RENAULT TWINGO 2009 2.G Air Conditioning Owners Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 122

Page 91 of 122

62A-10

AIR CONDITIONING

Refrigerant circuit: Draining - Filling

AIR CONDITIONING or CLIMATE CONTROL

62A

aTop up the oil with the recommended type and vol-

ume of oil and refrigerant, depending on the work

carried out (see 62A, Air conditioning, Air condi-

tioning: Parts and consumables for the repair,

page 62A-2) .

aCheck there are no leaks using the electronic de-

tector (see 62A, Air conditioning, Refrigerant cir-

cuit: Check, page 62A-7) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) . WARNING

After injecting dye into the refrigerant, be sure to

indicate this on a label (supplied with the dye

capsule), and the date of the operation.

Position the label so it is visible near to the cold

loop filler valve.

Page 92 of 122

62A-11

AIR CONDITIONING

Condenser: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDrain the cooling system (see Cooling system:

Draining - Refilling) (19A, Cooling).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front upper structure).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the cooling radiator (see Cooling radiator:

Removal - Refitting) (19A, Cooling). Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

WARNING

Consult the device's operating manual to avoid

incorrect use.D4F, and 780 – K9K – K4M

D4F, and 780 – K9K – K4M

Page 93 of 122

62A-12

AIR CONDITIONING

Condenser: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

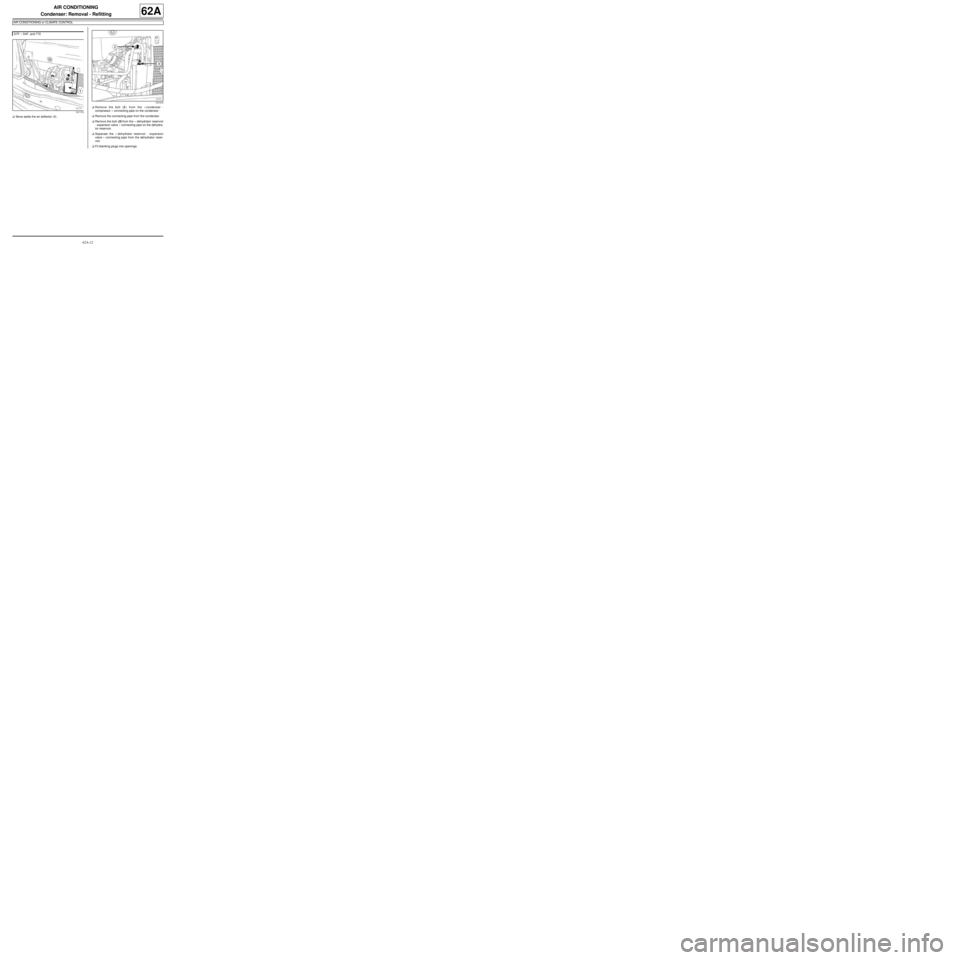

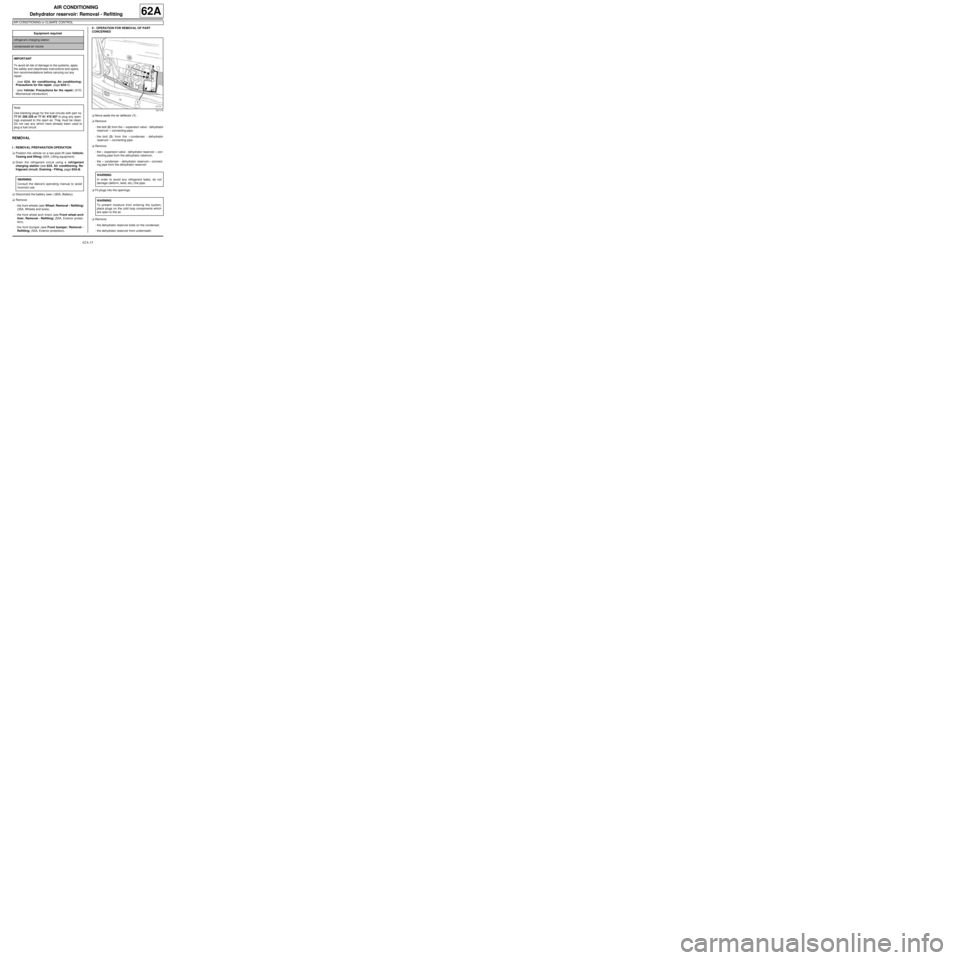

aMove aside the air deflector (1) .aRemove the bolt (2) from the « condenser -

compressor » connecting pipe on the condenser.

aRemove the connecting pipe from the condenser.

aRemove the bolt (3) from the « dehydrator reservoir

- expansion valve » connecting pipe on the dehydra-

tor reservoir.

aSeparate the « dehydrator reservoir - expansion

valve » connecting pipe from the dehydrator reser-

voir.

aFit blanking plugs into openings. D7F – D4F, and 772

121174

121312

Page 94 of 122

62A-13

AIR CONDITIONING

Condenser: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

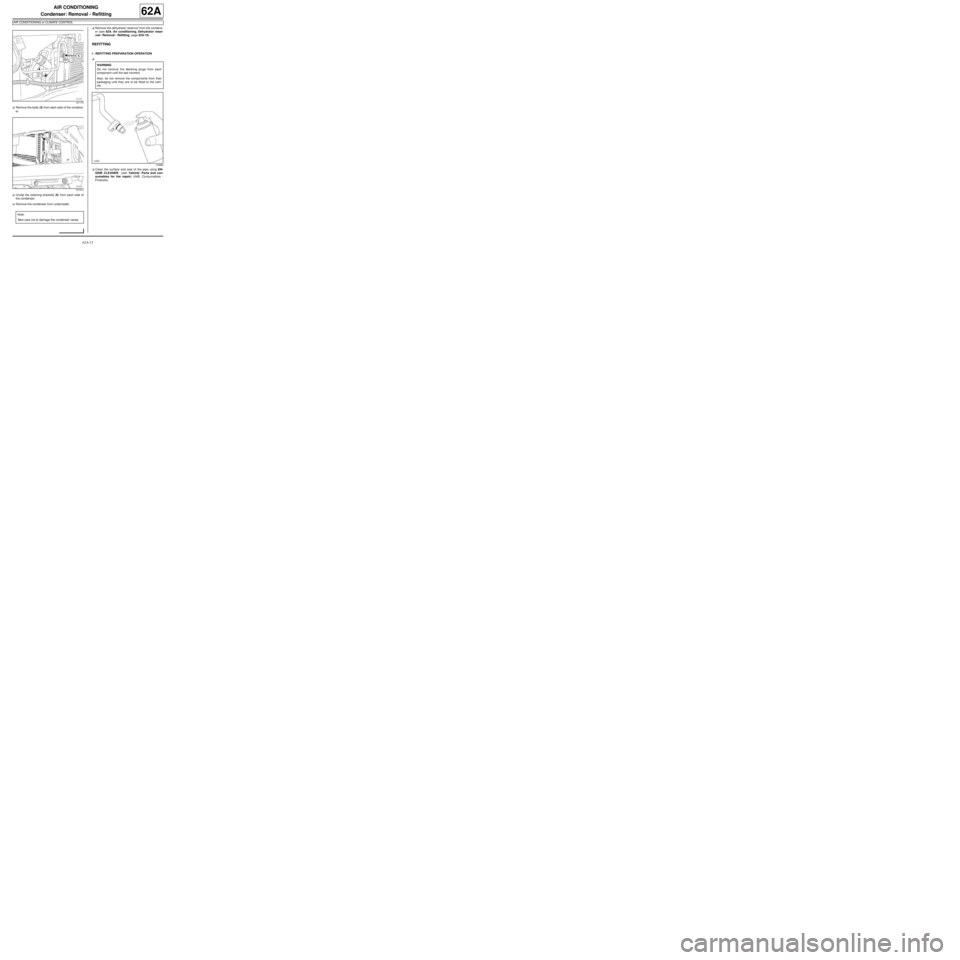

aRemove the bolts (5) from each side of the condens-

er.

aUnclip the retaining brackets (6) from each side of

the condenser.

aRemove the condenser from underneath.aRemove the dehydrator reservoir from the condens-

er (see 62A, Air conditioning, Dehydrator reser-

voir: Removal - Refitting, page 62A-15) .

REFITTING

I - REFITTING PREPARATION OPERATION

a

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

121175

121314

Note:

Take care not to damage the condenser vanes.

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

143880

Page 95 of 122

62A-14

AIR CONDITIONING

Condenser: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the condenser from underneath.

aPosition the condenser on the cooling radiator.

aClip the retaining brackets on each side of the con-

denser.

aRefit the bolts on each side of the condenser.

aFit the « dehydrator reservoir - expansion valve »

connecting pipe on the dehydrator reservoir.

aRefit the bolt of the « dehydrator reservoir - expan-

sion valve » connecting pipe on the dehydrator res-

ervoir.

aFit the « condenser - compressor » connecting pipe

on the condenser.

aRefit the bolt of the « condenser - compressor » con-

necting pipe on the condenser.aPosition the air deflector.

aRefit the cooling radiator (see Cooling radiator: Re-

moval - Refitting) (19A, Cooling).

III - FINAL OPERATION

aRefit:

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front upper structure),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aFill up and bleed the cooling system (see Cooling

system: Draining - Refilling) (19A, Cooling).

aConsult the amount of refrigerant and oil required

before filling the air conditioning circuit (see 62A, Air

conditioning, Air conditioning: Parts and con-

sumables for the repair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) .

143882

D7F – D4F, and 772

D4F, and 780 – K9K – K4M

D4F, and 780 – K9K – K4M

Page 96 of 122

62A-15

AIR CONDITIONING

Dehydrator reservoir: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aMove aside the air deflector (1) .

aRemove:

-the bolt (2) from the « expansion valve - dehydrator

reservoir » connecting pipe,

-the bolt (3) from the « condenser - dehydrator

reservoir » connecting pipe.

aRemove:

-the « expansion valve - dehydrator reservoir » con-

necting pipe from the dehydrator reservoir,

-the « condenser - dehydrator reservoir » connect-

ing pipe from the dehydrator reservoir.

aFit plugs into the openings.

aRemove:

-the dehydrator reservoir bolts on the condenser,

-the dehydrator reservoir from underneath. Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part no.

77 01 208 229 or 77 01 476 857 to plug any open-

ings exposed to the open air. They must be clean.

Do not use any which have already been used to

plug a fuel circuit.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121174

WARNING

In order to avoid any refrigerant leaks, do not

damage (deform, twist, etc.) the pipe.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which

are open to the air.

Page 97 of 122

62A-16

AIR CONDITIONING

Dehydrator reservoir: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

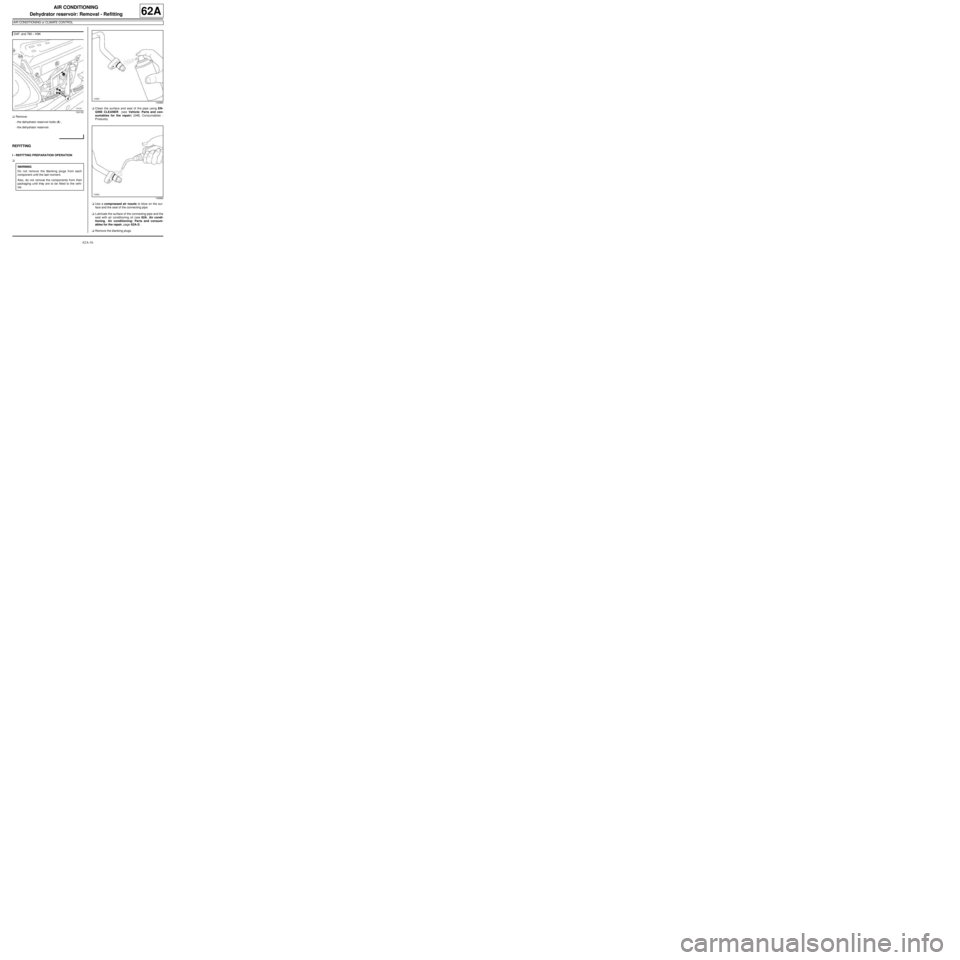

aRemove:

-the dehydrator reservoir bolts (4) ,

-the dehydrator reservoir.

REFITTING

I - REFITTING PREPARATION OPERATION

aaClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

aUse a compressed air nozzle to blow on the sur-

face and the seal of the connecting pipe.

aLubricate the surface of the connecting pipe and the

seal with air conditioning oil (see 62A, Air condi-

tioning, Air conditioning: Parts and consum-

ables for the repair, page 62A-2) .

aRemove the blanking plugs. D4F, and 780 – K9K

124102

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

143880

143882

Page 98 of 122

62A-17

AIR CONDITIONING

Dehydrator reservoir: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the dehydrator reservoir,

-the dehydrator reservoir bolts on the condenser.

aFit:

-the « condenser - dehydrator reservoir » connect-

ing pipe on the dehydrator reservoir,

-the « expansion valve - dehydrator reservoir » con-

necting pipe on the dehydrator reservoir.

aRefit:

-the bolt on the « condenser - dehydrator

reservoir » connecting pipe,

-the bolt on the « expansion valve - dehydrator

reservoir » connecting pipe.

aPosition the air deflector.

III - FINAL OPERATION

aRefit:

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres).

aConnect the battery (see ) (80A, Battery).

aConsult the refrigerant and oil quantity values before

filling the circuit (see 62A, Air conditioning, Air

conditioning: Parts and consumables for the re-

pair, page 62A-2) .

aFill the refrigerant circuit using a refrigerant charg-

ing station (see 62A, Air conditioning, Refriger-

ant circuit: Draining - Filling, page 62A-8) .

aCheck for leaks (see 62A, Air conditioning, Refrig-

erant circuit: Check, page 62A-7) .

aCheck that the air conditioning system is operating

correctly (see 62A, Air conditioning, Air condi-

tioning: Check, page 62A-4) . Note:

When replacing the dehydrator reservoir, add 15

ml of the recommended oil to the quantity of oil

recovered.

Page 99 of 122

62A-18

AIR CONDITIONING

Compressor: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).aDrain the refrigerant circuit using a refrigerant

charging station (see 62A, Air conditioning, Re-

frigerant circuit: Draining - Filling, page 62A-8) .

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the accessories belt (see Accessories belt: Re-

moval - Refitting) (10A, Engine and peripherals).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the bolts (1) from the connecting pipes on

the compressor. Equipment required

refrigerant charging station

compressed air nozzle

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 62A, Air conditioning, Air conditioning:

Precautions for the repair, page 62A-1) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

Note:

Use blanking plugs for the fuel circuits with part

numbers 77 01 208 229 or 77 01 476 857 to plug

any openings exposed to the open air. They must

be clean. Do not use any which have already been

used to plug a fuel circuit.

WARNING

To prevent moisture from entering the system,

place plugs on the cold loop components which are

open to the air.

WARNING

In order to avoid any refrigerant leaks, do not dam-

age (deform, twist, etc.) the pipe.

WARNING

Consult the device's operating manual to avoid

incorrect use.

121175

Page 100 of 122

62A-19

AIR CONDITIONING

Compressor: Removal - Refitting

AIR CONDITIONING or CLIMATE CONTROL

62A

aRemove the bolt (2) from the connecting pipe brack-

et on the compressor.

aMove aside the connecting pipes.

aPut blanking plugs in the openings.

aDisconnect the compressor connector (3) .

aRemove:

-the compressor bolts (4) ,

-the compressor.

REFITTING

I - REFITTING PREPARATION OPERATION

a

aClean the surface and seal of the pipe using EN-

GINE CLEANER (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

121174

121176

WARNING

Do not remove the blanking plugs from each

component until the last moment.

Also, do not remove the components from their

packaging until they are to be fitted to the vehi-

cle.

143880