air RENAULT TWINGO 2009 2.G Chasiss Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 268 of 281

38C-9

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F, and 780, and LEFT-HAND DRIVE – K4M, and LEFT-HAND DRIVE

38C

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove the "dehydrator reservoir - expansion

valve" connecting pipe (see Dehydrator reservoir -

expansion valve connecting pipe: Removal - Re-

fitting) (62A, Air conditioning).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the hydraulic unit computer connector

(5) .

aUndo the rigid brake pipe unions (6) on the hydraulic

unit.

aInsert the blanking plugs.aUnclip the fuel pipes (7) .

aRemove the bolts (8) from the hydraulic unit main

bracket.

aRemove the rear suspended engine mounting (see

Lower engine tie-bar: Removal - Refitting) (19D,

Engine mounting).

aFit theunder the engine.

aRemove the right-hand suspended engine mounting

(see Right-hand suspended engine mounting:

Removal - Refitting) (19D, Engine mounting).

aTilt the engine towards the front of the vehicle.

aRemove the "hydraulic unit bracket - hydraulic unit"

assembly from the body. K4M, and AIR CONDITIONING or CLIMATE CON-

TROL

122386

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

122385

K4M

Page 269 of 281

38C-10

ANTI-LOCK BRAKING SYSTEM

Hydraulic brake unit: Removal - Refitting

D4F, and 780, and LEFT-HAND DRIVE – K4M, and LEFT-HAND DRIVE

38C

aRemove:

-the hydraulic unit intermediate bracket bolts (10) ,

-the “intermediate bracket - hydraulic unit” assembly

from the main bracket,

-the hydraulic unit bolts,

-the hydraulic unit from its intermediate bracket.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the hydraulic unit on its intermediate bracket.

aTorque tighten the hydraulic unit bolts on its inter-

mediate bracket (8 Nm).

aRefit the "hydraulic unit intermediate bracket - hy-

draulic unit" assembly on the main bracket.

aTorque tighten the intermediate bracket bolts on

the hydraulic unit main bracket (8 N.m).

aRefit the "main bracket - hydraulic unit" assembly on

the body.

aRefit:

-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting),-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting).

aTorque tighten the hydraulic unit main mounting

bolts on the body (8 Nm).

aClip on the fuel pipes.

aRemove the blanking plugs.

aFit and tighten the rigid brake pipe unions on the hy-

draulic unit.

aTorque tighten the rigid brake pipe unions on the

hydraulic unit (13 Nm).

aConnect the hydraulic unit connector.

II - FINAL OPERATION.

aRefit the "dehydrator reservoir - expansion valve"

connecting pipe (see Dehydrator reservoir - ex-

pansion valve connecting pipe: Removal - Refit-

ting) (62A, Air conditioning).

aFill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aRefit the bulkhead heat shield.

aFit the fuel vapour rebreathing solenoid valve.

aRefit the union on the fuel vapour rebreathing sole-

noid valve.

aRefit the air filter unit (see Air filter unit: Removal -

Refitting) (12A, Fuel mixture)

aRefit:

-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front passenger side wheel (see 35A, Wheels

and tyres, Wheel: Removal - Refitting, page

35A-1) .

aRemove the pedal press from the brake pedal.

121456

K4M

K4M, and AIR CONDITIONING or CLIMATE CON-

TROL

D4F, and 780

Page 280 of 281

38C-21

ANTI-LOCK BRAKING SYSTEM

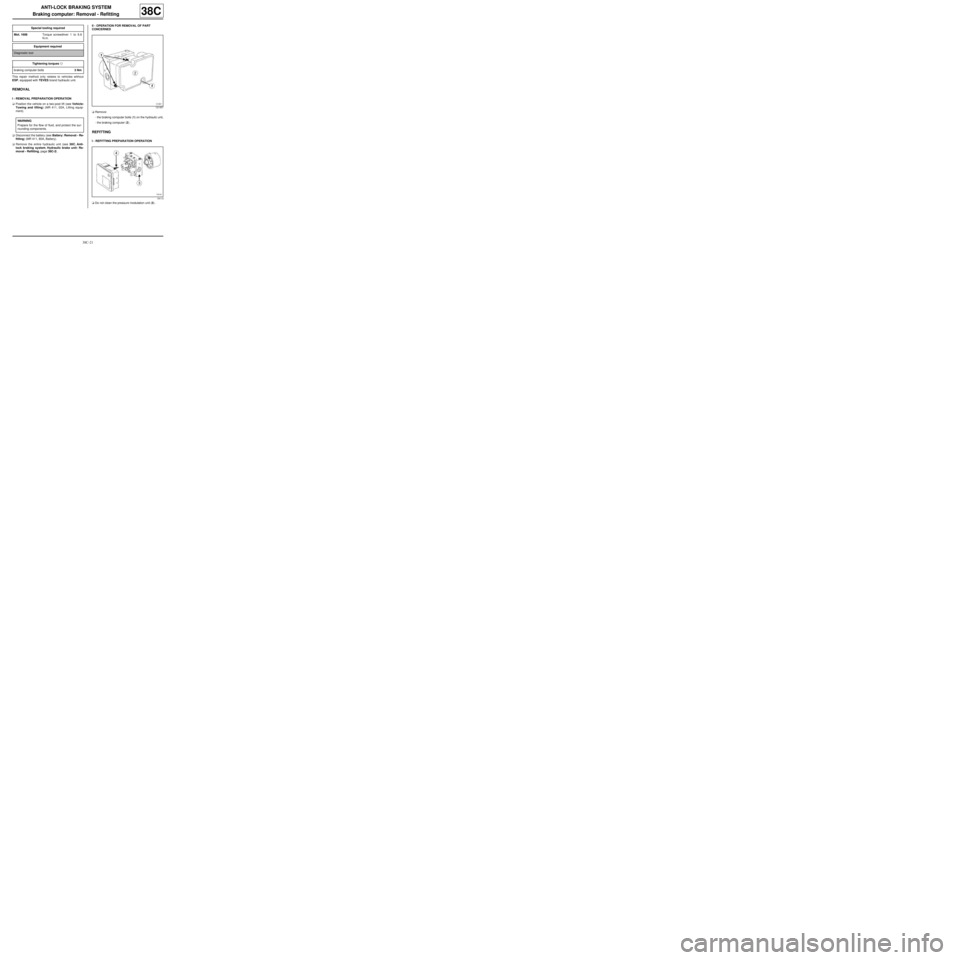

Braking computer: Removal - Refitting

38C

This repair method only relates to vehicles without

ESP, equipped with TEVES brand hydraulic unit.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove the entire hydraulic unit (see 38C, Anti-

lock braking system, Hydraulic brake unit: Re-

moval - Refitting, page 38C-2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the braking computer bolts (1) on the hydraulic unit,

-the braking computer (2) .

REFITTING

I - REFITTING PREPARATION OPERATION

aDo not clean the pressure modulation unit (3) . Special tooling required

Mot. 1608Torque screwdriver 1 to 6.6

N.m.

Equipment required

Diagnostic tool

Tightening torquesm

braking computer bolts3 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

121457

19113

Page 281 of 281

38C-22

ANTI-LOCK BRAKING SYSTEM

Braking computer: Removal - Refitting

38C

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the braking computer (2) , holding it by its edge.

aRefit the braking computer bolts on the pressure

modulation unit.

aTorque tighten the braking computer bolts (3 Nm)

using the (Mot. 1608).

III - FINAL OPERATION.

aRefit the entire hydraulic unit (see 38C, Anti-lock

braking system, Hydraulic brake unit: Removal -

Refitting, page 38C-2) .

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

aBleed the braking circuit (see 30A, General infor-

mation, Braking circuit: Bleed, page 30A-4) .

aConfigure the tachometric index using the Diagnos-

tic tool (see Fault finding - Replacement of com-

ponents) (MR 413 Fault finding, 38C, Anti-lock

braking system).

aClear any faults stored by the braking computer.

aCarry out a road test to confirm the repair.Note:

Do not try to force the braking computer into

place when refitting; it should fit in without any

resistance.

Note:

When a new braking computer is being fitted,

remember to attach the interconnection fork (4)

between the pressure modulation unit and the

braking computer.