air RENAULT TWINGO 2009 2.G Chasiss Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 199 of 281

37A-20

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove the "dehydrator reservoir - expansion

valve" connecting pipe (see Dehydrator reservoir -

expansion valve connecting pipe: Removal - Re-

fitting) (62A, Air conditioning).

aRemove:

-the air filter (see Air filter: Removal - Refitting)

(12A, Fuel mixture),

-the bolts (6) of the air filter unit heat-resistant pro-

tector,

-the air filter unit heat-resistant protector (7) .

aRemove:

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting),-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting).

aRemove the catalytic converter (see Catalytic con-

verter: Removal - Refitting) (19B, Exhaust).

aRemove the exhaust manifold (see Exhaust mani-

fold: Removal - Refitting) (12A, Fuel mixture). AIR CONDITIONING or CLIMATE CONTROL

D7F

123868

D4F

D4F, and 780

K4M

Page 202 of 281

37A-23

MECHANICAL COMPONENT CONTROLS

Brake servo: Removal - Refitting

RIGHT-HAND DRIVE

37A

II - REFITTING OPERATION FOR PART

CONCERNED

aPosition the brake servo by moving the engine for-

ward as far as possible and tilting the pushrod up-

wards.

aRefit the brake servo from underneath the vehicle.

aRefit the brake servo.

aPosition the “brake - clutch pedal” assembly on the

bulkhead.

aTorque tighten the “brake - clutch pedal” assem-

bly nuts (21 Nm).

aRefit:

-the new dual safety connecting shaft between the

brake servo pushrod and the brake pedal from right

to left and from top to bottom,

-the brake servo nuts.

aTorque tighten the brake servo nuts (21 Nm).

III - FINAL OPERATION.

aRefit:

-the clutch master cylinder support,

-the clutch master cylinder support bolts,

-the clutch master cylinder rod on the clutch pedal.

aRefit the exhaust manifold (see Exhaust manifold:

Removal - Refitting) (12A, Fuel mixture).aRefit the catalytic converter (see Catalytic convert-

er: Removal - Refitting) (19B, Exhaust).

aRefit:

-the right-hand suspended engine mounting (see

Right-hand suspended engine mounting: Re-

moval - Refitting) (19D, Engine mounting),

-the rear suspended engine mounting (see Lower

engine tie-bar: Removal - Refitting) (19D, En-

gine mounting).

aRefit:

-the air filter box heat-resistant protector,

-the air filter box heat-resistant protector bolts,

-the air filter (see Air filter: Removal - Refitting)

(12A, Fuel mixture).

aRefit the "dehydrator reservoir - expansion valve"

connection (see Dehydrator reservoir - expansion

valve connecting pipe: Removal - Refitting) (62A,

Air conditioning).

aFill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aRefit the ignition coil (see Coils: Removal - Refit-

ting) (17A, Ignition). D4F

K4M

JH3 or JR5

K4M

D4F, and 780

D4F

D7F

AIR CONDITIONING or CLIMATE CONTROL

D4F or D7F

Page 204 of 281

37A-25

MECHANICAL COMPONENT CONTROLS

Vacuum pump: Removal - Refitting

K9K

37A

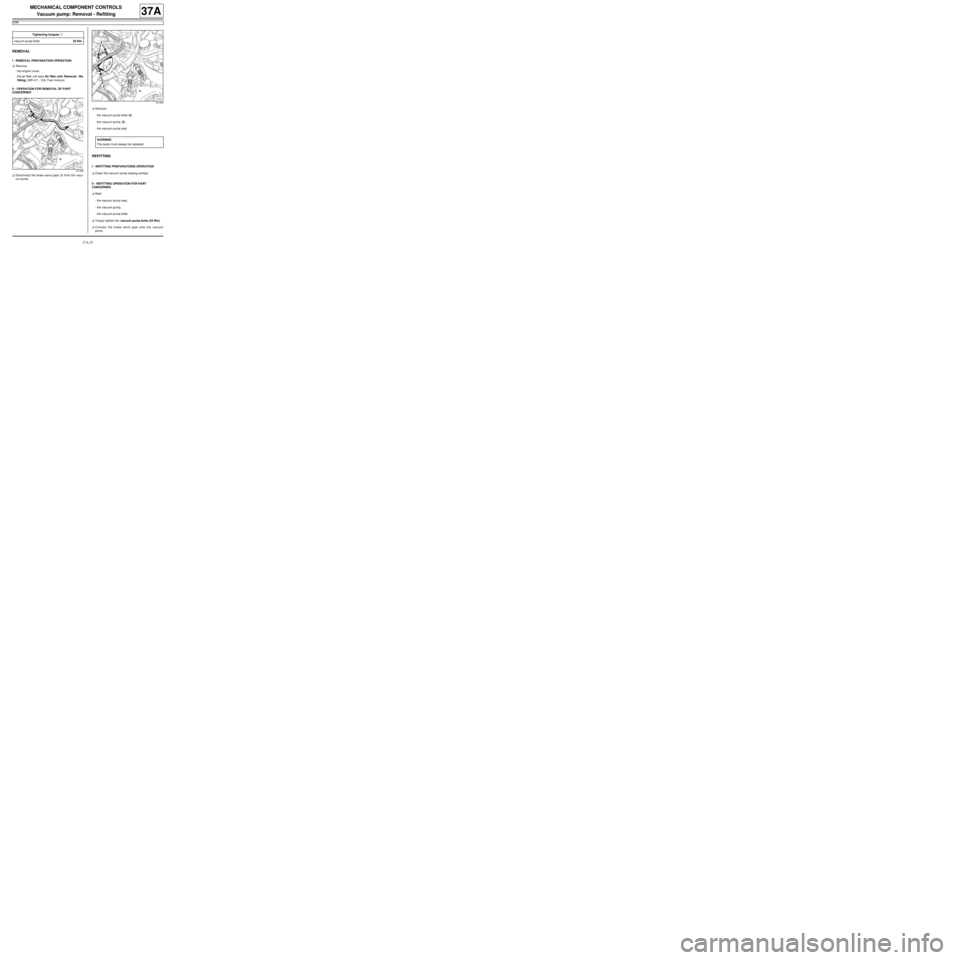

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the engine cover,

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake servo pipe (1) from the vacu-

um pump.aRemove:

-the vacuum pump bolts (2) ,

-the vacuum pump (3) ,

-the vacuum pump seal.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aClean the vacuum pump sealing surface.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the vacuum pump seal,

-the vacuum pump,

-the vacuum pump bolts.

aTorque tighten the vacuum pump bolts (25 Nm).

aConnect the brake servo pipe onto the vacuum

pump. Tightening torquesm

vacuum pump bolts25 Nm

121356

121355

WARNING

The seals m ust always be replaced.

Page 205 of 281

37A-26

MECHANICAL COMPONENT CONTROLS

Vacuum pump: Removal - Refitting

K9K

37A

III - FINAL OPERATION.

aRefit:

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture),

-the engine cover.

Page 208 of 281

37A-29

MECHANICAL COMPONENT CONTROLS

Accelerator pedal: Removal - Refitting

37A

REMOVAL

I - REMOVAL OPERATION FOR ALUMINIUM

PEDAL PAD

aHeat the pedal pad with a heat stripper to a maxi-

mum temperature of 80˚C.

aRemove the pad using a pair of pliers.

aClean the residue of adhesive on the pedal (see

Tools for stripping very thick soft mastic: Use) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the accelerator pedal potentiometer con-

nector (1) .

aRemove:

-the accelerator pedal nuts (2) ,-the accelerator pedal.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the aluminium pedal pad each time it

is removed.

II - REFITTING OPERATION FOR ALUMINIUM

PEDAL PAD

aCheck that the pedal is at ambient temperature.

aCheck that the surface of the pedal is clean.

aActivate the pedal bonding surface with some paper

soaked in HEPTANE.

Wipe immediately with a clean and dry cloth.

Remove the protection around the pad. Equipment required

heat str ipper

Tightening torquesm

accelerator pedal nuts8 N.m

EQ UIPMENT LEVEL SPORT

119134

EQUIPMENT LEVEL SPORT

EQUIPMENT LEVEL SPORT

Note:

If only the pad is being replaced, allow the pedal

to cool.

Note:

The bonding area must be clean, and free from

finger mar ks and fabric deposits.

Note:

It is essential to activate the surface and to wipe

in the same direction: there is a risk of contami-

nating the bonding surface when wiping.

Note:

Do not use the same paper to activate the sur-

face and to wipe the surface.

Throw the paper away after each use.

Page 210 of 281

37A-31

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

RIGHT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the dashboard lower trim (1) ,

-the brake pedal switch (see 37A, Mechanical

component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42) .

aRemove the accelerator pedal (see 37A, Mechani-

cal component controls, Accelerator pedal: Re-

moval - Refitting, page 37A-29) .aRemove the clutch pedal switch (see ) .

aRemove the dashboard side face (2) .

aDisconnect the airbag inhibitor switch connector (3) . Equipment required

heat str ipper

Tightening torquesm

bolts of the « brake -

clutch pedal assembly » 21 N.m

123870

JB1

CRUISE CONTROL

123870

123871

Page 211 of 281

37A-32

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

RIGHT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

aRemove:

-the clutch master cylinder rod (4) ,

-the nuts (5) from the clutch master cylinder sup-

port,

-the clutch master cylinder support (6) ,

-the connecting clip (7) between the outlet pipe and

the clutch master cylinder,

-the clutch master cylinder (8) .aRemove the dashboard bolts (9) .

aMove the dashboard away slightly.

II - REMOVAL OPERATION FOR THE ALUMINIUM

PEDAL PADS

aHeat the pedal pad with a heat stripper to a maxi-

mum temperature of 80˚C.

aRemove the pad using a pair of pliers.

aClean the residue of adhesive on the pedal (see

Tools for stripping very thick soft mastic: Use) . JH3 or JR5

123904

123871

EQUIPMENT LEVEL SPORT

Page 215 of 281

37A-36

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

RIGHT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

aBond the pedal pad (19) to the pedal (20) by press-

ing on the right-hand side.

Press the pad to ensure bonding.

IV - FINAL OPERATION

aFit the dashboard.

aRefit the dashboard bolts.

aConnect the airbag inhibition switch connector.

aRefit the dashboard side panel.

aRefit:

-the clutch master cylinder,

-the connecting clip between the outlet pipe and the

clutch master cylinder,

-the clutch master cylinder support,

-the clutch support bolts,

-the clutch master cylinder rod.aRefit the clutch pedal switch (see ) .

aRefit the accelerator pedal (see 37A, Mechanical

component controls, Accelerator pedal: Remov-

al - Refitting, page 37A-29) .

aRefit:

-the brake pedal switch (see 37A, Mechanical

component controls, Brake pedal switch: Re-

moval - Refitting, page 37A-42) ,

-the dashboard lower trim.

135017

Note:

Respect the range of motion when fitting.

JH3 or JR5

CRUISE CONTROL

JB1

Page 218 of 281

37A-39

MECHANICAL COMPONENT CONTROLS

Brake pedal: Removal - Refitting

LEFT-HAND DRIVE, and 5-SPEED MANUAL GEARBOX

37A

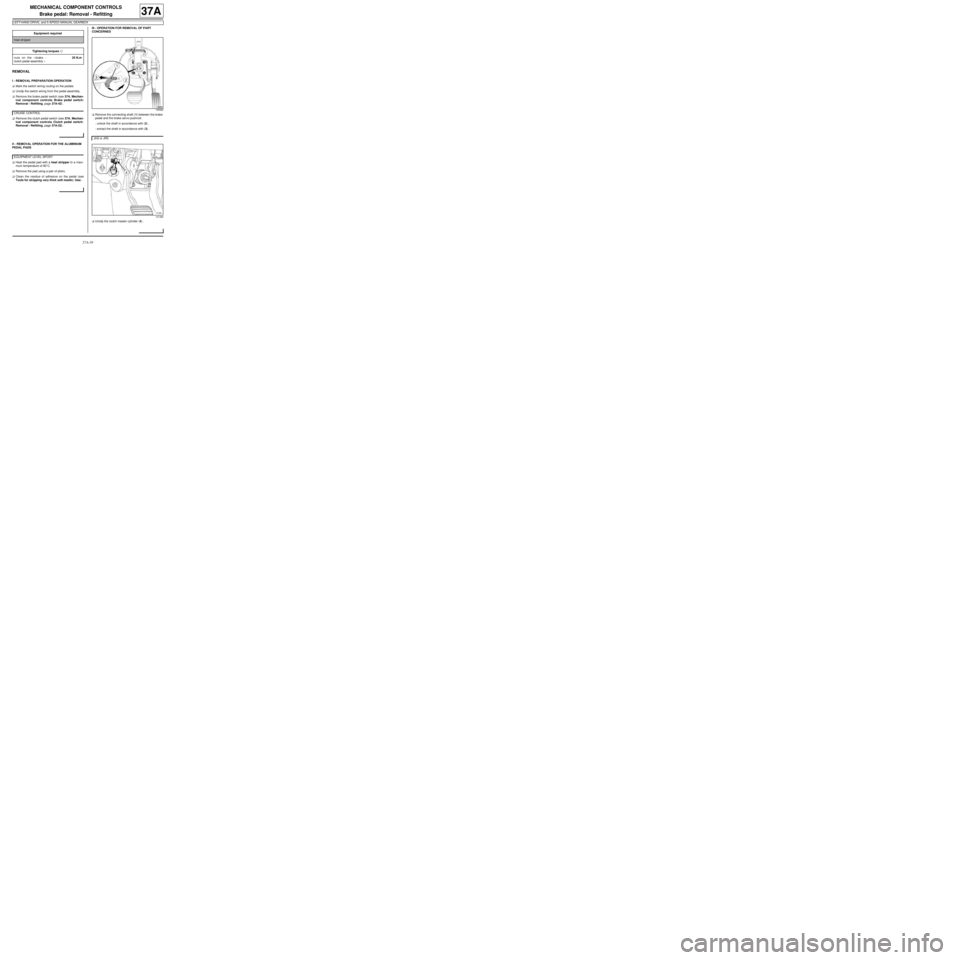

REMOVAL

I - REMOVAL PREPARATION OPERATION

aMark the switch wiring routing on the pedals.

aUnclip the switch wiring from the pedal assembly.

aRemove the brake pedal switch (see 37A, Mechan-

ical component controls, Brake pedal switch:

Removal - Refitting, page 37A-42) .

aRemove the clutch pedal switch (see 37A, Mechan-

ical component controls, Clutch pedal switch:

Removal - Refitting, page 37A-52) .

II - REMOVAL OPERATION FOR THE ALUMINIUM

PEDAL PADS

aHeat the pedal pad with a heat stripper to a maxi-

mum temperature of 80˚C.

aRemove the pad using a pair of pliers.

aClean the residue of adhesive on the pedal (see

Tools for stripping very thick soft mastic: Use) .III - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the connecting shaft (1) between the brake

pedal and the brake servo pushrod:

-unlock the shaft in accordance with (2) ,

-extract the shaft in accordance with (3) .

aUnclip the clutch master cylinder (4) . Equipment required

heat str ipper

Tightening torquesm

nuts on the « brake -

clutch pedal assembly » 25 N.m

CRUISE CONTROL

EQ UIPMENT LEVEL SPORT

128482

JH3 or JR5

121366

Page 227 of 281

37A-48

MECHANICAL COMPONENT CONTROLS

Parking brake lever: Adjustment

37A

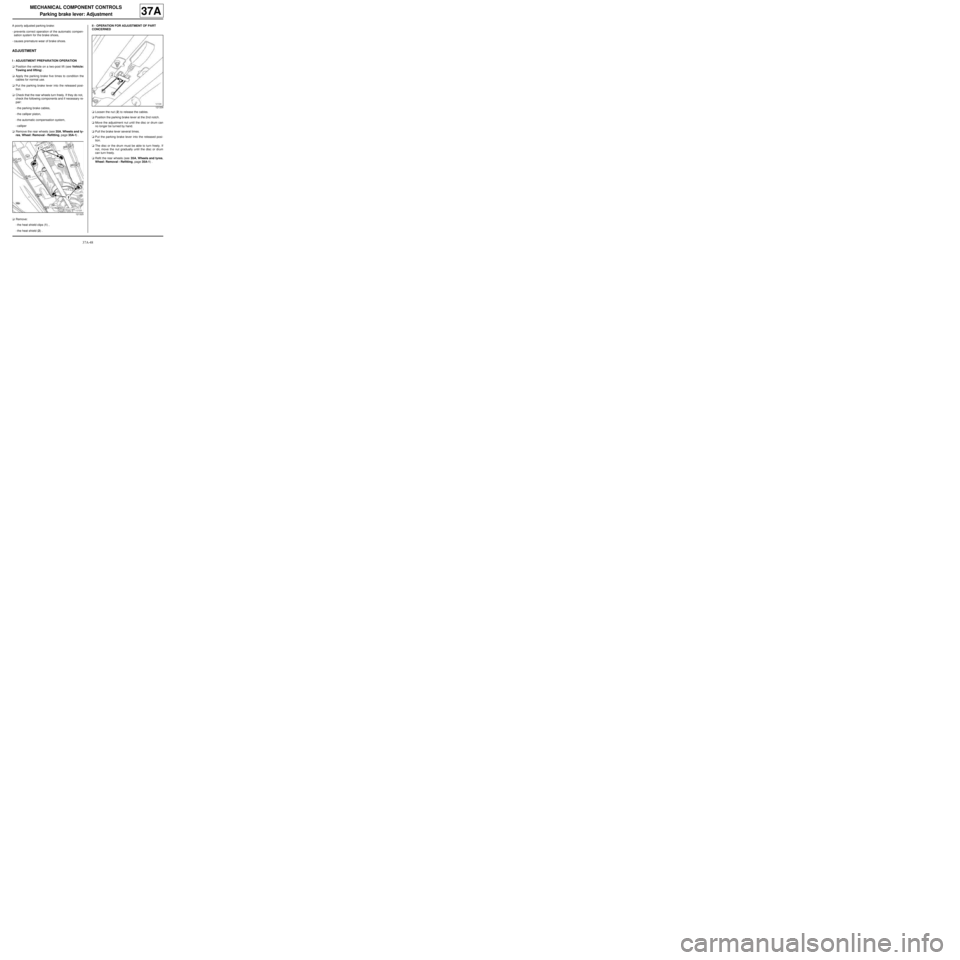

A poorly adjusted parking brake:

-prevents correct operation of the automatic compen-

sation system for the brake shoes,

-causes premature wear of brake shoes.

ADJUSTMENT

I - ADJUSTMENT PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aApply the parking brake five times to condition the

cables for normal use.

aPut the parking brake lever into the released posi-

tion.

aCheck that the rear wheels turn freely. If they do not,

check the following components and if necessary re-

pair:

-the parking brake cables,

-the calliper piston,

-the automatic compensation system,

-calliper

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .

aRemove:

-the heat shield clips (1) ,

-the heat shield (2) .II - OPERATION FOR ADJUSTMENT OF PART

CONCERNED

aLoosen the nut (2) to release the cables.

aPosition the parking brake lever at the 2nd notch.

aMove the adjustment nut until the disc or drum can

no longer be turned by hand.

aPull the brake lever several times.

aPut the parking brake lever into the released posi-

tion.

aThe disc or the drum must be able to turn freely. If

not, move the nut gradually until the disc or drum

can turn freely.

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

121325

121334