torque RENAULT TWINGO 2009 2.G Chasiss Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 281

Page 106 of 281

33A-8

REAR AXLE COMPONENTS

Rear brake calliper: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

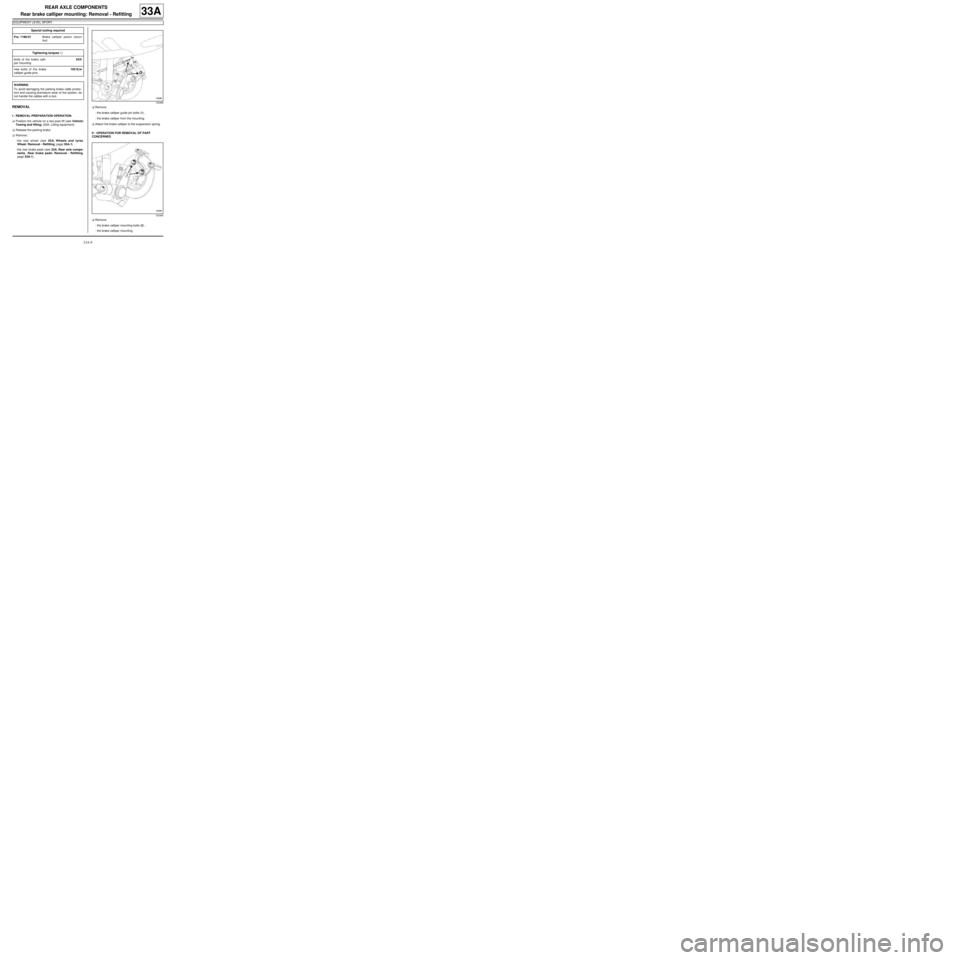

aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake calliper on the calliper mounting.

aTorque tighten:

-the new bolts on the brake calliper guide pins

(35 N.m),

-the brake pipe union on the calliper (13 N.m).

aFit the parking brake cable.

aClip the handbrake on the brake calliper.

III - FINAL OPERATION

aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aRemove the pedal press from the brake pedal.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

106309

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 107 of 281

33A-9

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove:

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

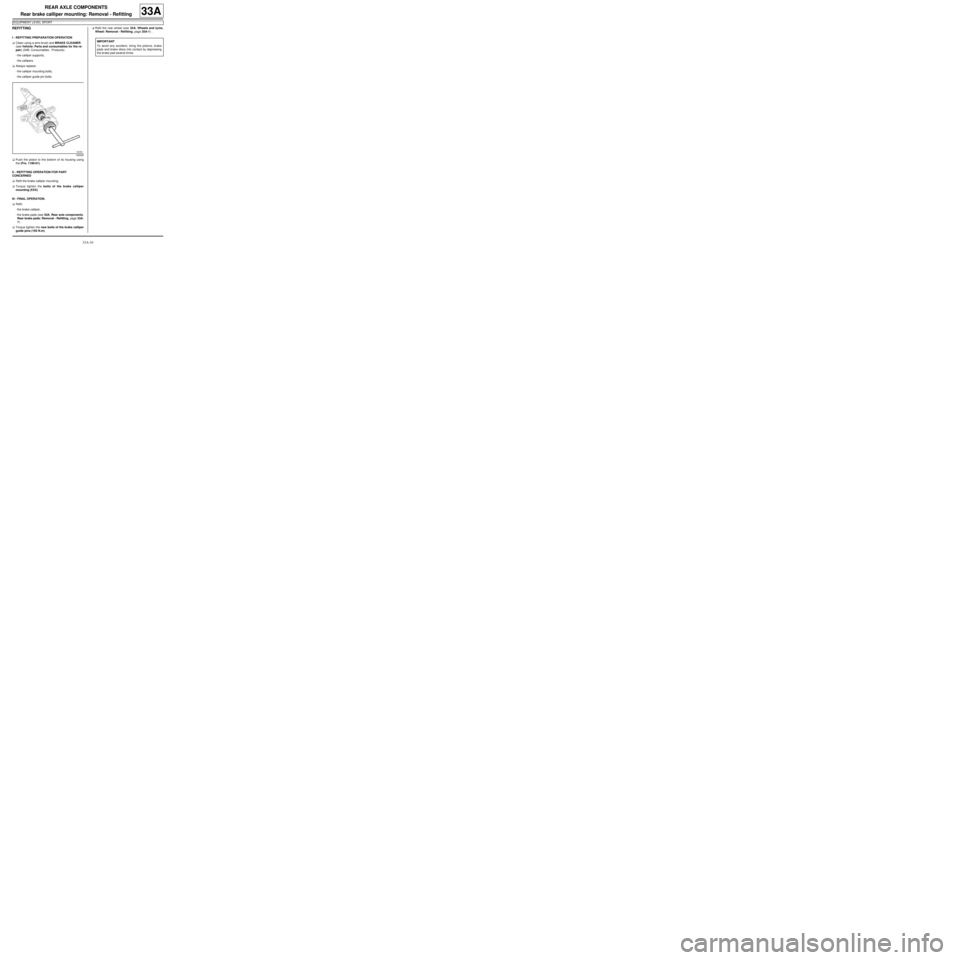

page 33A-1) .aRemove:

-the brake calliper guide pin bolts (1) ,

-the brake calliper from the mounting.

aAttach the brake calliper to the suspension spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake calliper mounting bolts (2) ,

-the brake calliper mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

bolts of the brake calli-

per mountingXXX

new bolts of the brake

calliper guide pins105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132465

Page 108 of 281

33A-10

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REFITTING

I - REFITTING PREPARATION OPERATION

aClean using a wire brush and BRAKE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products):

-the calliper supports,

-the callipers.

aAlways replace:

-the calliper mounting bolts,

-the calliper guide pin bolts.

aPush the piston to the bottom of its housing using

the (Fre. 1190-01).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake calliper mounting.

aTorque tighten the bolts of the brake calliper

mounting (XXX).

III - FINAL OPERATION.

aRefit:

-the brake calliper,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .

aTorque tighten the new bolts of the brake calliper

guide pins (105 N.m).aRefit the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

106309

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 109 of 281

33A-11

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

Brake discs cannot be reground. If there is excessive

scoring or wear, they will need to be replaced (see

30A, General information, Brake: Specifications,

page 30A-19) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

page 33A-1) .aRemove:

-the brake calliper mounting bolts (1) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "calliper mounting - brake calliper" to the

shock absorber spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the hub's nut cover (2) . Equipment required

par ts washer

Tightening torquesm

new hub nut175 N.m

brake calliper mounting

bolts105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132467

132456

Page 110 of 281

33A-12

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

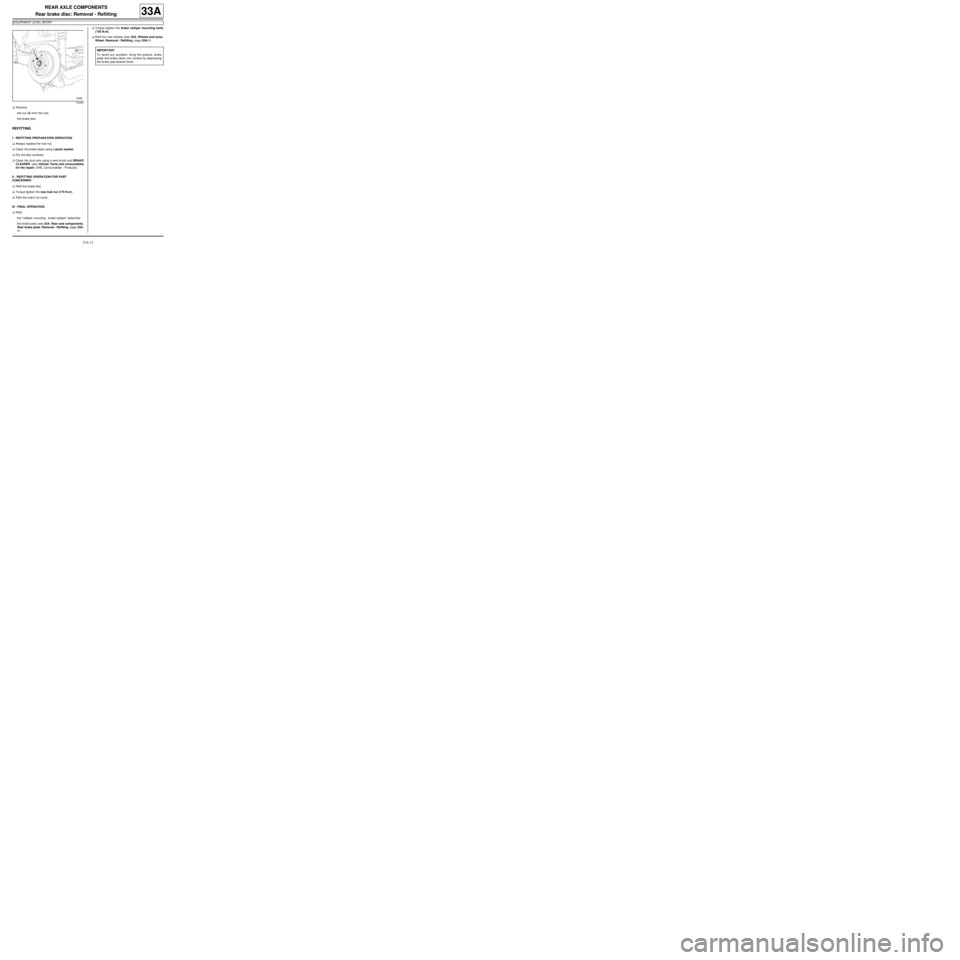

aRemove:

-the nut (3) from the hub,

-the brake disc.

REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the hub nut.

aClean the brake discs using a parts washer.

aDry the disc surfaces.

aClean the stub axle using a wire brush and BRAKE

CLEANER (see Vehicle: Parts and consumables

for the repair) (04B, Consumables - Products).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the brake disc.

aTorque tighten the new hub nut (175 N.m ).

aRefit the hub's nut cover.

III - FINAL OPERATION.

aRefit:

-the "calliper mounting - brake calliper" assembly,

-the brake pads (see 33A, Rear axle components,

Rear brake pads: Removal - Refitting, page 33A-

1) .aTorque tighten the brake calliper mounting bolts

(105 N.m).

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

132455

IMPORTANT

To avoid any accident, bring the pistons, brake

pads and brake discs into contact by depressing

the brake pad several times.

Page 115 of 281

33A-17

REAR AXLE COMPONENTS

Rear brake cylinder: Removal - Refitting

33A

REMOVAL

I - OPERATION FOR PREPARATION OF PART

CONCERNED

aPosition the vehicle on a lift ( (see Vehicle: Towing

and lifting) ).

aRelease the parking brake.

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) .

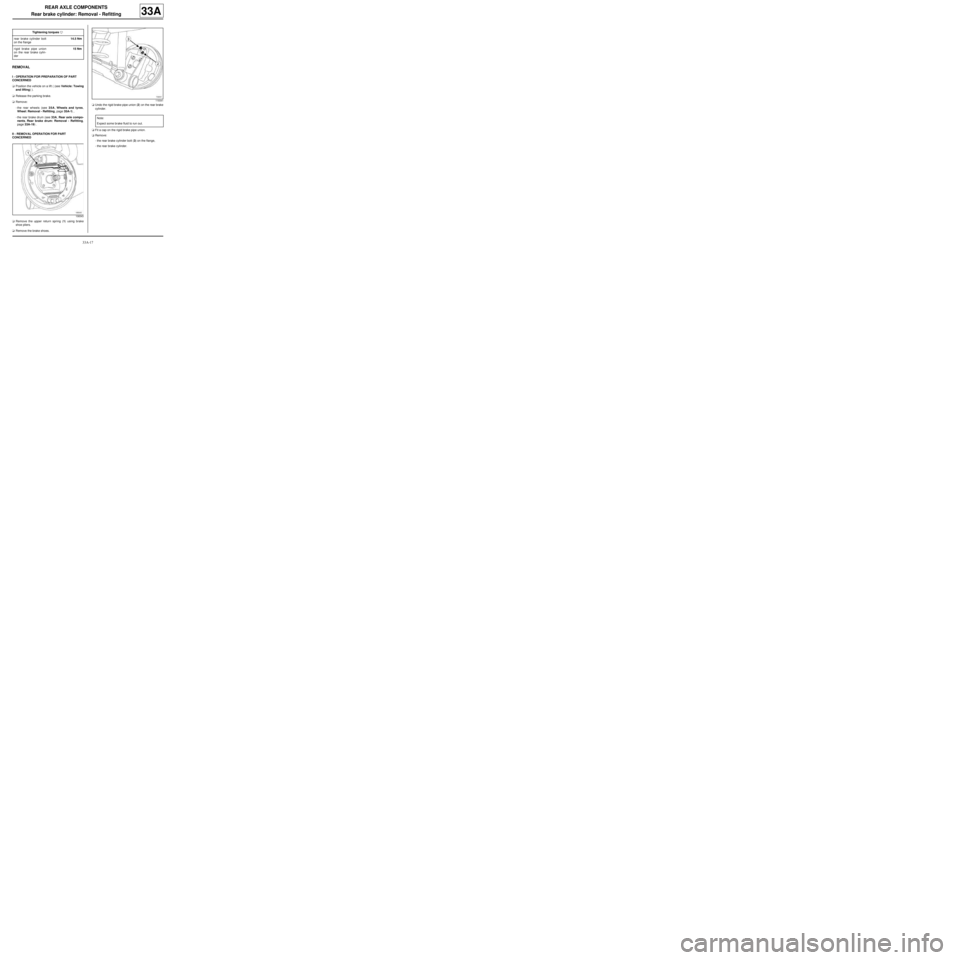

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the upper return spring (1) using brake

shoe pliers.

aRemove the brake shoes.aUndo the rigid brake pipe union (2) on the rear brake

cylinder.

aFit a cap on the rigid brake pipe union.

aRemove:

-the rear brake cylinder bolt (3) on the flange,

-the rear brake cylinder. Tightening torquesm

rear brake cylinder bolt

on the flange14.5 Nm

rigid brake pipe union

on the rear brake cylin-

der15 Nm

108343

119341

Note:

Expect some br ake fluid to run out.

Page 116 of 281

33A-18

REAR AXLE COMPONENTS

Rear brake cylinder: Removal - Refitting

33A

REFITTING

I - REFITTING PREPARATIONS OPERATION

aRemove any dust from the drums and the flanges

using the cleaning station.

aCheck the condition of the brake cylinder boots and

pistons (replace any faulty parts).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the rear brake cylinder,

-the rear brake cylinder bolt on the flange,

-the rigid brake pipe union on the rear brake cylin-

der,

-the upper return spring using brake shoe pliers.

aTorque tighten:

-the rear brake cylinder bolt on the flange (14.5

Nm),

-the rigid brake pipe union on the rear brake cyl-

inder (15 Nm).

III - FINAL OPERATION.

aRefit:

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) ,-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

aAdjust the brake pads by depressing the brake pedal

repeatedly.

117348

Page 117 of 281

33A-19

REAR AXLE COMPONENTS

Rear brake drum: Removal - Refitting

33A

When a brake drum is replaced, the brake drum on the

opposite side must be replaced as well.

Always replace the brake pads if the brake drums are

being replaced.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove the rear wheels (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the drum caps,

-the brake drum nuts,

-the brake drums.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck the internal diameter of the drum. Equipment required

par ts washer

Tightening torquesm

brake drum nuts175 N.m

IMPORTANT

To avoid brake imbalance, both drums must be of

the same diameter. Regrinding one drum necessi-

tates regrinding of the opposite drum.

109709

109710

Page 118 of 281

33A-20

REAR AXLE COMPONENTS

Rear brake drum: Removal - Refitting

33A

aAlways replace the brake drum nuts.

aparts always to be replaced: rear drum cap.

aReplace any faulty parts.

aUsing a parts washer, clean:

-the brake linings,

-the brake drums.

-the stub axle.

II - REFITTING OPERATION FOR PART

CONCERNED

aAdjust the parking brake if the lever stops between

the first and second position of the parking brake le-

ver's travel (see 37A, Mechanical component con-

trols, Parking brake lever: Removal - Refitting,

page 37A-46) .

aRefit:

-the brake drums.

-the brake drum nuts.

aTorque tighten the brake drum nuts (175 N.m) by

turning the drum while tightening the nut.

aRefit new brake drum caps.

III - FINAL OPERATION

aRefit the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

aAdjust the brake linings by depressing the brake

pedal repeatedly.

117348

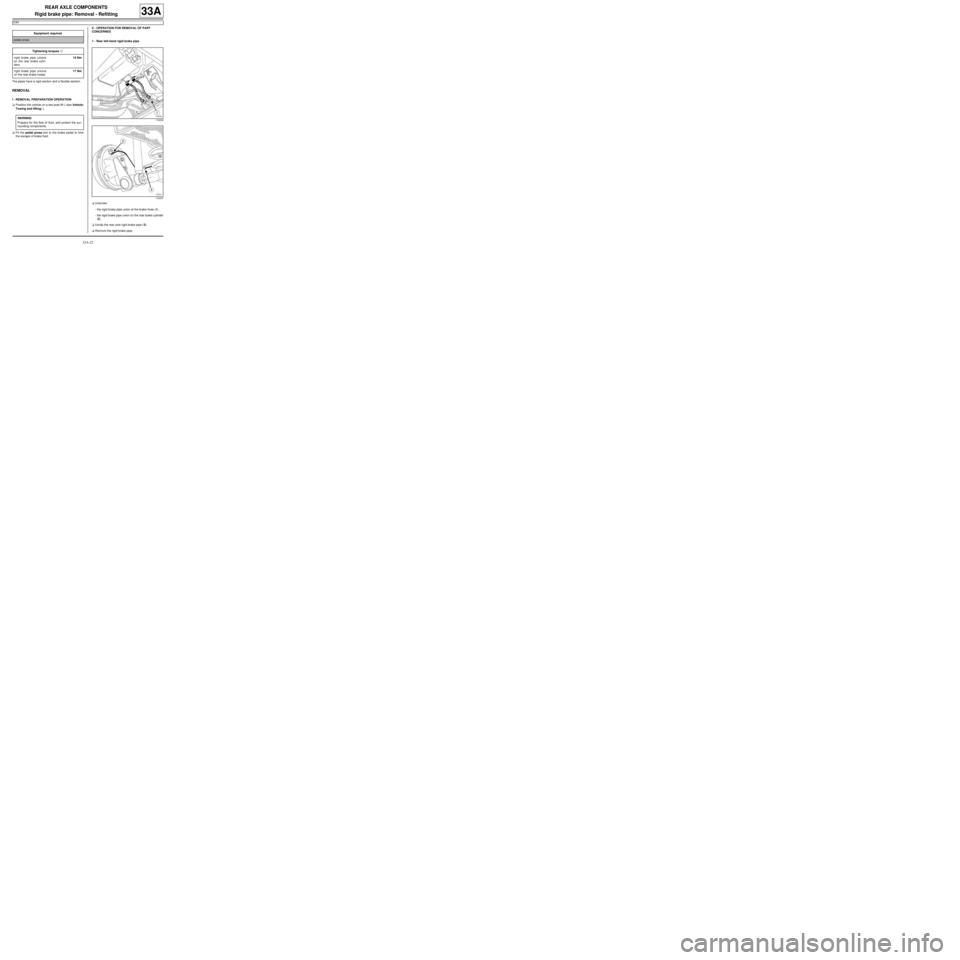

Page 120 of 281

33A-22

REAR AXLE COMPONENTS

Rigid brake pipe: Removal - Refitting

C44

33A

The pipes have a rigid section and a flexible section.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the pedal press tool to the brake pedal to limit

the escape of brake fluid.II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Rear left-hand rigid brake pipe

aUnscrew:

-the rigid brake pipe union at the brake hose (1) .

-the rigid brake pipe union on the rear brake cylinder

(2) .

aUnclip the rear axle rigid brake pipe (3) .

aRemove the rigid brake pipe. Equipment required

pedal press

Tightening torquesm

rigid brake pipe unions

on the rear brake cylin-

ders15 Nm

rigid brake pipe unions

on the rear brake hoses17 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

119337