fuel RENAULT TWINGO 2009 2.G Engine And Peripherals Owners Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 286 of 652

12A-21

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 780 or 782

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

a

aDisconnect the air inlet pipe from the air filter box (3)

.

aMove aside the air inlet pipe from the air filter unit.

aRemove the bolt (4) of the intercooler air inlet pipe

from the throttle valve. Tightening torquesm

throttle valve bolts10 N.m

122833

122673

Note:

If the intercooler air inlet pipe tightening clip (1) is

removed, the flexible rubber pipe (2) and the

tightening clip (1) must be replaced.

Page 287 of 652

12A-22

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 780 or 782

12A

aMove the intercooler air inlet pipe clip away from the

turbocharger in the direction of the arrow (5) .

aDisconnect the intercooler air inlet pipe from the tur-

bocharger.

aMove aside the intercooler air inlet pipe.

aDisconnect the vacuum pipe on the turbocharger

discharge solenoid valve (7) .aRemove the intercooler air outlet pipe bolts (8) from

the throttle valve.

aMove the intercooler air outlet pipe to one side.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the throttle valve connector (9) .

aUnclip the throttle valve wiring.

aRemove:

-the throttle valve bolts (10) , Note:

If the clip (6) is removed from the heat resistant

protector, the latter must be replaced.

122394

122390

122391

Page 288 of 652

12A-23

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 780 or 782

12A

-the throttle valve,

-the throttle valve seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Throttle valve seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean the bearing faces:

-on the inlet distributor,

-on the throttle valve if it is to be reused.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the throttle valve,

-the throttle valve,

-the throttle valve bolts.

aTorque tighten the throttle valve bolts (10 N.m).

aConnect the throttle valve connector.

aClip the wiring onto the throttle valve.

III - FINAL OPERATION

aRefit:

-the intercooler air outlet pipe on the throttle valve,

-the intercooler air outlet pipe bolts.

aTighten the intercooler air outlet pipe bolts.

aConnect the vacuum pipe onto the turbocharger dis-

charge solenoid valve.aPush the intercooler air inlet pipe clip in the direction

of the arrow (11) .

aFit the intercooler air inlet pipe.

aConnect the intercooler air inlet pipe on the turbo-

charger.

aRefit the intercooler air inlet pipe bolt on the throttle

valve.

aFit the air filter box air inlet pipe.

aConnect:

-the air filter unit air inlet pipe,

-the battery (see ) (80A, Battery).

aProgram the throttle valve (see Fault finding - Re-

placement of components) (17B, Petrol injection).

122666

Page 289 of 652

12A-24

FUEL MIXTURE

Throttle valve: Removal - Refitting

K4M

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUndo:

-the clip (1) of the air filter unit air outlet pipe on the

throttle valve side,

-the clip (2) of the air filter unit air outlet pipe on the

air filter unit side.

aDisconnect:

-the oil vapour rebreathing pipe (3) from the air filter

unit air outlet pipe,

-the air outlet pipe of the air filter unit.

aRemove the air outlet pipe from the air filter box.II - REMOVAL OPERATION

aDisconnect the connector (4) from the throttle valve.

aRemove:

-the throttle valve bolts (5) ,

-the throttle valve,

-the throttle valve seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Throttle valve seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the throttle valve joint face if it is to be re-used,

-the inlet distributor seal housing. Tightening torquesm

throttle valve bolts10 N.m

clip of the air filter unit

air outlet pipe on the

throttle valve3.5 N.m

clip of the air filter unit

air outlet pipe on the air

filter unit3.5 N.m

132382

132383

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

Page 290 of 652

12A-25

FUEL MIXTURE

Throttle valve: Removal - Refitting

K4M

12A

II - REFITTING OPERATION

aRefit:

-a new seal on the inlet distributor,

-the throttle valve.

aIn order, torque tighten the throttle valve bolts (10

N.m).

aConnect the throttle valve connector.

III - FINAL OPERATION

aRefit the air outlet pipe onto the air filter unit.

aConnect:

-the air outlet pipe of the air filter unit,

-the oil vapour rebreathing pipe on the air filter unit

air outlet pipe.

aTorque tighten:

-the clip of the air filter unit air outlet pipe on the

throttle valve (3.5 N.m),

-the clip of the air filter unit air outlet pipe on the

air filter unit (3.5 N.m).

132383

Page 291 of 652

12A-26

FUEL MIXTURE

Throttle valve: Cleaning

D4F or D7F or K4M

12A

CLEANING

I - CLEANING PREPARATION OPERATION

aRemove the throttle valve (see 12A, Fuel mixture,

Throttle valve: Removal - Refitting, page 12A-20)

.

II - CLEANING THE PART CONCERNED

a

aRemove the seal(s) of the throttle valve.aHold the throttle valve flap open manually.

aSpray CARBURETTOR CLEANER (see Vehicle:

Parts and consumables for the repair) (04B, Con-

sumables - Products) into the air vent until all traces

of clogging have disappeared. Equipment required

compressed air nozzle

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

Always wear protective gear (gloves, goggles and

breathing masks).

Note:

Be sure to work in a clean environment so as not to

allow any contamination of the throttle valve.

Note:

The CARBURETTOR CLEANING product dam-

ages the seals.

124736

Note:

Do not spray any cleaning product onto the out-

side of the cylinder, inside the spring housing or

onto the connector.

Page 292 of 652

12A-27

FUEL MIXTURE

Throttle valve: Cleaning

D4F or D7F or K4M

12A

aRemove the residues of CARBURETTOR CLEAN-

ER and the residual dirt using a LINT-FREE CLOTH

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products).

aUse a compressed air nozzle to blast the throttle

valve edges and the air vent.

parts always to be replaced: Throttle valve seal.III - FINAL OPERATION

aRefit the throttle valve (see 12A, Fuel mixture,

Throttle valve: Removal - Refitting, page 12A-20)

.

124737

124738

Note:

If the throttle valve is dropped or receives any

other impact, it will need to be replaced.

Page 293 of 652

12A-28

FUEL MIXTURE

Air flowmeter: Removal - Refitting

C44, and K9K

12A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-the air flowmeter seal on the air filter box.

REMOVAL

I - OPERATION FOR PREPARATION OF PART

CONCERNED

aRemove the air filter box (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aon the workbench, remove the two bolts (1) from the

air flowmeter on the air filter box.

aRemove the air flowmeter seal on the air filter box

and discard it.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new air flowmeter seal on the air filter box,

-the air flowmeter on the air filter box,

-the air flowmeter bolts.II - FINAL OPERATION.

aRefit the air filter box (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

24834

Page 294 of 652

12A-29

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

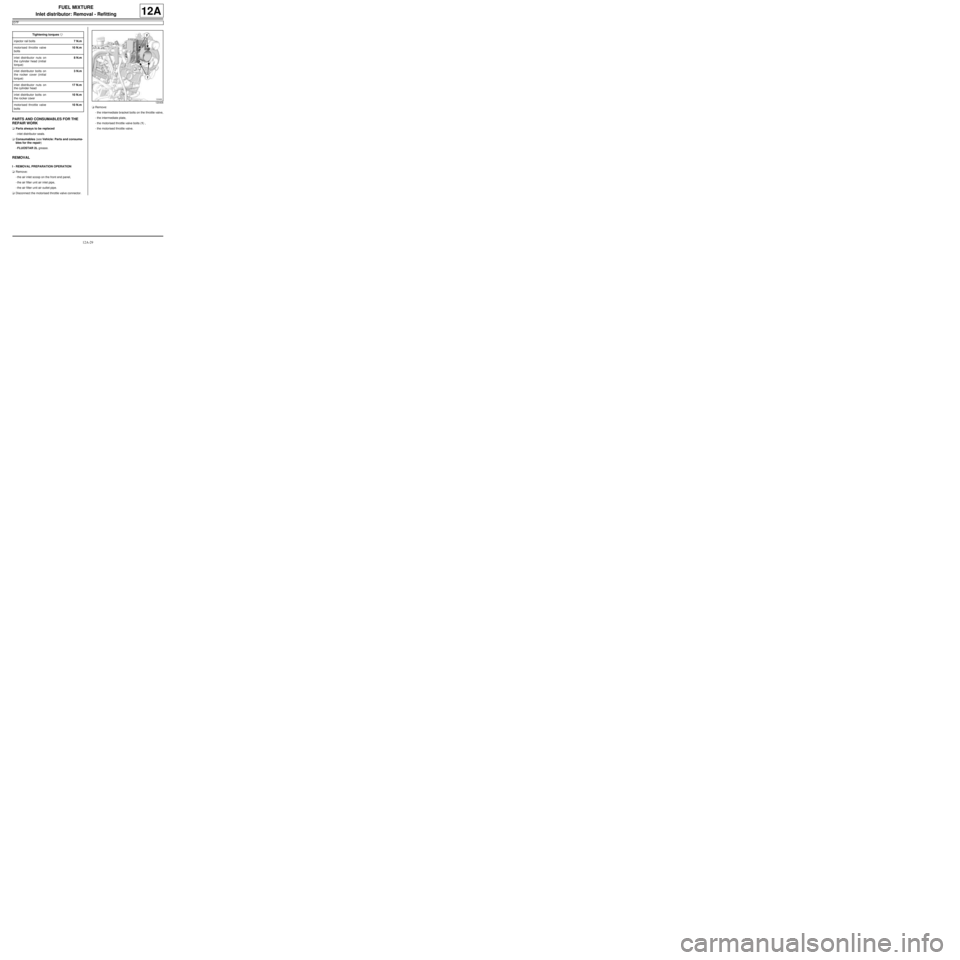

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced

-inlet distributor seals.

aConsumables (see Vehicle: Parts and consuma-

bles for the repair)

-FLUOSTAR 2L grease.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the air inlet scoop on the front end panel,

-the air filter unit air inlet pipe,

-the air filter unit air outlet pipe.

aDisconnect the motorised throttle valve connector.aRemove:

-the intermediate bracket bolts on the throttle valve,

-the intermediate plate,

-the motorised throttle valve bolts (1) ,

-the motorised throttle valve. Tightening torquesm

injector rail bolts7 N.m

motorised throttle valve

bolts10 N.m

inlet distributor nuts on

the cylinder head (initial

torque)8 N.m

inlet distributor bolts on

the rocker cover (initial

torque)3 N.m

inlet distributor nuts on

the cylinder head17 N.m

inlet distributor bolts on

the rocker cover10 N.m

motorised throttle valve

bolts10 N.m

120406

Page 295 of 652

12A-30

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

aDisconnect the spark plug high voltage wiring har-

ness (2) .

aMove aside the spark plug high voltage wiring har-

ness.

aDisconnect:

-the petrol vapour rebreather pipe from the inlet dis-

tributor (3) ,

-the non-return valve pipe on the inlet distributor (4)

,

-the air inlet pressure sensor connector (5) ,

-the air temperature sensor connector (6) ,

-the injector connector (7) ,-the fuel supply pipe intermediate union (8) ,

-the oil vapour rebreathing pipe from the inlet dis-

tributor.

aRemove the dipstick.

aRemove:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator upper bolt.

aTilt the alternator forward.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts from the air inlet distributor on the

cylinder head.

121737

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear latex gloves during the operation.

AIR CONDITIONING

121734