gearbox RENAULT TWINGO 2009 2.G Engine And Peripherals Repair Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 278 of 652

12A-13

FUEL MIXTURE

Air filter unit: Removal - Refitting

D4F, and 772

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the air duct on the front end panel.

aLoosen the air filter box clip .

aDisconnect the oil vapour rebreathing hose.

aUnclip the gearbox breather.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the air filter unit:

-lift out the air filter unit to remove it from the rocker

cover,

-push the air filter unit towards the right to remove it

from the motorised throttle valve.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefitting the air filter unit:

-push the air filter unit towards the left to attach it to

the motorised throttle valve,

-lower the air filter unit to attach it to the rocker cov-

er.

II - FINAL OPERATION.

aTighten the air filter unit clip.

aConnect the oil vapour rebreathing hoses.

aClip on the gearbox breather.

aRefit the air duct on the front end panel.

120409

Page 280 of 652

12A-15

FUEL MIXTURE

Air filter unit: Removal - Refitting

K9K

12A

REMOVAL

I - REFITTING OPERATION FOR PART

CONCERNED

aSlide the air filter box towards the gearbox side.

aCheck the condition of the air filter box mountings,

replace them if necessary.

aClip:

-the air filter box onto its mountings,

-the air filter air outlet pipe to the air filter.

aTighten the air pipe clip on the air filter outlet.

aRefit the air filter air inlet pipe on the vehicle.

aPosition the turbocharger pressure sensor on the air

filter box.

aRefit the bolt mounting the turbocharger pressure

sensor on the air filter box.

aConnect the connectors:

-of the inlet air temperature sensor,

-of the turbocharging pressure sensor,

-of the flow sensor,

-of the EGR.

aClip on the air filter box harnesses.

aClip the air filter inlet air pipe to the air filter box.

II - FINAL OPERATION.

aRefit the engine cover.Note:

Ensure that the centring lug of the box is fully

inserted in the cylinder head.

Page 320 of 652

12A-55

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

REMOVAL

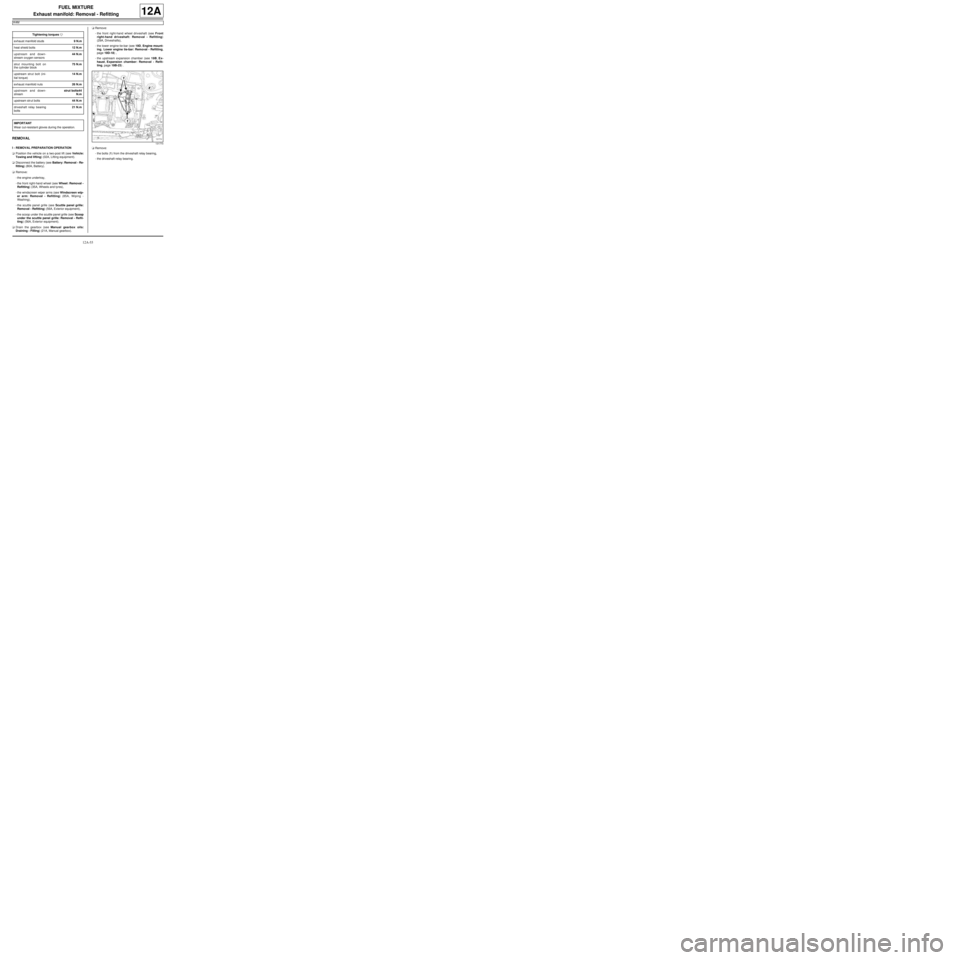

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aDrain the gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).aRemove:

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the upstream expansion chamber (see 19B, Ex-

haust, Expansion chamber: Removal - Refit-

ting, page 19B-23) .

aRemove:

-the bolts (1) from the driveshaft relay bearing,

-the driveshaft relay bearing. Tightening torquesm

exhaust manifold studs9 N.m

heat shield bolts12 N.m

upstream and down-

stream oxygen sensors44 N.m

strut mounting bolt on

the cylinder block75 N.m

upstream strut bolt (ini-

tial torque)14 N.m

exhaust manifold nuts26 N.m

upstream and down-

streamstrut bolts44

N.m

upstream strut bolts44 N.m

driveshaft relay bearing

bolts21 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.

131770

Page 325 of 652

12A-60

FUEL MIXTURE

Exhaust manifold: Removal - Refitting

K4M

12A

-the driveshaft relay bearing.

aTorque tighten the driveshaft relay bearing bolts

(21 N.m).

aRefit:

-the upstream expansion chamber (see 19B, Ex-

haust, Expansion chamber: Removal - Refit-

ting, page 19B-23) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts).

aFill the gearbox (see Manual gearbox oils: Drain-

ing - Filling) (21A, Manual gearbox).

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 333 of 652

12B-8

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine undertray.

aDrain the manual gearbox (see Manual gearbox

oils: Draining - Filling) (21A, Manual gearbox).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the turbocharger oil return pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) .

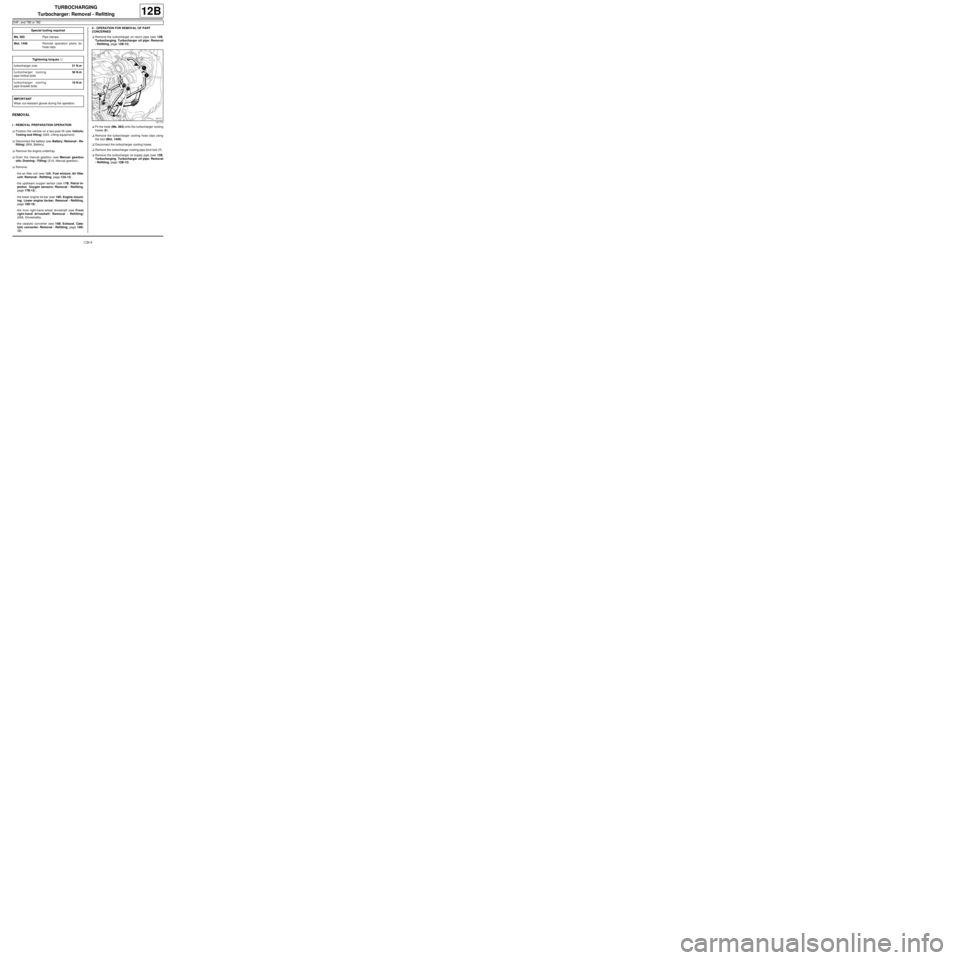

aFit the tools (Ms. 583) onto the turbocharger cooling

hoses (6) .

aRemove the turbocharger cooling hose clips using

the tool (Mot. 1448).

aDisconnect the turbocharger cooling hoses.

aRemove the turbocharger cooling pipe strut bolt (7) .

aRemove the turbocharger oil supply pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) . Special tooling required

Ms. 583Pipe clamps .

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

turbocharger nuts21 N.m

turbocharger cooling

pipe hollow bolts30 N.m

turbocharger cooling

pipe bracket bolts10 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.121773

Page 336 of 652

12B-11

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

III - FINAL OPERATION

aRefit:

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRefill:

-and bleed the cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the manual gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).

aRefit the engine undertray.

Page 429 of 652

14A-11

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the engine cover,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the EGR solenoid valve (see 14A, Antipollution,

Exhaust gas recirculation solenoid valve: Re-

moval - Refitting, page 14A-10) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,-the exhaust gas recirculation rigid pipe (see 14A,

Antipollution, Exhaust gas recirculation rigid

pipe: Removal - Refitting, page 14A-19) ,

-the exhaust gas recirculation assembly (see 14A,

Antipollution, Exhaust gas recirculation as-

sembly: Removal - Refitting, page 14A-15) .

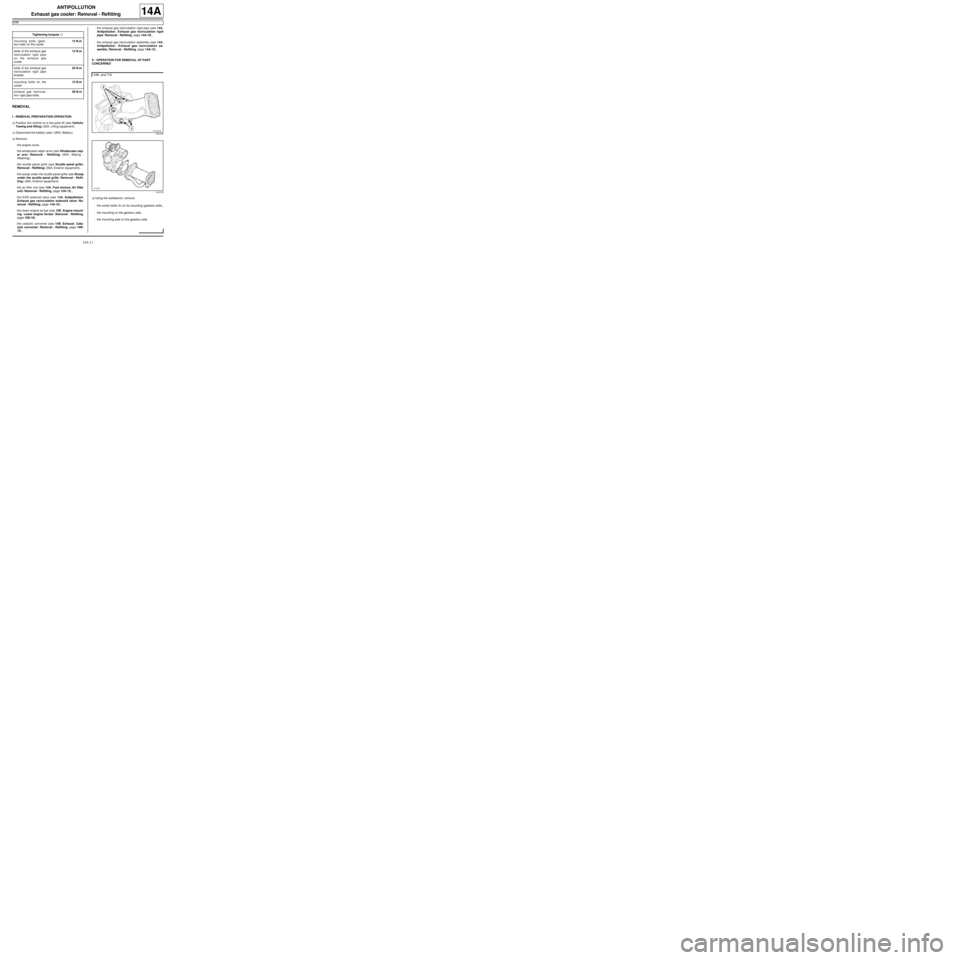

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUsing the workbench, remove:

-the cooler bolts (1) on its mounting (gearbox side),

-the mounting on the gearbox side,

-the mounting seal on the gearbox side. Tightening torquesm

mounting bolts (gear-

box side) on the cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

on the exhaust gas

cooler12 N.m

bolts of the exhaust gas

recirculation rigid pipe

bracket25 N.m

mounting bolts on the

cooler12 N.m

exhaust gas recircula-

tion r igid pipe bolts36 N.m

K9K, and 718

141215

141216

Page 430 of 652

14A-12

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

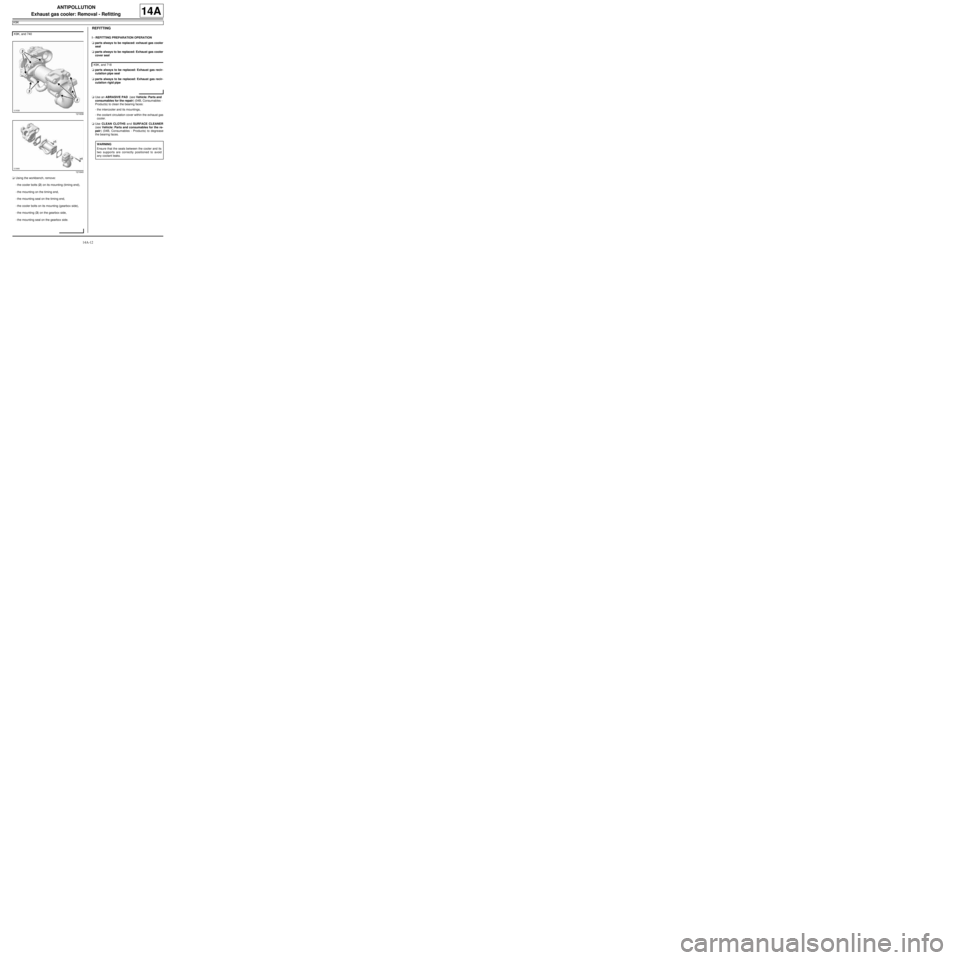

aUsing the workbench, remove:

-the cooler bolts (2) on its mounting (timing end),

-the mounting on the timing end,

-the mounting seal on the timing end,

-the cooler bolts on its mounting (gearbox side),

-the mounting (3) on the gearbox side,

-the mounting seal on the gearbox side.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: exhaust gas cooler

seal

aparts always to be replaced: Exhaust gas cooler

cover seal

aparts always to be replaced: Exhaust gas recir-

culation pipe seal

aparts always to be replaced: Exhaust gas recir-

culation rigid pipe

aUse an ABRASIVE PAD (see Vehicle: Parts and

consumables for the repair) (04B, Consumables -

Products) to clean the bearing faces:

-the intercooler and its mountings,

-the coolant circulation cover within the exhaust gas

cooler.

aUse CLEAN CLOTHS and SURFACE CLEANER

(see Vehicle: Parts and consumables for the re-

pair) (04B, Consumables - Products) to degrease

the bearing faces. K9K, and 740

121638

121640

K9K, and 718

WARNING

Ensure that the seals between the cooler and its

two supports are correctly positioned to avoid

any coolant leaks.

Page 431 of 652

14A-13

ANTIPOLLUTION

Exhaust gas cooler: Removal - Refitting

K9K

14A

II - REFITTING OPERATION FOR PART

CONCERNED

aOn the workbench, refit the following to the intercoo-

ler:

-a new mounting seal on the gearbox side,

-the mounting on the gearbox side,

-the mounting bolts (gearbox side) onto the inter-

cooler without tightening them,

-a new exhaust gas recirculation rigid pipe,

-the bolts of the exhaust gas recirculation rigid pipe

bracket on the cooler without tightening them.

aFit the exhaust gas recirculation assembly onto the

cylinder head.

aAdjust the mounting (gearbox side) and the exhaust

gas recirculation rigid pipe until they are flat against

the cylinder head.

aFit the exhaust gas recirculation unit assembly bolts,

without tightening them.

aTighten the bolts of the mounting (gearbox side) and

of the exhaust gas recirculation rigid pipe on the ex-

haust gas cooler to secure them on the exhaust gas

cooler.

aRemove the exhaust gas recirculation assembly.

aOn the workbench, torque tighten:

-the mounting bolts (gearbox side) on the cooler

(12 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe on the exhaust gas cooler (12 N.m),

-the bolts of the exhaust gas recirculation rigid

pipe bracket (25 N.m).aOn the workbench, refit the following to the intercoo-

ler:

-a new mounting seal on the gearbox side,

-the mounting on the gearbox side,

-the mounting bolts (gearbox side) onto the inter-

cooler without tightening them,

-a new mounting seal on the timing end,

-the mounting on the timing end,

-the mounting bolts (timing end) onto the intercooler

without tightening them.

aFit the exhaust gas recirculation assembly onto the

cylinder head.

aAdjust the two mountings until they are flat against

the cylinder head.

aFit the exhaust gas recirculation unit assembly bolts,

without tightening them.

aTighten the bolts of the two mountings on the ex-

haust gas cooler to immobilise them on the exhaust

gas cooler.

aRemove the exhaust gas recirculation assembly.

aOn the workbench, torque tighten the mounting

bolts on the cooler (12 N.m).

III - FINAL OPERATION

aRefit the exhaust gas recirculation assembly (see

14A, Antipollution, Exhaust gas recirculation as-

sembly: Removal - Refitting, page 14A-15) . K9K, and 718

Note:

The cooler must absolutely be able to move in

relation to the mounting (gearbox side) and to the

exhaust gas recirculation rigid pipe so that it can

be properly adjusted afterwards on the cylinder

head.

K9K, and 740

Note:

The cooler must absolutely be able to move in

relation to its tw o mountings so that it can be

properly adjusted afterwards on the cylinder

head.

Page 449 of 652

16A-10

STARTING - CHARGING

Starter: Removal - Refitting

D4F or D7F

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove the engine oil dipstick.

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aDisconnect the air filter unit air inlet pipe from the air

filter unit cover (1) .

aMove the air filter unit air inlet pipe away from the air

filter unit cover.aDisconnect the pinking sensor connector (2) .

aRemove the engine wiring channel bolt from the

gearbox.

aUnclip the engine wiring channel from the gearbox.

aMove aside the engine wiring channel. Tightening torquesm

starter upper bolt44 N.m

starter electrical supply

nut8N.m

D4F, and 772

D4F, and 780 or 782

122833

120512

120414