air RENAULT TWINGO 2009 2.G Chasiss Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 59 of 281

31A-16

FRONT AXLE COMPONENTS

Front brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

31A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the front wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

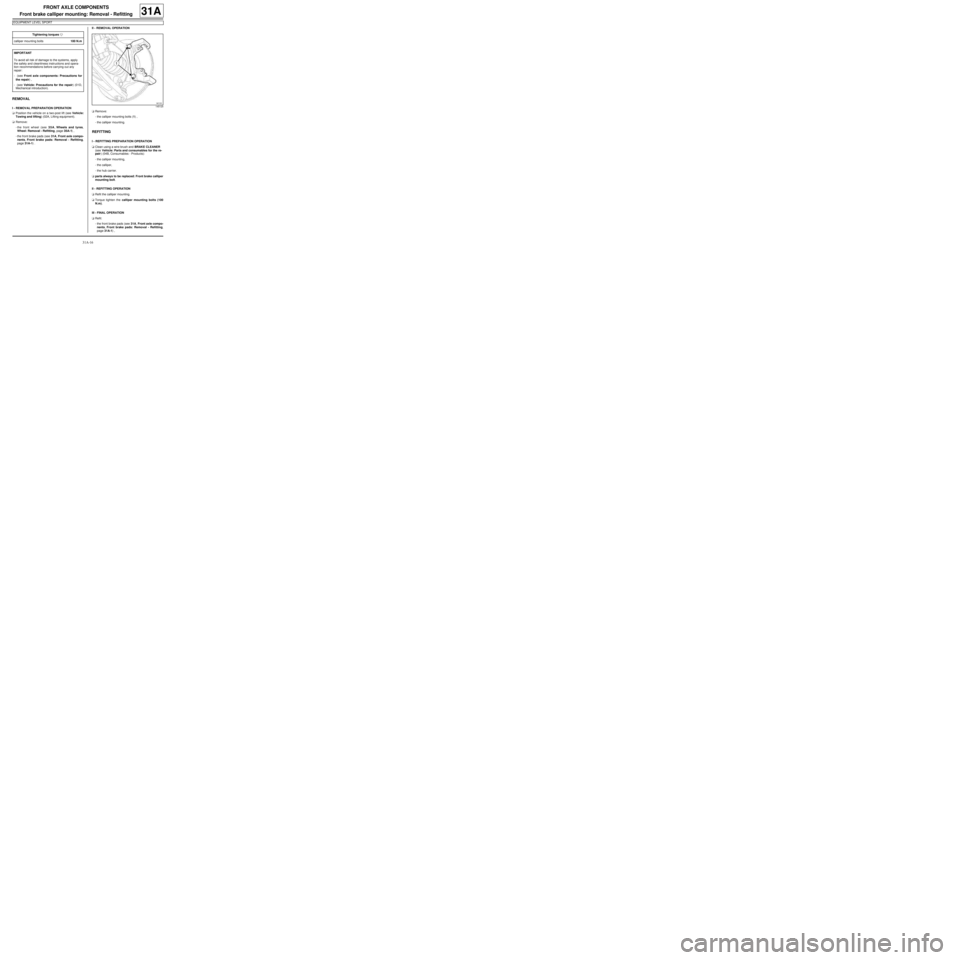

page 31A-1) .II - REMOVAL OPERATION

aRemove:

-the calliper mounting bolts (1) ,

-the calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper mounting,

-the calliper,

-the hub carrier.

aparts always to be replaced: Front brake calliper

mounting bolt.

II - REFITTING OPERATION

aRefit the calliper mounting.

aTorque tighten the calliper mounting bolts (100

N.m).

III - FINAL OPERATION

aRefit:

-the front brake pads (see 31A, Front axle compo-

nents, Front brake pads: Removal - Refitting,

page 31A-1) , Tightening torquesm

calliper mounting bolts100 N.m

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see Front axle components: Precautions for

the repair) ,

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

145125

Page 62 of 281

31A-19

FRONT AXLE COMPONENTS

Front brake disc: Removal - Refitting

31A

Brake discs cannot be reground. If there is excessive

scoring or wear, they will need to be replaced (see

30A, General information, Brake: Specifications,

page 30A-19) .

REMOVAL

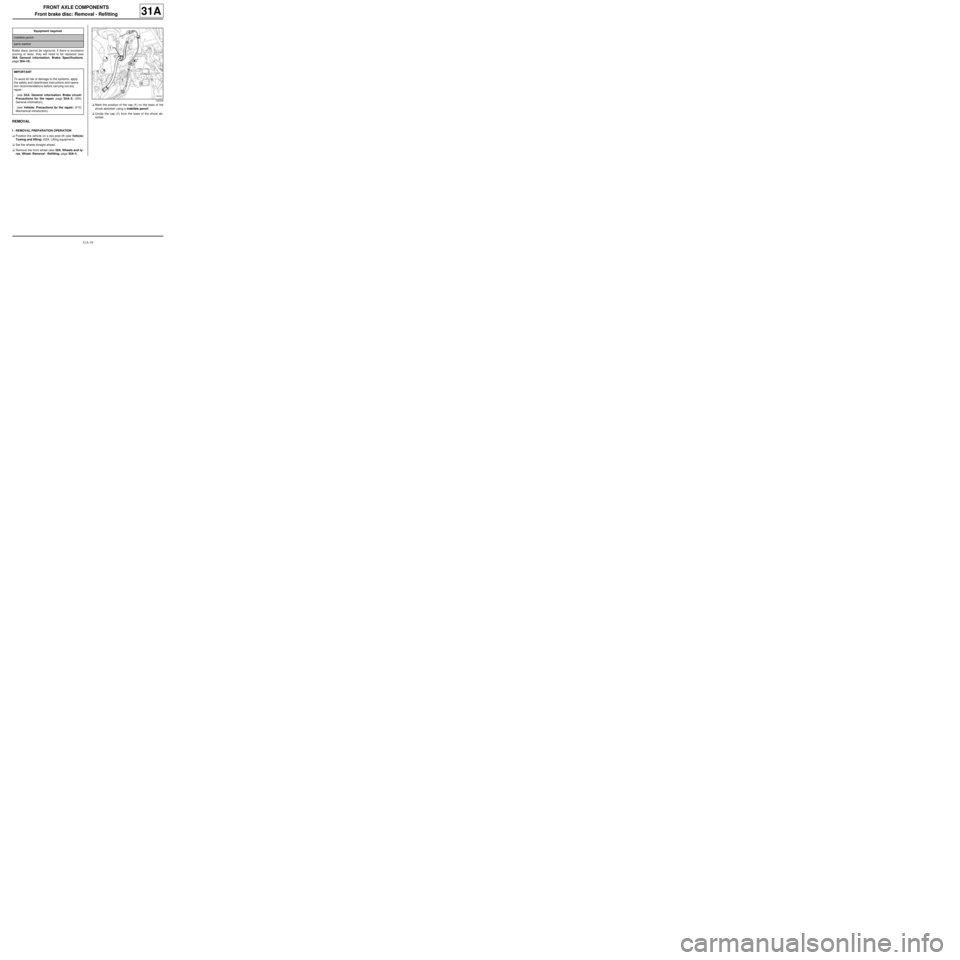

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aSet the wheels straight ahead.

aRemove the front wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .aMark the position of the cap (1) on the base of the

shock absorber using a indelible pencil.

aUnclip the cap (1) from the base of the shock ab-

sorber. Equipment required

indelible pencil

par ts washer

IMPORTANT

To avoid all risk of damage to the systems, apply

the safety and cleanliness instructions and opera-

tion recommendations before carrying out any

repair:

- (see 30A, General information, Brake circuit:

Precautions for the repair, page 30A-2) (30A,

General information),

- (see Vehicle: Precautions for the repair) (01D,

Mechanical introduction).

126339

Page 63 of 281

31A-20

FRONT AXLE COMPONENTS

Front brake disc: Removal - Refitting

31A

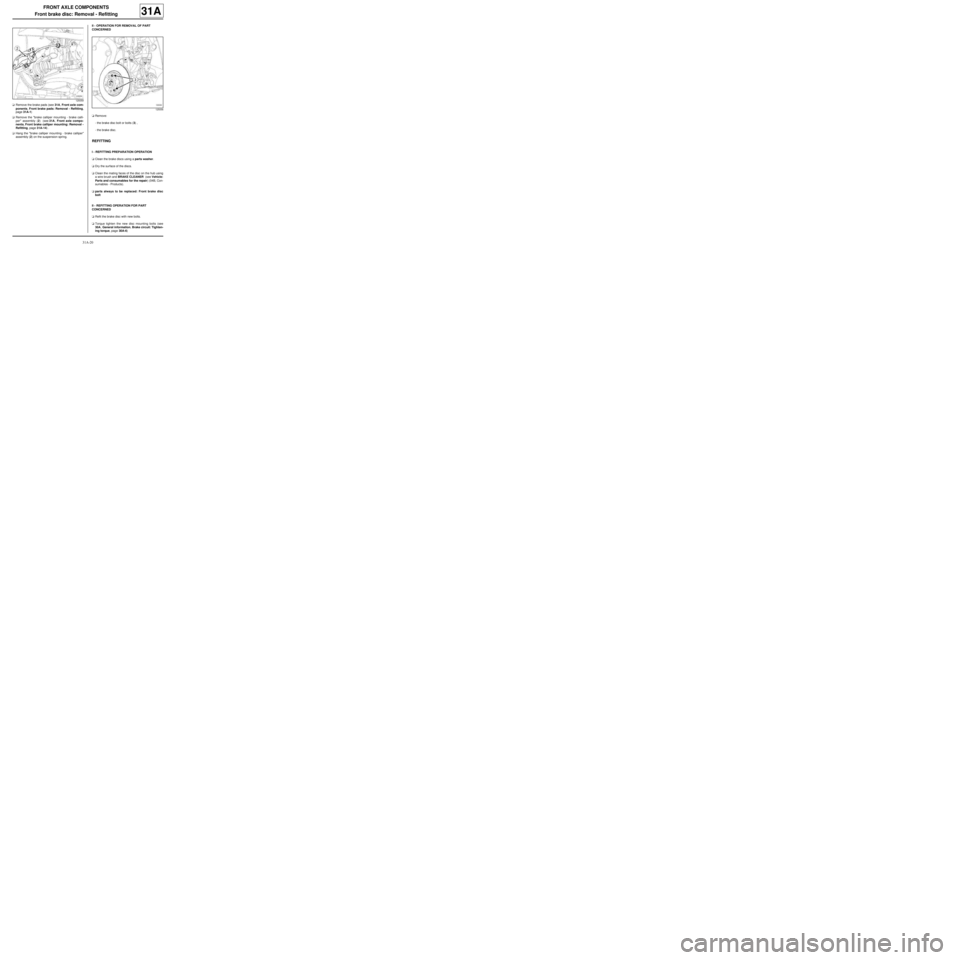

aRemove the brake pads (see 31A, Front axle com-

ponents, Front brake pads: Removal - Refitting,

page 31A-1)

aRemove the "brake calliper mounting - brake calli-

per" assembly (2) (see 31A, Front axle compo-

nents, Front brake calliper mounting: Removal -

Refitting, page 31A-14) .

aHang the "brake calliper mounting - brake calliper"

assembly (2) on the suspension spring.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake disc bolt or bolts (3) ,

-the brake disc.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the brake discs using a parts washer.

aDry the surface of the discs.

aClean the mating faces of the disc on the hub using

a wire brush and BRAKE CLEANER (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products).

aparts always to be replaced: Front brake disc

bolt

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake disc with new bolts.

aTorque tighten the new disc mounting bolts (see

30A, General information, Brake circuit: Tighten-

ing torque, page 30A-6)

125059

125056

Page 90 of 281

31A-47

FRONT AXLE COMPONENTS

Front axle subframe: Removal - Refitting

31A

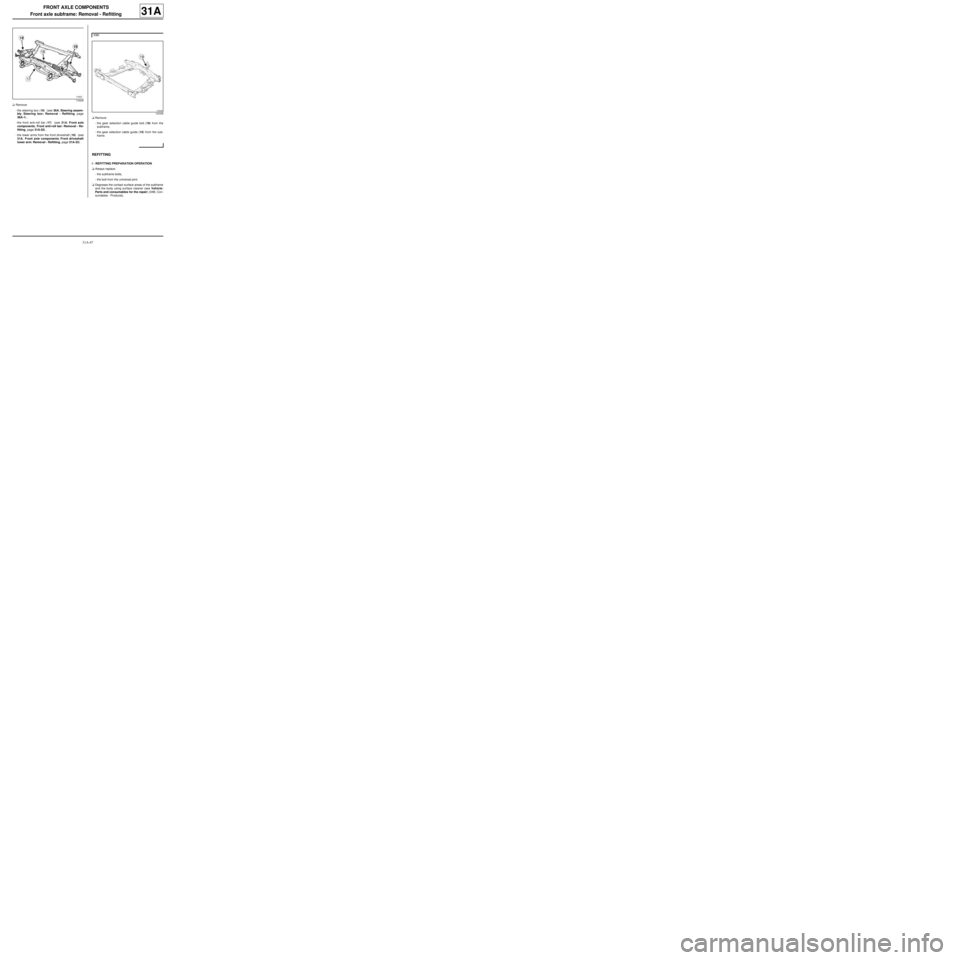

aRemove:

-the steering box (16) (see 36A, Steering assem-

bly, Steering box: Removal - Refitting, page

36A-1) ,

-the front anti-roll bar (17) (see 31A, Front axle

components, Front anti-roll bar: Removal - Re-

fitting, page 31A-52) ,

-the lower arms from the front driveshaft (18) (see

31A, Front axle components, Front driveshaft

lower arm: Removal - Refitting, page 31A-33) .aRemove:

-the gear selection cable guide bolt (19) from the

subframe,

-the gear selection cable guide (19) from the sub-

frame.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace:

-the subframe bolts,

-the bolt from the universal joint.

aDegrease the contact surface areas of the subframe

and the body using surface cleaner (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products).

119429

K9K

124348

Page 100 of 281

33A-2

REAR AXLE COMPONENTS

Rear brake pads: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

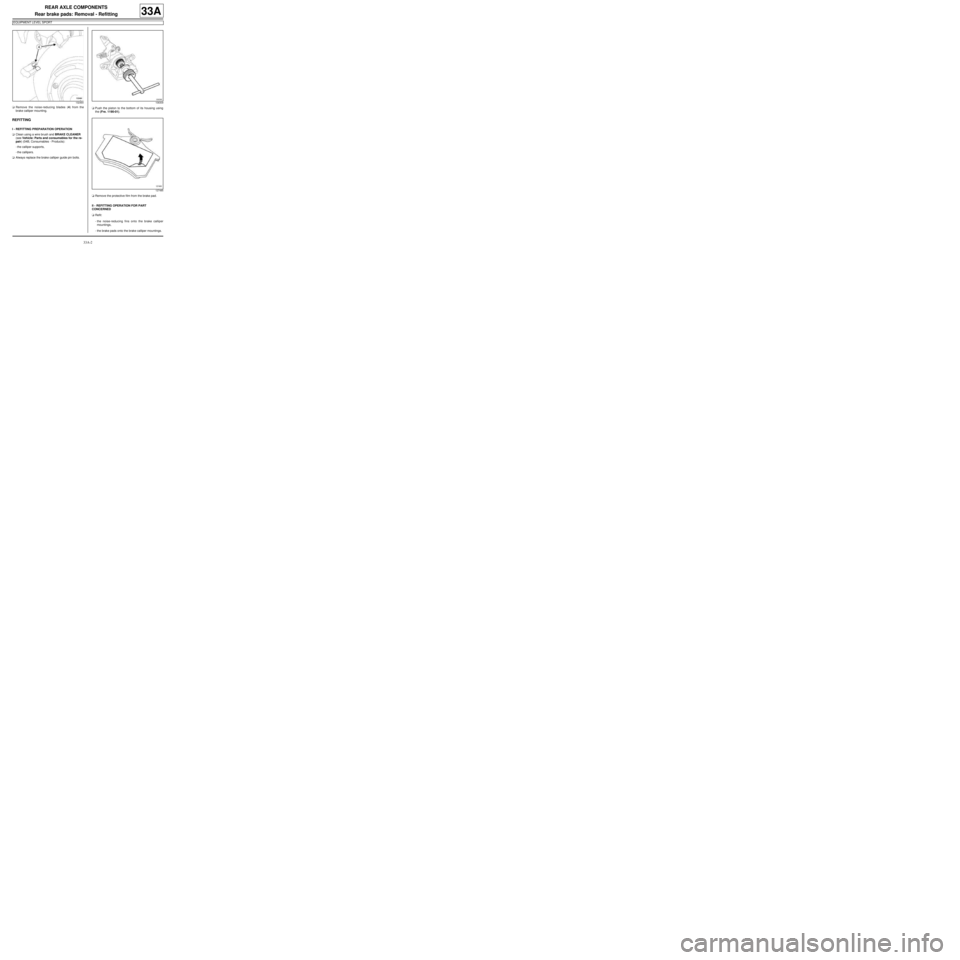

aRemove the noise-reducing blades (4) from the

brake calliper mounting.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace the brake calliper guide pin bolts.aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

aRemove the protective film from the brake pad.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the noise-reducing fins onto the brake calliper

mountings,

-the brake pads onto the brake calliper mountings.

132464106309

127485

Page 105 of 281

33A-7

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aPosition a pedal press on the brake pedal to limit

the outflow of brake fluid.

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the parking brake cable from the brake calli-

per at (1) .

aMove aside the parking brake cable.

aLoosen the calliper brake pipe union (2) .

aRemove:

-the brake calliper guide pin bolts (3) ,

-the brake calliper from the mounting,

-the union between the brake pipe and the calliper,

-the brake calliper.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace the brake calliper guide pin bolts. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Equipment required

pedal press

Tightening torquesm

new bolts on the brake

calliper guide pins35 N.m

brake pipe union on the

calliper13 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

Page 108 of 281

33A-10

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace:

-the calliper mounting bolts,

-the calliper guide pin bolts.

aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake calliper mounting.

aTorque tighten the bolts of the brake calliper

mounting (XXX).

III - FINAL OPERATION.

aRefit:

-the brake calliper,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .

aTorque tighten the new bolts of the brake calliper

guide pins (105 N.m).aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

106309

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 110 of 281

33A-12

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

aRemove:

-the nut (3) from the hub,

-the brake disc.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the hub nut.

aClean the brake discs using a parts washer.

aDry the disc surfaces.

aClean the stub axle using a wire brush and BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake disc.

aTorque tighten the new hub nut (175 N.m ).

aRefit the hub's nut cover.

III - FINAL OPERATION.

aRefit:

-the "calliper mounting - brake calliper" assembly,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .aTorque tighten the brake calliper mounting bolts

(105 N.m).

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

132455

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 142 of 281

35A-2

WHEELS AND TYRES

Wheel: Removal - Refitting

35A

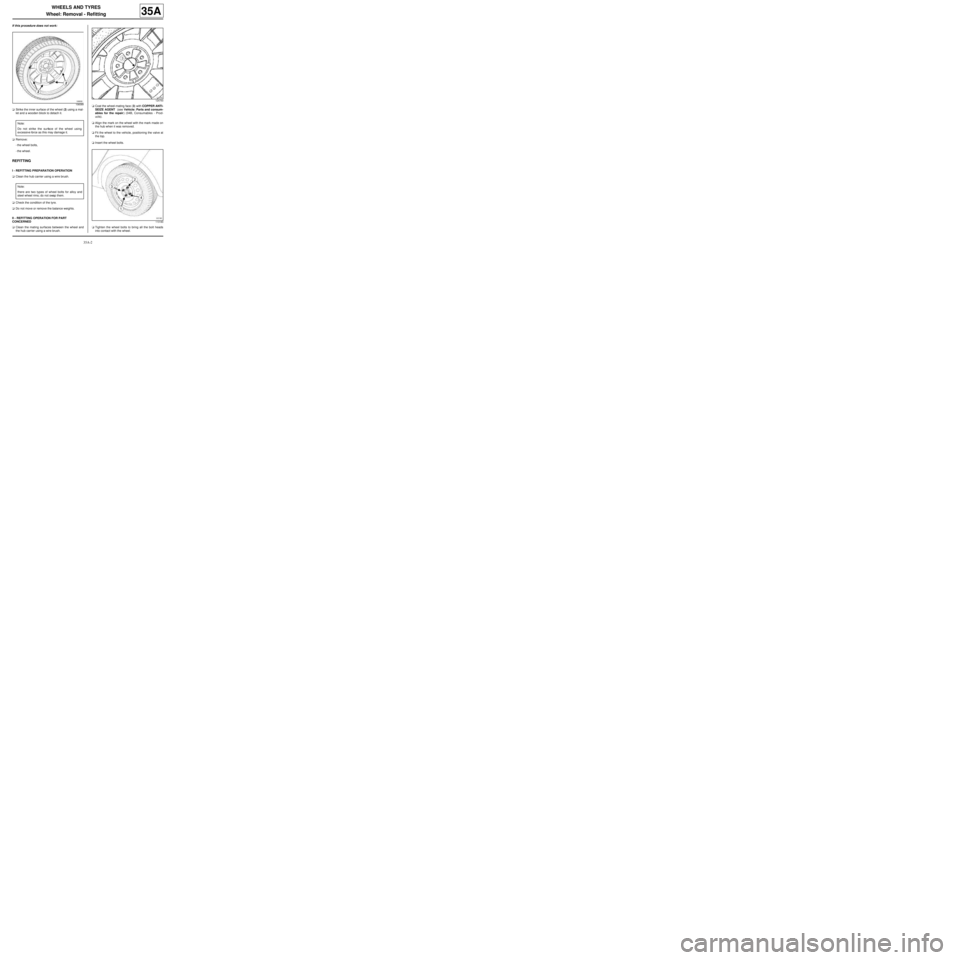

If this procedure does not work:

aStrike the inner surface of the wheel (2) using a mal-

let and a wooden block to detach it.

aRemove:

-the wheel bolts,

-the wheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the hub carrier using a wire brush.

aCheck the condition of the tyre.

aDo not move or remove the balance weights.

II - REFITTING OPERATION FOR PART

CONCERNED

aClean the mating surfaces between the wheel and

the hub carrier using a wire brush.aCoat the wheel-mating face (3) with COPPER ANTI-

SEIZE AGENT (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

aAlign the mark on the wheel with the mark made on

the hub when it was removed.

aFit the wheel to the vehicle, positioning the valve at

the top.

aInsert the wheel bolts.

aTighten the wheel bolts to bring all the bolt heads

into contact with the wheel.

106089

Note:

Do not strike the surface of the wheel using

excessive force as this may damage it.

Note:

there are two types of wheel bolts for alloy and

steel wheel rims; do not swap them.

124750

113180

Page 148 of 281

35A-8

WHEELS AND TYRES

Tyres: Removal - Refitting

35A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the wheel in question (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the balance weights,

-the valve mechanism.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDetach:

-the bead from the outside of the tyre, starting with

the side opposite the valve,

-the bead from the inside of the tyre.aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the exterior bead from the tyre.

aRemove the exterior bead of the tyre, finishing at the

valve.

aPosition the tyre lever approximately 15 cm from the

valve on the outside of the wheel rim in order to re-

move the bead from inside the tyre.

aRemove the interior bead of the tyre, finishing at the

valve.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Tyre valve

aLubricate the two tyre beads correctly using the

TYRE PASTE (see Vehicle: Parts and consum-

ables for the repair) (04B, Consumables - Prod-

ucts).

II - REFITTING OPERATION FOR PART

CONCERNED

aEngage the lower tyre bead approximately 15 cm af-

ter the valve.

aFinish fitting the tyre at the valve.

aFit the exterior bead approximately 15 cm after the

valve using the tyre lever.

aInflate the tyre to 3.5 bar to press the tyre beads

against the wheel rim.

18884

18885