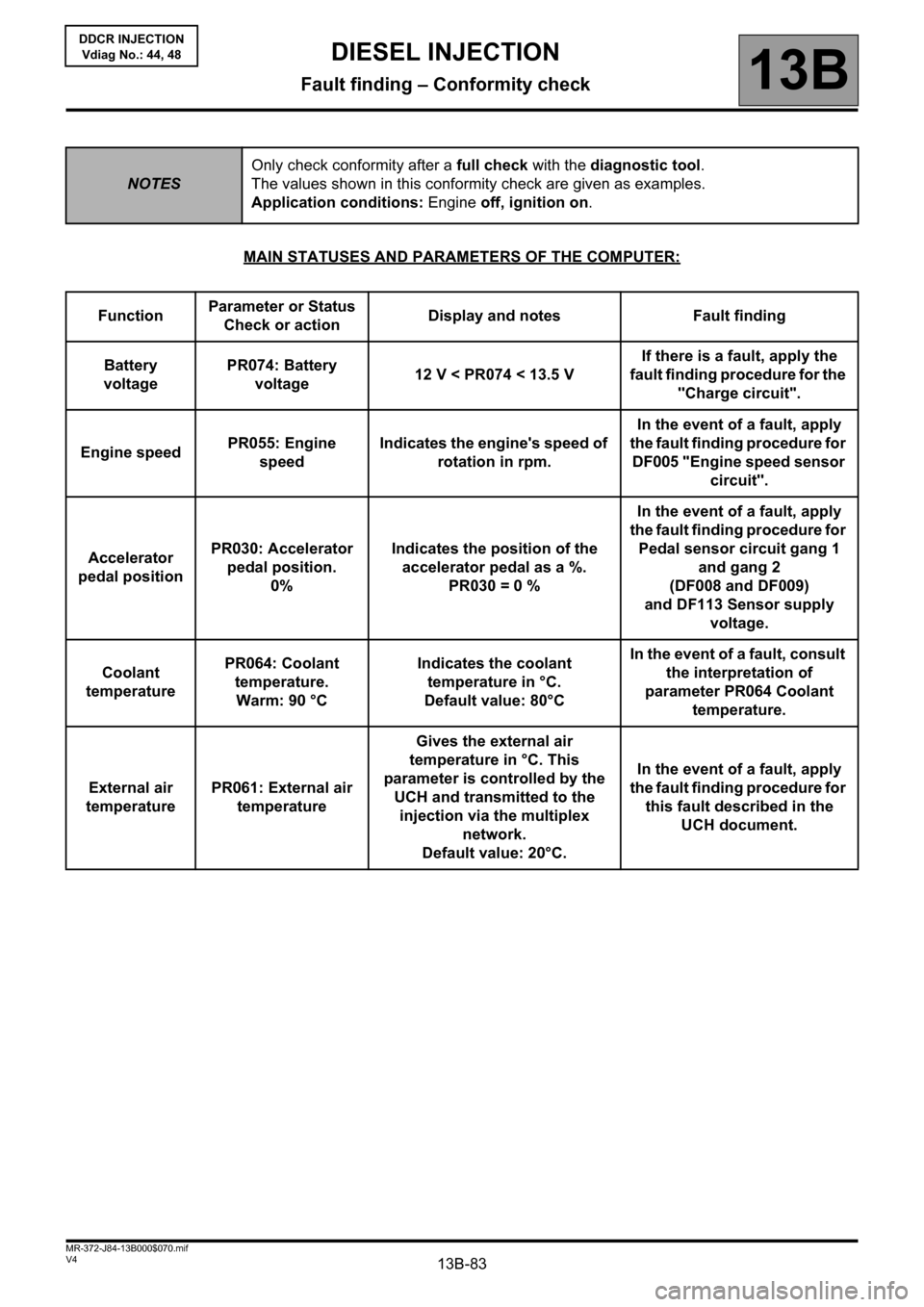

MAIN STATUSES AND PARAMETERS OF THE COMPUTER:

NOTESOnly check conformity after a full check with the diagnostic tool.

The values shown in this conformity check are given as examples.

Application conditions: Engine off, ignition on.

FunctionParameter or Status

Check or actionDisplay and notes Fault finding

Battery

voltagePR074: Battery

voltage12 V < PR074 < 13.5 VIf there is a fault, apply the

fault finding procedure for the

"Charge circuit".

Engine speedPR055: Engine

speedIndicates the engine's speed of

rotation in rpm.In the event of a fault, apply

the fault finding procedure for

DF005 "Engine speed sensor

circuit".

Accelerator

pedal positionPR030: Accelerator

pedal position.

0%Indicates the position of the

accelerator pedal as a %.

PR030 = 0 %In the event of a fault, apply

the fault finding procedure for

Pedal sensor circuit gang 1

and gang 2

(DF008 and DF009)

and DF113 Sensor supply

voltage.

Coolant

temperaturePR064: Coolant

temperature.

Warm: 90 °CIndicates the coolant

temperature in °C.

Default value: 80°CIn the event of a fault, consult

the interpretation of

parameter PR064 Coolant

temperature.

External air

temperaturePR061: External air

temperatureGives the external air

temperature in °C. This

parameter is controlled by the

UCH and transmitted to the

injection via the multiplex

network.

Default value: 20°C.In the event of a fault, apply

the fault finding procedure for

this fault described in the

UCH document.

DIESEL INJECTION

Fault finding – Conformity check