fuel filter RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 581 of 652

19A-71

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air filter unit (see 12A, Fuel mixture,

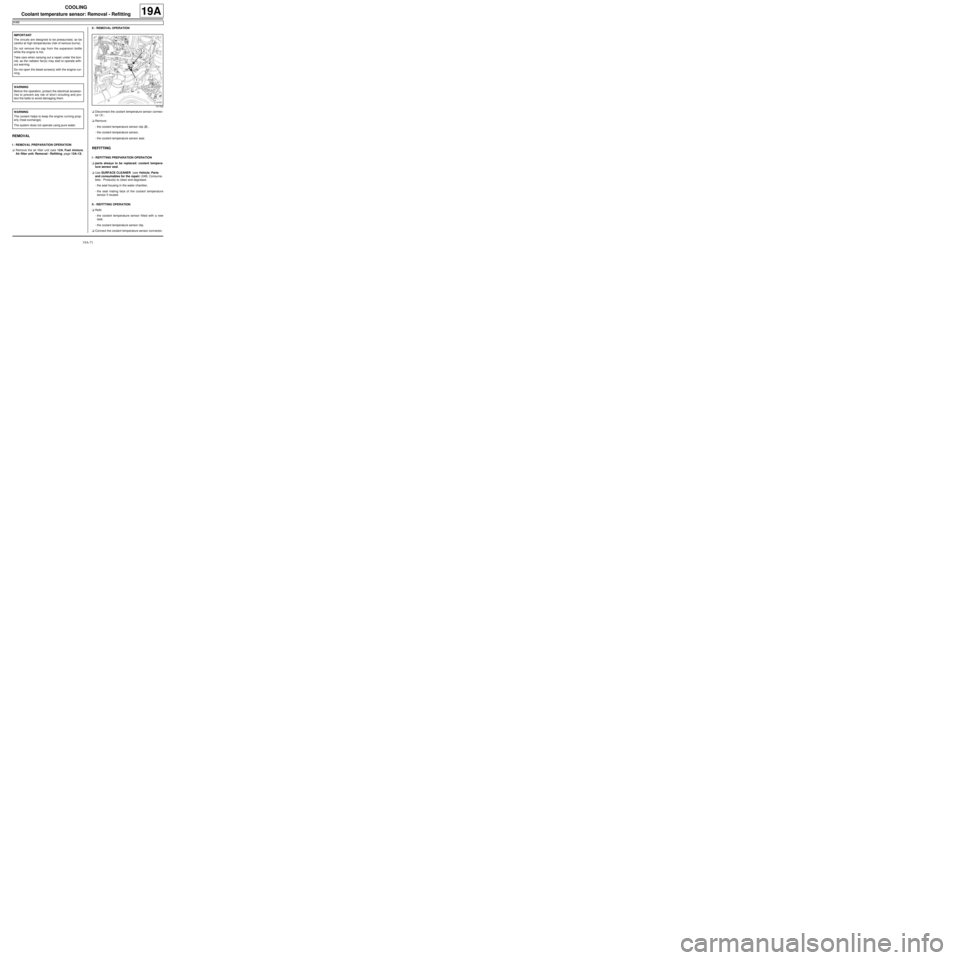

Air filter unit: Removal - Refitting, page 12A-13) .II - REMOVAL OPERATION

aDisconnect the coolant temperature sensor connec-

tor (1) .

aRemove:

-the coolant temperature sensor clip (2) ,

-the coolant temperature sensor,

-the coolant temperature sensor seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: coolant tempera-

ture sensor seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the seal housing in the water chamber,

-the seal mating face of the coolant temperature

sensor if reused.

II - REFITTING OPERATION

aRefit:

-the coolant temperature sensor fitted with a new

seal,

-the coolant temperature sensor clip.

aConnect the coolant temperature sensor connector. IMPORTANT

The circuits are designed to be pressurised, so be

careful at high temperatures (risk of serious burns).

Do not remove the cap from the expansion bottle

while the engine is hot.

Take care when carrying out a repair under the bon-

net, as the radiator fan(s) may start to operate with-

out warning.

Do not open the bleed screw(s) with the engine run-

ning.

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.

131762

Page 582 of 652

19A-72

COOLING

Coolant temperature sensor: Removal - Refitting

K4M

19A

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aPerform the following operations:

-top up the coolant level,

-bleed the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

Page 594 of 652

19B-12

EXHAUST

Catalytic converter: Removal - Refitting

K9K

19B

PARTS AND CONSUMABLES FOR THE REPAIR

Pièces à remplacer systématiquement :

-air inlet pipe seals,

-the catalytic converter seal on the turbocharger,

-any stud and/or nut on the turbocharger or damaged

catalytic converter,

-The exhaust system sealing ring on the catalytic con-

verter.

Ingrédients :

-ABRASIVE PADS,

-SURFACE CLEANER.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the windscreen wiper arms ( (see Windscreen

wiper arm: Removal - Refitting) ),

-the scuttle panel grille ( (see Scuttle panel grille:

Removal - Refitting) ),

-the scoop under the scuttle panel grille ( (see

Scoop under the scuttle panel grille: Removal -

Refitting) ),

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

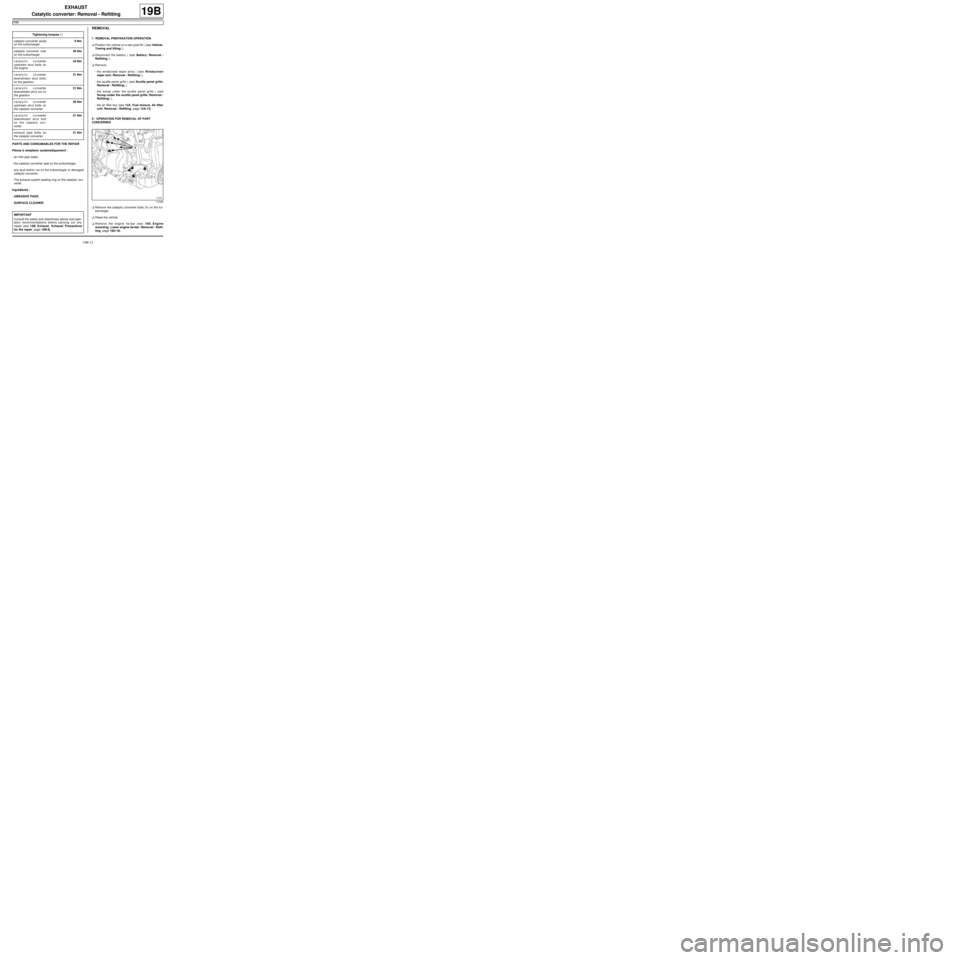

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the catalytic converter bolts (1) on the tur-

bocharger.

aRaise the vehicle.

aRemove the engine tie-bar (see 19D, Engine

mounting, Lower engine tie-bar: Removal - Refit-

ting, page 19D-18) . Tightening torquesm

catalytic converter studs

on the turbocharger9 Nm

catalytic converter nuts

on the turbocharger26 Nm

catalytic converter

upstream strut bolts on

the engine44 Nm

catalytic converter

downstream strut bolts

on the gearbox21 Nm

catalytic converter

downstream strut nut on

the gearbox21 Nm

catalytic converter

upstream strut bolts on

the catalytic converter26 Nm

catalytic converter

downstream strut bolt

on the catalytic con-

verter21 Nm

exhaust pipe bolts on

the catalytic converter21 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 19B, Exhaust, Exhaust: Precautions

for the repair, page 19B-8) .

112328

Page 596 of 652

19B-14

EXHAUST

Catalytic converter: Removal - Refitting

K9K

19B

aIf they are replaced, torque tighten the catalytic

converter studs on the turbocharger (9 Nm ).

II - REFITTING OPERATION FOR PART

CONCERNED

aFrom underneath the vehicle, fit:

-the catalytic converter on the turbocharger fitted

with a new seal between the catalytic converter

and the turbocharger,

-one of the catalytic converter nuts on the turbo-

charger.

aIn order, fit (without tightening):

-the catalytic converter upstream strut bolts on the

engine,

-the catalytic converter downstream strut bolt and

nut on the gearbox,

-the catalytic converter upstream strut bolts on the

catalytic converter,

-the catalytic converter downstream strut bolt on the

catalytic converter,

-the catalytic converter nuts on the turbocharger,

aTorque tighten and in order:

-the catalytic converter nuts on the turbocharger

(26 Nm),

-the catalytic converter upstream strut bolts on

the engine (44 Nm),

-the catalytic converter downstream strut bolts

on the gearbox (21 Nm),

-the catalytic converter downstream strut nut on

the gearbox (21 Nm),

-the catalytic converter upstream strut bolts on

the catalytic converter (26 Nm),

-the catalytic converter downstream strut bolt

on the catalytic converter (21 Nm).

aFit in order:

-a new exhaust system sealing ring on the catalytic

converter,

-the exhaust pipe on the catalytic converter,

-the exhaust pipe springs and bolts on the catalytic

converter.aTorque tighten the exhaust pipe bolts on the cata-

lytic converter (21 Nm).

aCheck the following and deal with if necessary:

-that there is no contact with the underbody,

-the presence and correct positioning of all the ex-

haust pipe heat shields.

III - FINAL OPERATION.

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille ( (see

Scoop under the scuttle panel grille: Removal -

Refitting) ),

-the scuttle panel grille ( (see Scuttle panel grille:

Removal - Refitting) ),

-the windscreen wiper arms ( (see Windscreen

wiper arm: Removal - Refitting) ).

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

aStart the engine.

aCheck that there are no leaks and deal with them if

necessary. Note:

Check that there is no contact between the cata-

lytic conver ter and the turbocharger oil return

pipe during the entire catalytic converter tighten-

ing operation.

Page 598 of 652

19B-16

EXHAUST

Catalytic converter: Removal - Refitting

D4F, and 780 or 782

19B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the air filter box strut bolt,-the air filter box strut,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) . Tightening torquesm

catalytic converter lower

bracket bolt on the gear-

box44 N.m

bolts of the catalytic

converter lower bracket

on the engine25 N.m

side bracket bolts on the

catalytic converter21 N.m

side bracket bolts on the

engine21 N.m

catalytic converter nuts

on the turbocharger (ini-

tial torque)20 N.m

catalytic converter nuts

on the turbocharger30 N.m

bolts of the catalytic

converter lower bracket

on the catalytic con-

verter (initial torque)20 N.m

bolts of the catalytic

converter lower bracket

on the catalytic con-

verter30 N.m

exhaust downpipe bolts21 N.m

catalytic converter strut

nut21 N.m

catalytic converter strut

bolt on the rocker cover21 N.m

Page 602 of 652

19B-20

EXHAUST

Catalytic converter: Removal - Refitting

D4F, and 780 or 782

19B

-the new nuts with the catalytic converter spacers

on the turbocharger.

aAttach the downstream oxygen sensor wiring har-

ness to the catalytic converter.

aClip on the catalytic converter downstream oxygen

sensor connector.

aConnect the catalytic converter downstream oxygen

sensor connector.

III - FINAL OPERATION

aRefit:

-the catalytic converter lower exhaust bracket,

-the bracket bolt on the gearbox,

-the bracket bolts on the engine,

-the catalytic converter side exhaust bracket,

-the catalytic converter side bracket bolts,

-the engine side bracket bolts.

aTorque tighten:

-the catalytic converter lower bracket bolt on the

gearbox (44 N.m),

-the bolts of the catalytic converter lower brack-

et on the engine (25 N.m),

-the side bracket bolts on the catalytic converter

(21 N.m),

-the side bracket bolts on the engine (21 N.m),

-the catalytic converter nuts on the turbocharger

(initial torque) (20 N.m),

-the catalytic converter nuts on the turbocharger

(30 N.m),

-the bolts of the catalytic converter lower brack-

et on the catalytic converter (initial torque) (20

N.m),

-the bolts of the catalytic converter lower brack-

et on the catalytic converter (30 N.m).

aRefit:

-the exhaust downpipe,

-the intermediate pipe clip.

aTighten the intermediate pipe clip.

aRefit the exhaust downpipe bolts on the catalytic

converter.

aTorque tighten the exhaust downpipe bolts (21

N.m).aRefit:

-the rear suspended engine mounting (see 19D,

Engine mounting, Lower engine tie-bar: Re-

moval - Refitting, page 19D-18) ,

-the turbocharger strut.

-the catalytic converter strut bolt on the rocker cov-

er,

-the catalytic converter strut nut.

aTorque tighten:

-the catalytic converter strut nut (21 N.m),

-the catalytic converter strut bolt on the rocker

cover (21 N.m).

aPosition the turbocharger air outlet pipe.

aPush the turbocharger air outlet pipe clip (15) in the

direction of the arrow.

aConnect the turbocharger air outlet pipe onto the tur-

bocharger.

aRefit:

-the turbocharger air outlet rigid pipe bolt on the

throttle valve,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the air filter box strut,

-the air filter box strut bolt,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

122666

Page 615 of 652

19C-1

TANK

Fuel tank: Draining

K9K

19C

I - DRAINING PREPARATION OPERATION

aDisconnect the battery (see ) (MR 441, 80A, Bat-

tery).

aRemove the front engine cover.aDisconnect the engine fuel supply quick-release

union (1) from the fuel filter outlet.

II - DRAINING THE FUEL TANK

aConnect a pneumatic transfer pump for fuels to

the fuel filter outlet.

aDrain the fuel tank.

III - FINAL OPERATION.

aDisconnect the pneumatic transfer pump for fuels

from the fuel filter.

aConnect the engine fuel filter outlet engine supply

quick-release union to the fuel filter.

aRefit the engine cover.

aConnect the battery (see ) (MR 441, 80A, Battery). Equipment required

pneumatic transfer pump for fuels

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear latex gloves during the operation.

WARNING

To prevent impurities from entering the circuit, plugs

must be fitted to the openings of all the fuel circuit

components exposed to the open air.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

121441

Page 640 of 652

19D-10

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

K4M

19D

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(80A, Battery),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

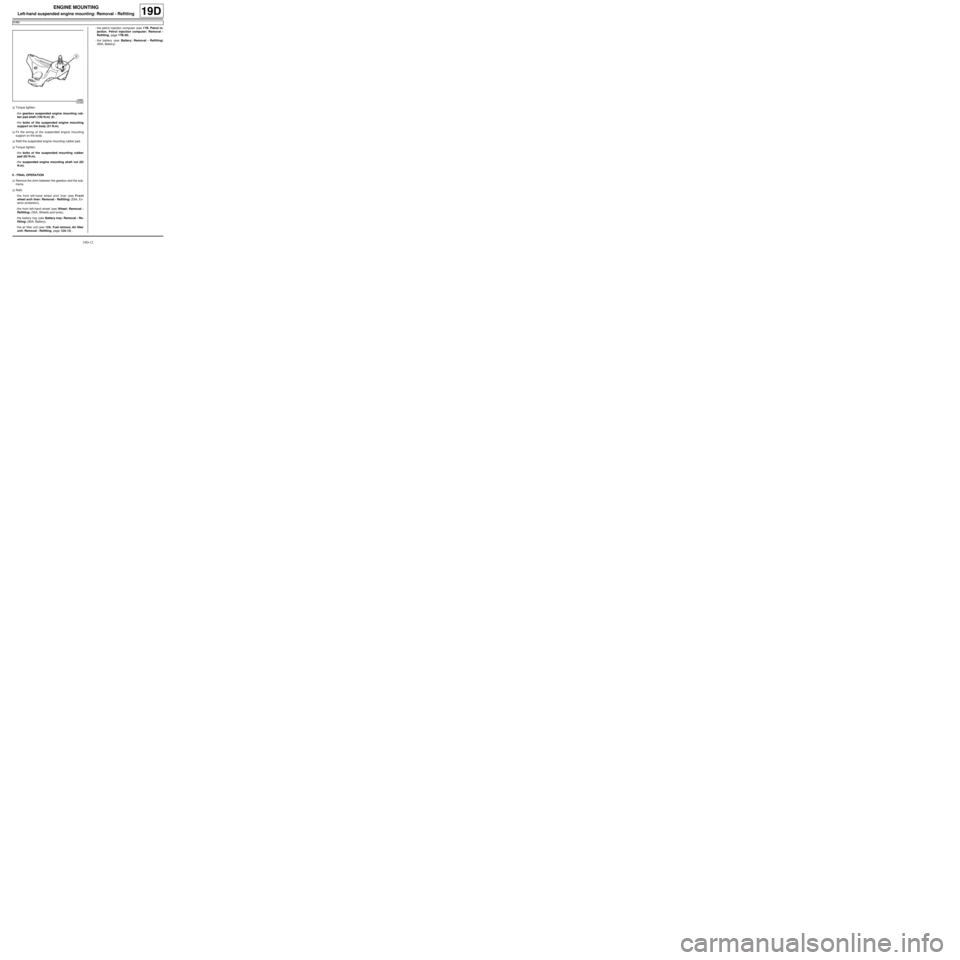

aMark the position of the left-hand suspended engine

mounting.aPut a 20 mm shim between the gearbox and the

sub-frame. Tightening torquesm

bolts of the suspended

engine mounting sup-

por t on the gearbox62 N.m

gearbox suspended

engine mounting rubber

pad shaft105 N.m

bolts of the suspended

engine mounting sup-

por t on the body21 N.m

bolts of the suspended

mounting r ubber pad62 N.m

suspended engine

mounting shaft nut62 N.m

120778

Page 642 of 652

19D-12

ENGINE MOUNTING

Left-hand suspended engine mounting: Removal - Refitting

K4M

19D

aTorque tighten:

-the gearbox suspended engine mounting rub-

ber pad shaft (105 N.m) (8) ,

-the bolts of the suspended engine mounting

support on the body (21 N.m).

aFit the wiring of the suspended engine mounting

support on the body.

aRefit the suspended engine mounting rubber pad.

aTorque tighten:

-the bolts of the suspended mounting rubber

pad (62 N.m),

-the suspended engine mounting shaft nut (62

N.m).

II - FINAL OPERATION

aRemove the shim between the gearbox and the sub-

frame.

aRefit:

-the front left-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front left-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery (see Battery: Removal - Refitting)

(80A, Battery).

130485

Page 643 of 652

19D-13

ENGINE MOUNTING

Right-hand suspended engine mounting: Removal - Refitting

C44, and K9K

19D

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-axle sub-frame bolt.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the (1) (Mot. 1672) to the vehicle after removing

the front right-hand bolt on the axle sub-frame and

the rear left-hand bolt on the axle sub-frame.

aSupport the lower engine cover on the (Mot. 1672)

by pressing on the tool support.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUnclip the fuel supply pipes (2) from the right-hand

suspended engine mounting.

aUndo the clip on the right-hand suspended engine

mounting.

aRemove the fuel filler cap from the expansion bottle.

aUndo the nut on the fuel filter cage.

aRemove the fuel filter.

aRemove the fuel filter cage bolts.

aRemove the fuel filter cage. Special tooling required

Mot. 1672Low er engine support.

Tightening torquesm

right-hand suspended

engine mounting bolts

on the engine62 Nm

right-hand suspended

engine mounting bolts

on the body62 Nm

axle sub-frame front

bolts62 Nm

axle sub-frame rear

bolts105 Nm

120040

120045