62C-61

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

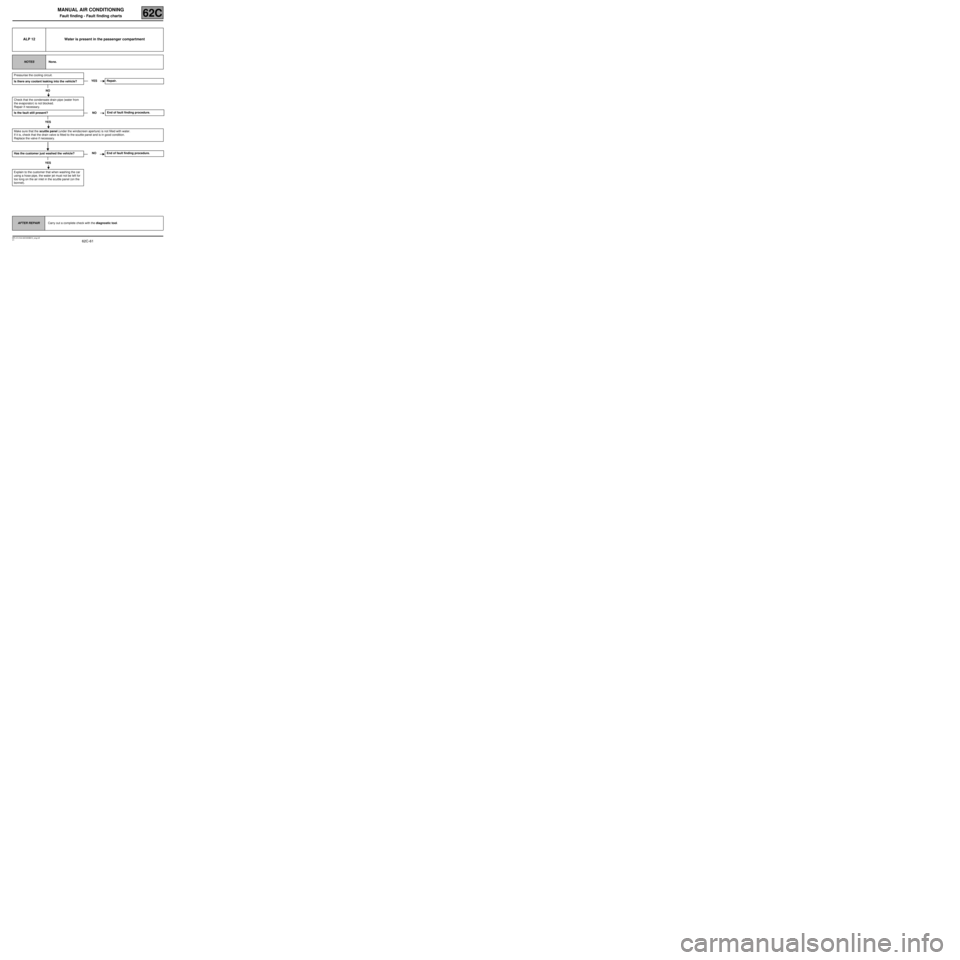

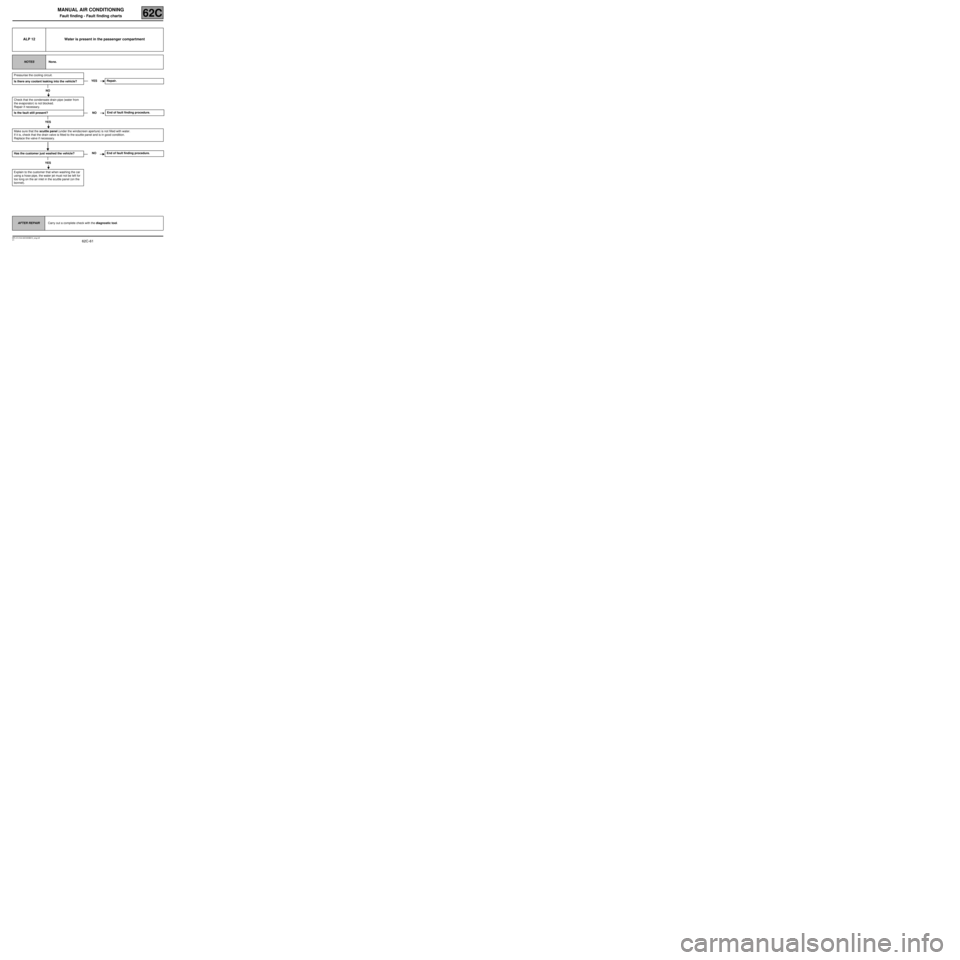

ALP 12 Water is present in the passenger compartment

NOTESNone.

Pressurise the cooling circuit.

Is there any coolant leaking into the vehicle?

NO

Check that the condensate drain pipe (water from

the evaporator) is not blocked.

Repair if necessary.

Is the fault still present?

YES

Make sure that the scuttle panel (under the windscreen aperture) is not filled with water.

If it is, check that the drain valve is fitted to the scuttle panel and is in good condition.

Replace the valve if necessary.

Has the customer just washed the vehicle?

YES

Explain to the customer that when washing the car

using a hose pipe, the water jet must not be left for

too long on the air inlet in the scuttle panel (on the

bonnet).

YES Repair.

NOEnd of fault finding procedure.

NO End of fault finding procedure.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

62C-62

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

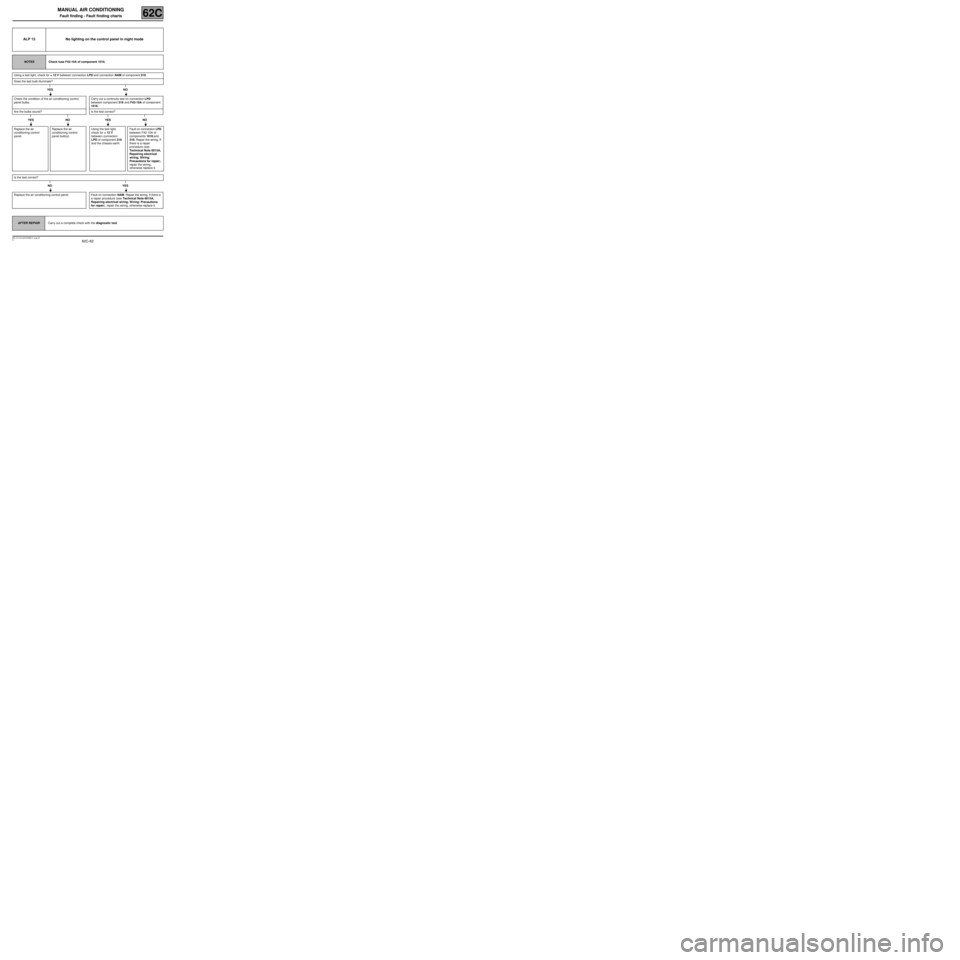

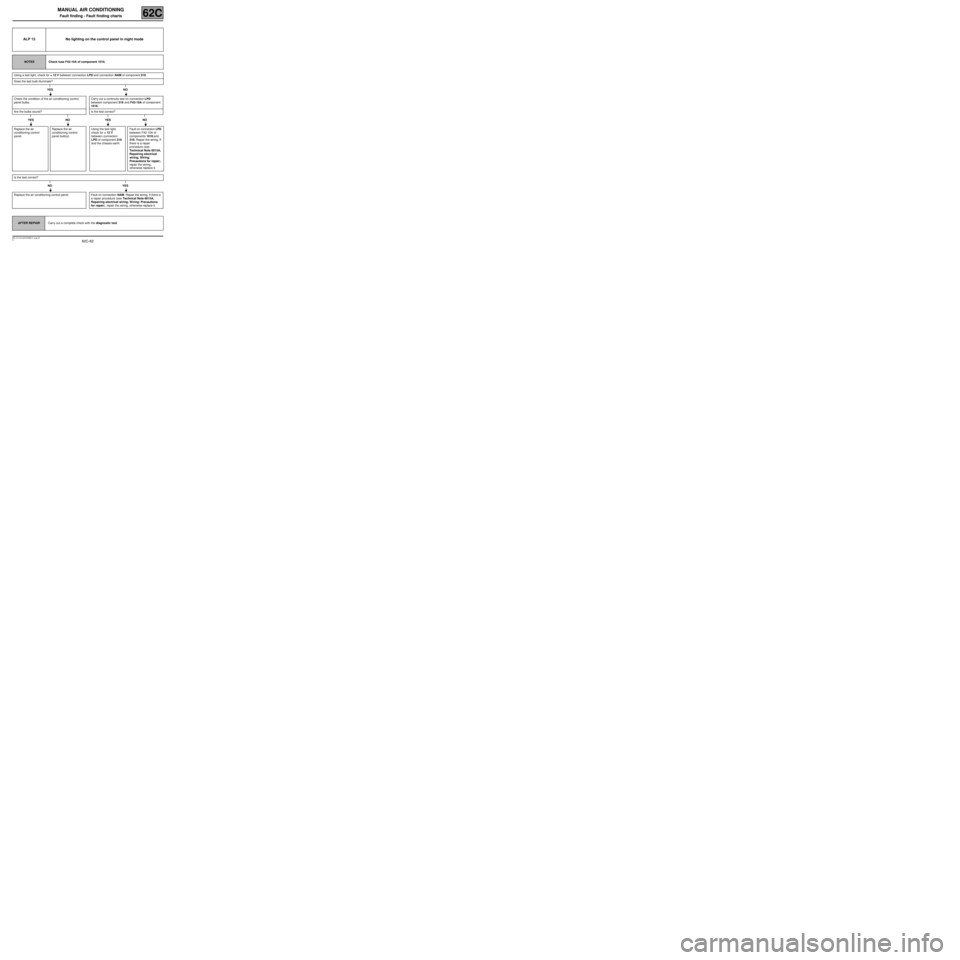

ALP 13 No lighting on the control panel in night mode

NOTESCheck fuse F42-10A of component 1016.

Using a test light, check for + 12 V between connection LPD and connection NAM of component 319.

Does the test bulb illuminate?

YES NO

Check the condition of the air conditioning control

panel bulbs.Carry out a continuity test on connection LPD

between component 319 and F42-10A of component

1016.

Are the bulbs sound? Is the test correct?

YES NO YES NO

Replace the air

conditioning control

panel.Replace the air

conditioning control

panel bulb(s).Using the test light,

check for + 12 V

between connection

LPD of component 319

and the chassis earth.Fault on connection LPD

between F42-10A of

components 1016 and

319. Repair the wiring. If

there is a repair

procedure (see

Technical Note 6015A,

Repairing electrical

wiring, Wiring:

Precautions for repair),

repair the wiring,

otherwise replace it.

Is the test correct?

NO YES

Replace the air conditioning control panelFault on connection NAM. Repair the wiring. If there is

a repair procedure (see Technical Note 6015A,

Repairing electrical wiring, W iring: Precautions

for repair), repair the wiring, otherwise replace it.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

62C-63

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

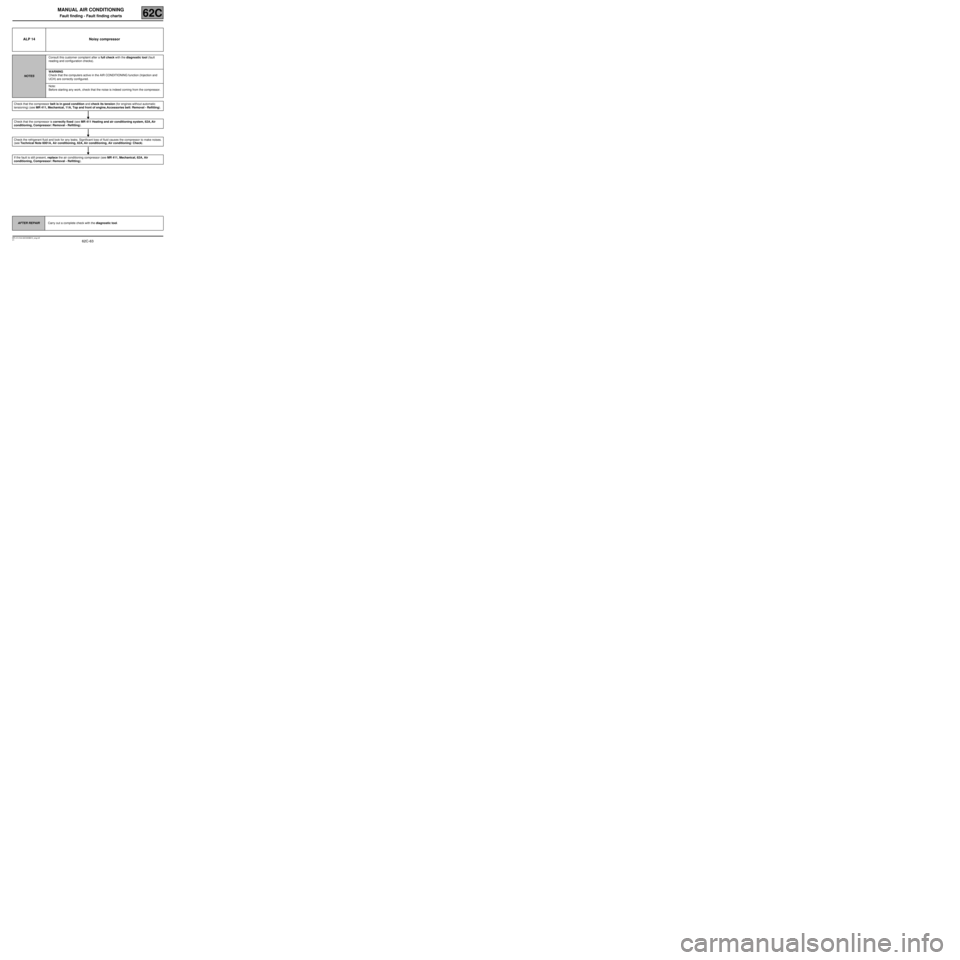

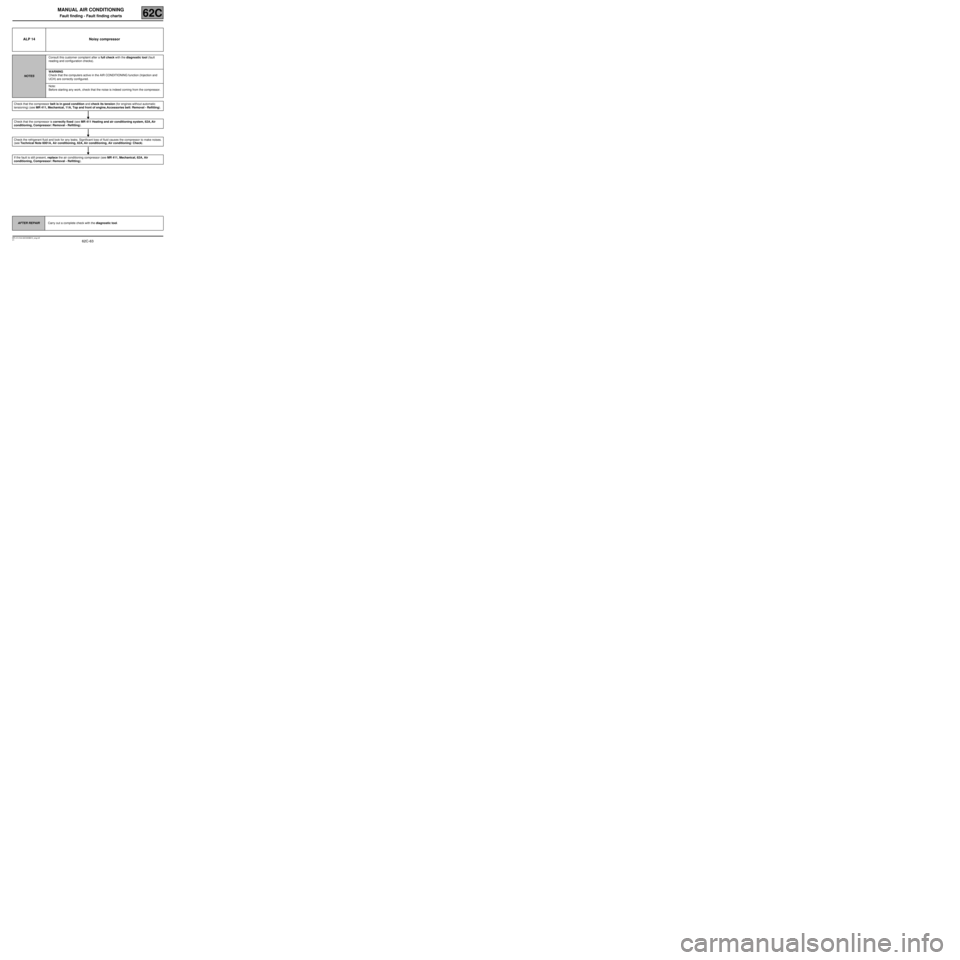

ALP 14 Noisy compressor

NOTESConsult this customer complaint after a full check with the diagnostic tool (fault

reading and configuration checks).

WARNING

Check that the computers active in the AIR CONDITIONING function (Injection and

UCH) are correctly configured.

Note:

Before starting any work, check that the noise is indeed coming from the compressor.

Check that the compressor belt is in good condition and check its tension (for engines without automatic

tensioning) (see MR 411, Mechanical, 11A, Top and front of engine, Accessories belt: Removal - Refitting).

Check that the compressor is correctly fixed (see MR 411 Heating and air conditioning system, 62A, Air

conditioning, Compressor: Removal - Refitting).

Check the refrigerant fluid and look for any leaks. Significant loss of fluid causes the compressor to make noises.

(see Technical Note 6001A, Air conditioning, 62A, Air conditioning, Air conditioning: Check).

If the fault is still present, replace the air conditioning compressor (see MR 411, Mechanical, 62A, Air

conditioning, Compressor: Removal - Refitting).

AFTER REPAIRCarry out a complete check with the diagnostic tool.