display RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 3 of 181

PETROL INJECTION

Fault finding – Introduction17B

17B-3V12 MR-372-J84-17B000$045.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

Faults

Faults are declared present or stored (depending on whether they appeared in a certain context and have

disappeared since, or whether they remain present but are not diagnosed within the current context).

The present or stored status of faults should be taken into consideration when the diagnostic tool is switched on

following + after ignition feed being activated (without any system components being active).

For a present fault, apply the procedure described in the Interpretation of faults section.

For a stored fault, note the faults displayed and apply the Notes section.

If the fault is confirmed when the instructions in the Notes section are applied, the fault is present. Deal with the

fault.

If the fault is not confirmed, check:

– the electrical lines which correspond to the fault,

– the connectors for these lines (for oxidation, bent pins, etc.),

– the resistance of the component detected as faulty,

– the condition of the wires (melted or split insulation, wear).

Conformity check

The aim of the conformity check is to check the statuses and parameters that do not produce a fault display on the

diagnostic tool when they are inconsistent. Therefore, this stage is used to:

– carry out fault finding on faults that do not have a fault display, and which may correspond to a customer complaint.

– check that the system is operating correctly and that there is no risk of a fault recurring after repairs.

This section gives the fault finding procedures for statuses and parameters and the conditions for checking them.

If a status is not behaving normally or a parameter is outside the permitted tolerance values, consult the

corresponding fault finding page.

Customer complaints - Fault finding chart

If the test with the diagnostic tool is OK but the customer complaint is still present, the fault should be treated by

customer complaints.

A summary of the overall procedure to follow is provided on the following

page in the form of a flow chart.

JSAA741.0

Page 9 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 9V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

2. OPERATIONAL SAFETY

Warning lights illumination

The S3000 injection system manages the illumination of three warning lights and the issuing of warning messages

according to the severity of the faults detected, to inform the customer and to direct fault finding.

The injection computer manages the illumination of warning lights and warning messages displayed on the instrument

panel. These warning lights illuminate during the starting phase and in the event of an injection fault or engine

overheating.

The warning light illumination signals reach the instrument panel via the multiplex network.

Warning light illumination principle

During the starting phase (START button pressed) the OBD (On Board Diagnostic) warning light comes on for

approximately 3 seconds then goes out.

If there is an injection fault (severity 1), the INJECTION FAULT written message lights up followed by the SERVICE

warning light. It indicates a reduced level of operation and a limited safety level.

The driver should carry out repairs as soon as possible.

Components involved:

– motorised throttle valve,

– accelerator pedal potentiometer,

– inlet manifold pressure sensor,

–computer,

– actuator feed,

– computer feed.

If there is a serious injection fault (severity 2), the red engine symbol and the word STOP appear (display with

information display only), with the ENGINE OVERHEATING written message followed by the STOP warning light

and a buzzer. If this happens, the vehicle must be stopped immediately.

When a fault causing excessive pollution in the exhaust fumes is detected, the orange OBD warning light, an engine

symbol, will be lit:

–flashing in the event of a fault which might irreparably damaged the catalytic converter (destructive misfire). If this

happens you must stop the vehicle immediately,

–constantly in the case of non-compliance with the anti-pollution standards (pollutant misfire, catalytic converter

fault, oxygen sensor faults, inconsistency between the oxygen sensors and canister fault).

Mileage travelled with fault

This parameter serves to measure the distance travelled with one of the injection fault warning lights on: level 1 fault

warning light (amber), coolant temperature overheating warning light, or OBD warning light.

The counter can be reset to 0 using the diagnostic tool.

JSAA741.0

Page 90 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-90V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Conformity check

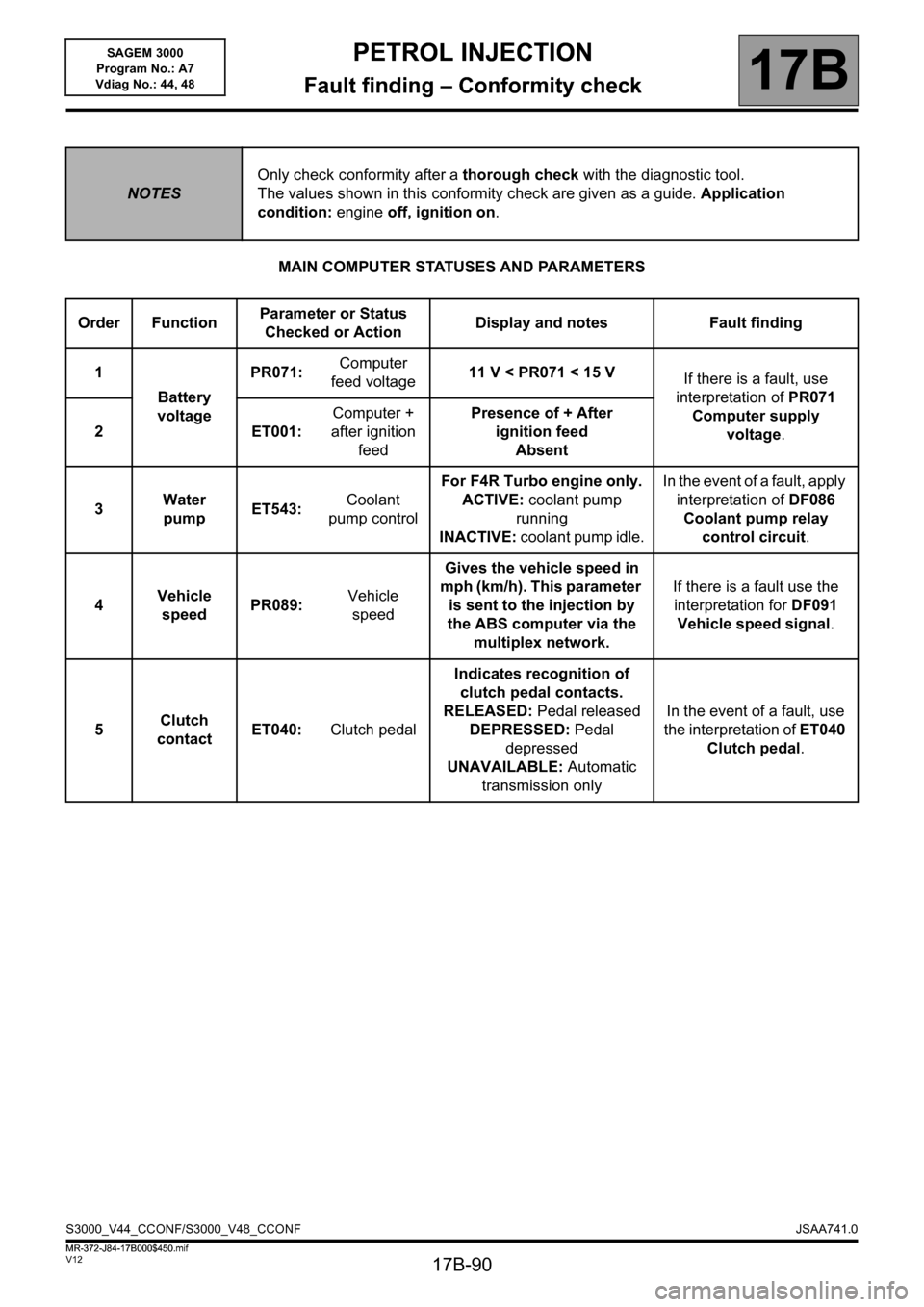

MAIN COMPUTER STATUSES AND PARAMETERS

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide. Application

condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Battery

voltagePR071: Computer

feed voltage11V

interpretation of PR071

Computer supply

voltage. 2 ET001: Computer +

after ignition

feedPresence of + After

ignition feed

Absent

3Water

pumpET543: Coolant

pump controlFor F4R Turbo engine only.

ACTIVE: coolant pump

running

INACTIVE: coolant pump idle.In the event of a fault, apply

interpretation of DF086

Coolant pump relay

control circuit.

4Vehicle

speedPR089: Vehicle

speedGives the vehicle speed in

mph (km/h). This parameter

is sent to the injection by

the ABS computer via the

multiplex network.If there is a fault use the

interpretation for DF091

Vehicle speed signal.

5Clutch

contactET040: Clutch pedalIndicates recognition of

clutch pedal contacts.

RELEASED: Pedal released

DEPRESSED: Pedal

depressed

UNAVAILABLE: Automatic

transmission onlyIn the event of a fault, use

the interpretation of ET040

Clutch pedal.

S3000_V44_CCONF/S3000_V48_CCONFJSAA741.0

MR-372-J84-17B000$450.mif

Page 91 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-91V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

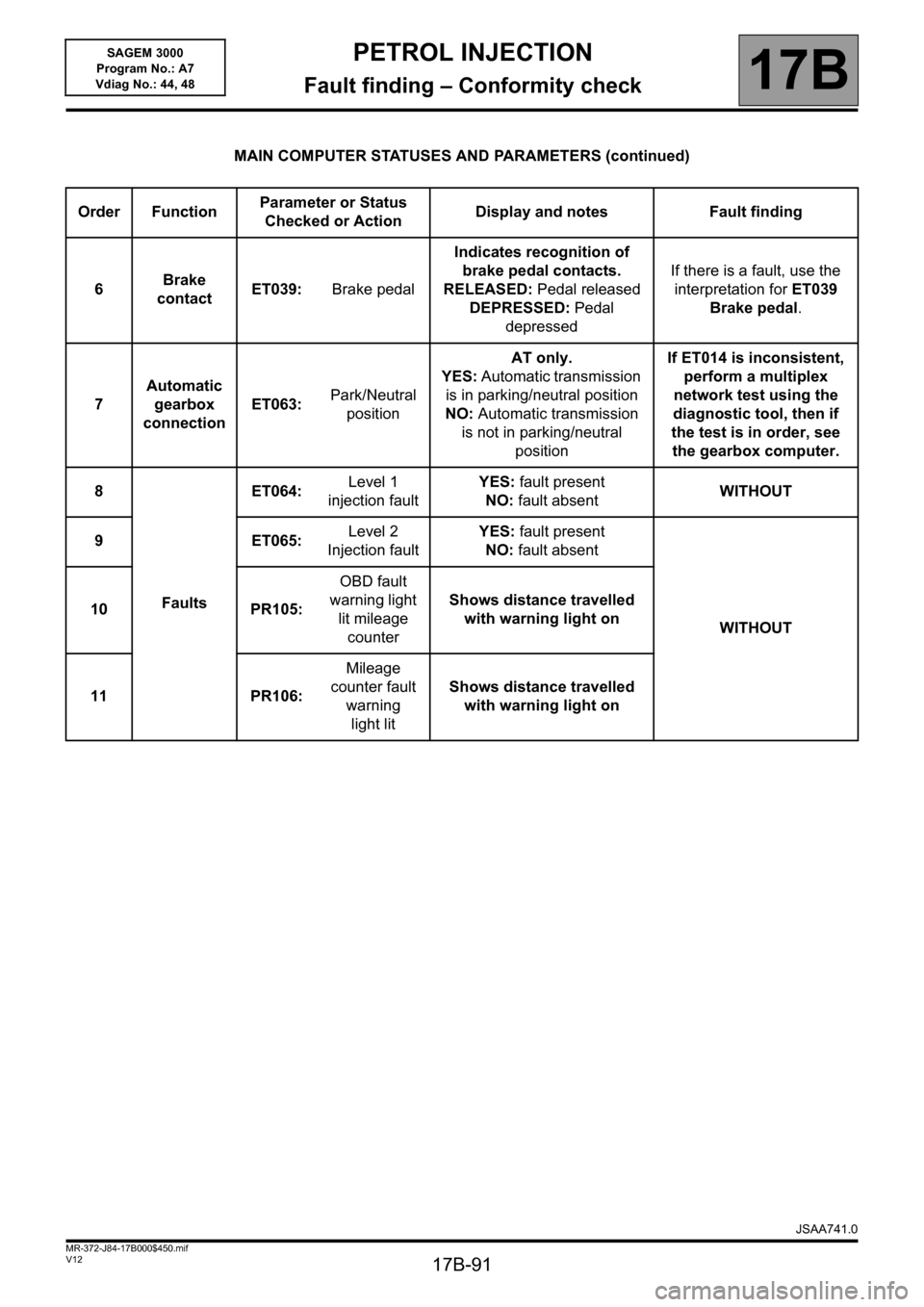

MAIN COMPUTER STATUSES AND PARAMETERS (continued)

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

6Brake

contactET039: Brake pedalIndicates recognition of

brake pedal contacts.

RELEASED: Pedal released

DEPRESSED: Pedal

depressedIf there is a fault, use the

interpretation for ET039

Brake pedal.

7 Automatic

gearbox

connectionET063: Park/Neutral

positionAT only.

YES: Automatic transmission

is in parking/neutral position

NO: Automatic transmission

is not in parking/neutral

positionIf ET014 is inconsistent,

perform a multiplex

network test using the

diagnostic tool, then if

the test is in order, see

the gearbox computer.

8

FaultsET064: Level 1

injection faultYES: fault present

NO: fault absentWITHOUT

9 ET065: Level 2

Injection faultYES: fault present

NO: fault absent

WITHOUT 10 PR105: OBD fault

warning light

lit mileage

counterShows distance travelled

with warning light on

11 PR106: Mileage

counter fault

warning

light litShows distance travelled

with warning light on

JSAA741.0

Page 92 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-92V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

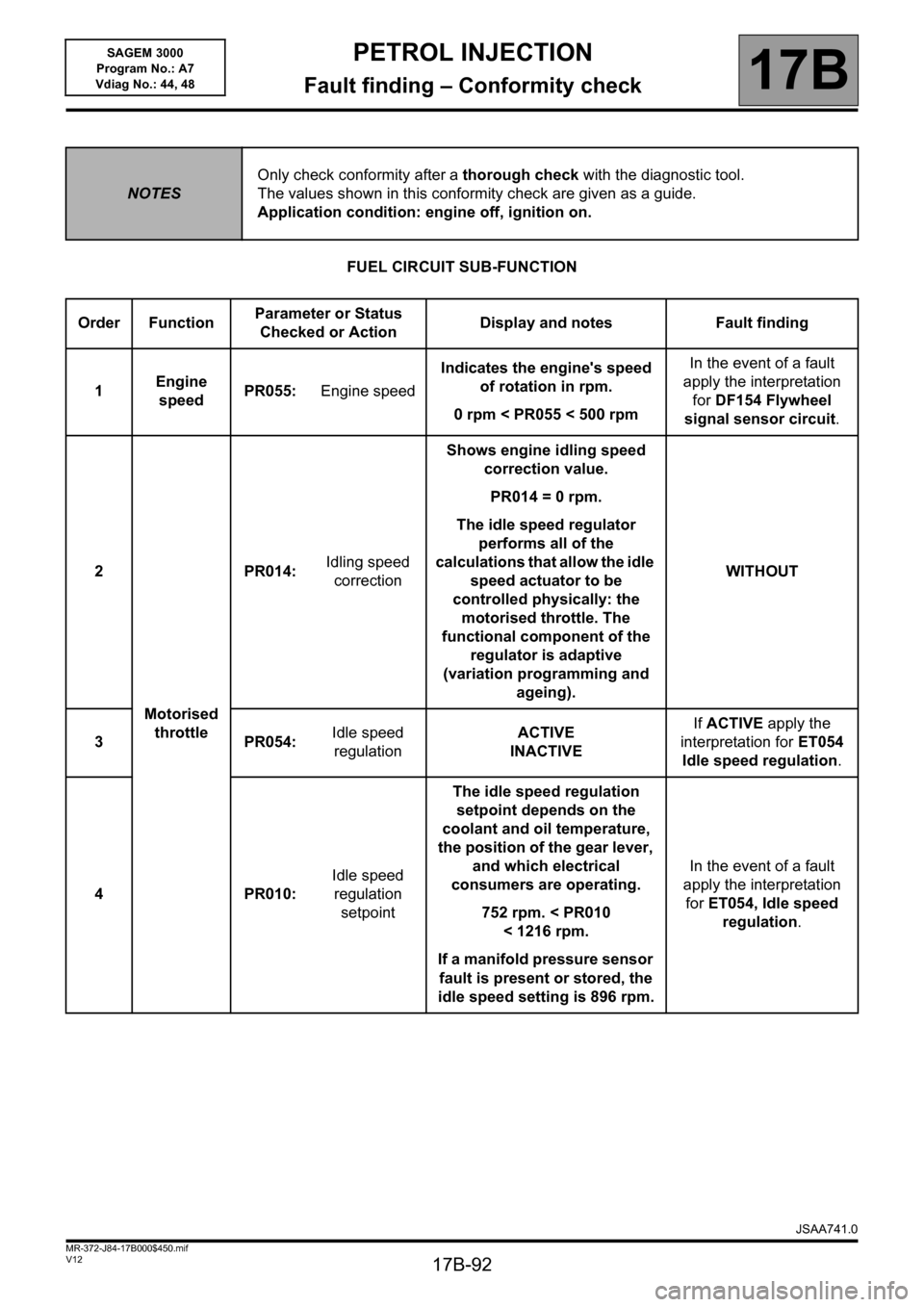

FUEL CIRCUIT SUB-FUNCTION

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1Engine

speedPR055: Engine speedIndicates the engine's speed

of rotation in rpm.

0 rpm < PR055 < 500 rpmIn the event of a fault

apply the interpretation

for DF154 Flywheel

signal sensor circuit.

2

Motorised

throttlePR014: Idling speed

correctionShows engine idling speed

correction value.

PR014= 0rpm.

The idle speed regulator

performs all of the

calculations that allow the idle

speed actuator to be

controlled physically: the

motorised throttle. The

functional component of the

regulator is adaptive

(variation programming and

ageing).WITHOUT

3 PR054: Idle speed

regulationACTIVE

INACTIVEIf ACTIVE apply the

interpretation for ET054

Idle speed regulation.

4 PR010: Idle speed

regulation

setpointThe idle speed regulation

setpoint depends on the

coolant and oil temperature,

the position of the gear lever,

and which electrical

consumers are operating.

752 rpm. < PR010

< 1216 rpm.

If a manifold pressure sensor

fault is present or stored, the

idle speed setting is 896 rpm.In the event of a fault

apply the interpretation

for ET054, Idle speed

regulation.

JSAA741.0

Page 93 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-93V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

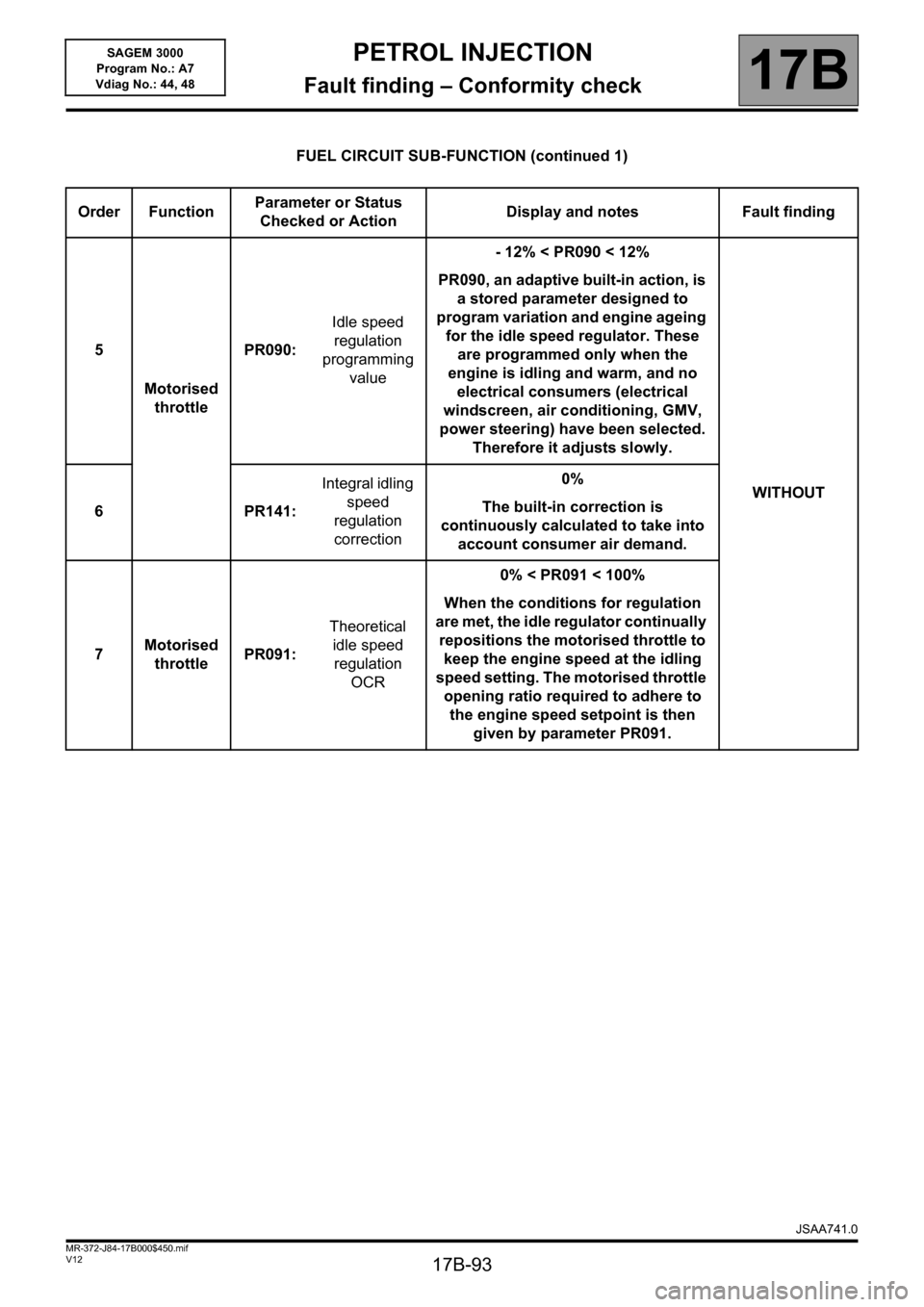

FUEL CIRCUIT SUB-FUNCTION (continued 1)

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

5

Motorised

throttlePR090: Idle speed

regulation

programming

value- 12% < PR090 < 12%

PR090, an adaptive built-in action, is

a stored parameter designed to

program variation and engine ageing

for the idle speed regulator. These

are programmed only when the

engine is idling and warm, and no

electrical consumers (electrical

windscreen, air conditioning, GMV,

power steering) have been selected.

Therefore it adjusts slowly.

WITHOUT

6 PR141: Integral idling

speed

regulation

correction0%

The built-in correction is

continuously calculated to take into

account consumer air demand.

7 Motorised

throttlePR091: Theoretical

idle speed

regulation

OCR0% < PR091 < 100%

When the conditions for regulation

are met, the idle regulator continually

repositions the motorised throttle to

keep the engine speed at the idling

speed setting. The motorised throttle

opening ratio required to adhere to

the engine speed setpoint is then

given by parameter PR091.

JSAA741.0

Page 94 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-94V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

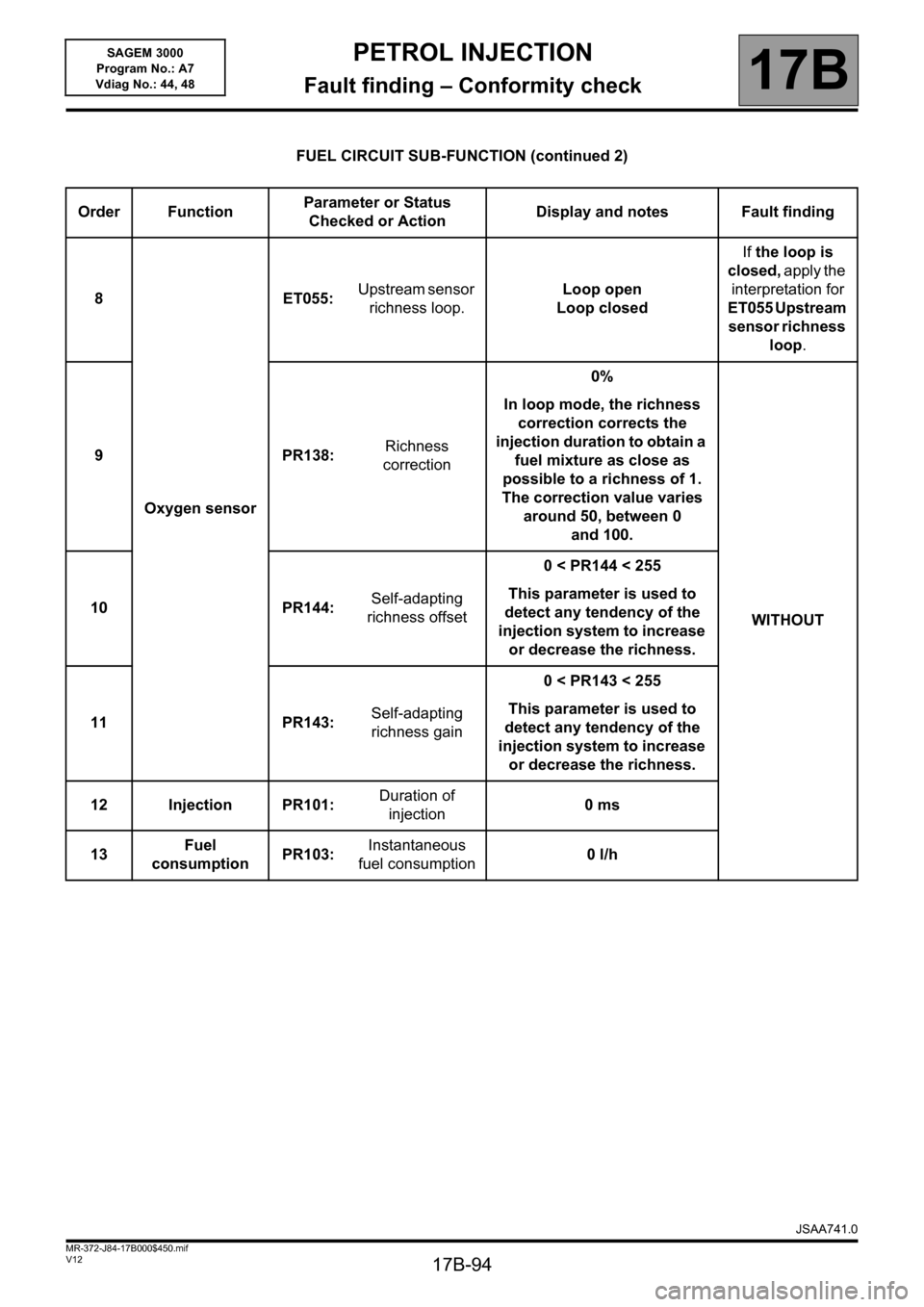

FUEL CIRCUIT SUB-FUNCTION (continued 2)

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

8

Oxygen sensorET055: Upstream sensor

richness loop.Loop open

Loop closedIf the loop is

closed, apply the

interpretation for

ET055 Upstream

sensor richness

loop.

9 PR138: Richness

correction0%

In loop mode, the richness

correction corrects the

injection duration to obtain a

fuel mixture as close as

possible to a richness of 1.

The correction value varies

around 50, between 0

and 100.

WITHOUT 10 PR144: Self-adapting

richness offset0 < PR144 < 255

This parameter is used to

detect any tendency of the

injection system to increase

or decrease the richness.

11 PR143: Self-adapting

richness gain0 < PR143 < 255

This parameter is used to

detect any tendency of the

injection system to increase

or decrease the richness.

12 Injection PR101: Duration of

injection0ms

13Fuel

consumptionPR103: Instantaneous

fuel consumption0l/h

JSAA741.0

Page 95 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-95V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

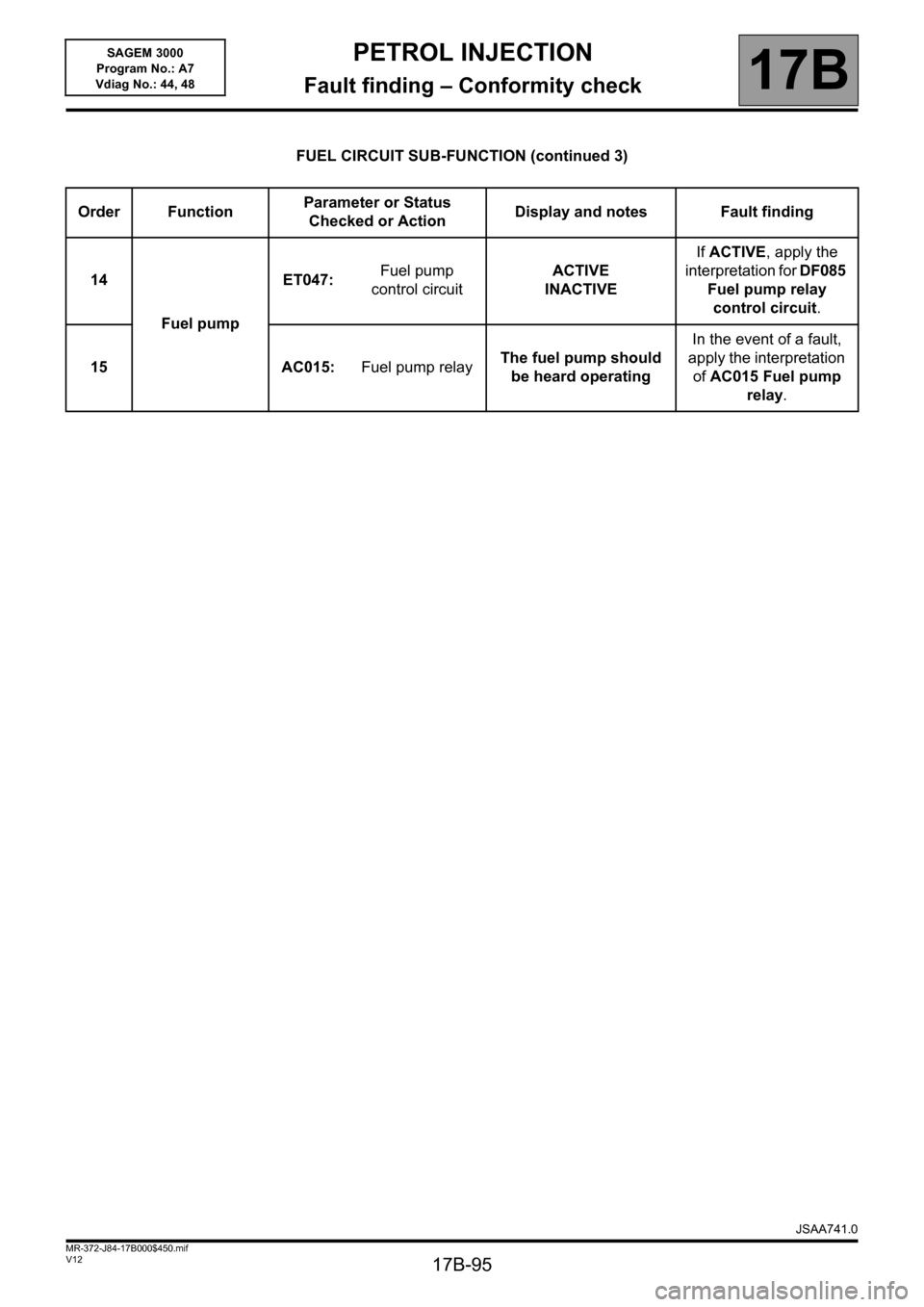

FUEL CIRCUIT SUB-FUNCTION (continued 3)

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

14

Fuel pumpET047: Fuel pump

control circuitACTIVE

INACTIVEIf ACTIVE, apply the

interpretation for DF085

Fuel pump relay

control circuit.

15 AC015: Fuel pump relayThe fuel pump should

be heard operatingIn the event of a fault,

apply the interpretation

of AC015 Fuel pump

relay.

JSAA741.0

Page 96 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-96V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

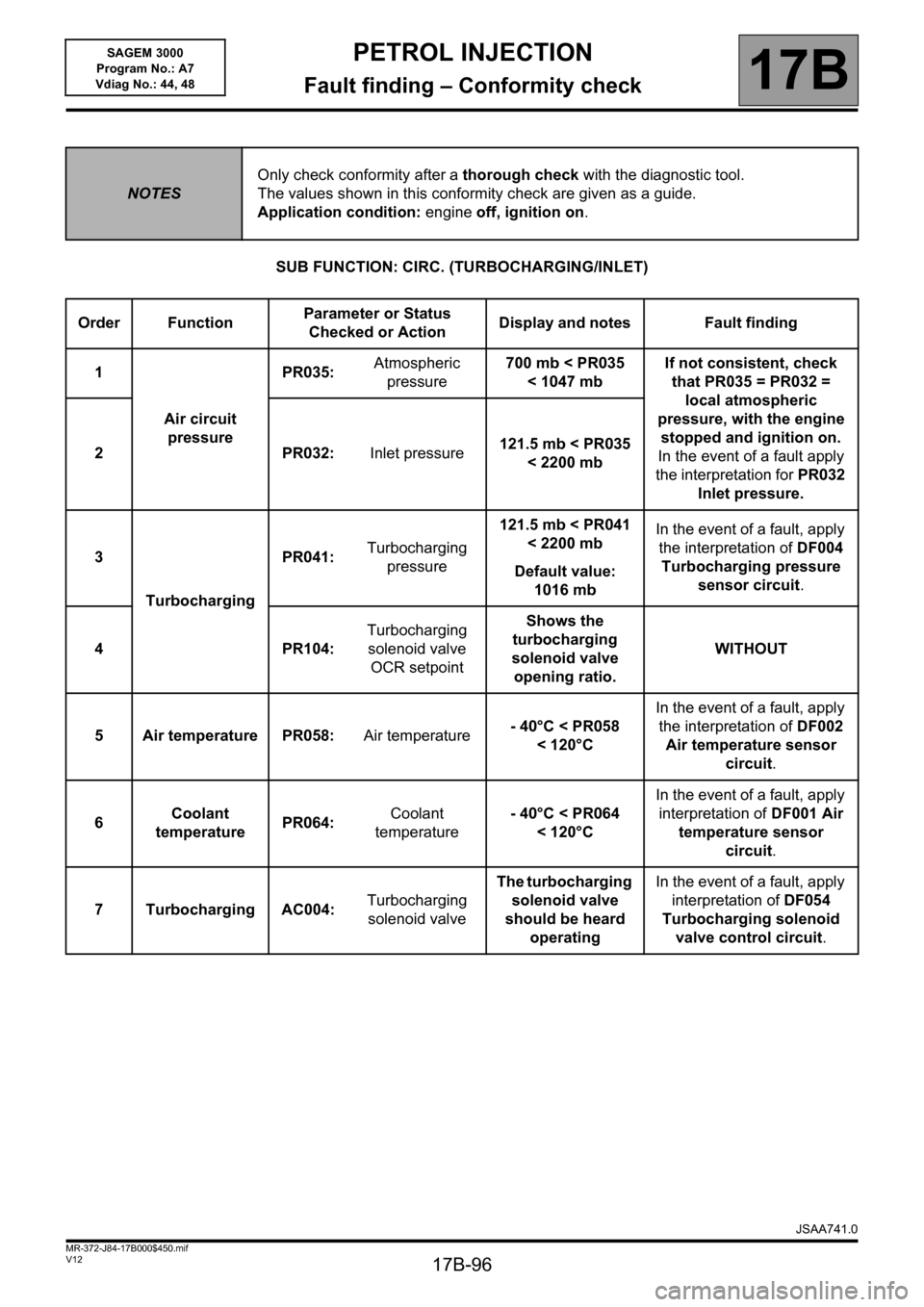

SUB FUNCTION: CIRC. (TURBOCHARGING/INLET)

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Air circuit

pressurePR035: Atmospheric

pressure700 mb < PR035

<1047mbIf not consistent, check

that PR035 = PR032 =

local atmospheric

pressure, with the engine

stopped and ignition on.

In the event of a fault apply

the interpretation for PR032

Inlet pressure. 2 PR032: Inlet pressure121.5 mb < PR035

<2200mb

3

TurbochargingPR041: Turbocharging

pressure121.5 mb < PR041

<2200mb

Default value:

1016 mbIn the event of a fault, apply

the interpretation of DF004

Turbocharging pressure

sensor circuit.

4 PR104: Turbocharging

solenoid valve

OCR setpointShows the

turbocharging

solenoid valve

opening ratio.WITHOUT

5 Air temperature PR058: Air temperature- 40°C < PR058

< 120°CIn the event of a fault, apply

the interpretation of DF002

Air temperature sensor

circuit.

6Coolant

temperaturePR064: Coolant

temperature- 40°C < PR064

< 120°CIn the event of a fault, apply

interpretation of DF001 Air

temperature sensor

circuit.

7 Turbocharging AC004: Turbocharging

solenoid valveThe turbocharging

solenoid valve

should be heard

operatingIn the event of a fault, apply

interpretation of DF054

Turbocharging solenoid

valve control circuit.

JSAA741.0

Page 97 of 181

PETROL INJECTION

Fault finding – Conformity check17B

17B-97V12 MR-372-J84-17B000$450.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

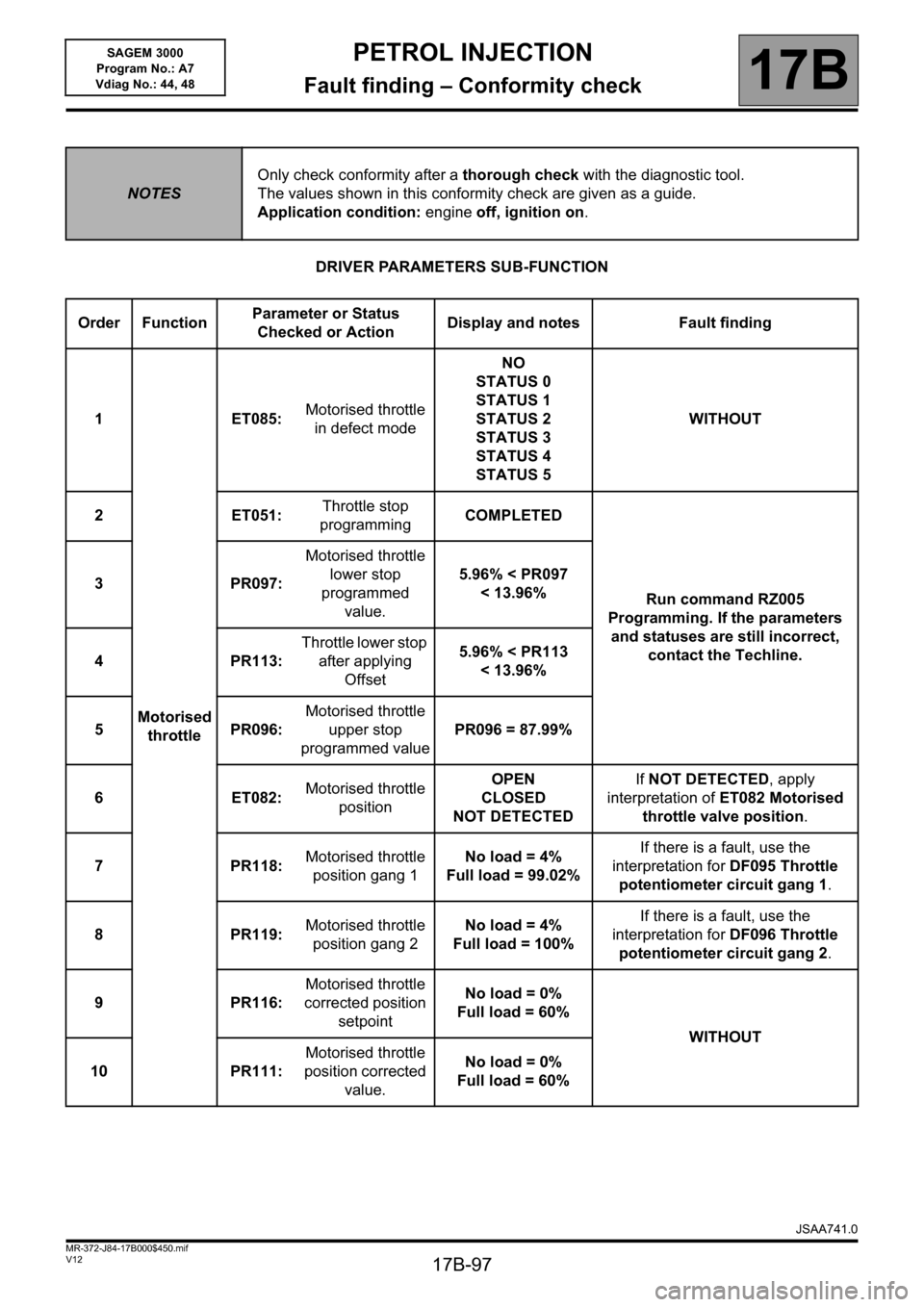

DRIVER PARAMETERS SUB-FUNCTION

NOTESOnly check conformity after a thorough check with the diagnostic tool.

The values shown in this conformity check are given as a guide.

Application condition: engine off, ignition on.

Order FunctionParameter or Status

Checked or ActionDisplay and notes Fault finding

1

Motorised

throttleET085: Motorised throttle

in defect modeNO

STATUS 0

STATUS 1

STATUS 2

STATUS 3

STATUS 4

STATUS 5WITHOUT

2 ET051: Throttle stop

programmingCOMPLETED

Run command RZ005

Programming. If the parameters

and statuses are still incorrect,

contact the Techline. 3 PR097: Motorised throttle

lower stop

programmed

value.5.96% < PR097

< 13.96%

4 PR113: Throttle lower stop

after applying

Offset5.96% < PR113

< 13.96%

5 PR096: Motorised throttle

upper stop

programmed valuePR096 = 87.99%

6 ET082: Motorised throttle

positionOPEN

CLOSED

NOT DETECTEDIf NOT DETECTED, apply

interpretation of ET082 Motorised

throttle valve position.

7 PR118: Motorised throttle

position gang 1No load = 4%

Full load = 99.02%If there is a fault, use the

interpretation for DF095 Throttle

potentiometer circuit gang 1.

8 PR119: Motorised throttle

position gang 2No load = 4%

Full load = 100%If there is a fault, use the

interpretation for DF096 Throttle

potentiometer circuit gang 2.

9 PR116: Motorised throttle

corrected position

setpointNo load = 0%

Full load = 60%

WITHOUT

10 PR111: Motorised throttle

position corrected

value.No load = 0%

Full load = 60%

JSAA741.0