air conditioning RENAULT TWINGO 2009 2.G Engine And Peripherals Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 138 of 652

11A-21

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

aLock the flywheel by inserting a large flat-blade

screwdriver into the gearbox aperture.

aRemove:

-the accessories pulley bolt (2) ,

-the accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the crankshaft accessories pulley V-grooves

with a brush to prevent any deposits.aparts always to be replaced: Accessories belt,

parts always to be replaced: Accessories belt

tensioning roller,

parts always to be replaced: Accessories ten-

sioning roller bolt (to be replaced by the hexagonal

head bolt, part no. 77 03 101 075),

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

aparts always to be replaced: Accessories belt,

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the crankshaft accessories pulley using a new

bolt.

aTorque tighten the crankshaft accessories pulley

bolt (40 N.m + 75˚ ±± ± ±

6).

aRemove the large flat screwdriver from the opening

in the gearbox.

aRemove the immobilising tool (Mot. 582-01).

aRefit the flywheel protector.

III - FINAL OPERATION

aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) , D4F, and 780 or 782

122665

WARNING

Only use brushes with plastic or non-corrosive

metal (brass) bristles.

AIR CONDITIONING

STANDARD HEATING

D4F, and 780 or 782

D4F, and 772 – D7F

Page 139 of 652

11A-22

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

Page 295 of 652

12A-30

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

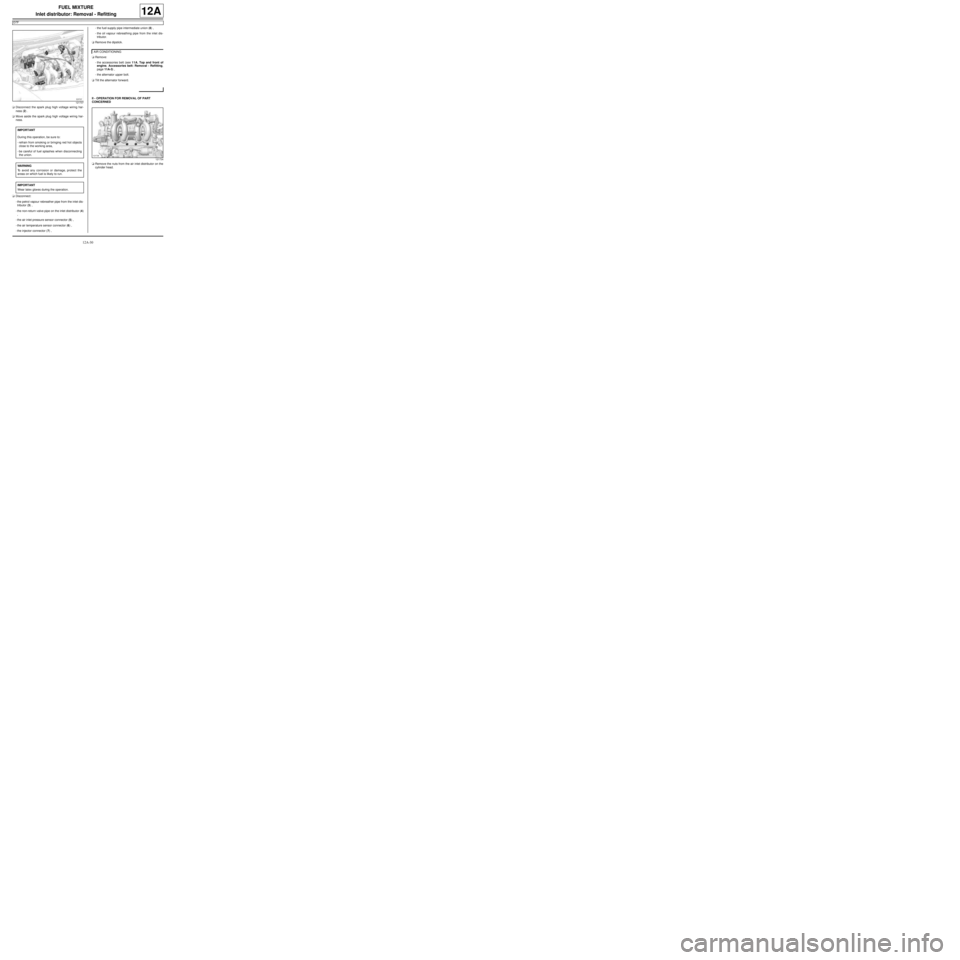

aDisconnect the spark plug high voltage wiring har-

ness (2) .

aMove aside the spark plug high voltage wiring har-

ness.

aDisconnect:

-the petrol vapour rebreather pipe from the inlet dis-

tributor (3) ,

-the non-return valve pipe on the inlet distributor (4)

,

-the air inlet pressure sensor connector (5) ,

-the air temperature sensor connector (6) ,

-the injector connector (7) ,-the fuel supply pipe intermediate union (8) ,

-the oil vapour rebreathing pipe from the inlet dis-

tributor.

aRemove the dipstick.

aRemove:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the alternator upper bolt.

aTilt the alternator forward.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the nuts from the air inlet distributor on the

cylinder head.

121737

IMPORTANT

During this operation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting

the union.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

IMPORTANT

Wear latex gloves during the operation.

AIR CONDITIONING

121734

Page 297 of 652

12A-32

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D7F

12A

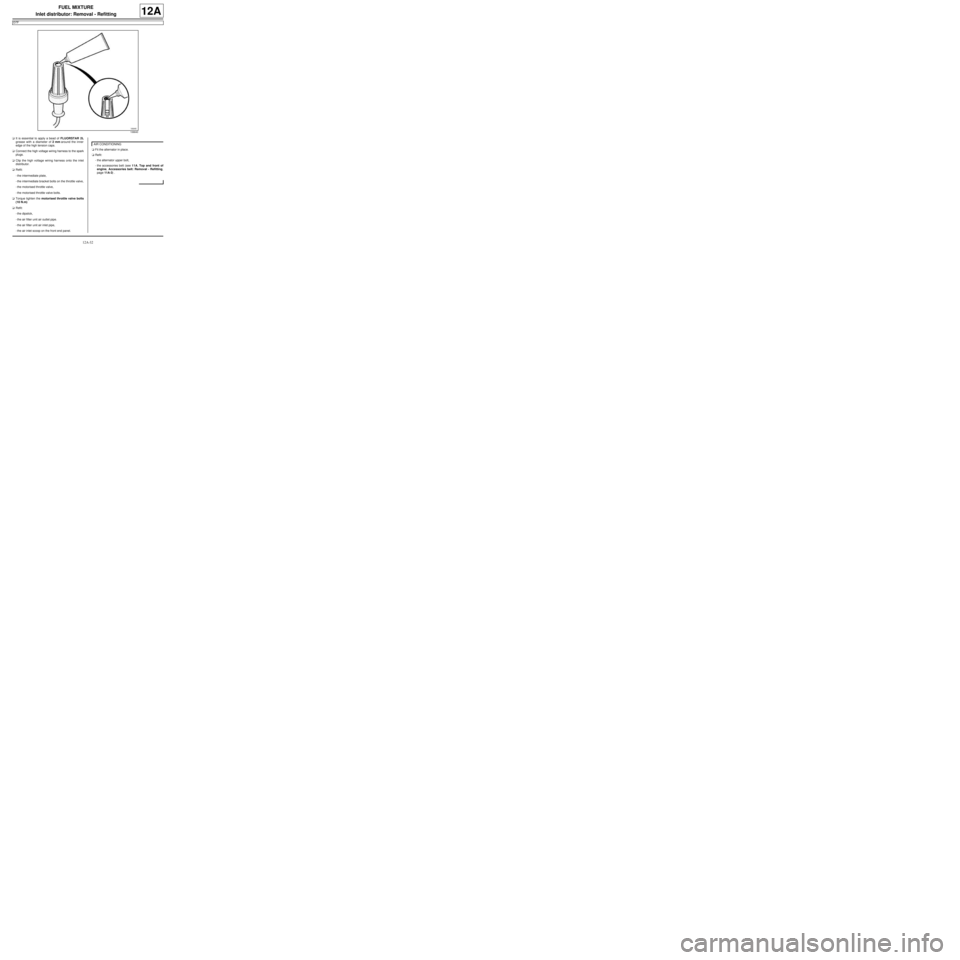

aIt is essential to apply a bead of FLUORSTAR 2L

grease with a diameter of 2 mm around the inner

edge of the high tension caps.

aConnect the high voltage wiring harness to the spark

plugs.

aClip the high voltage wiring harness onto the inlet

distributor.

aRefit:

-the intermediate plate,

-the intermediate bracket bolts on the throttle valve,

-the motorised throttle valve,

-the motorised throttle valve bolts.

aTorque tighten the motorised throttle valve bolts

(10 N.m)

aRefit:

-the dipstick,

-the air filter unit air outlet pipe.

-the air filter unit air inlet pipe,

-the air inlet scoop on the front end panel.aFit the alternator in place.

aRefit:

-the alternator upper bolt,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

106640

AIR CONDITIONING

Page 443 of 652

16A-4

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aRemove the inlet distributor (see 12A, Fuel mixture,

Inlet distributor: Removal - Refitting, page 12A-

29) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the alternator connector.

aRemove the alternator positive terminal nut.

aRemove:

-the alternator bolts,

-the alternator. Tightening torquesm

alter nator bolts25 N.m

D4F

120519

Page 444 of 652

16A-5

STARTING - CHARGING

Alternator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

16A

REFITTING

I - REFITTING PREPARATION OPERATION

aPush in the alternator rings using pliers or a vice to

facilitate fitting the alternator.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the alternator,

-the alternator bolts.

aTorque tighten the alternator bolts (25 N.m).

aRefit the alternator positive terminal nut.

aConnect the alternator connector.

III - FINAL OPERATION

aRefit the inlet distributor (see 12A, Fuel mixture, In-

let distributor: Removal - Refitting, page 12A-29)

.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

18987

D4F

Page 445 of 652

16A-6

STARTING - CHARGING

Alternator: Removal - Refitting

K9K

16A

aFor removing and refitting the alternator (see 11A,

Top and front of engine, Accessories belt: Re-

moval - Refitting, page 11A-3) .

aFor removing and refitting the alternator (see 11A,

Top and front of engine, Accessories belt: Re-

moval - Refitting, page 11A-3) . AIR CONDITIONING or CLIMATE CONTROL

STANDARD HEATING

Page 522 of 652

19A-12

COOLING

Cooling radiator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

19A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable : (see Vehicle: Parts and consuma-

bles for the repair)

-COOLANT.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aRemove:

-the battery ( (see Battery: Removal - Refitting) ),

-the battery tray ( (see Battery tray: Removal - Re-

fitting) ),

-the front wheels ( (see Wheel: Removal - Refit-

ting) ), (see Front wheel arch liner: Removal -

Refitting)

-the wheel arch liners (see MR 412 Bodywork,

55A, Exterior protection, Wheel arch liners: Re-

moval-Refitting),

-the front bumper ( (see Front bumper: Removal -

Refitting) ).aDisconnect the injection computer connectors.

aRemove:

-the computer mounting bolts (1) ,

-the computer wiring harness clip nut,

-the computer mounting.

aDrain the cooling system (see 19A, Cooling, Cool-

ing system: Draining - Refilling, page 19A-9) .

aRemove the engine cooling fan assembly (see 19A,

Cooling, Engine cooling fan assembly: Removal

- Refitting, page 19A-51) .

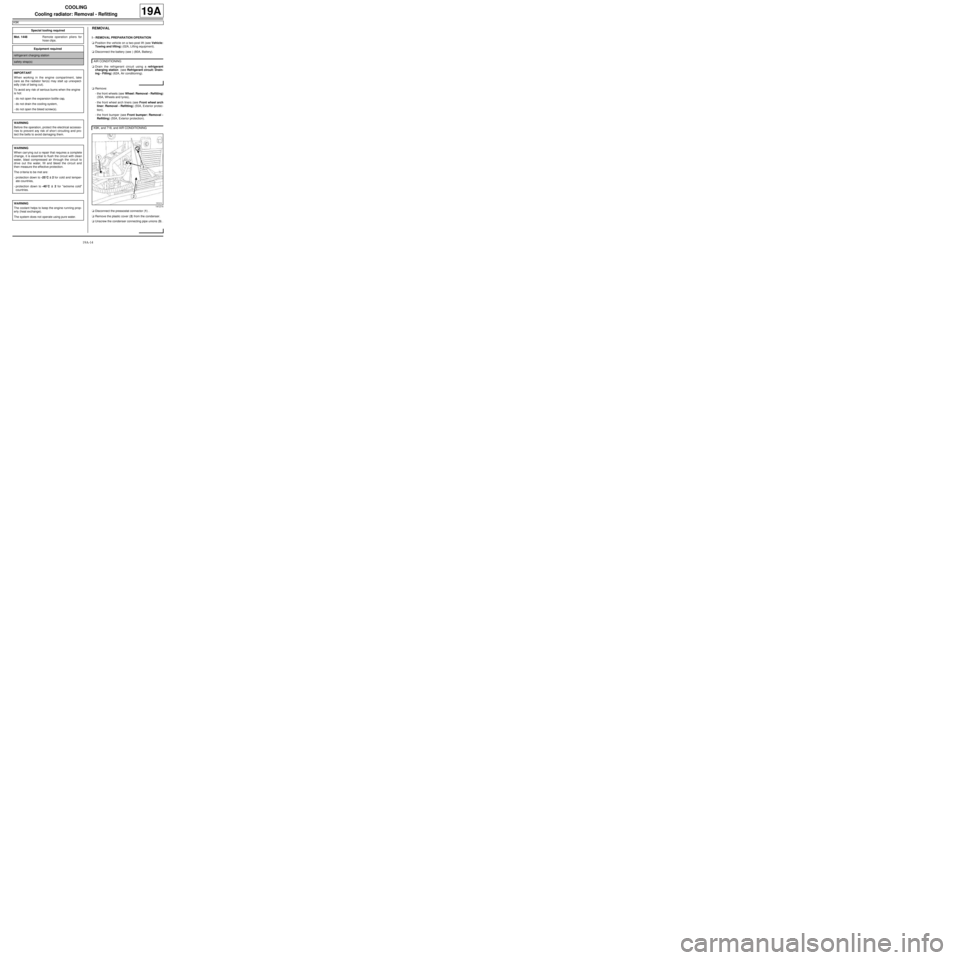

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aRemove:

-the air deflector on the dehydrator reservoir side,

-the engine cooling system radiator upper right-

hand retaining lug,

-the engine cooling system radiator upper left-hand

retaining lug.

aUsing the (Mot. 1448), remove:

-the engine cooling system radiator degassing

hose,

-the engine cooling system radiator top hose, Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

safety strap(s)

120779

IMPORTANT

Wear protective gloves during the operation.

Page 523 of 652

19A-13

COOLING

Cooling radiator: Removal - Refitting

D4F or D7F, and AIR CONDITIONING

19A

-the engine cooling system radiator bottom hose.

aAttach the condenser to the upper cross member of

the front end panel with a safety strap(s).

aRemove the condenser bolts from the radiator.

aUncouple the condenser from the cooling radiator.

aRemove the radiator mounting cross member ( (see

Radiator mounting cross member: Removal -

Refitting) ).

aWithdraw the air deflectors from the sliding adjust-

ers.

aRemove the engine cooling system radiator.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the engine cooling system radiator.

aFit the air deflector to the sliding adjusters.

aRefit the radiator mounting cross member ( (see Ra-

diator mounting cross member: Removal - Refit-

ting) ).

aCouple the condenser to the engine cooling system

radiator.

aDetach the condenser from the front end panel up-

per cross member.

aUsing the (Mot. 1448), refit:

-the engine cooling system radiator degassing

hose,

-the engine cooling system radiator top hose,

-the engine cooling system radiator bottom hose.

aRefit:

-the engine cooling system radiator upper retaining

lug on the dehydrator reservoir side,

-the engine cooling system radiator upper left-hand

retaining lug.

aRefit the air deflector on the dehydrator reservoir

side.

II - FINAL OPERATION

aRefit the engine cooling fan assembly (see 19A,

Cooling, Engine cooling fan assembly: Removal

- Refitting, page 19A-51) .

aRefit:

-the computer mounting.-the computer wiring harness clip nut,

-the computer mounting bolts.

aConnect the injection computer connectors.

aRefit:

-the battery tray ( (see Battery tray: Removal - Re-

fitting) ),

-the battery ( (see Battery: Removal - Refitting) ),

-the front bumper ( (see Front bumper: Removal -

Refitting) ),

-the wheel arch liners (see MR 412 Bodywork,

55A, Exterior protection, Wheel arch liners: Re-

moval-Refitting),

-the front wheels ( (see Wheel: Removal - Refit-

ting) ).

aFill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) .

Page 524 of 652

19A-14

COOLING

Cooling radiator: Removal - Refitting

K9K

19A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aDrain the refrigerant circuit using a refrigerant

charging station (see Refrigerant circuit: Drain-

ing - Filling) (62A, Air conditioning).

aRemove:

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDisconnect the pressostat connector (1) .

aRemove the plastic cover (2) from the condenser.

aUnscrew the condenser connecting pipe unions (3) . Special tooling required

Mot. 1448Remote operation pliers for

hose clips .

Equipment required

refrigerant charging station

safety strap(s)

IMPORTANT

When working in the engine compartment, take

care as the radiator fan(s) may start up unexpect-

edly (risk of being cut).

To avoid any risk of serious burns when the engine

is hot:

-do not open the expansion bottle cap,

-do not drain the cooling system,

-do not open the bleed screw(s).

WARNING

Before the operation, protect the electrical accesso-

ries to prevent any risk of shor t circuiting and pro-

tect the belts to avoid damaging them.

WARNING

When carr ying out a repair that requires a complete

change, it is essential to flush the circuit with clean

water, blast compressed air through the circuit to

drive out the water, fill and bleed the circuit and

then measure the effective protection.

The cr iteria to be met are:

-protection down to -25˚C ±± ± ±

2 for cold and temper-

ate countries,

-protection down to -40˚C ±± ± ±

2 for "extreme cold"

countries.

WARNING

The coolant helps to keep the engine running prop-

erly (heat exchange).

The system does not operate using pure water.AIR CONDITIONING

K9K, and 718, and AIR CONDITIONING

141214