sensor RENAULT SCENIC 2014 J95 / 3.G Petrol Injection - Sagem3000 Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2014, Model line: SCENIC, Model: RENAULT SCENIC 2014 J95 / 3.GPages: 181

Page 6 of 181

PETROL INJECTION

Fault finding – Introduction17B

17B-6V12 MR-372-J84-17B000$045.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

5. FAULT FINDING LOG

You will always be asked for this log:

– when requesting technical assistance from Techline,

– for approval requests when replacing parts for which approval is mandatory,

– to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any damage or injury:

– check the battery voltage to avoid incorrect operation of computer functions,

– use the proper tools.

7. FAULT FINDING

Stored faults are managed the same way for all sensors and actuators.

A stored fault is cleared after 128 recurrence-free starts.IMPORTANT!IMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools. The

FAULT FINDING LOG, which should be completed during the fault finding procedure, ensures a

record is kept of the procedure carried out. It is an essential document when consulting the

manufacturer.

IT IS THEREFORE MANDATORY TO FILL OUT A FAULT FINDING LOG EACH TIME FAULT FINDING IS

CARRIED OUT.

JSAA741.0

Page 7 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 7V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – System operation

1. SYSTEM OPERATION

Composition

The injection system consists of the:

– accelerator potentiometer,

– accelerator pedal switch,

– TDC sensor,

– atmospheric pressure sensor,

– air temperature sensor,

– coolant temperature sensor,

– freon pressure sensor,

– upstream oxygen sensor,

– downstream oxygen sensor,

– cruise control switch,

– steering column switch,

– cruise control on/off switch,

– brake lights switch,

– fuel vapour absorber,

– injection computer,

– motorised throttle valve,

– four injectors,

– four pencil coils,

– + turbocharging pressure sensor,

– coolant pump

– turbocharging solenoid valve.

Computer

SAGEM S3000 flash EEPROM 128-track computer controlling the injection and the ignition.

Multipoint injection in sequential mode.

Connections to the other computers:

– Protection and Switching Unit (UPC)

– Passenger Compartment Control Unit (UCH),

– Automatic Transmission Electronic Control Unit (AUTO ECU).

JSAA741.0

MR-372-J84-17B000$090.mif

Page 9 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 9V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

2. OPERATIONAL SAFETY

Warning lights illumination

The S3000 injection system manages the illumination of three warning lights and the issuing of warning messages

according to the severity of the faults detected, to inform the customer and to direct fault finding.

The injection computer manages the illumination of warning lights and warning messages displayed on the instrument

panel. These warning lights illuminate during the starting phase and in the event of an injection fault or engine

overheating.

The warning light illumination signals reach the instrument panel via the multiplex network.

Warning light illumination principle

During the starting phase (START button pressed) the OBD (On Board Diagnostic) warning light comes on for

approximately 3 seconds then goes out.

If there is an injection fault (severity 1), the INJECTION FAULT written message lights up followed by the SERVICE

warning light. It indicates a reduced level of operation and a limited safety level.

The driver should carry out repairs as soon as possible.

Components involved:

– motorised throttle valve,

– accelerator pedal potentiometer,

– inlet manifold pressure sensor,

–computer,

– actuator feed,

– computer feed.

If there is a serious injection fault (severity 2), the red engine symbol and the word STOP appear (display with

information display only), with the ENGINE OVERHEATING written message followed by the STOP warning light

and a buzzer. If this happens, the vehicle must be stopped immediately.

When a fault causing excessive pollution in the exhaust fumes is detected, the orange OBD warning light, an engine

symbol, will be lit:

–flashing in the event of a fault which might irreparably damaged the catalytic converter (destructive misfire). If this

happens you must stop the vehicle immediately,

–constantly in the case of non-compliance with the anti-pollution standards (pollutant misfire, catalytic converter

fault, oxygen sensor faults, inconsistency between the oxygen sensors and canister fault).

Mileage travelled with fault

This parameter serves to measure the distance travelled with one of the injection fault warning lights on: level 1 fault

warning light (amber), coolant temperature overheating warning light, or OBD warning light.

The counter can be reset to 0 using the diagnostic tool.

JSAA741.0

Page 10 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 10V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

Defect modes

Motorised throttle valve

In defect mode, the motorised throttle valve can have 6 different statuses.

Type 1

The throttle opening is less than the Safe mode position. The throttle is no longer activated and is

automatically in Safe mode. The ESP, distance control and cruise control/speed limiter systems are

disabled. The automatic transmission is in "Safe mode".

Type 2

The throttle opening is no longer actuated. The engine speed is limited by injection cut-off.

Type 3

Defect mode is associated with restructuring of the pedal setpoints (constant pedal setpoint for each gear).

Type 4

The associated defect mode restricts the throttle opening. The maximum throttle valve opening threshold

results in a speed below 54 mph (90 km/h).

Type 5

The computer no longer processes torque changes requested by the ESP, distance control, cruise control/

speed limiter and automatic gearbox systems.

This defect mode results from a computer malfunction, or a fault with the manifold or turbocharging

pressure sensor.

The system then only uses the accelerator pedal signal.

The ESP, distance control and cruise control/speed limiter systems are disabled. The automatic

transmission system is in Safe mode.

Type 6

The turbocharging valve no longer works.

JSAA741.0

Page 11 of 181

PETROL INJECTION

Fault finding – System operation17B

17B - 11V12 MR-372-J84-17B000$090.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

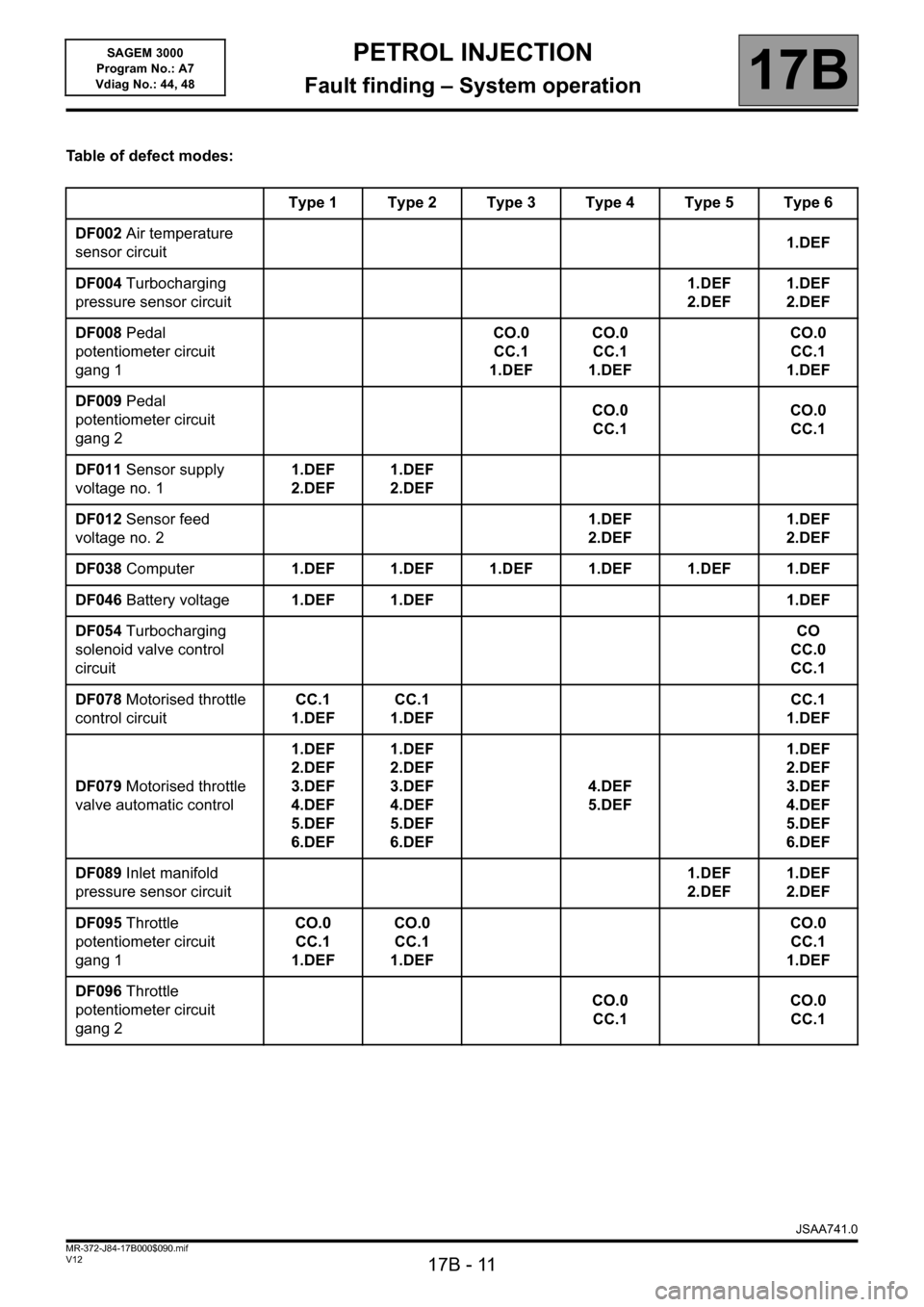

Table of defect modes:

Type 1 Type 2 Type 3 Type 4 Type 5 Type 6

DF002 Air temperature

sensor circuit1.DEF

DF004 Turbocharging

pressure sensor circuit1.DEF

2.DEF1.DEF

2.DEF

DF008 Pedal

potentiometer circuit

gang 1CO.0

CC.1

1.DEFCO.0

CC.1

1.DEFCO.0

CC.1

1.DEF

DF009 Pedal

potentiometer circuit

gang 2CO.0

CC.1CO.0

CC.1

DF011 Sensor supply

voltage no. 11.DEF

2.DEF1.DEF

2.DEF

DF012 Sensor feed

voltage no. 21.DEF

2.DEF1.DEF

2.DEF

DF038 Computer1.DEF 1.DEF 1.DEF 1.DEF 1.DEF 1.DEF

DF046 Battery voltage1.DEF 1.DEF 1.DEF

DF054 Turbocharging

solenoid valve control

circuitCO

CC.0

CC.1

DF078 Motorised throttle

control circuitCC.1

1.DEFCC.1

1.DEFCC.1

1.DEF

DF079 Motorised throttle

valve automatic control1.DEF

2.DEF

3.DEF

4.DEF

5.DEF

6.DEF1.DEF

2.DEF

3.DEF

4.DEF

5.DEF

6.DEF4.DEF

5.DEF1.DEF

2.DEF

3.DEF

4.DEF

5.DEF

6.DEF

DF089 Inlet manifold

pressure sensor circuit1.DEF

2.DEF1.DEF

2.DEF

DF095 Throttle

potentiometer circuit

gang 1CO.0

CC.1

1.DEFCO.0

CC.1

1.DEFCO.0

CC.1

1.DEF

DF096 Throttle

potentiometer circuit

gang 2CO.0

CC.1

CO.0

CC.1

JSAA741.0

Page 13 of 181

PETROL INJECTION

Fault finding – Allocation of computer tracks17B

17B - 13V12 MR-372-J84-17B000$135.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

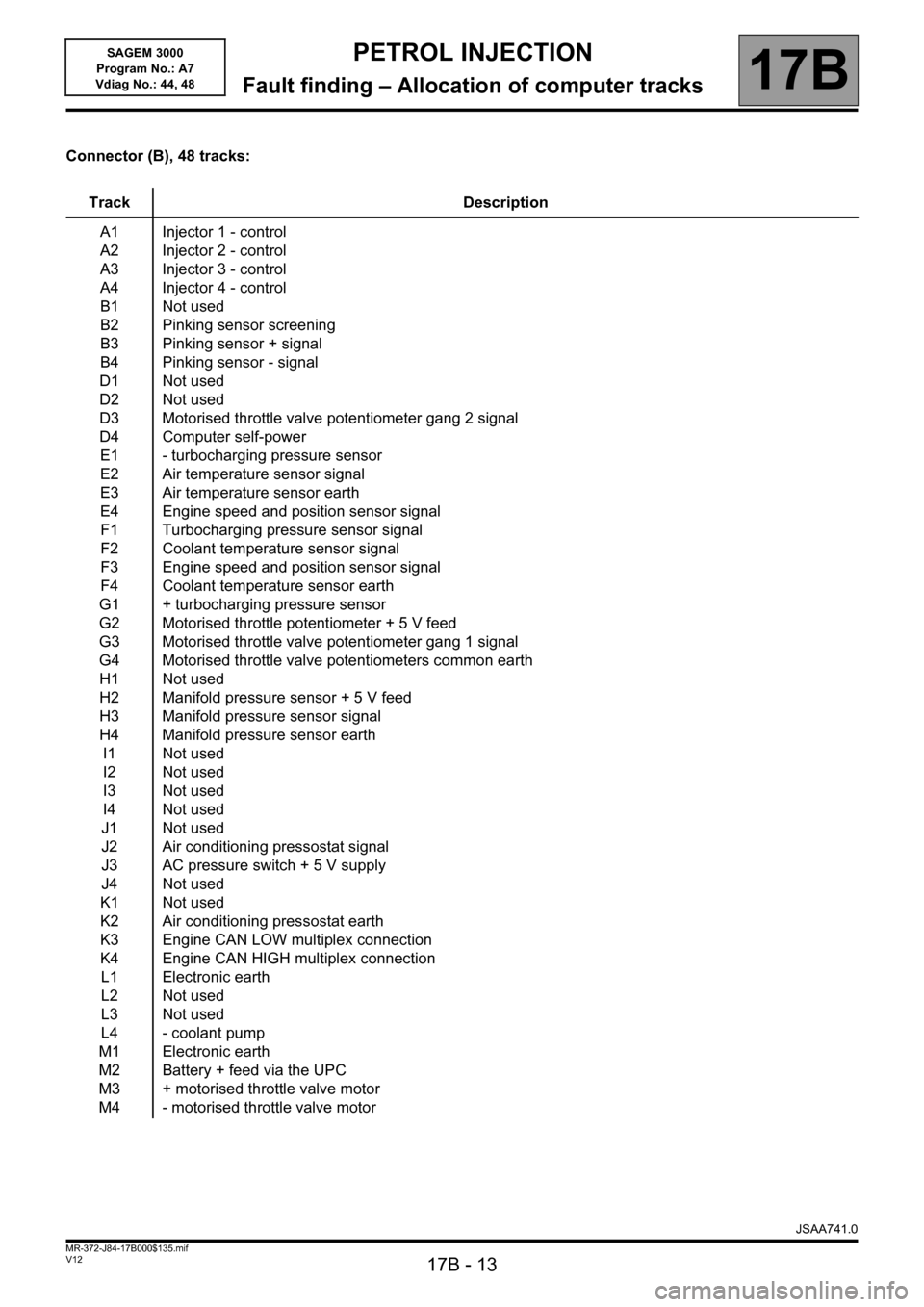

Connector (B), 48 tracks:

Track Description

A1

A2

A3

A4

B1

B2

B3

B4

D1

D2

D3

D4

E1

E2

E3

E4

F1

F2

F3

F4

G1

G2

G3

G4

H1

H2

H3

H4

I1

I2

I3

I4

J1

J2

J3

J4

K1

K2

K3

K4

L1

L2

L3

L4

M1

M2

M3

M4Injector 1 - control

Injector 2 - control

Injector 3 - control

Injector 4 - control

Not used

Pinking sensor screening

Pinking sensor + signal

Pinking sensor - signal

Not used

Not used

Motorised throttle valve potentiometer gang 2 signal

Computer self-power

- turbocharging pressure sensor

Air temperature sensor signal

Air temperature sensor earth

Engine speed and position sensor signal

Turbocharging pressure sensor signal

Coolant temperature sensor signal

Engine speed and position sensor signal

Coolant temperature sensor earth

+ turbocharging pressure sensor

Motorised throttle potentiometer + 5 V feed

Motorised throttle valve potentiometer gang 1 signal

Motorised throttle valve potentiometers common earth

Not used

Manifold pressure sensor + 5 V feed

Manifold pressure sensor signal

Manifold pressure sensor earth

Not used

Not used

Not used

Not used

Not used

Air conditioning pressostat signal

AC pressure switch + 5 V supply

Not used

Not used

Air conditioning pressostat earth

Engine CAN LOW multiplex connection

Engine CAN HIGH multiplex connection

Electronic earth

Not used

Not used

- coolant pump

Electronic earth

Battery + feed via the UPC

+ motorised throttle valve motor

- motorised throttle valve motor

JSAA741.0

Page 14 of 181

PETROL INJECTION

Fault finding – Allocation of computer tracks17B

17B - 14V12 MR-372-J84-17B000$135.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48

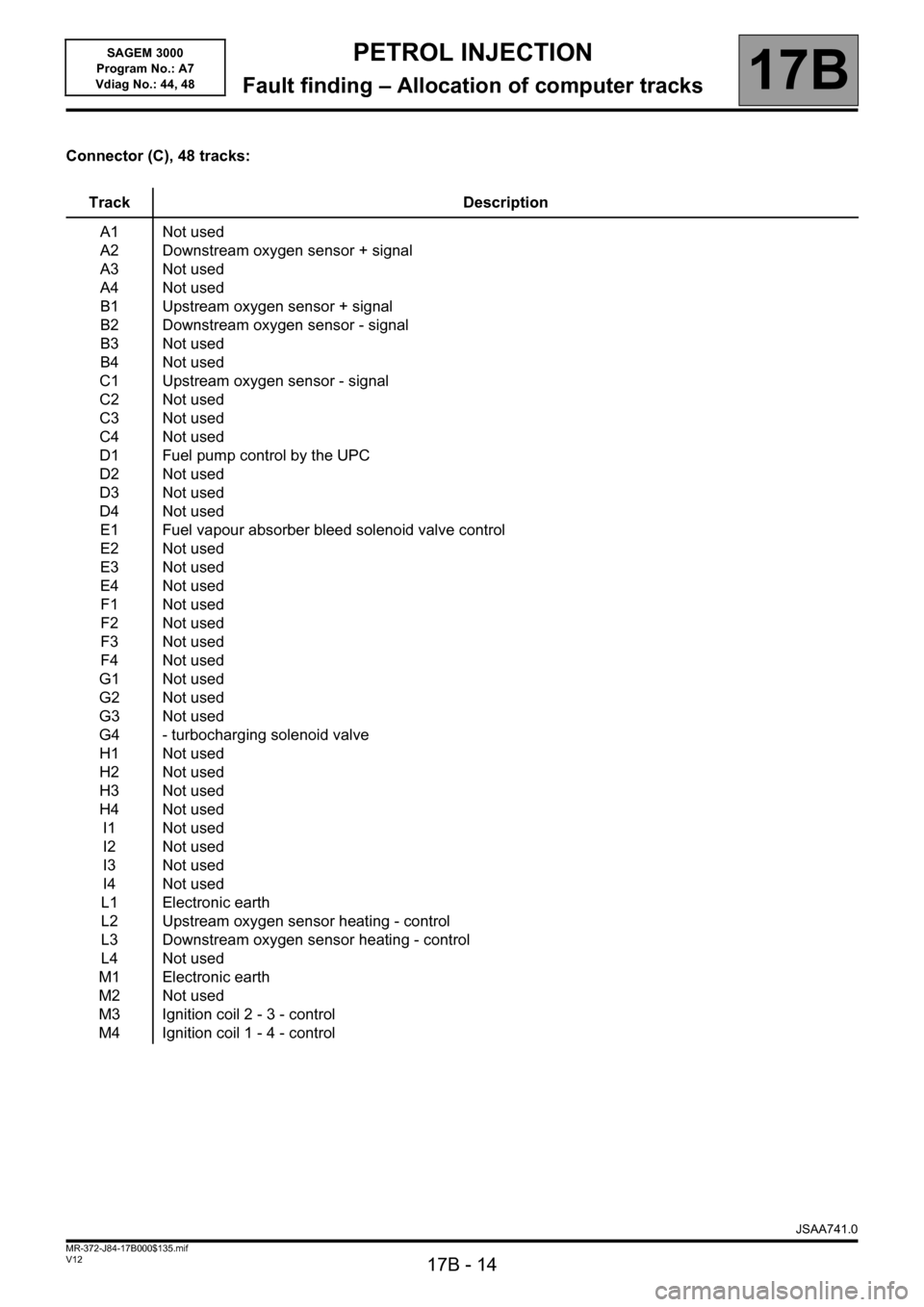

Connector (C), 48 tracks:

Track Description

A1

A2

A3

A4

B1

B2

B3

B4

C1

C2

C3

C4

D1

D2

D3

D4

E1

E2

E3

E4

F1

F2

F3

F4

G1

G2

G3

G4

H1

H2

H3

H4

I1

I2

I3

I4

L1

L2

L3

L4

M1

M2

M3

M4Not used

Downstream oxygen sensor + signal

Not used

Not used

Upstream oxygen sensor + signal

Downstream oxygen sensor - signal

Not used

Not used

Upstream oxygen sensor - signal

Not used

Not used

Not used

Fuel pump control by the UPC

Not used

Not used

Not used

Fuel vapour absorber bleed solenoid valve control

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

- turbocharging solenoid valve

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Electronic earth

Upstream oxygen sensor heating - control

Downstream oxygen sensor heating - control

Not used

Electronic earth

Not used

Ignition coil 2 - 3 - control

Ignition coil 1 - 4 - control

JSAA741.0

Page 15 of 181

PETROL INJECTION

Fault finding – Replacement of components17B

17B - 15V12 MR-372-J84-17B000$180.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Replacement of components

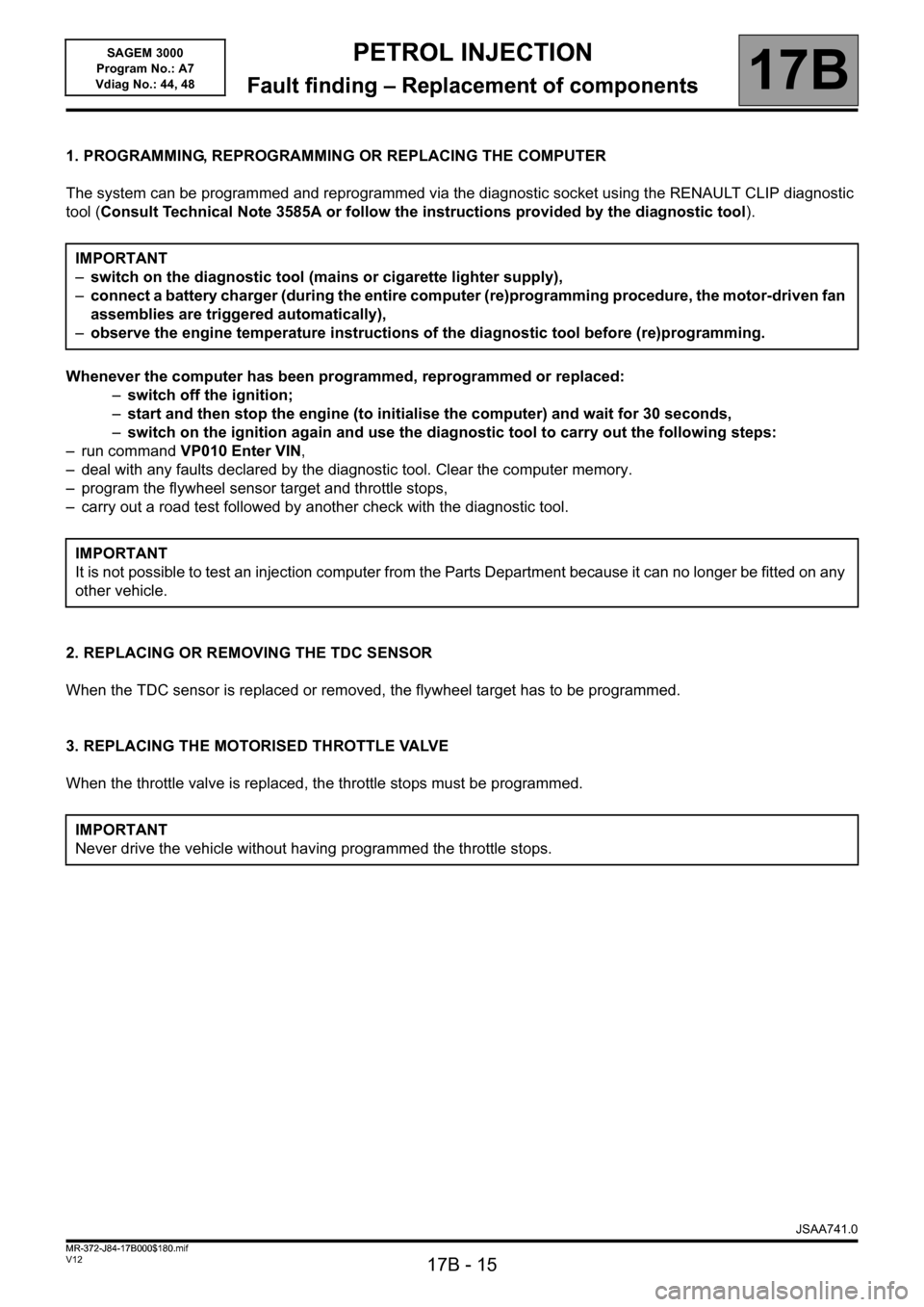

1. PROGRAMMING, REPROGRAMMING OR REPLACING THE COMPUTER

The system can be programmed and reprogrammed via the diagnostic socket using the RENAULT CLIP diagnostic

tool (Consult Technical Note 3585A or follow the instructions provided by the diagnostic tool).

Whenever the computer has been programmed, reprogrammed or replaced:

–switch off the ignition;

–start and then stop the engine (to initialise the computer) and wait for 30 seconds,

–switch on the ignition again and use the diagnostic tool to carry out the following steps:

– run command VP010 Enter VIN,

– deal with any faults declared by the diagnostic tool. Clear the computer memory.

– program the flywheel sensor target and throttle stops,

– carry out a road test followed by another check with the diagnostic tool.

2. REPLACING OR REMOVING THE TDC SENSOR

When the TDC sensor is replaced or removed, the flywheel target has to be programmed.

3. REPLACING THE MOTORISED THROTTLE VALVE

When the throttle valve is replaced, the throttle stops must be programmed.IMPORTANT

–switch on the diagnostic tool (mains or cigarette lighter supply),

–connect a battery charger (during the entire computer (re)programming procedure, the motor-driven fan

assemblies are triggered automatically),

–observe the engine temperature instructions of the diagnostic tool before (re)programming.

IMPORTANT

It is not possible to test an injection computer from the Parts Department because it can no longer be fitted on any

other vehicle.

IMPORTANT

Never drive the vehicle without having programmed the throttle stops.

JSAA741.0

MR-372-J84-17B000$180.mif

Page 16 of 181

PETROL INJECTION

Fault finding – Configurations and programming17B

17B - 16V12 MR-372-J84-17B000$225.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Configurations and programming

1. CONFIGURATION

Computer configuration by automatic detection

The computer can automatically configure itself based on the sensors or vehicle options it detects.

2. PROGRAMMING

Programming the flywheel target

Accelerate up to 4000 rpm in 3rd gear then decelerate to power take-up* speed. Then repeat immediately.

Check the programming with ET089.

Programming the throttle end stops

After replacing the computer or motorised throttle valve, after switching on the ignition, wait 30 seconds for the

computer to memorise the MAXIMUM and MINIMUM stops.

Check the programming with ET051.

* This is the moment when, during deceleration with no load, the engine drops to idle speed and recovers torque.

JSAA741.0

MR-372-J84-17B000$225.mif

Page 17 of 181

PETROL INJECTION

Fault finding – Fault summary table17B

17B - 17V12 MR-372-J84-17B000$270.mif

SAGEM 3000

Program No.: A7

Vdiag No.: 44, 48PETROL INJECTION

Fault finding – Fault summary table

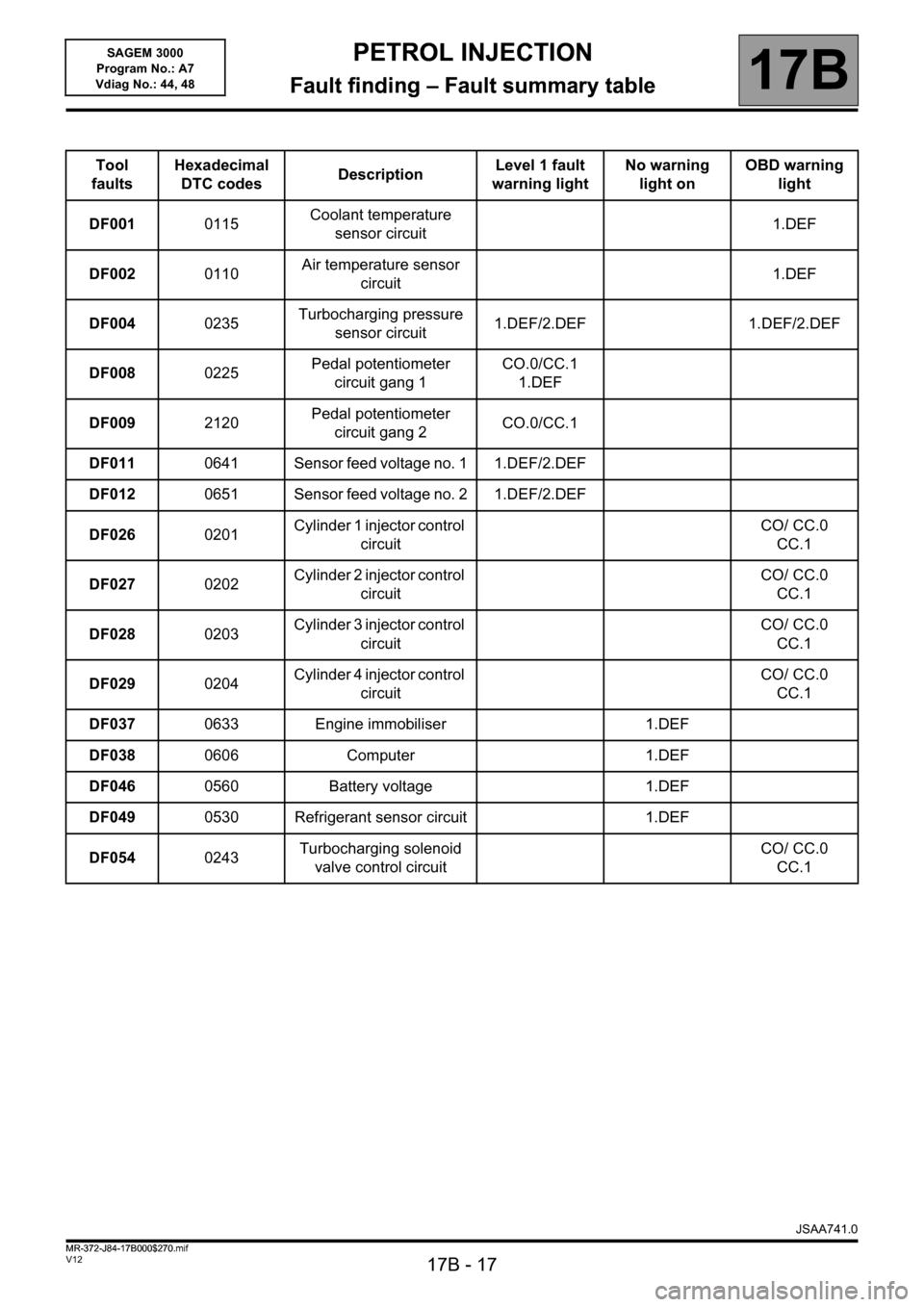

Tool

faultsHexadecimal

DTC codesDescriptionLevel 1 fault

warning lightNo warning

light onOBD warning

light

DF0010115Coolant temperature

sensor circuit1.DEF

DF0020110Air temperature sensor

circuit1.DEF

DF0040235Turbocharging pressure

sensor circuit1.DEF/2.DEF 1.DEF/2.DEF

DF0080225Pedal potentiometer

circuit gang 1CO.0/CC.1

1.DEF

DF0092120Pedal potentiometer

circuit gang 2CO.0/CC.1

DF0110641 Sensor feed voltage no. 1 1.DEF/2.DEF

DF0120651 Sensor feed voltage no. 2 1.DEF/2.DEF

DF0260201Cylinder 1 injector control

circuitCO/ CC.0

CC.1

DF0270202Cylinder 2 injector control

circuitCO/ CC.0

CC.1

DF0280203Cylinder 3 injector control

circuitCO/ CC.0

CC.1

DF0290204Cylinder 4 injector control

circuitCO/ CC.0

CC.1

DF0370633 Engine immobiliser 1.DEF

DF0380606 Computer 1.DEF

DF0460560 Battery voltage 1.DEF

DF0490530 Refrigerant sensor circuit 1.DEF

DF0540243Turbocharging solenoid

valve control circuitCO/ CC.0

CC.1

JSAA741.0

MR-372-J84-17B000$270.mif