fuel pump RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 351 of 652

13A-8

FUEL SUPPLY

Fuel circuit: Operating diagram

D4F or D7F or K4M

13A

Operating diagram of the fuel supply circuit ( « pump - sender - fuel filter » assembly)

The fuel supply circuit does not have a return.

The fuel pressure does not vary with engine load.

The circuit comprises:

-a rail (1) without a return pipe union and without a

supply pressure regulator,

-a single pipe (2) coming from the tank,

-a « pump - sender - fuel filter » supply assembly fitted

with a pressure regulator (3) , fuel pump (4) and fuel

filter (5) (all located in the tank),

-a fuel vapour recirculation tank (6) .

109471

Page 357 of 652

13A-14

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

CHECK

a

I - PREPARATION OPERATION FOR CHECK

aRemove the oil filler neck.

aDisconnect the fuel supply union.aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union. Special tooling required

Mot. 1311-08Union for taking fuel pres-

sure measurements .

Equipment required

graduated measuring cylinder

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

D4F

D4F, and 772

121778

Page 358 of 652

13A-15

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union.aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union.

II - CHECK

aImmerse the pipe into a graduated measuring cyl-

inder (2000 ml).

aRemove the cover from the engine compartment

connection unit. D4F, and 780 or 782

121729

D7F

121779

Page 359 of 652

13A-16

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

aRemove the relay (1) .

aShunt the relay to supply the electric fuel pump.

III - FINAL OPERATION

aRefit:

-the fuel pump relay,

-the cover of the engine compartment connection

unit.

aRemove the “T” union (Mot. 1311-08).

aConnect the fuel supply union.

aRefit the oil filler neck.

119373

Note:

The flow reading should be 80 to 120 l/h.

D4F

Page 361 of 652

13A-18

FUEL SUPPLY

Fuel flow: Check

K4M

13A

aRemove the relay (1) .

aShunt the relay in order to supply the electric fuel

pump.

III - FINAL OPERATION

aRefit:

-the relay,

-the engine compartment connection unit cover.

aDisconnect:

-the fuel supply union on the "T" union (Mot. 1311-

08),

-the "T" union (Mot. 1311-08) from the injector rail.

aConnect the fuel supply union on the injector rail.

aSeparate the test tool (Mot. 1311-01) from the "T"

union (Mot. 1311-08).

119373

Note:

The flow reading should be 80 to 120 l/h.

Page 363 of 652

13B-2

DIESEL INJECTION

Diesel injection: Precautions for the repair

K9K

13B

II - ADVICE TO BE FOLLOWED BEFORE ANY

OPERATION

1) Carry out the work in a clean working area and take

care to protect removed components from dust using

plastic bags which are hermetically-resealable, for ex-

ample.

2) Always order the following from the Parts Depart-

ment before carrying out work:

-a new set of blanking plugs, specific to the engine,

-enough lint-free cleaning cloths.

-one of the two cleaning products for fuel pipe

unions,

-the parts that are always to be replaced after each

removal operation, mentioned in the operational pro-

cedures specific to the vehicle (see related Workshop

Repair Manual).

3) Wear safety goggles fitted with side shields to pre-

vent the cleaning product from splashing the eyes.

4) Wear leaktight protective gloves (Nitrile type) to

avoid prolonged contact with the skin.

5) Before carrying out work on the injection system,

use plastic bags or clean rags, for example, to protect:

-the accessories and timing belts,

-the electrical accessories (starter, alternator, power-

assisted steering pump, sensors and electrical con-

nectors),

-the flywheel face.

III - INSTRUCTIONS TO BE FOLLOWED DURING

THE OPERATION

Wash your hands before and while carrying out the

work.

Replace leaktight protective gloves (Nitrile type) when

they are soiled or damaged.

All components removed from the injection system

must be stored in a hermetically sealed plastic bag

once they have been capped.

Reseal the bag hermetically, for example using adhe-

sive tape, even if the bag must be opened shortly after-

wards: ambient air can be a source of impurities.After opening the fuel circuit, the use of brushes, clean-

ing agents, air blow guns, rifle-type brushes or stan-

dard cloths is strictly prohibited: these items are likely

to allow impurities to enter the system.

When replacing a component with a new one or when

refitting it after storing it in a plastic bag, do not unpack

it until it is time to fit it on the vehicle.

IV - CLEANING

There are currently two procedures for cleaning the

fuel circuit before opening it in order to carry out work in

the workshop.

These procedures enable the fuel circuit to be cleaned

to prevent contamination from entering: they both have

the same end result and neither is preferred over the

other.

1 - Cleaning using injector cleaner

Clear the access to the unions that need opening, fol-

lowing the work procedures specific to the vehicle (see

the relevant Workshop Repair Manual).

Protect sections which are sensitive to fuel leaks.

Pour the injector cleaning agent into a container which

is free from impurities.

Dip a clean brush, which is not shedding bristles, into

the container of injector cleaning agent.

Clean the unions carefully using the brush and the in-

jector cleaning agent.

Blast the components that have been cleaned with

compressed air (tools, workbench, and also parts,

unions and around the injection system). Check that no

bristles from the brush have come away and that the

area is clean.

Wipe the sections that were cleaned with fresh clean-

ing cloths.

Open the circuit at the unions and immediately fit the

relevant blanking plugs. Note:

When using leather protective gloves, wear a pair of

leaktight protective gloves (Nitrile type) over the top.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

Page 369 of 652

13B-8

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 740

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel fuel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer

Page 371 of 652

13B-10

DIESEL INJECTION

Diesel injection: List and location of components

K9K, and 718

13B

121418

(1) High pressure pump

(2) Venturi

(3) Injectors

(4) Heater plugs

102315

(5) Fuel fl ow actuator

(6) Diesel temperature sensor

(7) Accelerometer

121420

(8) Injector rail

(9) Injector rail pressure sensor

121422

(10) Diesel injection computer

Page 377 of 652

13B-16

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the dipstick,

-the oil level dipstick nut (1) ,

-the oil level dipstick guide.

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aDisconnect the following connectors :

-the heater plugs,

-of the injectors,

-the flow actuator,

-the diesel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1672Low er engine support.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Mot. 1606High pressure pump pulley

support tool.

Mot. 1525Gear extractor for tapered

hub injection pump.

Mot. 1525-02Adapter claws for Mot. 1525.

Equipment required

Diagnostic tool

Tightening torquesm

high pressure pump

bolts on the cylinder

head23 N.m

high pressure pump pul-

ley nut70 N.m

cylinder head sus-

pended mounting bolts25 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527

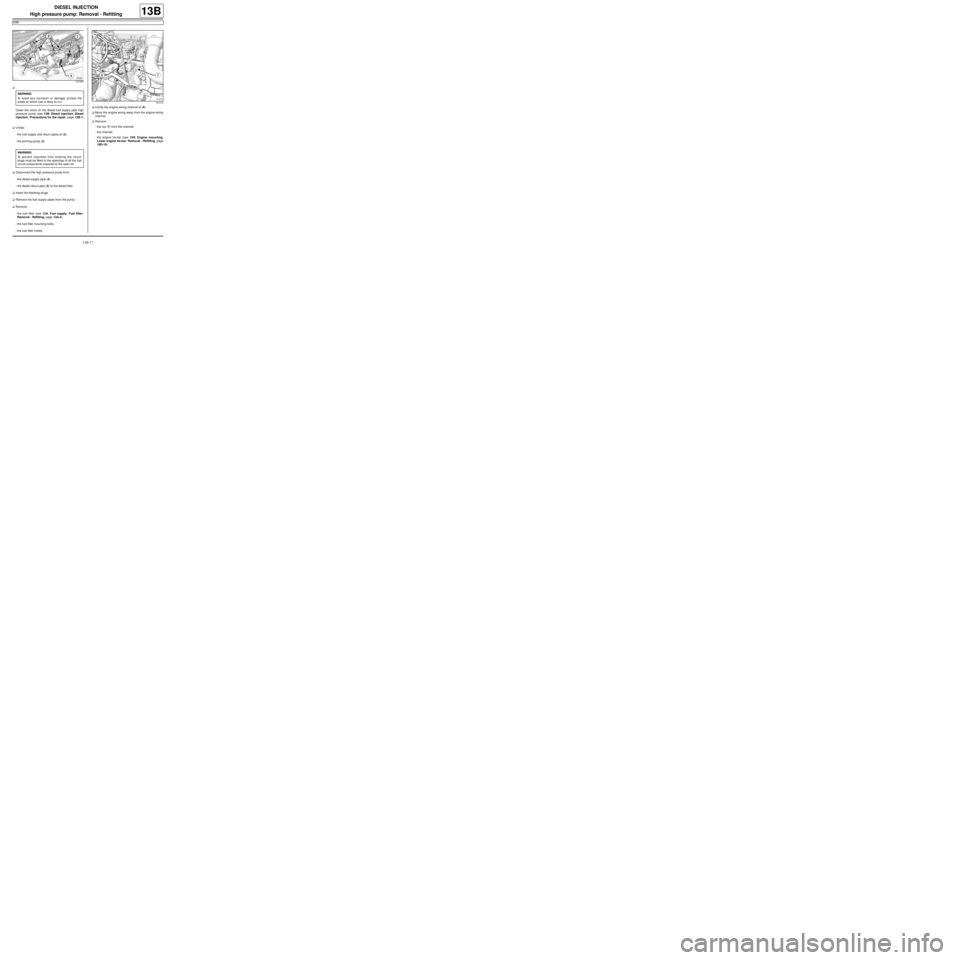

Page 378 of 652

13B-17

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

a

Clean the union on the diesel fuel supply pipe high

pressure pump (see 13B, Diesel injection, Diesel

injection: Precautions for the repair, page 13B-1)

.

aUnclip:

-the fuel supply and return pipes at (2) ,

-the priming pump (3) .

aDisconnect the high pressure pump from:

-the diesel supply pipe (4) ,

-the diesel return pipe (5) to the diesel filter.

aInsert the blanking plugs.

aRemove the fuel supply pipes from the pump.

aRemove:

-the fuel filter (see 13A, Fuel supply, Fuel filter:

Removal - Refitting, page 13A-4) ,

-the fuel filter mounting bolts,

-the fuel filter holder,aUnclip the engine wiring channel at (6) .

aMove the engine wiring away from the engine wiring

channel.

aRemove:

-the nut (7) from the channel,

-the channel,

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) .

121423

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit,

plugs must be fitted to the openings of all the fuel

circuit components exposed to the open air.

121419