RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 191 of 281

37A-12

MECHANICAL COMPONENT CONTROLS

Brake servo non-return valve: Removal - Refitting

RIGHT-HAND DRIVE

37A

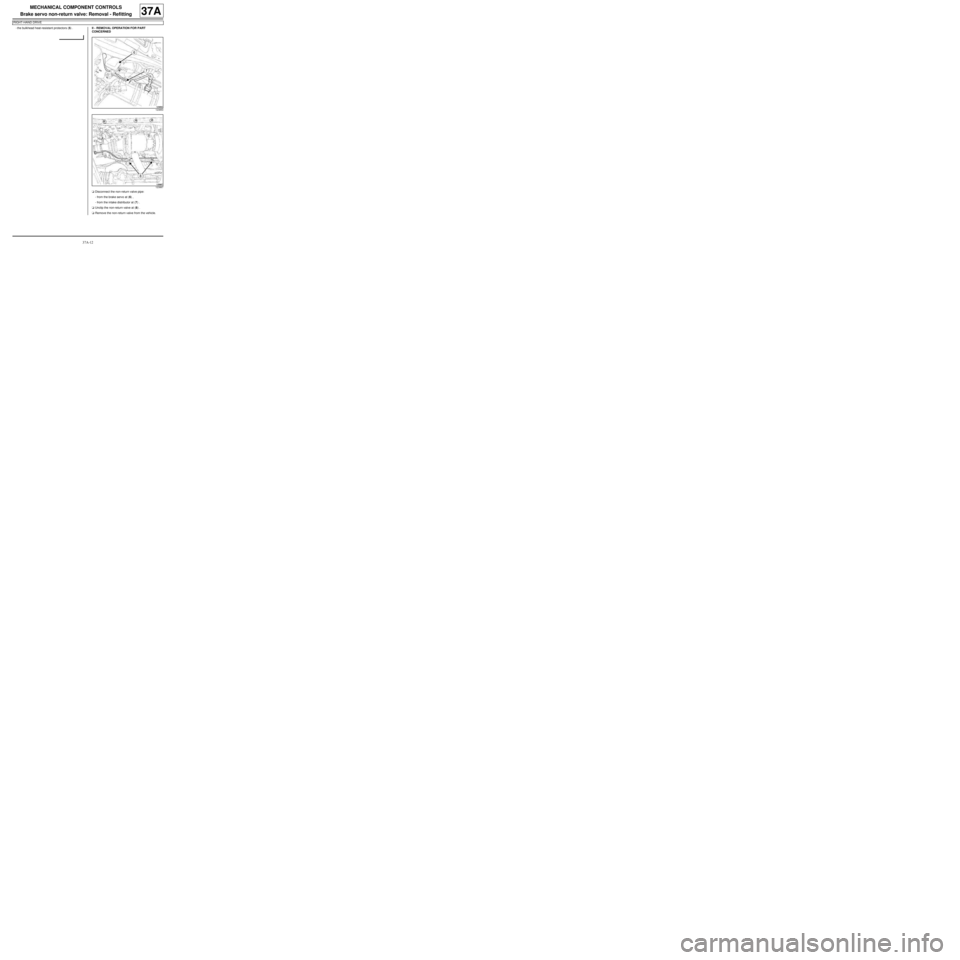

-the bulkhead heat-resistant protectors (5) .II - REMOVAL OPERATION FOR PART

CONCERNED

aDisconnect the non-return valve pipe:

-from the brake servo at (6) ,

-from the intake distributor at (7) .

aUnclip the non-return valve at (8) .

aRemove the non-return valve from the vehicle.

123850

123867

Page 192 of 281

37A-13

MECHANICAL COMPONENT CONTROLS

Brake servo non-return valve: Removal - Refitting

RIGHT-HAND DRIVE

37A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the non-return valve.

aClip on the non-return valve.

aConnect the non-return valve pipe:

-to the brake servo,

-to the intake distributor.

II - FINAL OPERATION.

aRefit:

-the bulkhead heat-resistant protectors,

-the bulkhead heat-resistant protector nuts,

-the bulkhead heat-resistant protector bolts,

-the upstream oxygen sensor (see Oxygen sen-

sors: Removal - Refitting) .

aRefit:

-the bulkhead heat-resistant protector,

-the bulkhead heat-resistant protector bolts.

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (MR 412, 56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (MR 412, 56A, Exterior

equipment),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (MR 412,

55A, Exterior protection),

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) . D4F, and 780

D4F or D7F

Page 193 of 281

37A-14

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

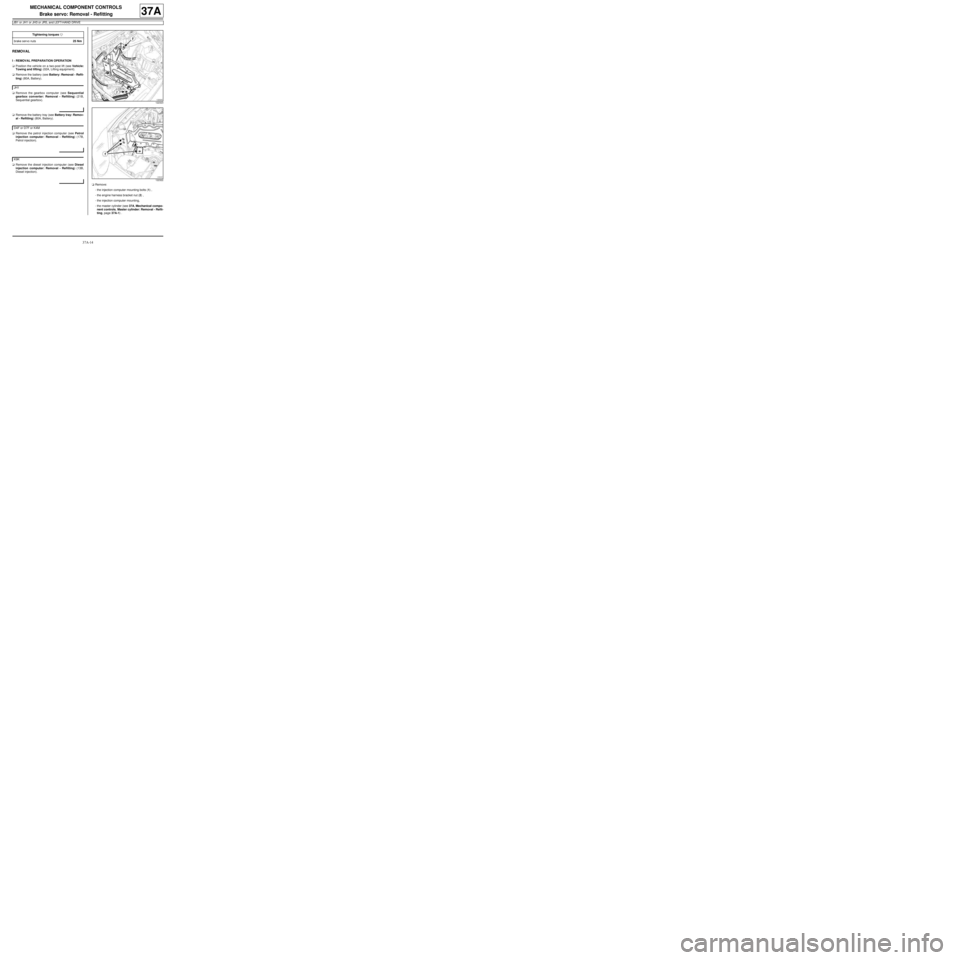

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRemove the gearbox computer (see Sequential

gearbox converter: Removal - Refitting) (21B,

Sequential gearbox).

aRemove the battery tray (see Battery tray: Remov-

al - Refitting) (80A, Battery).

aRemove the petrol injection computer (see Petrol

injection computer: Removal - Refitting) (17B,

Petrol injection).

aRemove the diesel injection computer (see Diesel

injection computer: Removal - Refitting) (13B,

Diesel injection).

aRemove:

-the injection computer mounting bolts (1) ,

-the engine harness bracket nut (2) ,

-the injection computer mounting,

-the master cylinder (see 37A, Mechanical compo-

nent controls, Master cylinder: Removal - Refit-

ting, page 37A-1) . Tightening torquesm

brake servo nuts25 Nm

JH1

D4F or D7F or K4M

K9K

122323

122322

Page 194 of 281

37A-15

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

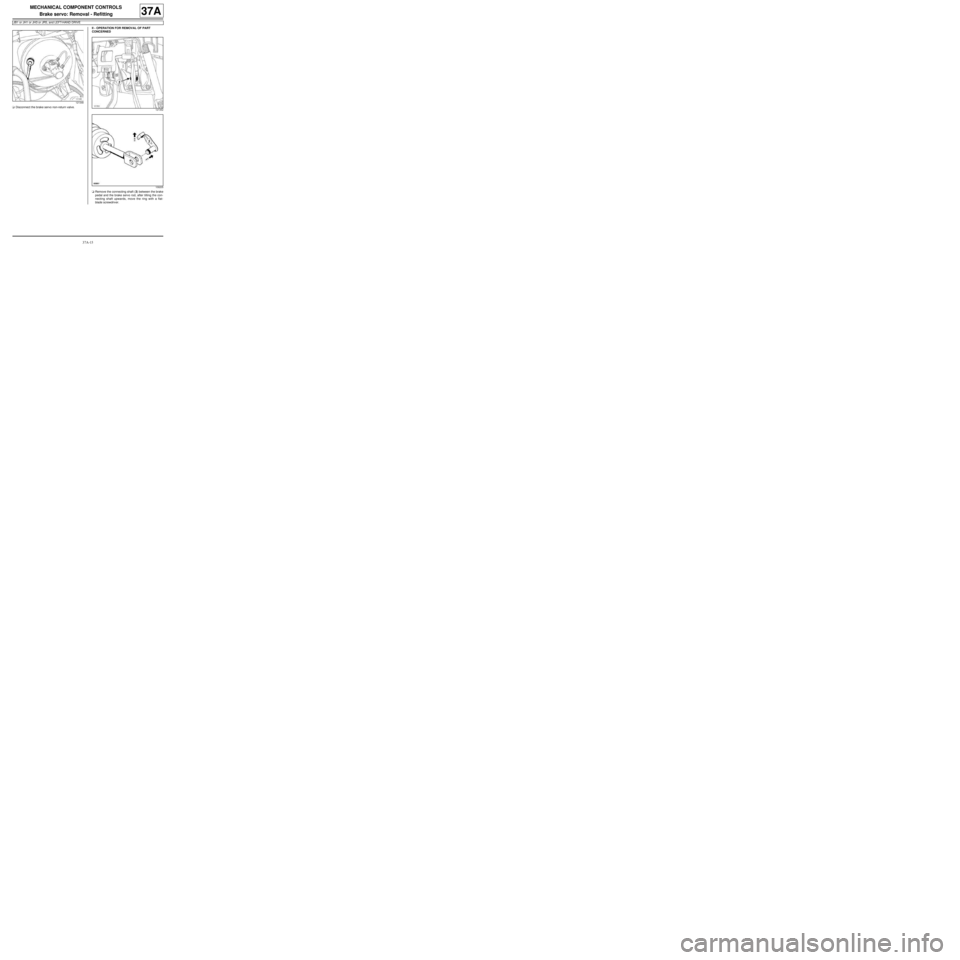

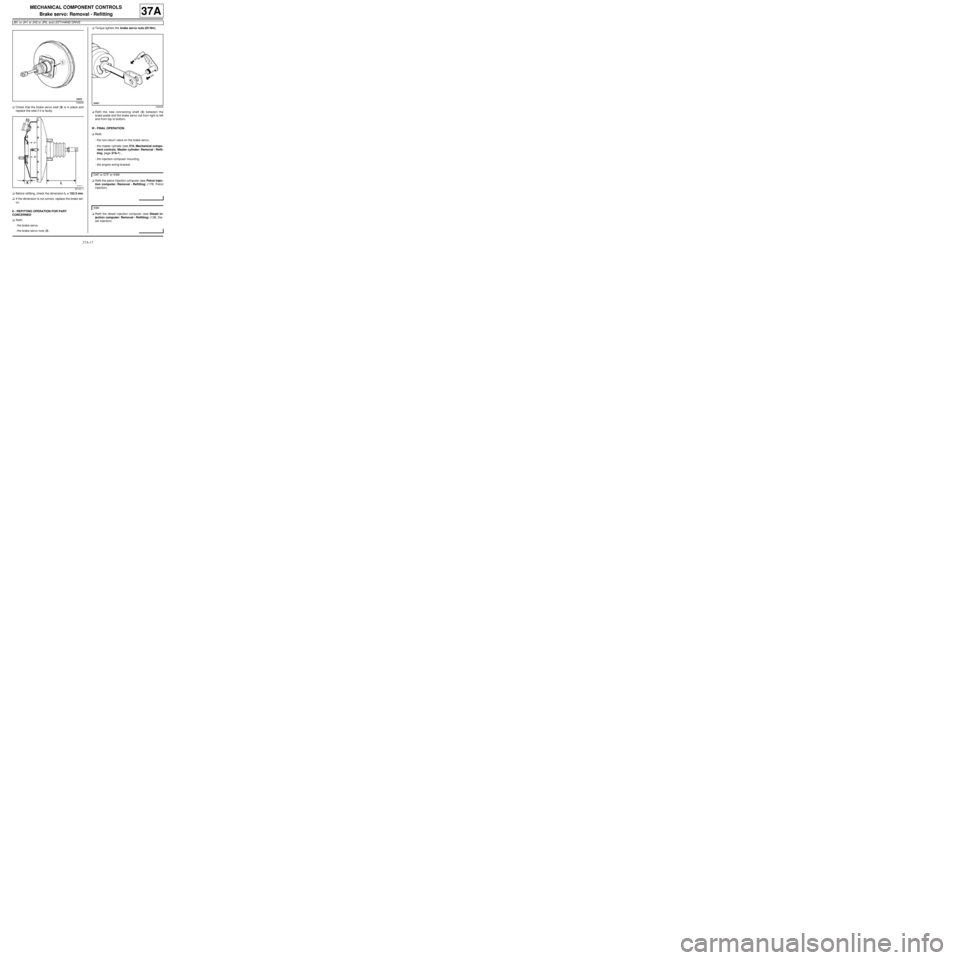

aDisconnect the brake servo non-return valve.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the connecting shaft (3) between the brake

pedal and the brake servo rod, after tilting the con-

necting shaft upwards, move the ring with a flat-

blade screwdriver.

121348

121352

109205

Page 195 of 281

37A-16

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

aRemove:

-the nuts (4) from the brake servo on the « brake

pedal - clutch » assembly,

-the brake servo.aRemove:

-the brake servo nuts (4) from the brake pedal plate,

-the brake servo.

REFITTING

I - REFITTING PREPARATION OPERATION

aThe shaft connecting the brake servo pushrod and

the brake pedal must be replaced every time it is re-

moved. JB1 or JH3 or JR5

121353

JH1

122227

Page 196 of 281

37A-17

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

aCheck that the brake servo seal (5) is in place and

replace the seal if it is faulty.

aBefore refitting, check the dimension L = 153.3 mm.

aIf the dimension is not correct, replace the brake ser-

vo.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the brake servo,

-the brake servo nuts (3) .aTorque tighten the brake servo nuts (25 Nm).

aRefit the new connecting shaft (3) between the

brake pedal and the brake servo rod from right to left

and from top to bottom.

III - FINAL OPERATION.

aRefit:

-the non-return valve on the brake servo,

-the master cylinder (see 37A, Mechanical compo-

nent controls, Master cylinder: Removal - Refit-

ting, page 37A-1) ,

-the injection computer mounting,

-the engine wiring bracket.

aRefit the petrol injection computer (see Petrol injec-

tion computer: Removal - Refitting) (17B, Petrol

injection).

aRefit the diesel injection computer (see Diesel in-

jection computer: Removal - Refitting) (13B, Die-

sel injection).

109206

91101-1

109205

D4F or D7F or K4M

K9K

Page 197 of 281

37A-18

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

JB1 or JH1 or JH3 or JR5, and LEFT-HAND DRIVE

37A

aRefit the battery tray (see Battery tray: Removal -

Refitting) (80A, Battery).

aRefit the gearbox computer (see Sequential gear-

box converter: Removal - Refitting) (21B, Se-

quential gearbox).

aRefit the battery (see Battery: Removal - Refitting)

(80A, Battery). JH1

Page 198 of 281

37A-19

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

REMOVAL

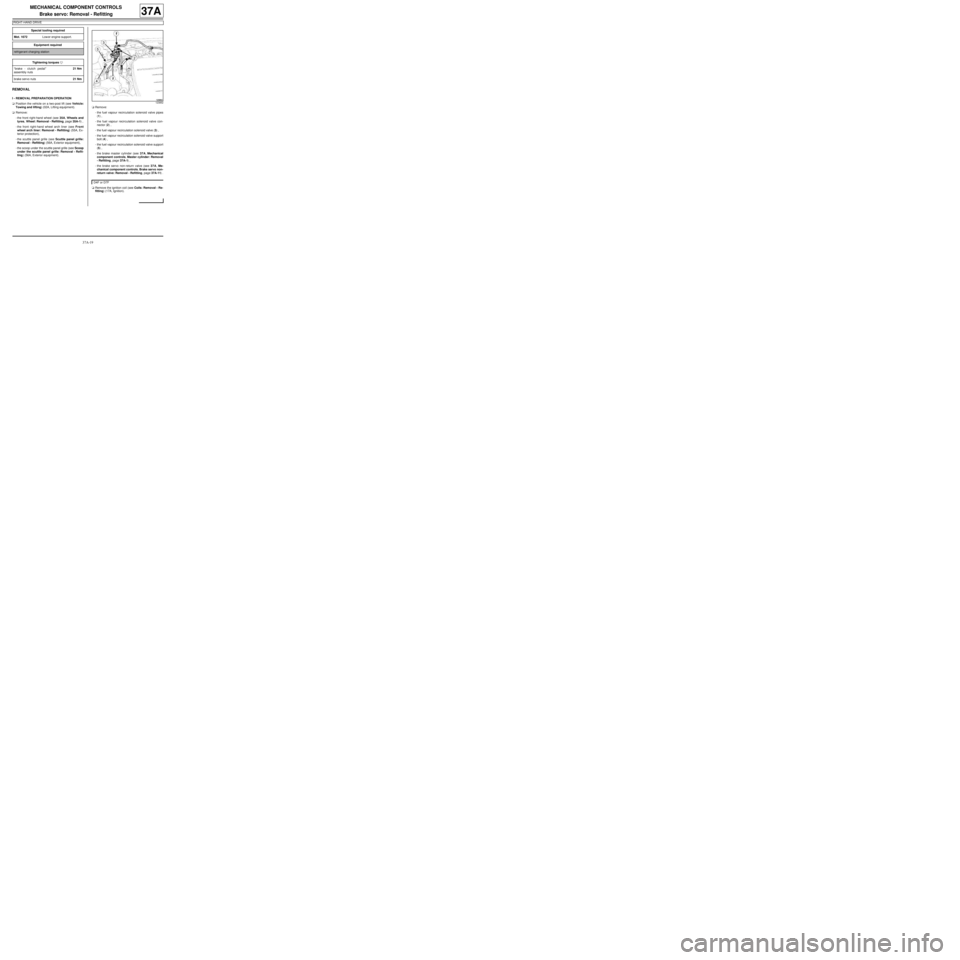

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front right-hand wheel (see 35A, Wheels and

tyres, Wheel: Removal - Refitting, page 35A-1) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).aRemove:

-the fuel vapour recirculation solenoid valve pipes

(1) ,

-the fuel vapour recirculation solenoid valve con-

nector (2) ,

-the fuel vapour recirculation solenoid valve (3) ,

-the fuel vapour recirculation solenoid valve support

bolt (4) ,

-the fuel vapour recirculation solenoid valve support

(5) ,

-the brake master cylinder (see 37A, Mechanical

component controls, Master cylinder: Removal

- Refitting, page 37A-1) ,

-the brake servo non-return valve (see 37A, Me-

chanical component controls, Brake servo non-

return valve: Removal - Refitting, page 37A-11) .

aRemove the ignition coil (see Coils: Removal - Re-

fitting) (17A, Ignition). Special tooling required

Mot. 1672Low er engine support.

Equipment required

refrigerant charging station

Tightening torquesm

“brake - clutch pedal”

assembly nuts21 Nm

brake servo nuts21 Nm

123852

D4F or D7F

Page 199 of 281

37A-20

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

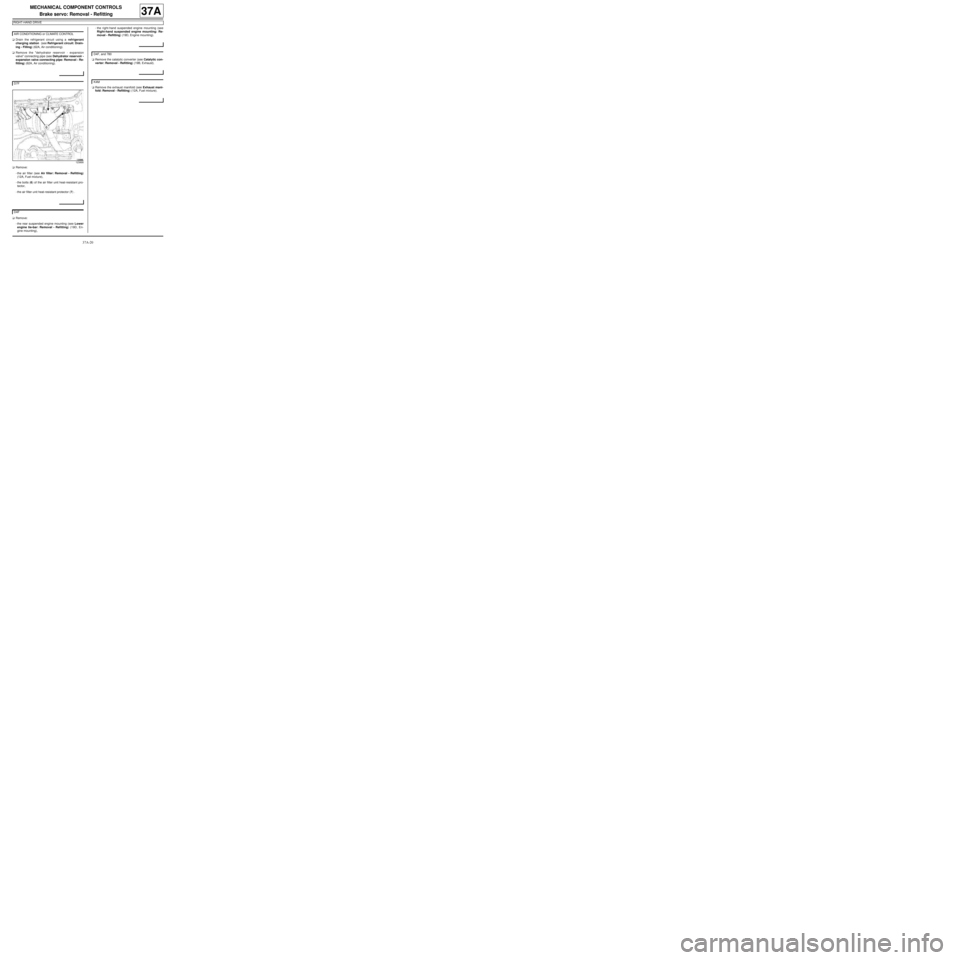

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove the "dehydrator reservoir - expansion

valve" connecting pipe (see Dehydrator reservoir -

expansion valve connecting pipe: Removal - Re-

fitting) (62A, Air conditioning).

aRemove:

-the air filter (see Air filter: Removal - Refitting)

(12A, Fuel mixture),

-the bolts (6) of the air filter unit heat-resistant pro-

tector,

-the air filter unit heat-resistant protector (7) .

aRemove:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting).

aRemove the catalytic converter (see Catalytic con-

verter: Removal - Refitting) (19B, Exhaust).

aRemove the exhaust manifold (see Exhaust mani-

fold: Removal - Refitting) (12A, Fuel mixture). AIR CONDITIONING or CLIMATE CONTROL

D7F

123868

D4F

D4F, and 780

K4M

Page 200 of 281

37A-21

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

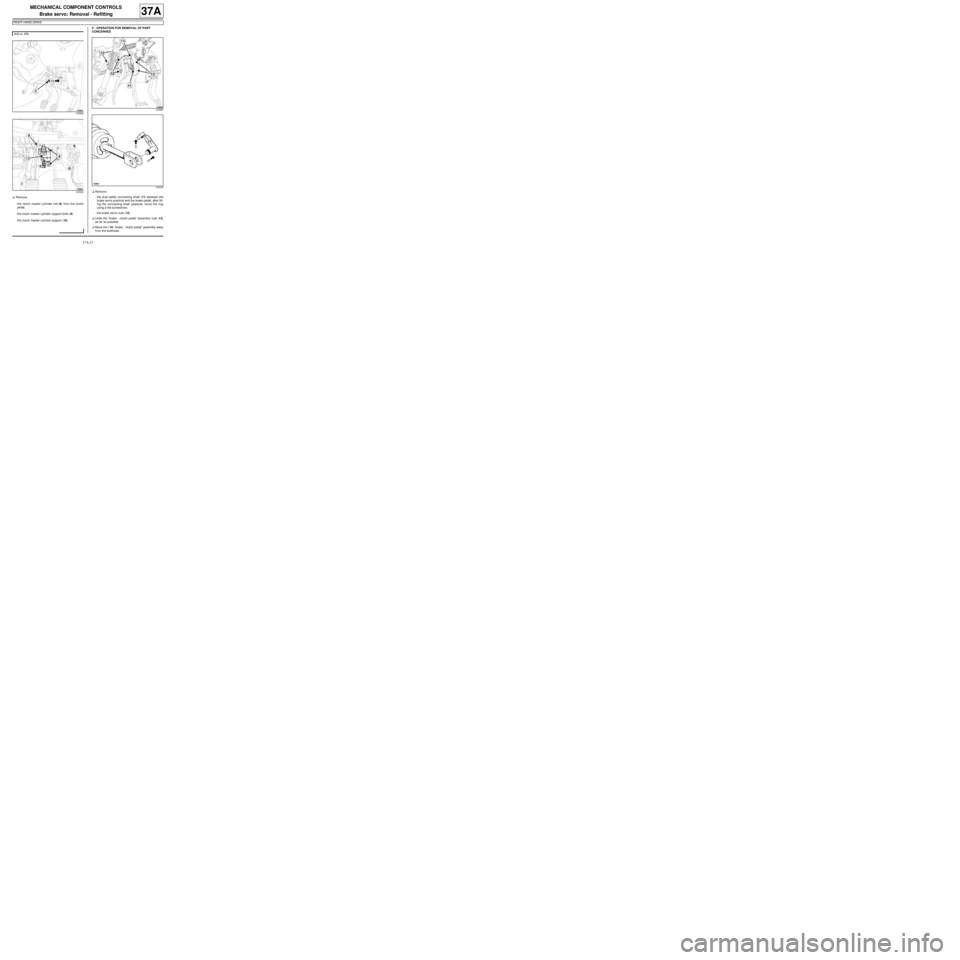

aRemove:

-the clutch master cylinder rod (8) from the clutch

pedal,

-the clutch master cylinder support bolts (9) ,

-the clutch master cylinder support (10) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the dual safety connecting shaft (11) between the

brake servo pushrod and the brake pedal; after tilt-

ing the connecting shaft upwards, move the ring

using a flat screwdriver,

-the brake servo nuts (12) .

aUndo the “brake - clutch pedal” assembly nuts (13)

as far as possible.

aMove the (14) “brake - clutch pedal” assembly away

from the bulkhead. JH3 or JR5

123905

123904

123860

109205