RENAULT TWINGO 2009 2.G Chasiss Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 221 of 281

37A-42

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

REMOVAL

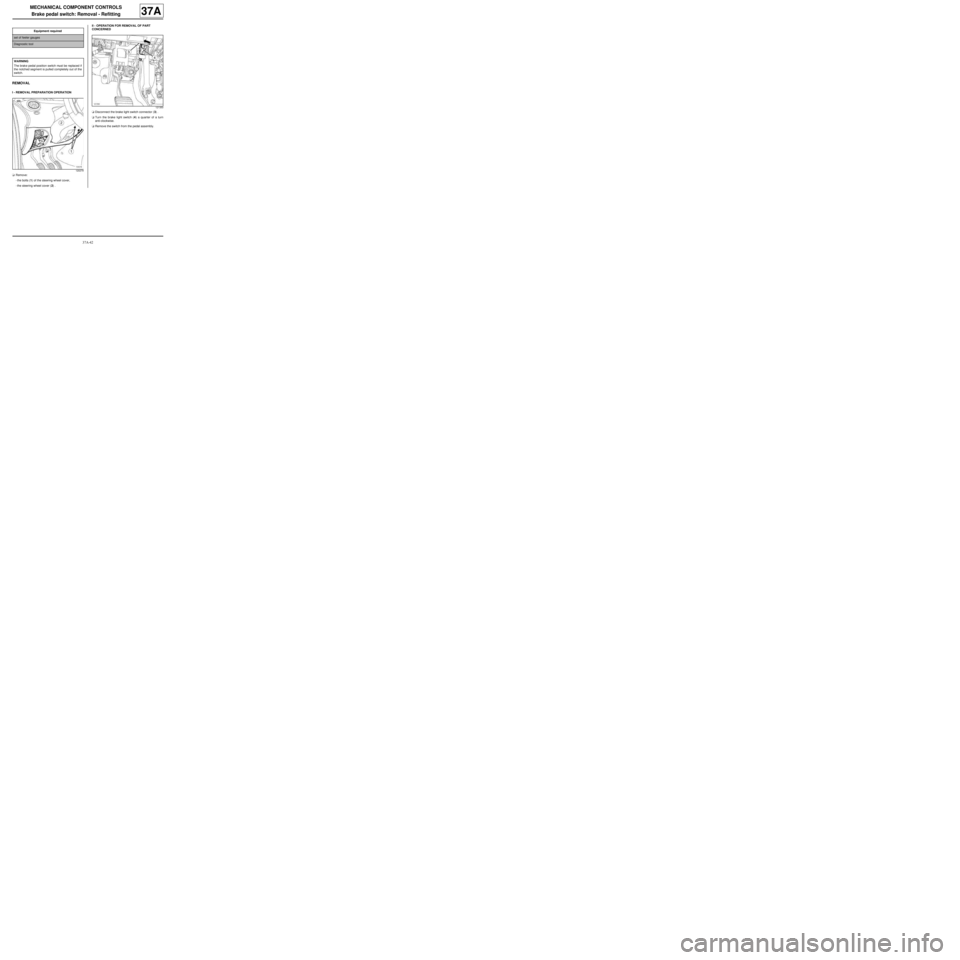

I - REMOVAL PREPARATION OPERATION

aRemove:

-the bolts (1) of the steering wheel cover,

-the steering wheel cover (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake light switch connector (3) .

aTurn the brake light switch (4) a quarter of a turn

anti-clockwise.

aRemove the switch from the pedal assembly. Equipment required

set of feeler gauges

Diagnostic tool

WARNING

The brake pedal position switch must be replaced if

the notched segment is pulled completely out of the

switch.

120279

121350

Page 222 of 281

37A-43

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

REFITTING

I - REFITTING PREPARATION OPERATION

a

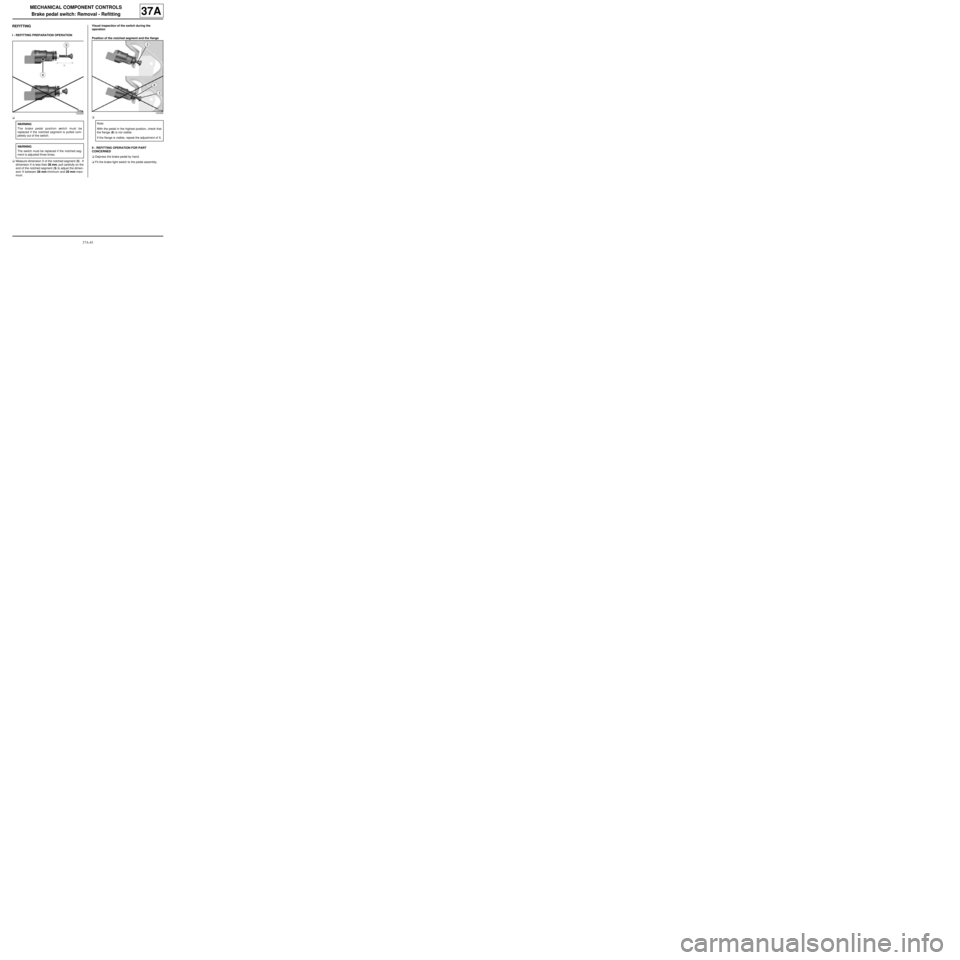

aMeasure dimension X of the notched segment (5) . If

dimension X is less than 28 mm, pull carefully on the

end of the notched segment (5) to adjust the dimen-

sion X between 28 mm minimum and 29 mm maxi-

mum.Visual inspection of the switch during the

operation

Position of the notched segment and the flange

a

II - REFITTING OPERATION FOR PART

CONCERNED

aDepress the brake pedal by hand.

aFit the brake light switch to the pedal assembly.

134304

WARNING

The brake pedal position switch must be

replaced if the notched segment is pulled com-

pletely out of the switch.

WARNING

The switch must be replaced if the notched seg-

ment is adjusted three times.

134305

Note:

With the pedal in the highest position, check that

the flange (8) is not visible.

If the flange is visible, repeat the adjustment of X.

Page 223 of 281

37A-44

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

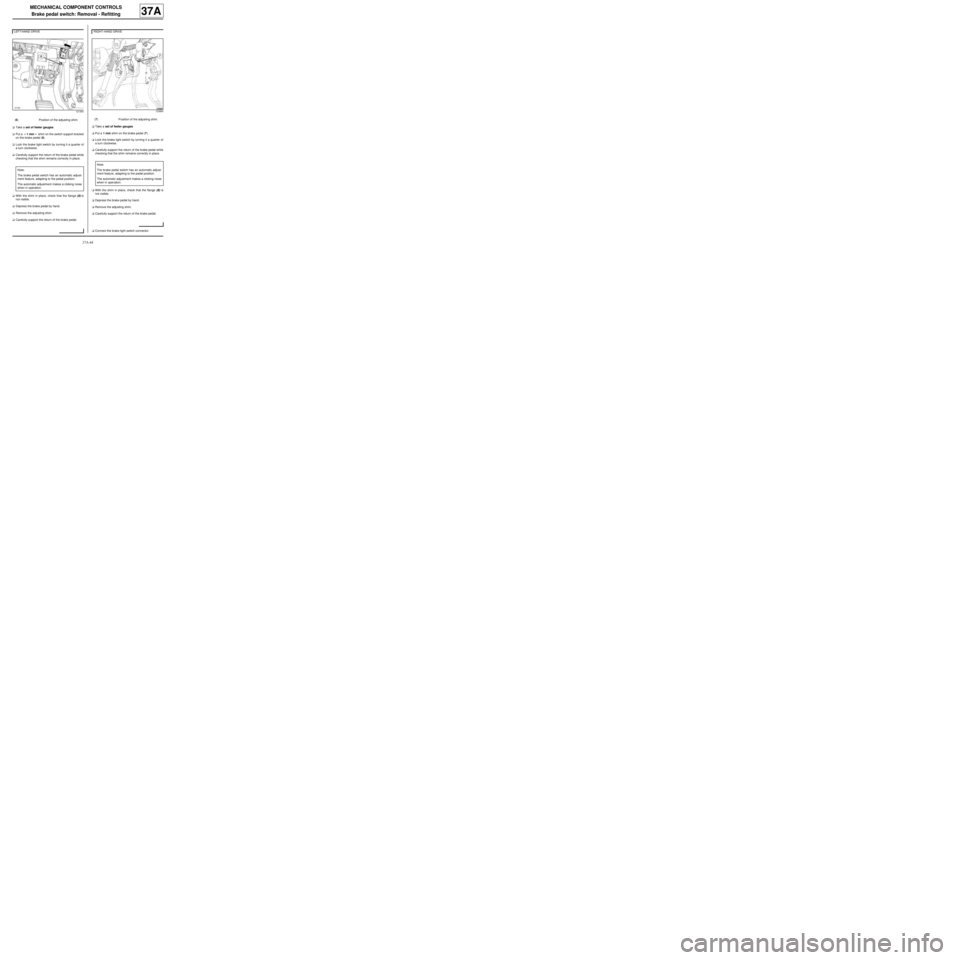

aTake a set of feeler gauges

aPut a « 1 mm » shim on the switch support bracket

on the brake pedal (6) .

aLock the brake light switch by turning it a quarter of

a turn clockwise.

aCarefully support the return of the brake pedal while

checking that the shim remains correctly in place.

aWith the shim in place, check that the flange (8) is

not visible.

aDepress the brake pedal by hand.

aRemove the adjusting shim.

aCarefully support the return of the brake pedal.aTake a set of feeler gauges

aPut a 1 mm shim on the brake pedal (7) .

aLock the brake light switch by turning it a quarter of

a turn clockwise.

aCarefully support the return of the brake pedal while

checking that the shim remains correctly in place.

aWith the shim in place, check that the flange (8) is

not visible.

aDepress the brake pedal by hand.

aRemove the adjusting shim.

aCarefully support the return of the brake pedal.

aConnect the brake light switch connector. LEFT-HAND DRIVE

121350

(6) Position of the adjusting shim.

Note:

The brake pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in operation.

RIGHT-HAND DRIVE

123860

(7) Position of the adjusting shim.

Note:

The br ake pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in oper ation.

Page 224 of 281

37A-45

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

III - CHECKING THE ELECTRICAL OPERATION OF

THE PART

aCheck that the brake light switch is operating cor-

rectly:

-depress the brake pedal to switch on the lights,

-release the brake pedal to switch off the lights.

aConnect the Diagnostic tool

aDepress the brake pedal by 10 mm.

aCheck that the first signal of the switch has not

switched (the first signal does not illuminate the

bulbs).

IV - FINAL OPERATION

aRefit:

-the steering wheel cover,

-the bolts on the steering wheel cover.

Page 225 of 281

37A-46

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Removal - Refitting

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRelease the parking brake lever.

aRemove:

-the heat shield clips (1) ,

-the heat shield (2) .aRemove the parking brake lever adjusting nut (3) .

aDetach the parking brake cables from the compen-

sator.

aRemove:

-the parking brake lever compensator (4) ,

-the front seats, completely (see Complete front

seat: Removal - Refitting) (MR 412 Bodywork,

75A, Front seat frames and runners).

aDepending on the equipment level, remove:

-the rear bench seatback (see Rear bench seat-

back: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),

-the rear bench seat base (see Rear bench seat

base: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners)

-the rear seats, completely (see Complete rear

seat: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners).

aPartially remove the floor carpet to access the park-

ing brake lever (see Floor carpet: Removal - Refit-

ting) (MR 412 Bodywork, 71A, Body internal trim). Tightening torquesm

par king brake lever nuts8 Nm

121325

121334

Page 226 of 281

37A-47

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Removal - Refitting

37A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (6) from the parking brake lever,

-the parking brake lever (7) .

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the parking brake lever,

-the parking brake lever nuts.

aTorque tighten the parking brake lever nuts (8

Nm).

II - FINAL OPERATION.

aFit the floor carpet (see Floor carpet: Removal -

Refitting) (MR 412 Bodywork, 71A, Body internal

trim).

aRefit (depending on equipment level):

-the rear seats, completely (see Complete rear

seat: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),

-the rear bench seat base (see Rear bench seat

base: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners),-the rear bench seatback (see Rear bench seat-

back: Removal - Refitting) (MR 412 Bodywork,

76A, Rear seat frames and runners).

aRefit the front seats, completely (see Complete

front seat: Removal - Refitting) (MR 412 Body-

work, 75A, Front seat frames and runners).

aAttach the parking brake cables to the compensator.

aRefit the parking brake lever adjusting nut.

aAdjust the parking brake lever (see 37A, Mechani-

cal component controls, Parking brake lever:

Adjustment, page 37A-48) .

aRefit:

-the heat shield,

-the heat shield clips.

121607

Page 227 of 281

37A-48

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Adjustment

37A

A poorly adjusted parking brake:

-prevents correct operation of the automatic compen-

sation system for the brake shoes,

-causes premature wear of brake shoes.

ADJUSTMENT

I - ADJUSTMENT PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aApply the parking brake five times to condition the

cables for normal use.

aPut the parking brake lever into the released posi-

tion.

aCheck that the rear wheels turn freely. If they do not,

check the following components and if necessary re-

pair:

-the parking brake cables,

-the calliper piston,

-the automatic compensation system,

-calliper

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove:

-the heat shield clips (1) ,

-the heat shield (2) .II - OPERATION FOR ADJUSTMENT OF PART

CONCERNED

aLoosen the nut (2) to release the cables.

aPosition the parking brake lever at the 2nd notch.

aMove the adjustment nut until the disc or drum can

no longer be turned by hand.

aPull the brake lever several times.

aPut the parking brake lever into the released posi-

tion.

aThe disc or the drum must be able to turn freely. If

not, move the nut gradually until the disc or drum

can turn freely.

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121325

121334

Page 228 of 281

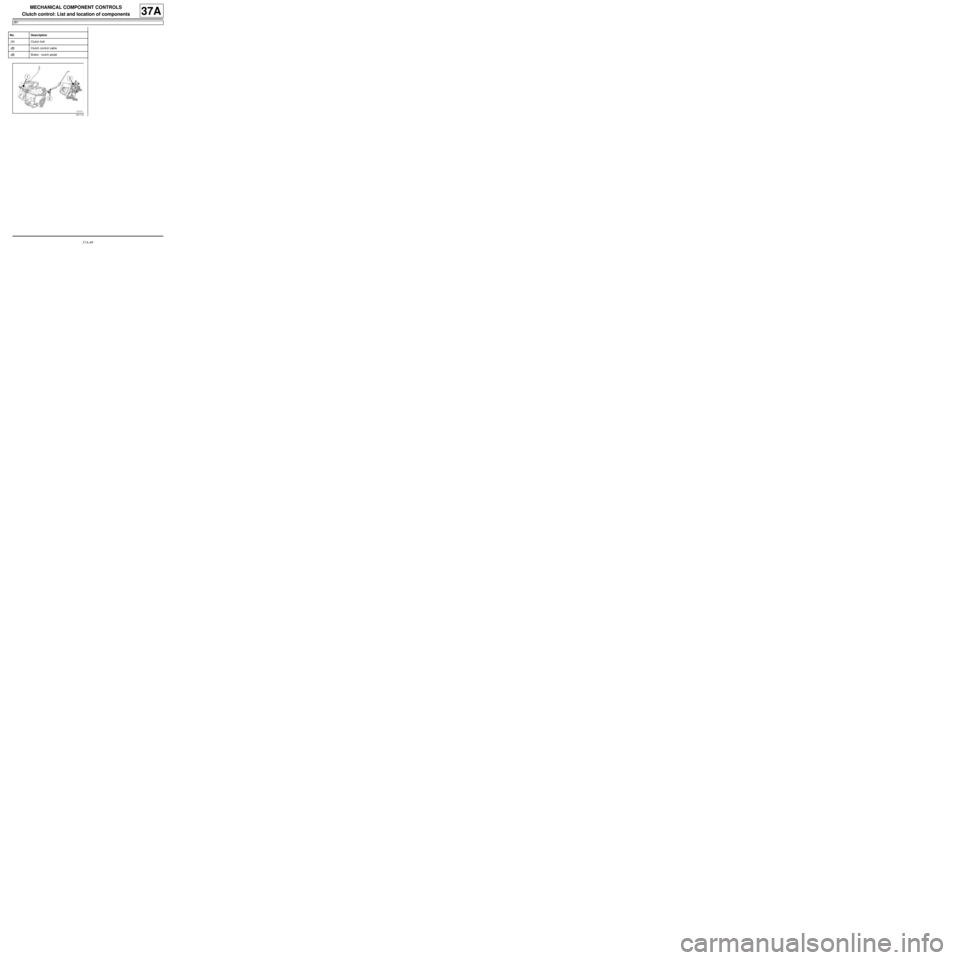

37A-49

MECHANICAL COMPONENT CONTROLS

Clutch control: List and location of components

JB1

37A

No. Description

(1) Clutch fork

(2) Clutch control cable

(3) Brake - clutch pedal

121113

Page 229 of 281

37A-50

MECHANICAL COMPONENT CONTROLS

Clutch control: List and location of components

JH3

37A

No. Description

(1) Clutch slave cylinder (clutch thr ust bearing)

(2) Hydraulic clutch control pipes

(3) Filter

(4) Clutch master cylinder

(5) Brake fluid supply duct

(6) Brake fluid reservoir

(7) Clutch pedal

121114

Page 230 of 281

37A-51

MECHANICAL COMPONENT CONTROLS

Clutch cable: Removal - Refitting

JB1

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery),

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the « brake pedal - clutch » assembly (see ) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the cable sleeve stop (1) from the bulkhead

and remove the passenger compartment cable.

aDetach the clutch cable at (2) .

aDetach the cable sleeve stop (3) from the fork on the

gearbox.

aDetach the clutch cable from the clutch fork at (4) .

aRemove the clutch cable.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the clutch cable.

aAttach the clutch cable to the clutch fork.

aFit the cable sleeve stop to the fork on the gearbox.

aAttach the clutch cable.

aFit the clutch cable through the opening in the bulk-

head and clip on the cable sleeve stop.II - FINAL OPERATION.

aRefit:

-the « brake pedal - clutch » assembly (see ) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (MR 411, 80A, Battery),

-the battery (see Battery: Removal - Refitting)

(MR 411, 80A, Battery).

121113