gearbox RENAULT TWINGO 2009 2.G Engine And Peripherals Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO, Model: RENAULT TWINGO 2009 2.GPages: 652

Page 110 of 652

10A-104

ENGINE AND CYLINDER BLOCK ASSEMBLY

Engine - gearbox assembly: Removal - Refitting

K4M

10A

aConnect:

-the top hose on the water chamber,

-the hoses on the heater matrix.

aUsing the (Mot. 1448), fit:

-the clip on the top hose on the water chamber,

-the clip on each hose on the heater matrix.

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .

aRefit:

-the differential output seal (see Differential output

seal: Removal - Refitting) (21A, Manual gear-

box),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the radiator mounting cross member (see Radiator

mounting cross member: Removal - Refitting)

(41A, Front lower structure),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the strap of the « engine cooling radiator -

condenser » assembly on the front upper cross

member,

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the fuel injection computer (see 17B, Petrol injec-

tion, Petrol injection computer: Removal - Refit-

ting, page 17B-20) .

aRefit the battery (see Battery: Removal - Refitting)

(80A, Battery).

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .aRefill:

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),

-and bleed the cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the engine if necessary (see 10A, Engine and cyl-

inder block assembly, Engine oil: Draining - Re-

filling, page 10A-22) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning).

aBleed the clutch circuit (see Clutch circuit: Bleed)

(37A, Mechanical component controls).

aRefit the engine undertray.

Page 113 of 652

10A-107

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

D4F – D7F – K9K

10A

REMOVAL

I - REFITTING PREPARATIONS OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the gearbox (see Manual gearbox: Removal - Re-

fitting) ,

-the clutch plate and pressure plate (see Pressure

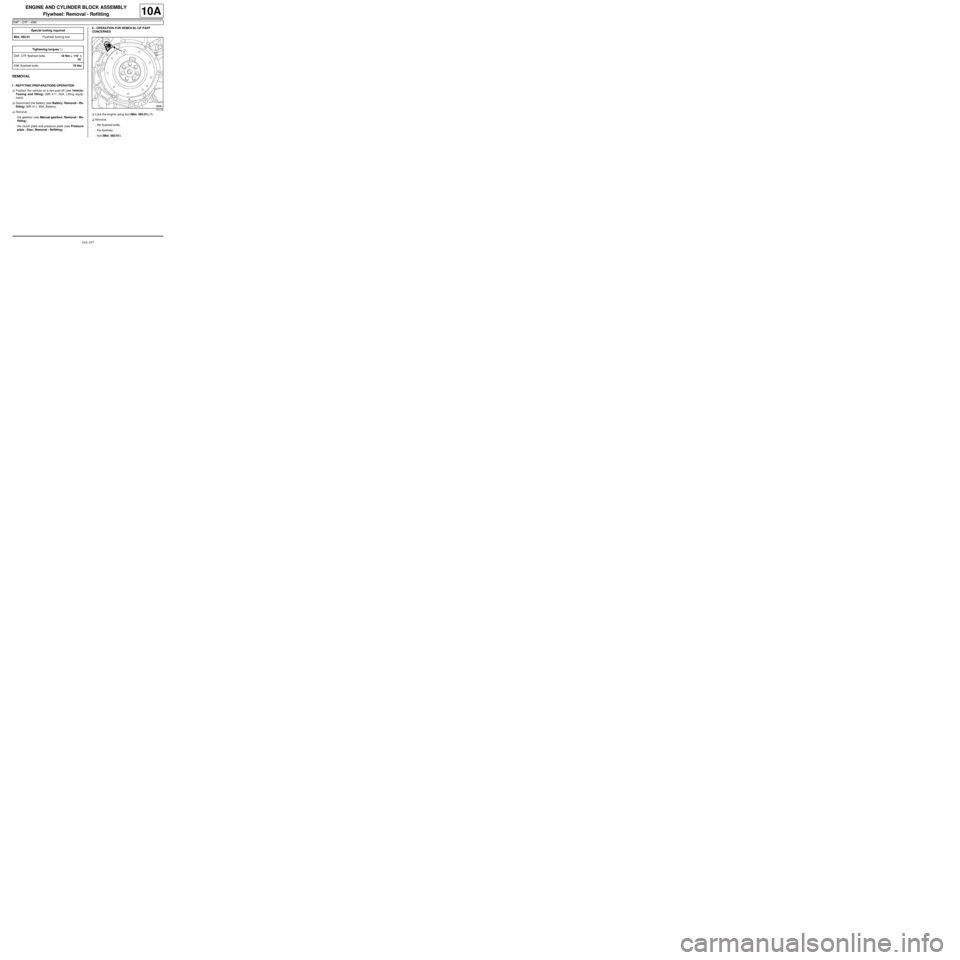

plate - Disc: Removal - Refitting) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aLock the engine using tool (Mot. 582-01) (1) .

aRemove:

-the flywheel bolts,

-the flywheel,

-tool (Mot. 582-01). Special tooling required

Mot. 582-01Flywheel locking tool.

Tightening torquesm

D4F, D7F flywheel bolts18 Nm + 110˚ ±± ± ±

10˚

K9K flywheel bolts70 Nm

109158

Page 115 of 652

10A-109

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

D4F – D7F – K9K

10A

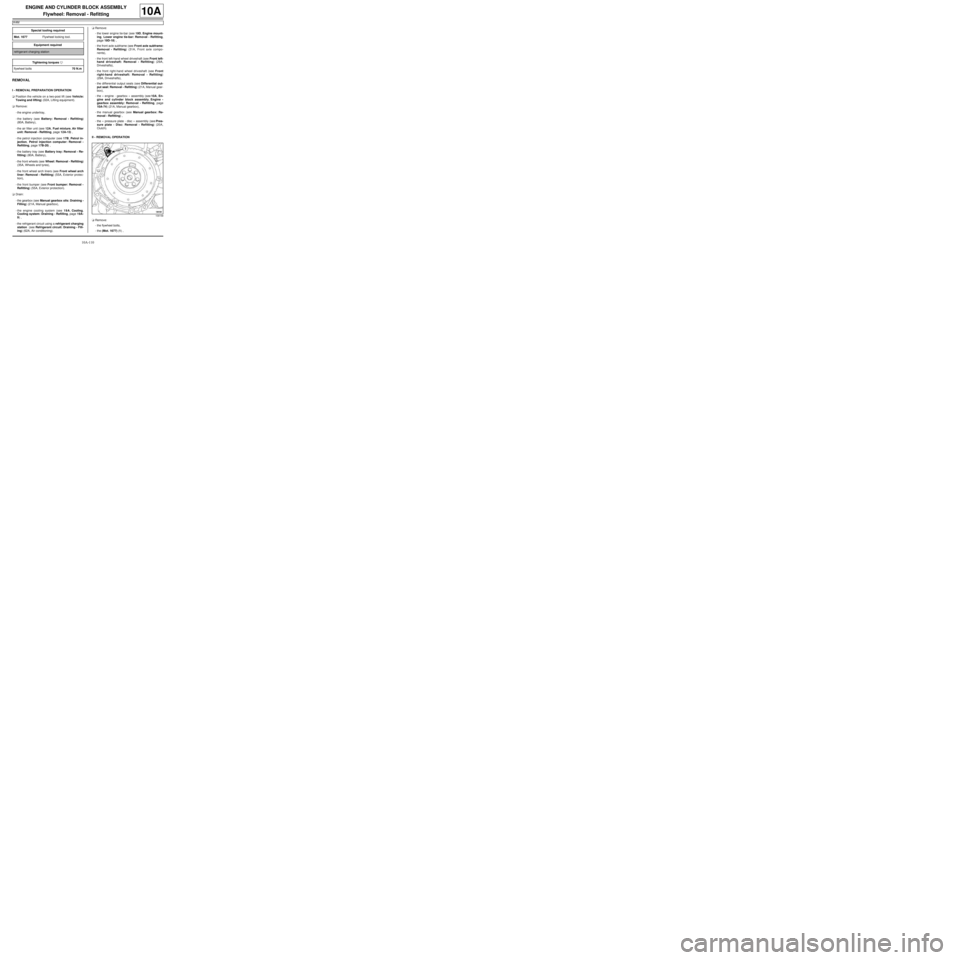

Tightening order

aObserve the tightening order.

aTorque and angle tighten, in order, the D4F, D7F fly-

wheel bolts (18 Nm + 110˚ ±± ± ±

10˚).

aTighten to torque and in order the K9K flywheel

bolts (70 Nm).

aRemove tool (Mot. 582-01).

III - FINAL OPERATION.

aRefit:

-the clutch plate and pressure plate (see Pressure

plate - Disc: Removal - Refitting) ,

-the gearbox (see Manual gearbox: Removal - Re-

fitting) .

aConnect the battery (see Battery: Removal - Refit-

ting) (MR 411, 80A, Battery).

23326

D4F – D7F

K9K

Page 116 of 652

10A-110

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

K4M

10A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray,

-the battery (see Battery: Removal - Refitting)

(80A, Battery),

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection).

aDrain:

-the gearbox (see Manual gearbox oils: Draining -

Filling) (21A, Manual gearbox),

-the engine cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the refrigerant circuit using a refrigerant charging

station (see Refrigerant circuit: Draining - Fill-

ing) (62A, Air conditioning).aRemove:

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the differential output seals (see Differential out-

put seal: Removal - Refitting) (21A, Manual gear-

box),

-the « engine - gearbox » assembly (see 10A, En-

gine and cylinder block assembly, Engine -

gearbox assembly: Removal - Refitting, page

10A-74) (21A, Manual gearbox),

-the manual gearbox (see Manual gearbox: Re-

moval - Refitting) ,

-the « pressure plate - disc » assembly (see Pres-

sure plate - Disc: Removal - Refitting) (20A,

Clutch).

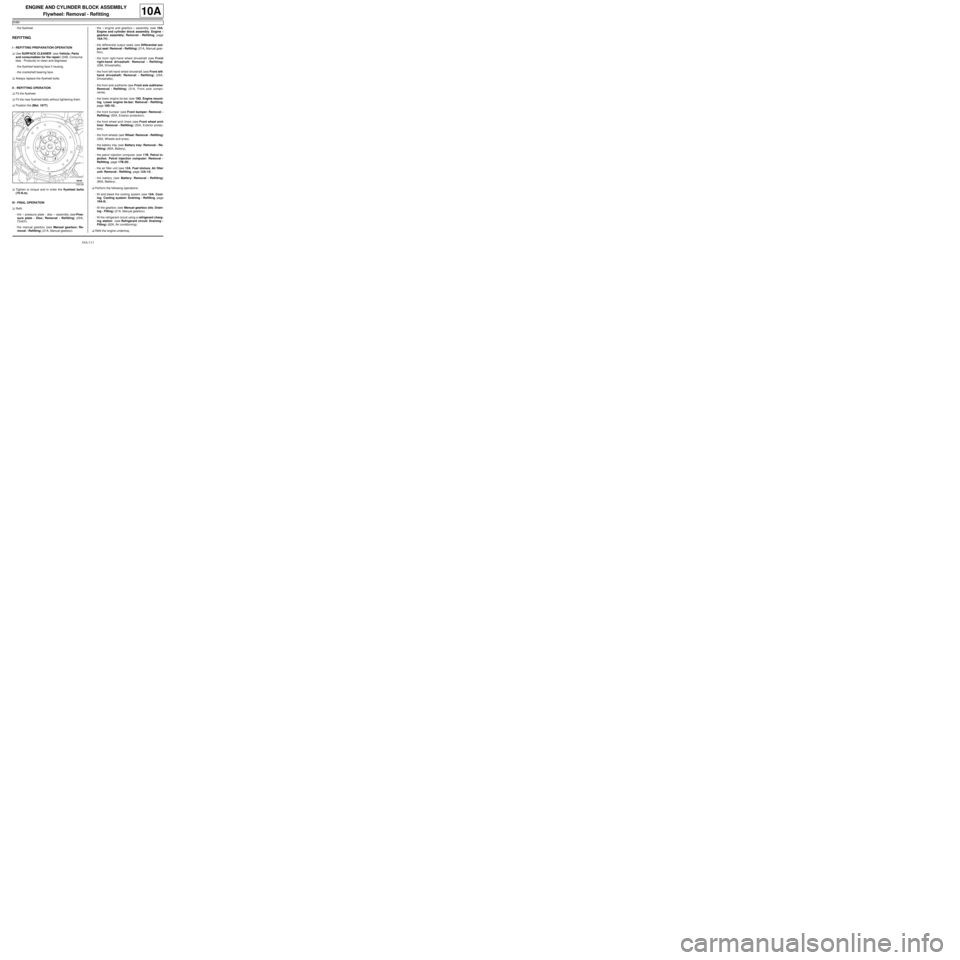

II - REMOVAL OPERATION

aRemove:

-the flywheel bolts,

-the (Mot. 1677) (1) , Special tooling required

Mot. 1677Flywheel locking tool.

Equipment required

refrigerant charging station

Tightening torquesm

flywheel bolts70 N.m

109158

Page 117 of 652

10A-111

ENGINE AND CYLINDER BLOCK ASSEMBLY

Flywheel: Removal - Refitting

K4M

10A

-the flywheel.

REFITTING

I - REFITTING PREPARATION OPERATION

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the flywheel bearing face if reusing,

-the crankshaft bearing face.

aAlways replace the flywheel bolts.

II - REFITTING OPERATION

aFit the flywheel.

aFit the new flywheel bolts without tightening them.

aPosition the (Mot. 1677).

aTighten to torque and in order the flywheel bolts

(70 N.m).

III - FINAL OPERATION

aRefit:

-the « pressure plate - disc » assembly (see Pres-

sure plate - Disc: Removal - Refitting) (20A,

Clutch),

-the manual gearbox (see Manual gearbox: Re-

moval - Refitting) (21A, Manual gearbox).-the « engine and gearbox » assembly (see 10A,

Engine and cylinder block assembly, Engine -

gearbox assembly: Removal - Refitting, page

10A-74) ,

-the differential output seals (see Differential out-

put seal: Removal - Refitting) (21A, Manual gear-

box),

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the front left-hand wheel driveshaft (see Front left-

hand driveshaft: Removal - Refitting) (29A,

Driveshafts),

-the front axle subframe (see Front axle subframe:

Removal - Refitting) (31A, Front axle compo-

nents),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front wheel arch liners (see Front wheel arch

liner: Removal - Refitting) (55A, Exterior protec-

tion),

-the front wheels (see Wheel: Removal - Refitting)

(35A, Wheels and tyres),

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery),

-the petrol injection computer (see 17B, Petrol in-

jection, Petrol injection computer: Removal -

Refitting, page 17B-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the battery (see Battery: Removal - Refitting)

(80A, Battery).

aPerform the following operations:

-fill and bleed the cooling system (see 19A, Cool-

ing, Cooling system: Draining - Refilling, page

19A-9) ,

-fill the gearbox (see Manual gearbox oils: Drain-

ing - Filling) (21A, Manual gearbox).

-fill the refrigerant circuit using a refrigerant charg-

ing station (see Refrigerant circuit: Draining -

Filling) (62A, Air conditioning).

aRefit the engine undertray.

109158

Page 138 of 652

11A-21

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

aLock the flywheel by inserting a large flat-blade

screwdriver into the gearbox aperture.

aRemove:

-the accessories pulley bolt (2) ,

-the accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the crankshaft accessories pulley V-grooves

with a brush to prevent any deposits.aparts always to be replaced: Accessories belt,

parts always to be replaced: Accessories belt

tensioning roller,

parts always to be replaced: Accessories ten-

sioning roller bolt (to be replaced by the hexagonal

head bolt, part no. 77 03 101 075),

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

aparts always to be replaced: Accessories belt,

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the crankshaft accessories pulley using a new

bolt.

aTorque tighten the crankshaft accessories pulley

bolt (40 N.m + 75˚ ±± ± ±

6).

aRemove the large flat screwdriver from the opening

in the gearbox.

aRemove the immobilising tool (Mot. 582-01).

aRefit the flywheel protector.

III - FINAL OPERATION

aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) , D4F, and 780 or 782

122665

WARNING

Only use brushes with plastic or non-corrosive

metal (brass) bristles.

AIR CONDITIONING

STANDARD HEATING

D4F, and 780 or 782

D4F, and 772 – D7F

Page 232 of 652

11A-115

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

aFit blanking plugs to the fuel pipes and the high pres-

sure pump (see 13B, Diesel injection, Diesel in-

jection: Precautions for the repair, page 13B-1) .

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

aUnclip:

-the breather pipe on the gearbox,

-the wiring on the engine lifting eye on the gearbox

side.

aMove aside the engine wiring.

aDisconnect the brake servo pipe from the vacuum

pump.

aRemove the cooling hose clip from the EGR cooler

using the (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aDisconnect the cooling hose from the EGR cooler.

aSeparate the clip on the cooling hose of the coolant

pump inlet pipe using the tool (Mot. 1202-01) or

(Mot. 1202-02) or (Mot. 1448).

aDisconnect the cooling hose from the coolant pump

inlet pipe.

aRemove the heater matrix cooling hose clip from the

water chamber using the (Mot. 1202-01) or (Mot.

1202-02) or (Mot. 1448).

aDisconnect:

-the heater matrix cooling hose from the water

chamber,

-the coolant temperature sensor connector.

aRemove the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .aRemove:

-the oil return pipe bolts (1) from the turbocharger,

-the oil return pipe by detaching it from the cylinder

block,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the two high pressure pipes between the rail and

injector at the timing end (see 13B, Diesel injec-

tion, High pressure pipe between rail and injec-

tor: Removal - Refitting, page 13B-39) ,

-the timing end bracket bolt from the air filter box,

-the timing end bracket from the air filter box.

112327

Page 234 of 652

11A-117

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K9K

11A

aIf necessary, carry out a complete check of the cylin-

der head (see Cylinder head: Check) .

II - REFITTING OPERATION FOR PART

CONCERNED

aBring the pistons to mid-stroke position to prevent

them from coming into contact with the valves during

the tightening of the cylinder head.

aRefit:

-a new cylinder head gasket,

-the cylinder head.

Cylinder head tightening procedure

aRefit the cylinder head bolts.

aFit the cylinder head bolts, without tightening them.

aTighten to torque and in order the cylinder head

bolts (initial torque) (25 N.m).

aCheck that the cylinder head bolts are tightened to

25 Nm.

aAngle tighten the cylinder head bolts (270˚ ±± ± ±

10˚) in

order using a cylinder head bolt tightening gauge

(angular measuring type).

III - FINAL OPERATION

aRefit:

-the timing end bracket on the air filter box.

-the timing end bracket bolt on the air filter box,-the two high pressure pipes between the rail and

injector at the timing end (see 13B, Diesel injec-

tion, High pressure pipe between rail and injec-

tor: Removal - Refitting, page 13B-39) ,

-the rocker cover (see 11A, Top and front of en-

gine, Rocker cover: Removal - Refitting, page

11A-66) ,

-the oil return pipe fitted with new seals, fitting it into

the cylinder block (see 12B, Turbocharging, Tur-

bocharger oil pipe: Removal - Refitting, page

12B-12) .

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .

aConnect:

-the coolant temperature sensor connector,

-the heater matrix cooling hose to the water cham-

ber.

aFit the clip on the heater matrix cooling hose onto

the water chamber using the (Mot. 1202-01) or

(Mot. 1202-02) or (Mot. 1448).

aConnect the coolant pump inlet pipe cooling hose.

aFit the cooling hose clip at the coolant pump inlet

pipe end using the (Mot. 1202-01) or (Mot. 1202-02)

or (Mot. 1448).

aConnect the EGR cooler cooling hose.

aFit the cooling hose clip at the EGR cooler end using

the (Mot. 1202-01) or (Mot. 1202-02) or (Mot.

1448).

aConnect the brake servo pipe onto the vacuum

pump.

aFit the engine wiring.

aClip:

-the breather pipe onto the gearbox,

-the wiring on the engine lifting eye on the gearbox

side.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aRemove the blanking plugs from the fuel pipes and

high pressure pump.

aConnect the fuel inlet and return pipes to the high

pressure pump.

aFit the engine wiring.

aConnect:

-the accelerometer connector,

-injector rail pressure sensor connector, WARNING

In order to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

19712

Page 237 of 652

11A-120

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K4M

11A

-the camshafts (see 11A, Top and front of engine,

Camshaft: Removal - Refitting, page 11A-82) .

aDrain the gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).

aRemove:

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the exhaust manifold (see 12A, Fuel mixture, Ex-

haust manifold: Removal - Refitting, page 12A-

48) .

aRemove:

-the dipstick,

-the bolts (1) from the dipstick guide,

-the dipstick guide.aUsing the (Mot. 1448) or (Mot. 1202-01) or (Mot.

1202-02) remove:

-the cooling radiator top hose clip (2) on the water

chamber.

-the heater matrix inlet hose clip (3) on the water

chamber.

aDisconnect:

-the cooling radiator top hose from the water cham-

ber.

-the heater matrix inlet hose of the water chamber,

-the connector (4) from the coolant temperature

sensor.

aUnclip the water chamber wiring.

132368

128616

Page 241 of 652

11A-124

TOP AND FRONT OF ENGINE

Cylinder head: Removal - Refitting

K4M

11A

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the oil decanter (see 11A, Top and front of en-

gine, Oil decanter: Removal - Refitting, page

11A-147) ,

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the coils (see 17A, Ignition, Coils: Removal - Re-

fitting, page 17A-1) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aPerform the following operations:

-fill the gearbox (see Manual gearbox oils: Drain-

ing - Filling) (21A, Manual gearbox).-fill and bleed the coolant circuit (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) .

aRefit the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).