fuel RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 306 of 652

12A-41

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

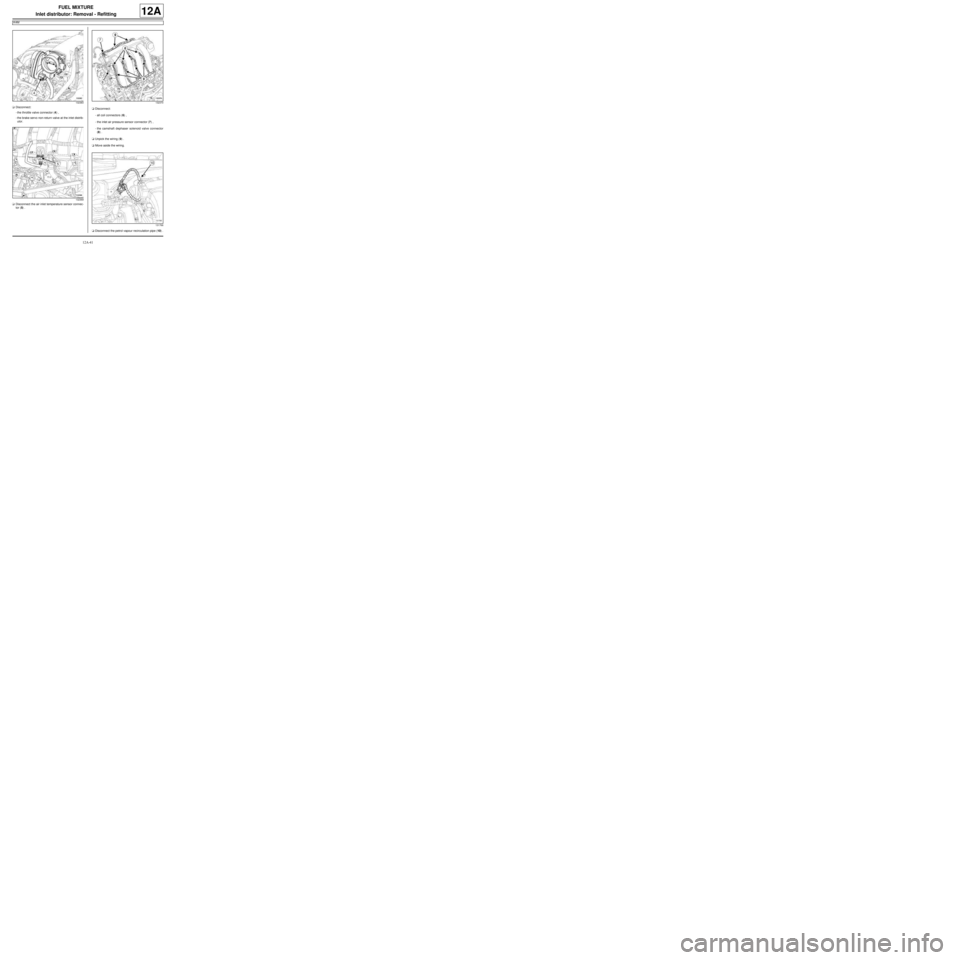

aDisconnect:

-the throttle valve connector (4) ,

-the brake servo non-return valve at the inlet distrib-

utor.

aDisconnect the air inlet temperature sensor connec-

tor (5) .aDisconnect:

-all coil connectors (6) ,

-the inlet air pressure sensor connector (7) ,

-the camshaft dephaser solenoid valve connector

(8) .

aUnpick the wiring (9) .

aMove aside the wiring.

aDisconnect the petrol vapour recirculation pipe (10) .

132383

132369132370

131766

Page 307 of 652

12A-42

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

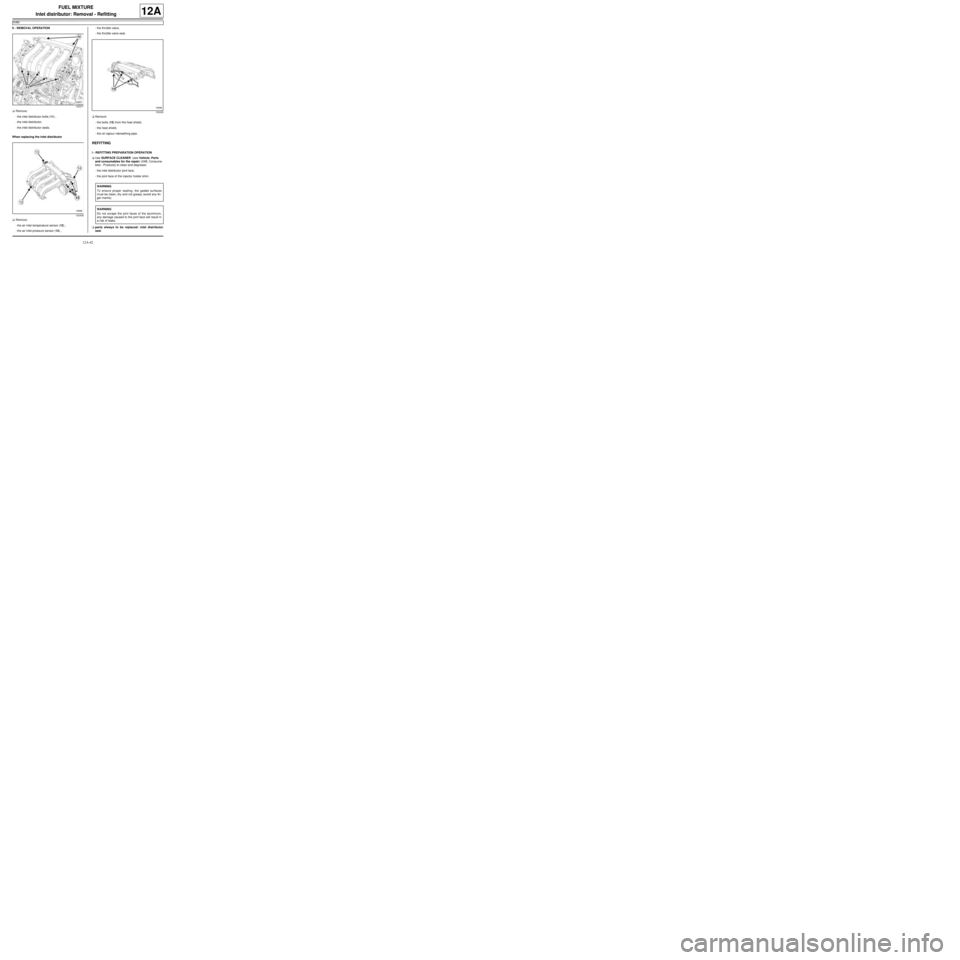

II - REMOVAL OPERATION

aRemove:

-the inlet distributor bolts (11) ,

-the inlet distributor,

-the inlet distributor seals.

When replacing the inlet distributor

aRemove:

-the air inlet temperature sensor (12) ,

-the air inlet pressure sensor (13) ,-the throttle valve,

-the throttle valve seal.

aRemove:

-the bolts (15) from the heat shield,

-the heat shield,

-the oil vapour rebreathing pipe.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the inlet distributor joint face,

-the joint face of the injector holder shim.

aparts always to be replaced: inlet distributor

seal.

132371

132438

132439

WARNING

To ensure proper sealing, the gasket surfaces

must be clean, dry and not greasy (avoid any fin-

ger mar ks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

Page 308 of 652

12A-43

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

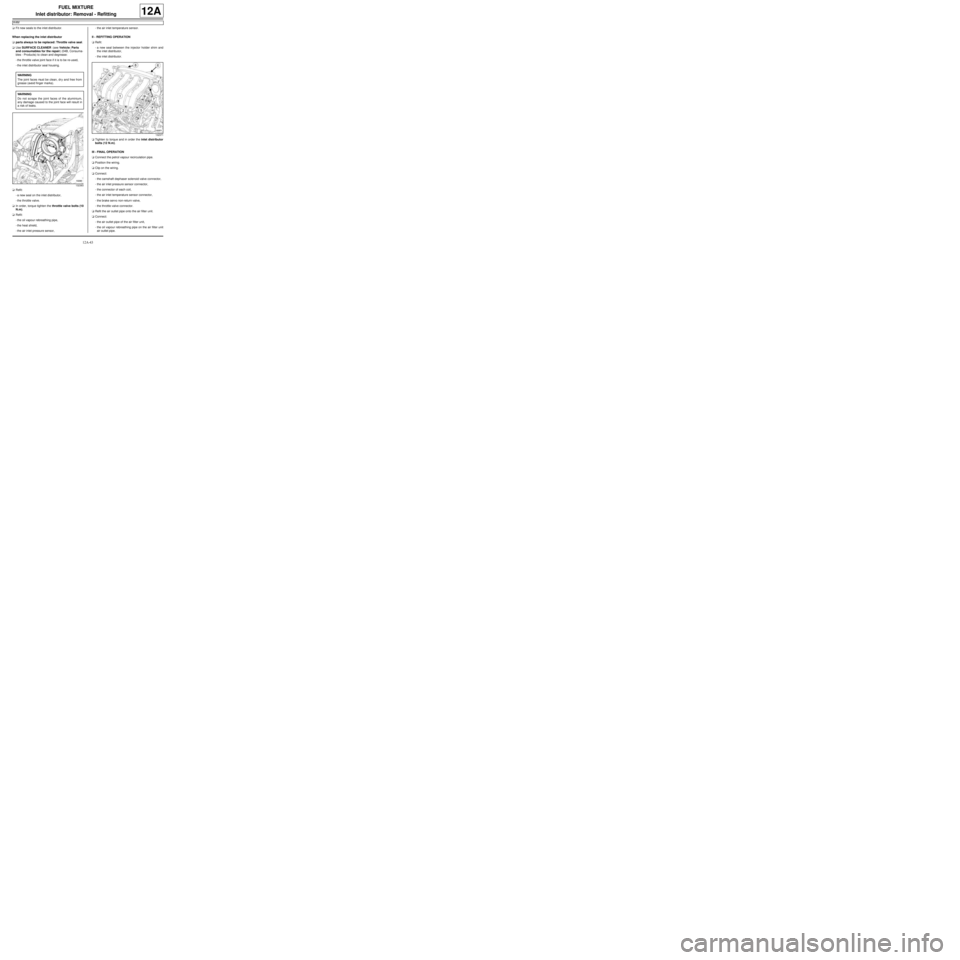

aFit new seals to the inlet distributor.

When replacing the inlet distributor

aparts always to be replaced: Throttle valve seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the throttle valve joint face if it is to be re-used,

-the inlet distributor seal housing.

aRefit:

-a new seal on the inlet distributor,

-the throttle valve.

aIn order, torque tighten the throttle valve bolts (10

N.m).

aRefit:

-the oil vapour rebreathing pipe,

-the heat shield,

-the air inlet pressure sensor,-the air inlet temperature sensor.

II - REFITTING OPERATION

aRefit:

-a new seal between the injector holder shim and

the inlet distributor,

-the inlet distributor.

aTighten to torque and in order the inlet distributor

bolts (12 N.m).

III - FINAL OPERATION

aConnect the petrol vapour recirculation pipe.

aPosition the wiring.

aClip on the wiring.

aConnect:

-the camshaft dephaser solenoid valve connector,

-the air inlet pressure sensor connector,

-the connector of each coil,

-the air inlet temperature sensor connector,

-the brake servo non-return valve,

-the throttle valve connector.

aRefit the air outlet pipe onto the air filter unit.

aConnect:

-the air outlet pipe of the air filter unit,

-the oil vapour rebreathing pipe on the air filter unit

air outlet pipe. WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

132383

132371

Page 309 of 652

12A-44

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

aTorque tighten:

-the clip of the air filter unit air outlet pipe on the

throttle valve (3.5 N.m),

-the clip of the air filter unit air outlet pipe on the

air filter unit (3.5 N.m).

aRefit:

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 310 of 652

12A-45

FUEL MIXTURE

Injector holder shim: Removal - Refitting

K4M

12A

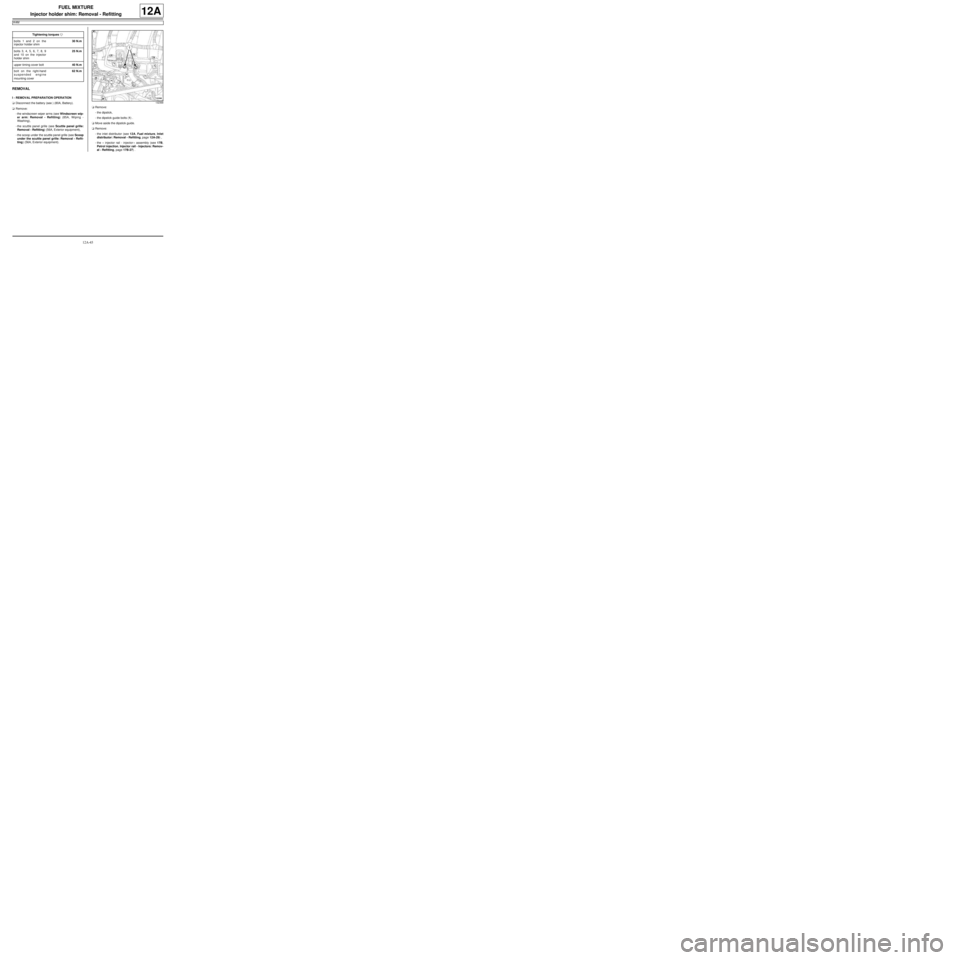

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).aRemove:

-the dipstick,

-the dipstick guide bolts (1) .

aMove aside the dipstick guide.

aRemove:

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the « injector rail - injector » assembly (see 17B,

Petrol injection, Injector rail - Injectors: Remov-

al - Refitting, page 17B-27) . Tightening torquesm

bolts 1 and 2 on the

injector holder shim30 N.m

bolts 3, 4, 5, 6, 7, 8, 9

and 10 on the injector

holder shim25 N.m

upper timing cover bolt40 N.m

bolt on the right-hand

suspended engine

mounting cover62 N.m

132368

Page 311 of 652

12A-46

FUEL MIXTURE

Injector holder shim: Removal - Refitting

K4M

12A

II - REMOVAL OPERATION

aRemove the bolt (2) from the right-hand suspended

engine mounting cover.

aRemove:

-the bolt (3) from the upper timing cover,

-the injector holder shim bolts,

-the injector holder shim,

-the injector holder shim seal.REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Inlet shim seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the cylinder head joint face,

-the gasket face of the injector holder shim, in case

of reuse.

II - REFITTING OPERATION

aRefit:

-a new seal on the injector holder shim,

-the injector holder shim.

aTighten to torque and in order:

-bolts 1 and 2 on the injector holder shim (30

N.m),

131777

102303

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

102303

Page 312 of 652

12A-47

FUEL MIXTURE

Injector holder shim: Removal - Refitting

K4M

12A

-bolts 3, 4, 5, 6, 7, 8, 9 and 10 on the injector

holder shim (25 N.m).

aTorque tighten:

-the upper timing cover bolt (40 N.m),

-the bolt on the right-hand suspended engine

mounting cover (62 N.m).

III - FINAL OPERATION

aRefit:

-the « injector rail - injector » assembly (see 17B,

Petrol injection, Injector rail - Injectors: Remov-

al - Refitting, page 17B-27) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-dipstick guide ,

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see ) (80A, Battery).

Page 313 of 652

12A-48

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

D4F, and 772 – D7F

12A

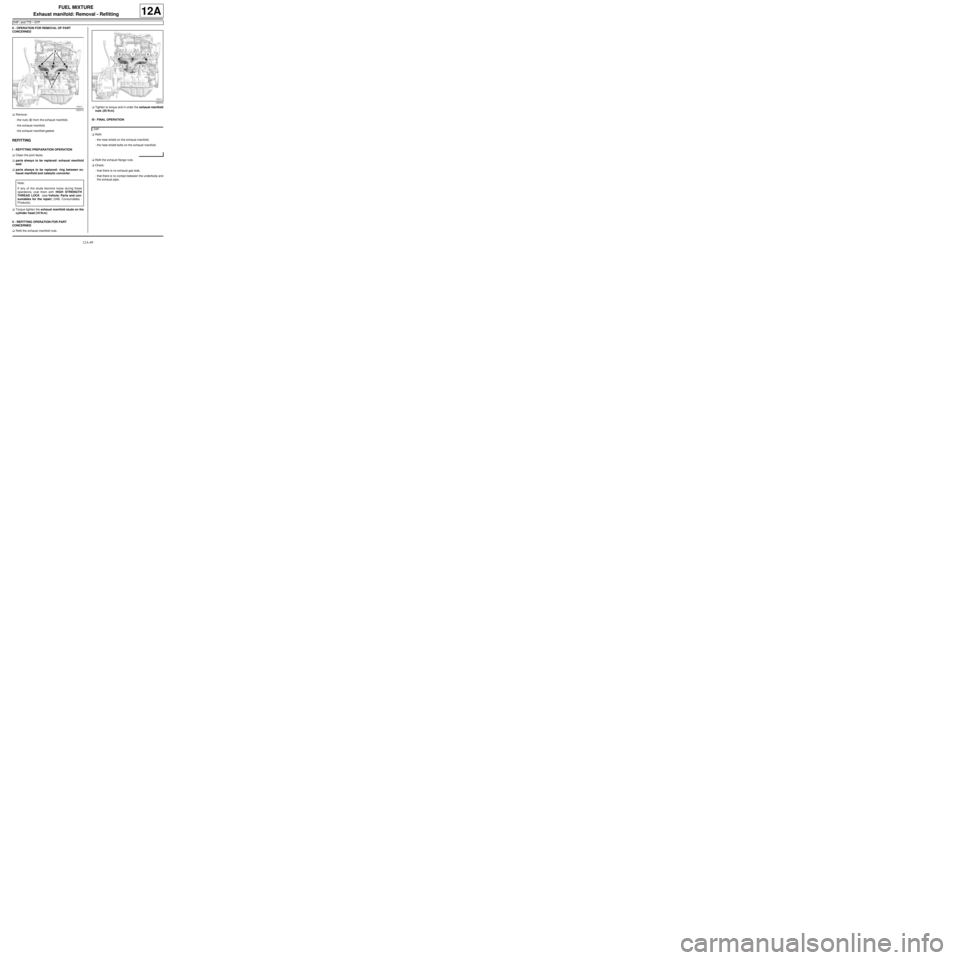

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the nuts (1) from the exhaust flange.aRemove:

-the bolts (2) from the heat shield,

-the heat shield. Tightening torquesm

exhaust manifold studs

on the cylinder head10 N.m

exhaust manifold nuts25 N.m

121731

D4F

120301

Page 314 of 652

12A-49

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

D4F, and 772 – D7F

12A

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (3) from the exhaust manifold,

-the exhaust manifold,

-the exhaust manifold gasket.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the joint faces.

aparts always to be replaced: exhaust manifold

seal.

aparts always to be replaced: ring between ex-

haust manifold and catalytic converter.

aTorque tighten the exhaust manifold studs on the

cylinder head (10 N.m).

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the exhaust manifold nuts.aTighten to torque and in order the exhaust manifold

nuts (25 N.m).

III - FINAL OPERATION

aRefit:

-the heat shield on the exhaust manifold,

-the heat shield bolts on the exhaust manifold.

aRefit the exhaust flange nuts.

aCheck:

-that there is no exhaust gas leak,

-that there is no contact between the underbody and

the exhaust pipe,

120312

Note:

If any of the studs become loose during these

operations, coat them with HIGH STRENGTH

THREAD LOCK (see Vehicle: Parts and con-

sumables for the repair) (04B, Consumables -

Products).

120312

D4F

Page 315 of 652

12A-50

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K9K

12A

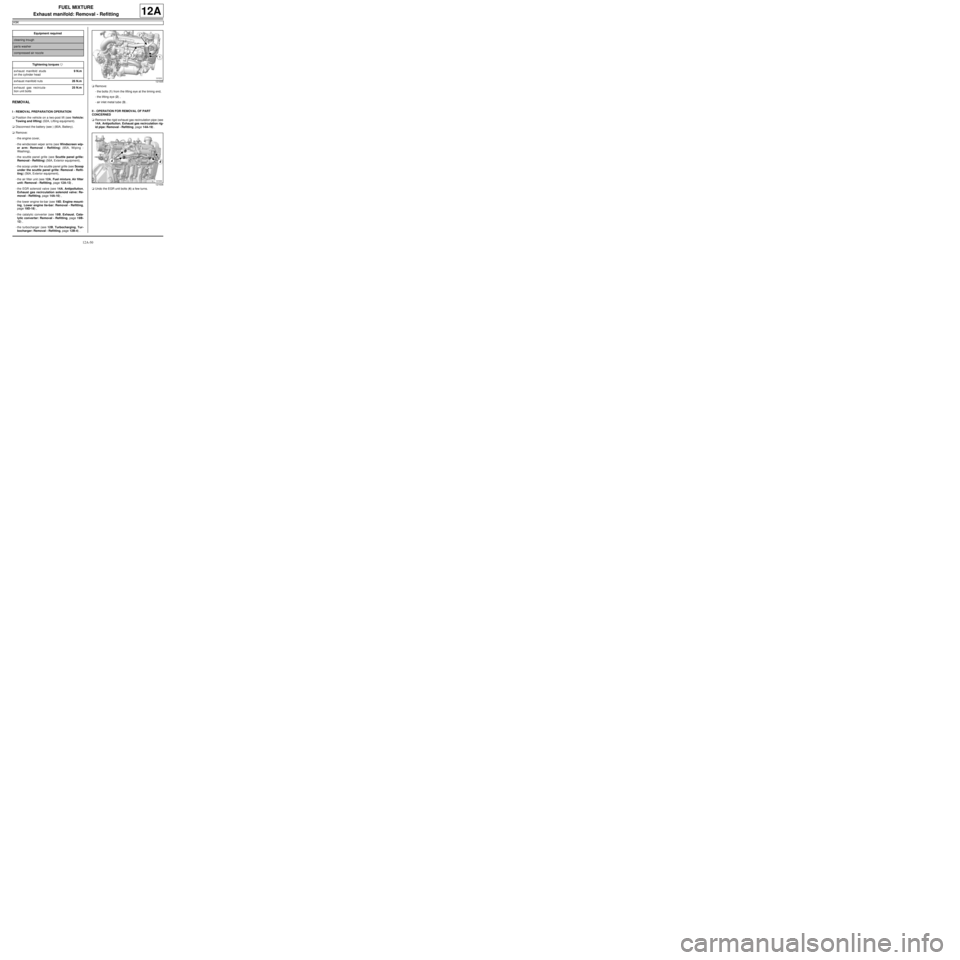

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the turbocharger (see 12B, Turbocharging, Tur-

bocharger: Removal - Refitting, page 12B-4) .aRemove:

-the bolts (1) from the lifting eye at the timing end,

-the lifting eye (2) ,

-air inlet metal tube (3) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the rigid exhaust gas recirculation pipe (see

14A, Antipollution, Exhaust gas recirculation rig-

id pipe: Removal - Refitting, page 14A-19) .

aUndo the EGR unit bolts (4) a few turns. Equipment required

cleaning trough

par ts washer

compressed air nozzle

Tightening torquesm

exhaust manifold studs

on the cylinder head9 N.m

exhaust manifold nuts26 N.m

exhaust gas recircula-

tion unit bolts25 N.m

121635

121636