RENAULT TWINGO 2009 2.G Chasiss User Guide

TWINGO 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1719/w960_1719-0.png

RENAULT TWINGO 2009 2.G Chasiss User Guide

Page 18 of 281

30A-14

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

aFit the pipe in the rivet press (see Garage Equip-

ment Catalogue).

aAdjust the length of the pipe to be shaped.

aTorque tighten the press end piece(40 N.m).

III - CHECKING THE RIVETS

aVisually inspect:

-the uniformity of the rivets' diameter,

-the rivet centring in relation to the pipe shaft.aVisually check that the internal diameter of the pipe

is not oval-shaped.

aCheck that the diameter of the end panel is not oval

shaped using a sliding calliper.

Correct diameter if (X1) = (X2)

IV - PREPARATION OF THE PIPE BEFORE

BENDING

a

aBlow inside the pipe in both directions using a com-

pressed air nozzle.

aPut plugs on the bolts or nuts at the ends of the pipe.

aPut the original pipe on a flat base plate that is the

length of the pipe.

128667

128669

128668

128645

Note:

Impurities may spread inside the pipe while the

rivets are being made.

Page 21 of 281

30A-17

GENERAL INFORMATION

Rigid brake pipe: Repair

30A

V - CHECKING BENDING

aCheck the out-of-roundness of the outer diameter at

the centre of the curve radius (2) using a sliding cal-

liper (the out-of-roundness of the outer diameter is

correct if it is less than 10% flattening):

-nominal diameter of the pipe: 4.75 mm,

-minimum diameter after bending: 4.30 mm.VI - REFITTING THE PIPE

a

aTorque tighten the brake pipe bolts (8 N.m).

aTorque tighten the underbody unions (female/

male) (6 N.m).

128664

128670

Note:

When refitting the rigid brake pipe:

-respect the original routing as much as possi-

ble,

-adjust the pipe routing by hand when fitting

inside the clips.

WARNING

Contact points between the rigid brake pipe and

the surrounding components could cause dam-

age to the pipe. In order to avoid these contacts,

adjust the pipe routing by hand.

128644

128646

Page 24 of 281

30A-20

GENERAL INFORMATION

Steering: Tightening torque

30A

119483

119647119883

119544

Page 25 of 281

30A-21

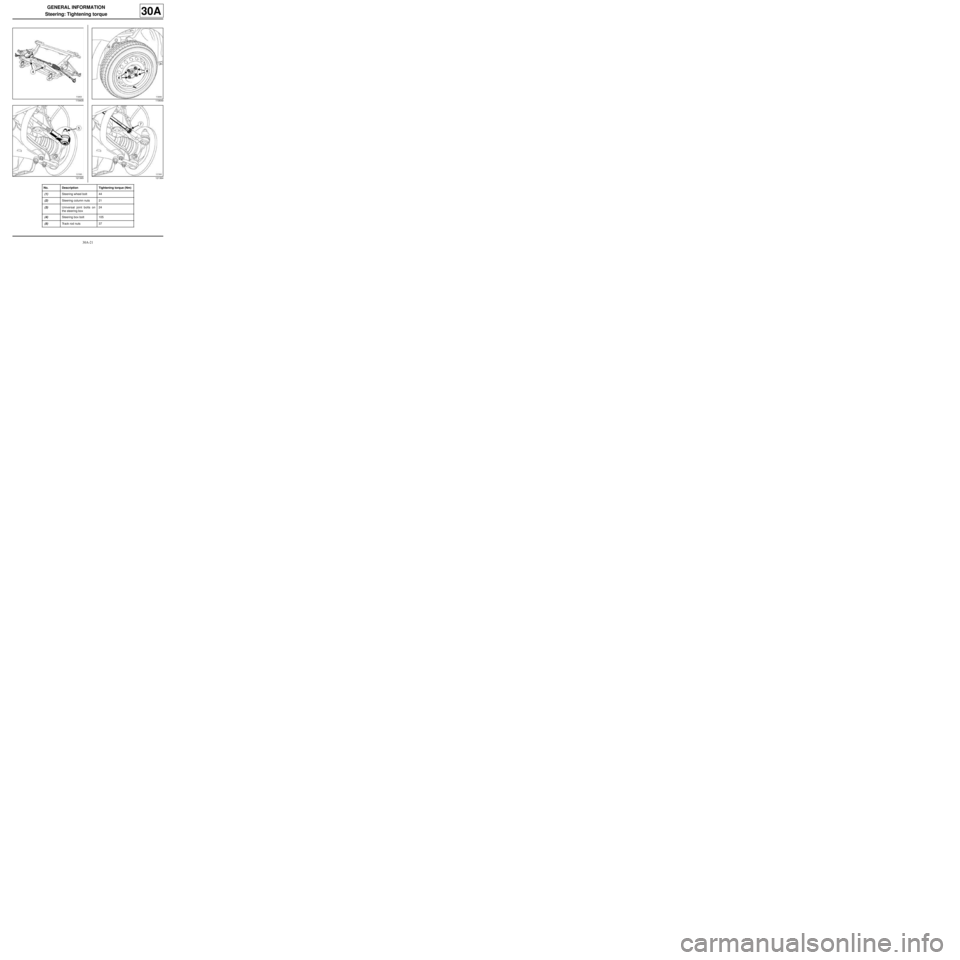

GENERAL INFORMATION

Steering: Tightening torque

30A

119405

121365119649

121364

No. Description Tightening torque (Nm)

(1) Steering wheel bolt 44

(2) Steering column nuts 21

(3) Universal joint bolts on

the steering box24

(4) Steering box bolt 105

(5) Track rod nuts 37

Page 26 of 281

30A-22

GENERAL INFORMATION

Steering: Tightening torque

30A

(6) Wheel bolt 105

(7) Wheel alignment lock nut 53 No. Description Tightening torque (Nm)

Page 31 of 281

30A-27

GENERAL INFORMATION

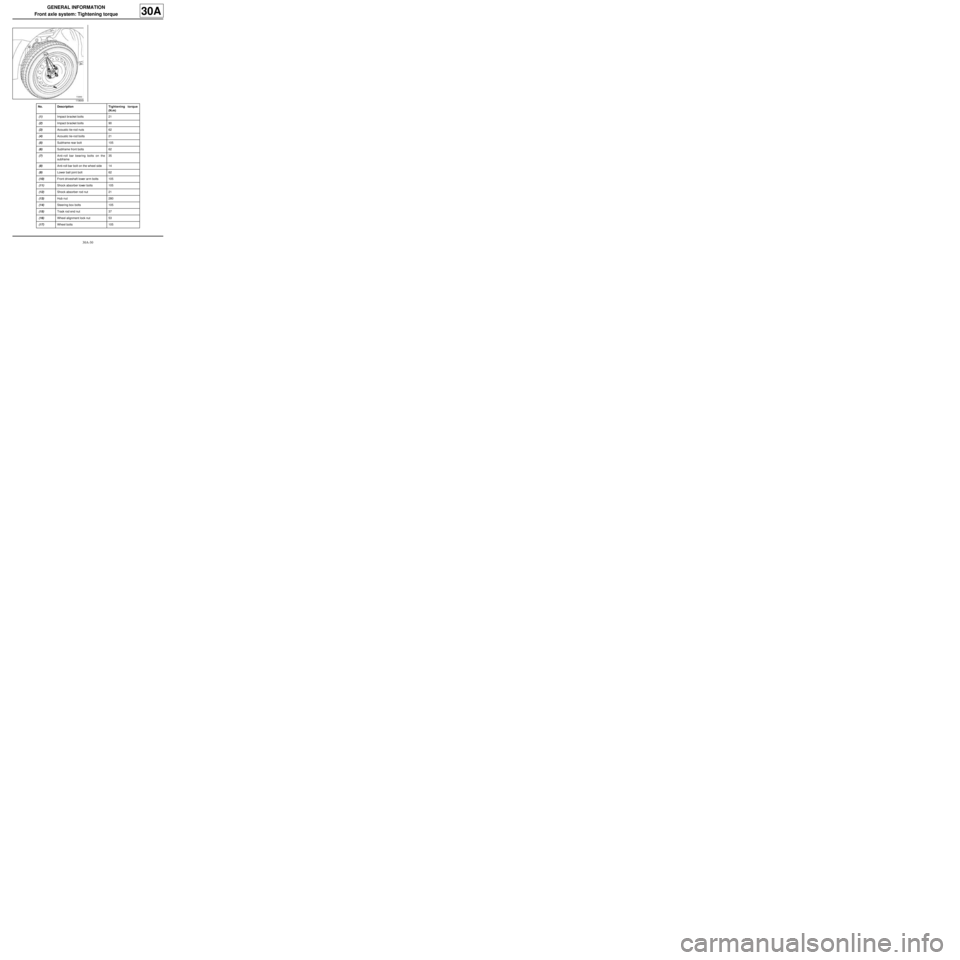

Front axle system: Tightening torque

30A

119335

119210

119336

119406

Page 32 of 281

30A-28

GENERAL INFORMATION

Front axle system: Tightening torque

30A

119224

119344

119654

119221

Page 33 of 281

30A-29

GENERAL INFORMATION

Front axle system: Tightening torque

30A

119543

119405121365

121364

Page 34 of 281

30A-30

GENERAL INFORMATION

Front axle system: Tightening torque

30A

119649

No. DescriptionTightening torque

(N.m)

(1) Impact bracket bolts 21

(2) Impact bracket bolts 90

(3) Acoustic tie-rod nuts 62

(4) Acoustic tie-rod bolts 21

(5) Subframe rear bolt 105

(6) Subframe front bolts 62

(7) Anti-roll bar bearing bolts on the

subframe35

(8) Anti-roll bar bolt on the wheel side 14

(9) Lower ball joint bolt 62

(10) Front driveshaft lower arm bolts 105

(11) Shock absorber lower bolts 105

(12) Shock absorber rod nut 21

(13) Hub nut 280

(14) Steering box bolts 105

(15) Track rod end nut 37

(16) Wheel alignment lock nut 53

(17) Wheel bolts 105

Page 40 of 281

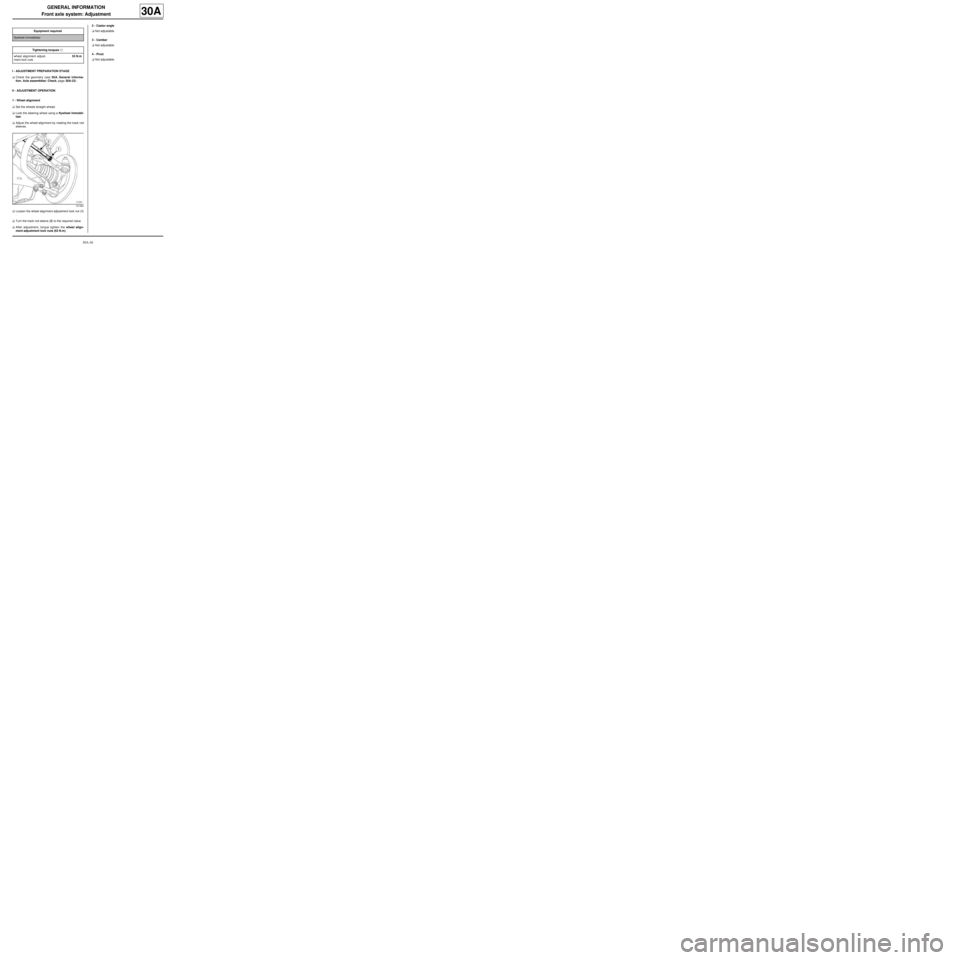

30A-36

GENERAL INFORMATION

Front axle system: Adjustment

30A

I - ADJUSTMENT PREPARATION STAGE

aCheck the geometry (see 30A, General informa-

tion, Axle assemblies: Check, page 30A-23) .

II - ADJUSTMENT OPERATION

1 - Wheel alignment

aSet the wheels straight ahead.

aLock the steering wheel using a flywheel immobil-

iser.

aAdjust the wheel alignment by rotating the track rod

sleeves.

aLoosen the wheel alignment adjustment lock nut (1)

.

aTurn the track rod sleeve (2) to the required value.

aAfter adjustment, torque tighten the wheel align-

ment adjustment lock nuts (53 N.m).2 - Castor angle

aNot adjustable.

3 - Camber

aNot adjustable.

4 - Pivot

aNot adjustable. Equipment required

flywheel immobiliser

Tightening torquesm

wheel alignment adjust-

ment lock nuts53 N.m

121364