RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

TWINGO 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1710/w960_1710-0.png

RENAULT TWINGO 2009 2.G Engine And Peripherals Workshop Manual

Trending: oil change, diagram, handbrake, glove box, oil dipstick, change time, heater

Page 351 of 652

13A-8

FUEL SUPPLY

Fuel circuit: Operating diagram

D4F or D7F or K4M

13A

Operating diagram of the fuel supply circuit ( « pump - sender - fuel filter » assembly)

The fuel supply circuit does not have a return.

The fuel pressure does not vary with engine load.

The circuit comprises:

-a rail (1) without a return pipe union and without a

supply pressure regulator,

-a single pipe (2) coming from the tank,

-a « pump - sender - fuel filter » supply assembly fitted

with a pressure regulator (3) , fuel pump (4) and fuel

filter (5) (all located in the tank),

-a fuel vapour recirculation tank (6) .

109471

Page 352 of 652

13A-9

FUEL SUPPLY

Fuel pressure: Check

D4F or D7F

13A

CHECK

aI - PREPARATION OPERATION FOR CHECK

aEnsure you have a checking tool (Mot. 1311-01) and

a “T” union (Mot. 1311-08).

aRemove the oil filler neck.

II - TEST OPERATION

aDisconnect the petrol inlet pipe from the injector rail. Special tooling required

Mot. 1311-01Pressure gauges and petrol

pressure measur ing unions.

Mot. 1311-08Union for taking fuel pres-

sure measurements .

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

116887

D4F

Page 353 of 652

13A-10

FUEL SUPPLY

Fuel pressure: Check

D4F or D7F

13A

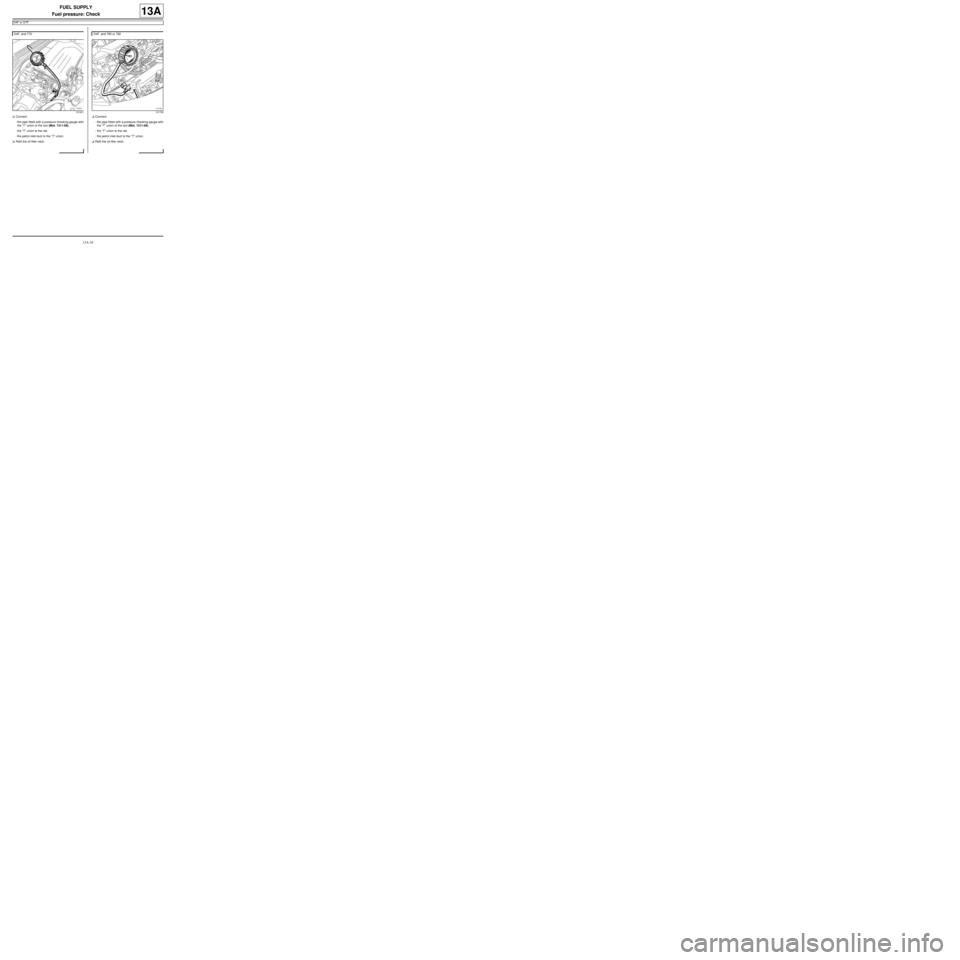

aConnect:

-the pipe fitted with a pressure checking gauge with

the “T” union of the tool (Mot. 1311-08),

-the “T” union to the rail,

-the petrol inlet duct to the “T” union.

aRefit the oil filler neck.aConnect:

-the pipe fitted with a pressure checking gauge with

the “T” union of the tool (Mot. 1311-08),

-the “T” union to the rail,

-the petrol inlet duct to the “T” union.

aRefit the oil filler neck. D4F, and 772

121821

D4F, and 780 or 782

121728

Page 354 of 652

13A-11

FUEL SUPPLY

Fuel pressure: Check

D4F or D7F

13A

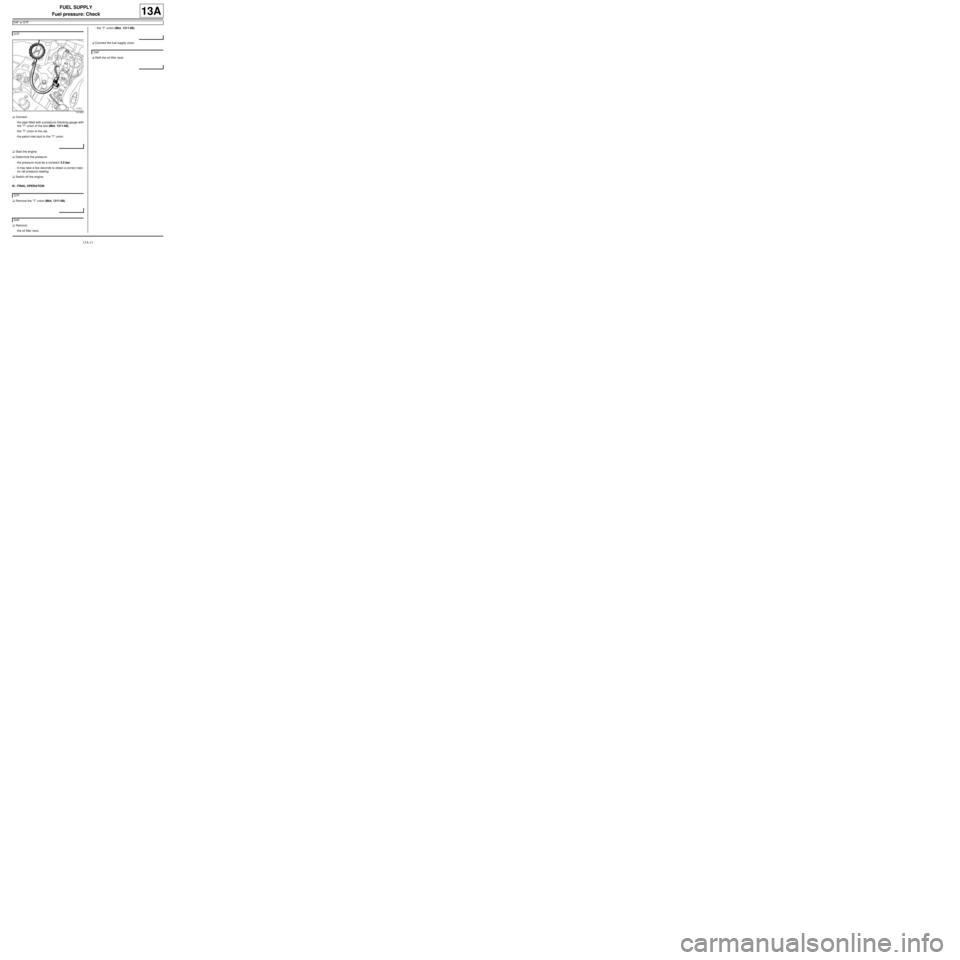

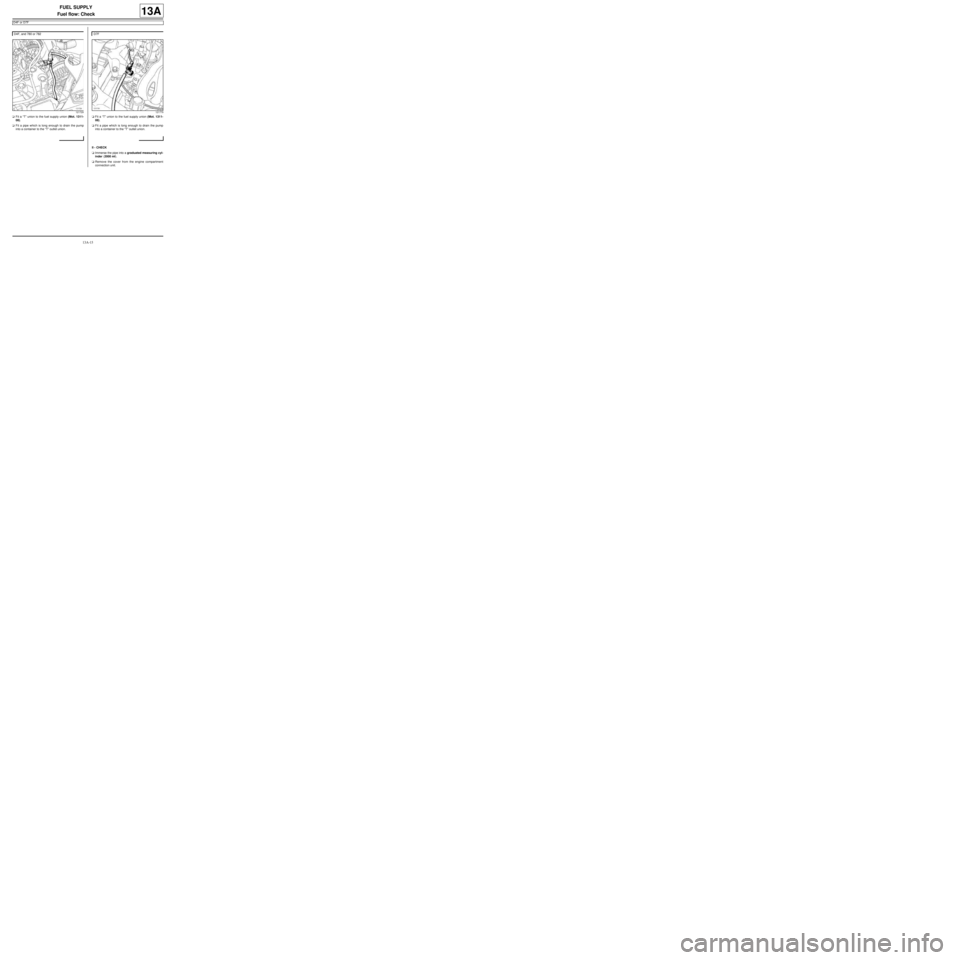

aConnect:

-the pipe fitted with a pressure checking gauge with

the “T” union of the tool (Mot. 1311-08),

-the “T” union to the rail,

-the petrol inlet duct to the “T” union.

aStart the engine.

aDetermine the pressure:

-the pressure must be a constant 3.5 bar,

-It may take a few seconds to obtain a correct injec-

tor rail pressure reading.

aSwitch off the engine.

III - FINAL OPERATION

aRemove the “T” union (Mot. 1311-08).

aRemove:

-the oil filler neck,-the “T” union (Mot. 1311-08).

aConnect the fuel supply union.

aRefit the oil filler neck. D7F

121822

D7F

D4F

D4F

Page 355 of 652

13A-12

FUEL SUPPLY

Fuel pressure: Check

K4M

13A

CHECK

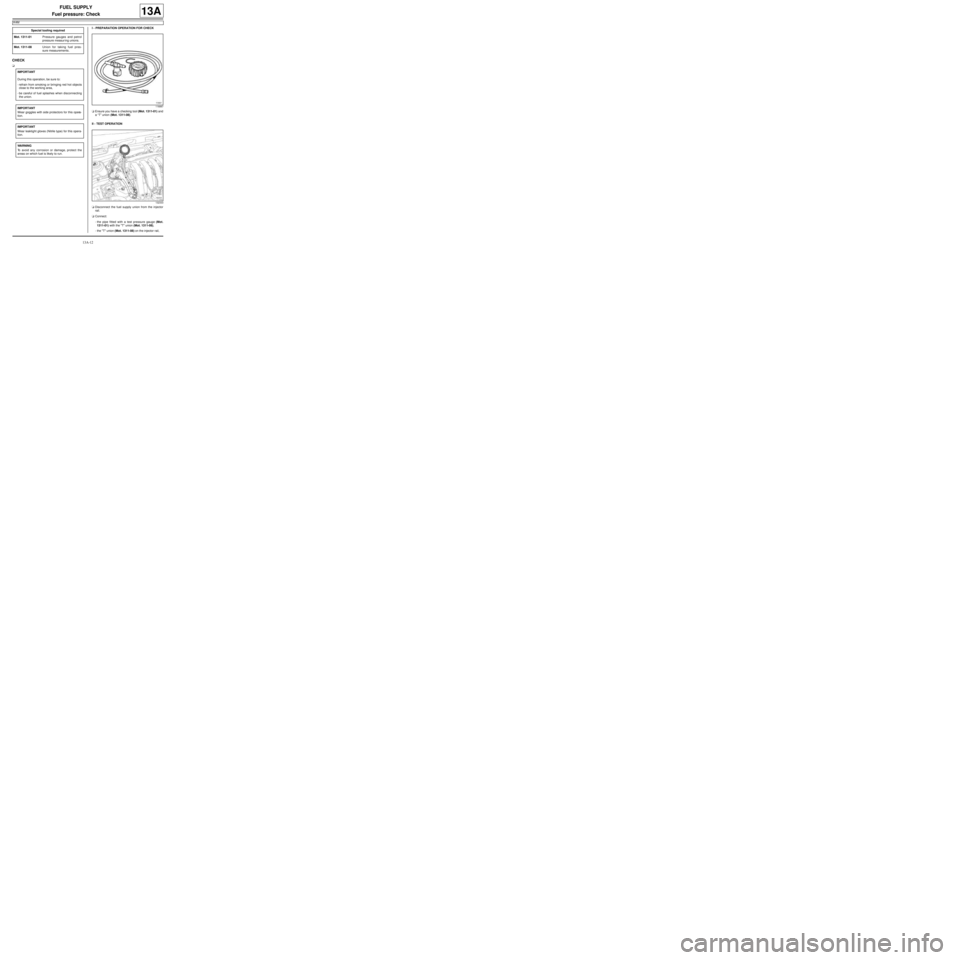

aI - PREPARATION OPERATION FOR CHECK

aEnsure you have a checking tool (Mot. 1311-01) and

a “T” union (Mot. 1311-08).

II - TEST OPERATION

aDisconnect the fuel supply union from the injector

rail.

aConnect:

-the pipe fitted with a test pressure gauge (Mot.

1311-01) with the "T" union (Mot. 1311-08),

-the "T" union (Mot. 1311-08) on the injector rail, Special tooling required

Mot. 1311-01Pressure gauges and petrol

pressure measur ing unions.

Mot. 1311-08Union for taking fuel pres-

sure measurements .

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

116887

132333

Page 356 of 652

13A-13

FUEL SUPPLY

Fuel pressure: Check

K4M

13A

-the injector rail fuel supply union to the "T" union

(Mot. 1311-08).

aStart the engine.

aRecord the pressure; this should be constant at 3.5

bar.

aSwitch off the engine.

III - FINAL OPERATION

aDisconnect the "T" union (Mot. 1311-08) from the in-

jector rail.

aConnect the fuel supply pipe union on the injector

rail.Note:

It may take a few seconds to obtain a correct

injector rail pressure reading.

Page 357 of 652

13A-14

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

CHECK

a

I - PREPARATION OPERATION FOR CHECK

aRemove the oil filler neck.

aDisconnect the fuel supply union.aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union. Special tooling required

Mot. 1311-08Union for taking fuel pres-

sure measurements .

Equipment required

graduated measuring cylinder

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

D4F

D4F, and 772

121778

Page 358 of 652

13A-15

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union.aFit a “T” union to the fuel supply union (Mot. 1311-

08).

aFit a pipe which is long enough to drain the pump

into a container to the “T” outlet union.

II - CHECK

aImmerse the pipe into a graduated measuring cyl-

inder (2000 ml).

aRemove the cover from the engine compartment

connection unit. D4F, and 780 or 782

121729

D7F

121779

Page 359 of 652

13A-16

FUEL SUPPLY

Fuel flow: Check

D4F or D7F

13A

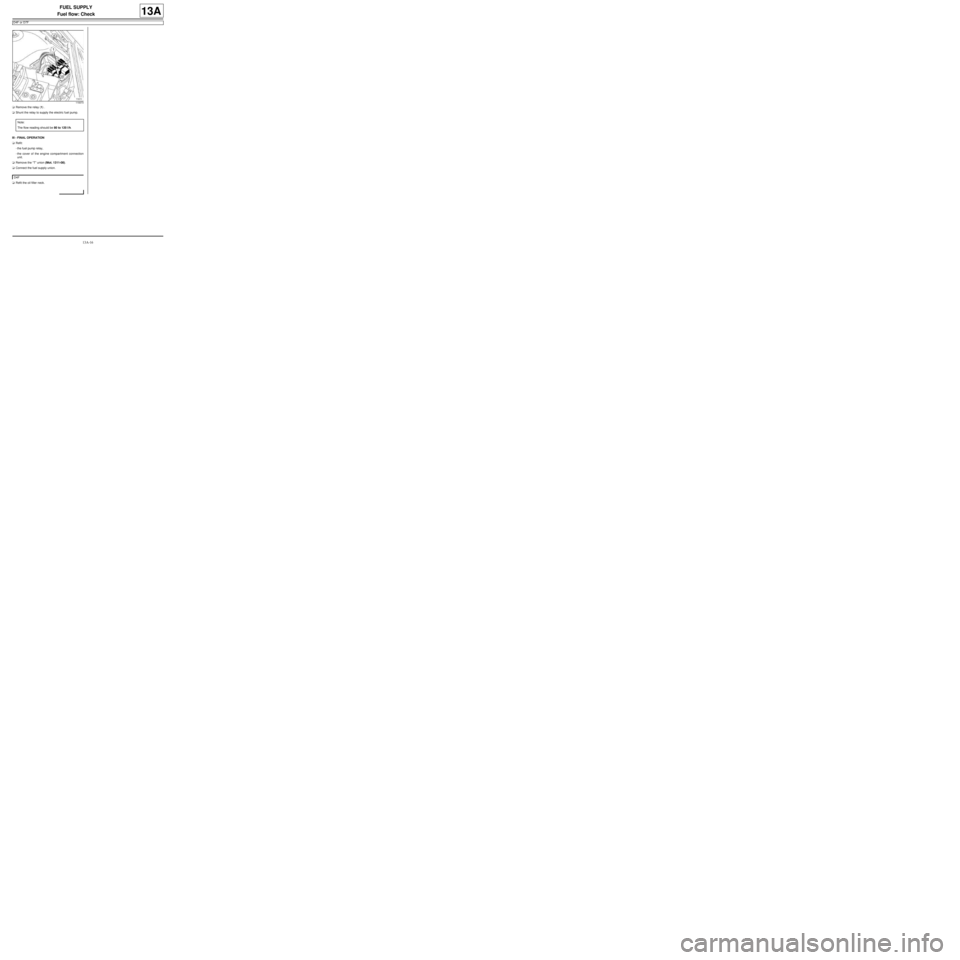

aRemove the relay (1) .

aShunt the relay to supply the electric fuel pump.

III - FINAL OPERATION

aRefit:

-the fuel pump relay,

-the cover of the engine compartment connection

unit.

aRemove the “T” union (Mot. 1311-08).

aConnect the fuel supply union.

aRefit the oil filler neck.

119373

Note:

The flow reading should be 80 to 120 l/h.

D4F

Page 360 of 652

13A-17

FUEL SUPPLY

Fuel flow: Check

K4M

13A

I - PREPARATION OPERATION FOR CHECK

aEnsure you have a checking tool (Mot. 1311-01) and

a “T” union (Mot. 1311-08).

aAssemble the long hose of the test tool (Mot. 1311-

01) and the "T" union (Mot. 1311-08).

aDisconnect the fuel supply union on the injector rail.aConnect:

-the "T" union (Mot. 1311-08) on the injector rail,

-the fuel supply union to the "T" union (Mot. 1311-

08).

II - FUEL FLOW CHECK

aImmerse the hose in a 2000 ml graduated measur-

ing cylinder.

aRemove the cover from the engine compartment

connection unit. Special tooling required

Mot. 1311-01Pressure gauges and petrol

pressure measur ing unions.

Mot. 1311-08Union for taking fuel pres-

sure measurements .

Equipment required

graduated measuring cylinder

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

IMPORTANT

Wear goggles with side protectors for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

132334

Trending: clock setting, wheel size, heating, towing, air conditioning, glove box, technical specifications