sensor RENAULT TWINGO RS 2009 2.G Chasiss ESP Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 101

Page 51 of 101

38C-51

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF108

PRESENT

OR

STOREDSTEERING WHEEL ANGLE SENSOR

DEF: sensor fault

NOTESNone.

Check the internal fault code of the steering wheel angle sensor using parameter PR113 Steering wheel angle

sensor internal fault code.

Is the internal fault code of the steering wheel angle sensor 10 or 11?

YESCalibrate component 583 using command VP003 Steering wheel angle sensor

(see Configurations and programming).

Clear the ESP sensor offsets using command RZ011 Sensor offsets.

NONote the internal fault code of the steering wheel angle sensor for the purposes of

completing the approval request.

Replace component 583 (see MR 411, Mechanical, 36A, Steering assembly,

Steering column, Removal - Refitting).

ESP_V05_DF108

Page 52 of 101

38C-52

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$101.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF126

PRESENT

OR

STOREDCOMBINED SENSOR SIGNAL PLAUSIBILITY

NOTESSpecial notes:

If the fault appears while the vehicle is being driven on a steep gradient, during a very

tight turn or while the vehicle is being transported on a lorry, train, boat etc., with the

engine running, clear the fault and test drive, if possible, to check that the fault does

not return.

Conditions for applying fault finding procedures to stored faults:

The fault is declared present after a road test.

Check that component 1175 is fitted and attached correctly (the arrow indicating the front of the vehicle).

Check the conformity of the tyres (see MR 411, Mechanical, 35A, Wheels and tyres, Tyres: Identification

and Tyre pressure, Identification).

Check the axle assembly geometry (see MR 411, Mechanical, Chassis, Front axle adjustment).

Calibrate component 583 using command VP003 Steering wheel angle sensor (see Configurations

and programming).

Clear the ESP sensor offsets using command RZ011 Sensor offset.

Re-establish dialogue with the ABS/ESP computer, and if no other fault is to be dealt with, clear the computer fault

memory.

Carry out a road test.

If the fault is still present, contact the Techline.

ESP_V05_DF126

Page 59 of 101

38C-59

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF189

PRESENT

OR

STOREDCOMBINED SENSOR CIRCUIT

NOTESUse Wiring Diagram Technical Note, New Twingo.

Check the condition and position of fuse F10 (5 A) in the passenger compartment fuse box (see 81C, Fuse

box).

Check the connection and condition (possible wiring damage) of the connectors of components 1175,1094 and

1016.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check the connection and condition (possible wiring damage) of intermediate connector R107.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Connector of components 1175, 1094, 1016 and intermediate union R107 disconnected.

–check the insulation and continuity of connection AP5 between components 1175 and 1016.

–check the insulation and continuity of connection AP5 between component 1094 and intermediate connector

R107.

–check the insulation and continuity of connection MAM of component 1175 (tightness, oxidation, etc.).

If the connection or connections are faulty (see Technical Note 6015A, Electrical wiring repair, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

ESP_V05_DF189

Page 60 of 101

38C-60

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF190

PRESENT

OR

STOREDCOMBINED SENSOR

1.DEF: Sensor internal electronic fault

2.DEF: Sensor incorrectly fitted

3.DEF: Abnormal voltage

NOTESUse the Wiring Diagram Technical Note for New Twingo.

1.DEF

NOTESNone.

Replace component 1175 (see MR 411 Mechanical, 38C, Anti-lock braking system, Lateral acceleration and

yaw speed sensor, Removal - Refitting) then it is essential to clear the ESP sensor offsets using command

RZ011 Sensor offsets.

2.DEF

NOTESNone.

Check the connection and condition (possible wiring damage) of the connector of component 1094.

Check the connection and condition (possible wiring damage) of the connector of component 1175.

Check the connection and condition (possible wiring damage) of intermediate connector R107.

If the connector is faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring: Precautions for

repair), repair the connector, otherwise replace the wiring.

Check the continuity of connections 4AP and 4AH between components 1094 and 1175.

If the connection or connections are faulty (see Technical Note 6015A, Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring, otherwise replace it.

Check that component 1175 is fitted and attached correctly (the arrow indicates the front of the vehicle).

ESP_V05_DF190

Page 61 of 101

38C-61

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF190

CONTINUED

3.DEFNOTESNone.

Check the tightness and condition of the battery terminals (see 80A, Battery).

Check the charging circuit (see 16A, Starting - Charging).

Apply the fault finding procedure for fault DF189 Combined sensor circuit.

Page 65 of 101

38C-65

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool

If the fault is still present, contact the Techline.

V3 MR-413-X44-38C050$102.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of faults38C

Bosch 8.1 ESP

Vdiag No.: 05

DF216

PRESENT

OR

STOREDSTEERING WHEEL ANGLE PROGRAMMING OFFSET

NOTESConditions for applying the fault finding procedure to stored faults:

The fault is declared present after an extended road test.

With the steering wheel horizontal and the wheels set straight ahead (the wheels must be directly in line with the

vehicle), read the value of the steering wheel angle using parameter PR033 Steering wheel angle.

If the value is not close to 0 ± 5˚, calibrate component 583 using command VP003 Steering wheel angle sensor

(see Configurations and programming).

Clear the ESP sensor offsets using command RZ011 Sensor offsets.

With the steering wheel horizontal and the wheels set straight ahead, turn the steering wheel a quarter of a turn

to the left.

Using parameter PR033 Steering wheel angle, check that the steering wheel angle value is close to - 90.

With the steering wheel horizontal and the wheels set straight ahead, turn the steering wheel a quarter of a turn

to the right.

Using parameter PR033 Steering wheel angle, check that the steering wheel angle value is close to + 90.

If the values are not correct, replace component 583 (see MR 411, Mechanical, 36A, Steering assembly,

Steering column, Removal - Refitting).

Drive in a straight line.

If the steering wheel is not horizontal when the vehicle is driving straight ahead (the vehicle "pulls" to the left or

right).

Check the conformity of the tyres, pressures, wear, and dimensions (see MR 411, Mechanical, 35A, Wheels and

tyres, Tyres: Identification and Tyre pressure, Identification).

Replace the tyre(s) if necessary (see MR 411, Mechanical, 35A, Wheels and tyres, Tyres, Removal -

Refitting).

Adjust the wheel alignment (see MR 411, Mechanical, 30A, General information, Front axle: Adjustment).

With the steering wheel horizontal and the wheels set straight ahead, calibrate component 583 using command

VP003 Steering wheel angle sensor.

Clear the ESP sensor offsets using command RZ011 Sensor offsets.

ESP_V05_DF216

Page 77 of 101

38C-77

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V3 MR-413-X44-38C050$140.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

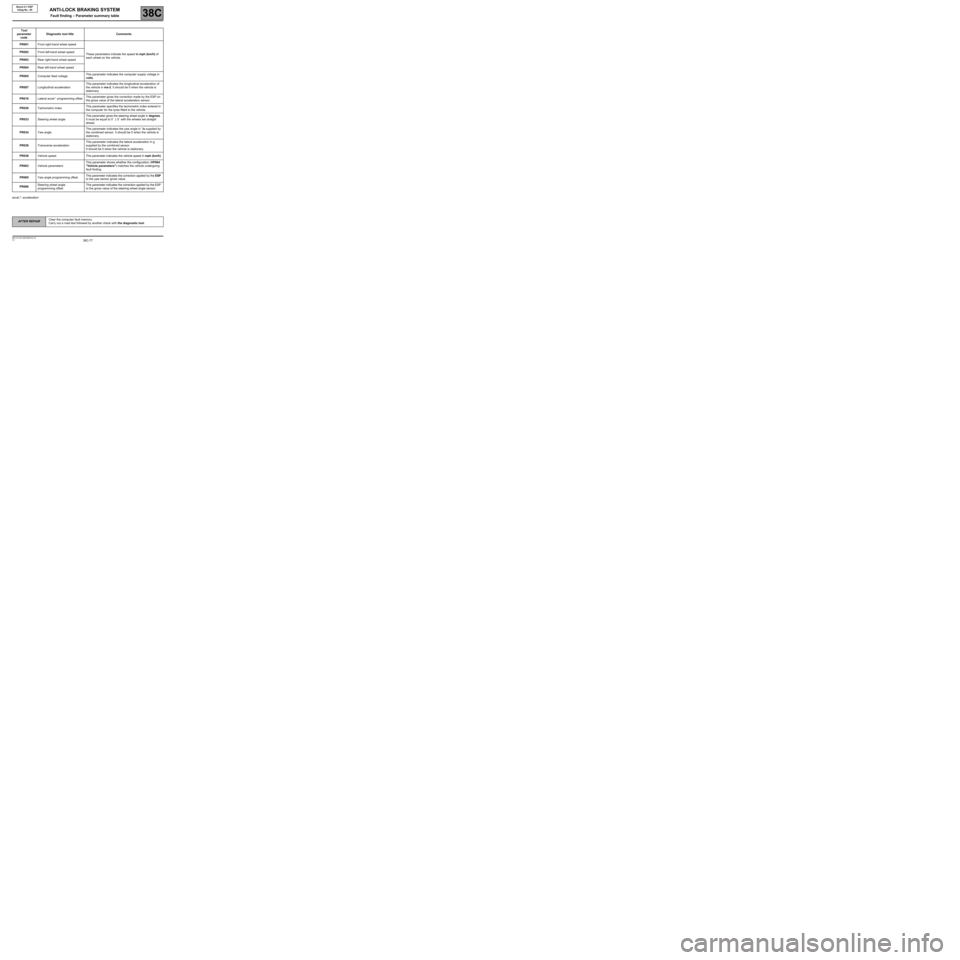

accel.*: accelerationTool

parameter

codeDiagnostic tool title Comments

PR001Front right-hand wheel speed

These parameters indicate the speed in mph (km/h) of

each wheel on the vehicle. PR002Front left-hand wheel speed

PR003Rear right-hand wheel speed

PR004Rear left-hand wheel speed

PR005Computer feed voltageThis parameter indicates the computer supply voltage in

volts.

PR007Longitudinal accelerationThis parameter indicates the longitudinal acceleration of

the vehicle in ms-2. It should be 0 when the vehicle is

stationary.

PR016Lateral accel.* programming offsetThis parameter gives the correction made by the ESP on

the gross value of the lateral acceleration sensor.

PR030Tachometric indexThis parameter specifies the tachometric index entered in

the computer for the tyres fitted to the vehicle.

PR033Steering wheel angleThis parameter gives the steering wheel angle in degrees.

It must be equal to 0˚

± 5˚ with the wheels set straight

ahead.

PR034Yaw angleThis parameter indicates the yaw angle in ˚/s supplied by

the combined sensor. It should be 0 when the vehicle is

stationary.

PR036Transverse accelerationThis parameter indicates the lateral acceleration in g

supplied by the combined sensor.

It should be 0 when the vehicle is stationary.

PR038Vehicle speedThis parameter indicates the vehicle speed in mph (km/h).

PR063Vehicle parametersThis parameter shows whether the configuration (VP004

"Vehicle parameters") matches the vehicle undergoing

fault finding.

PR065Yaw angle programming offsetThis parameter indicates the correction applied by the ESP

to the yaw sensor gross value.

PR066Steering wheel angle

programming offsetThis parameter indicates the correction applied by the ESP

to the gross value of the steering wheel angle sensor.

ANTI-LOCK BRAKING SYSTEM

Fault finding – Parameter summary table

Page 78 of 101

38C-78

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V3 MR-413-X44-38C050$150.mif

38C

Bosch 8.1 ESP

Vdiag No.: 05

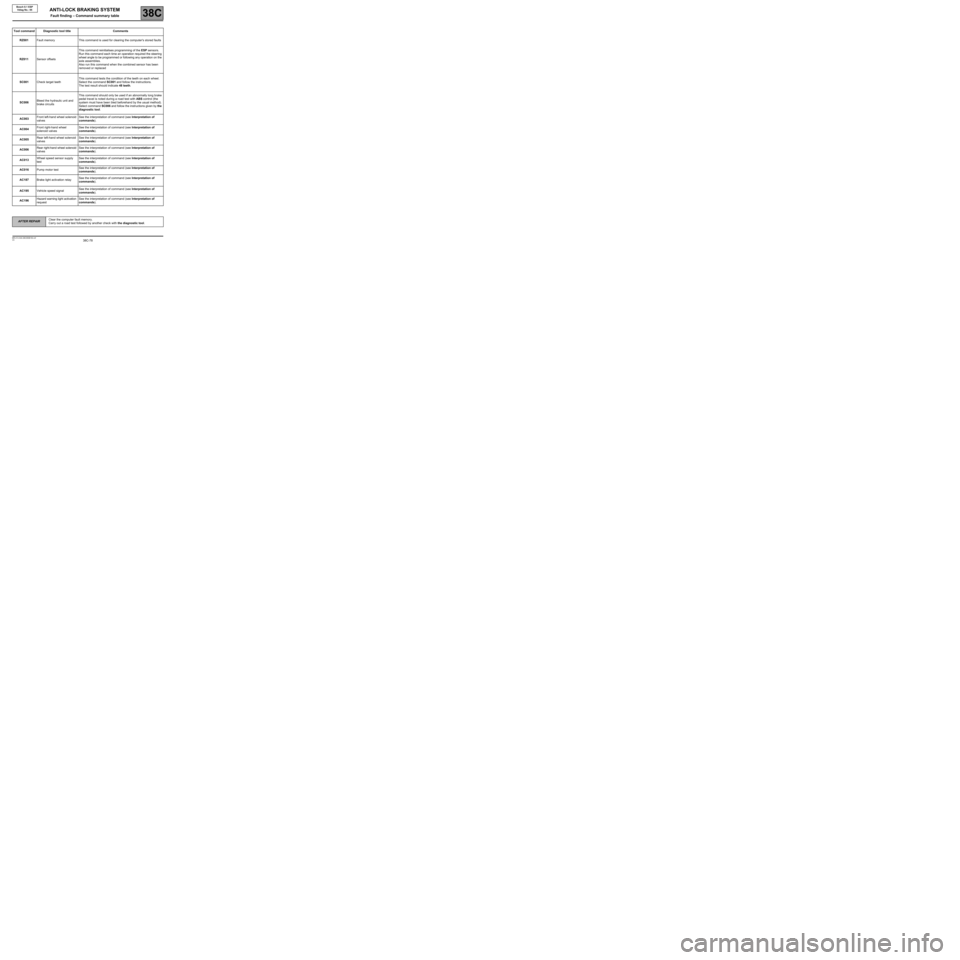

Tool command Diagnostic tool title Comments

RZ001Fault memory This command is used for clearing the computer's stored faults

RZ011Sensor offsetsThis command reinitialises programming of the ESP sensors.

Run this command each time an operation required the steering

wheel angle to be programmed or following any operation on the

axle assemblies.

Also run this command when the combined sensor has been

removed or replaced

SC001Check target teethThis command tests the condition of the teeth on each wheel.

Select the command SC001 and follow the instructions.

The test result should indicate 48 teeth.

SC006Bleed the hydraulic unit and

brake circuitsThis command should only be used if an abnormally long brake

pedal travel is noted during a road test with ABS control (the

system must have been bled beforehand by the usual method).

Select command SC006 and follow the instructions given by the

diagnostic tool.

AC003Front left-hand wheel solenoid

valvesSee the interpretation of command (see Interpretation of

commands).

AC004Front right-hand wheel

solenoid valvesSee the interpretation of command (see Interpretation of

commands).

AC005Rear left-hand wheel solenoid

valvesSee the interpretation of command (see Interpretation of

commands).

AC006Rear right-hand wheel solenoid

valvesSee the interpretation of command (see Interpretation of

commands).

AC013Wheel speed sensor supply

testSee the interpretation of command (see Interpretation of

commands).

AC016Pump motor testSee the interpretation of command (see Interpretation of

commands).

AC187Brake light activation relaySee the interpretation of command (see Interpretation of

commands).

AC195Vehicle speed signalSee the interpretation of command (see Interpretation of

commands).

AC196Hazard warning light activation

requestSee the interpretation of command (see Interpretation of

commands).

ANTI-LOCK BRAKING SYSTEM

Fault finding – Command summary table

Page 80 of 101

38C-80

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V3 MR-413-X44-38C050$160.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Interpretation of commands38C

Bosch 8.1 ESP

Vdiag No.: 05

AC013WHEEL SPEED SENSOR SUPPLY TEST

NOTESConditions of use of the command.

Ignition on, engine off.

This command is used to test the supply to every wheel speed sensor.

Select command AC013 and check for 12 V between:

–connections 4T and 4S of component 150,

–connections 4H and 4G of component 151,

–connections 4E and 4C of component 153,

–connections 4N and 4M of component 152.

ESP_V05_AC013

Page 88 of 101

38C-88

AFTER REPAIRClear the computer fault memory.

Carry out a road test followed by another check with the diagnostic tool.

V3 MR-413-X44-38C050$180.mif

ANTI-LOCK BRAKING SYSTEM

Fault finding – Fault finding chart38C

Bosch 8.1 ESP

Vdiag No.: 05

ALP2 Locking or braking of one or more wheels

NOTESOnly consult this customer complaint after a full check with the diagnostic tool.

Check the conformity of the mechanical components (see MR 411, Mechanical,

30A, General information, Brake, Specifications).

REMINDERLocking of wheels on a vehicle fitted with ABS or squealing of the tyres, which feels like

locking to the customer, may be linked to normal operation of the system and should not

always be considered a fault.

Braking with ABS regulation on very poor roads can cause significant squealing.

However, if the wheel(s) is/are actually locking, lift the vehicle in order to be able to rotate the wheels and check:

Possible inversion when connecting the speed sensors.

Use parameters PR001 Front right-hand wheel speed, PR002 Front left-hand wheel speed, PR003 Rear right-

hand wheel speed and PR004 Rear left-hand wheel speed whilst slowly turning the wheels in question and

checking the consistency of the results obtained.

If the value measured is zero, rotate the other wheels to confirm an electrical inversion of the sensors and repair

the wiring harness.

If a single reading is incorrect:

–Check that the sensor casing is secured when rotating.

–Check that the wheel speed sensor mounting is in good condition.

–If that is unsuccessful, replace the corresponding sensor and repeat the check procedure (see MR 411

Mechanical, 38C, Anti-lock braking system, Wheel speed sensor: Removal - Refitting).

–A possible inversion of the pipes on the hydraulic unit (see MR 411, Mechanical, 38C, Anti-lock braking

system, Hydraulic braking unit, List and location of components).

Run commands AC003 Front left-hand wheel solenoid valves, AC004 Front right-hand wheel solenoid

valves, AC005 Rear left-hand wheel solenoid valves and AC006 Rear right-hand wheel solenoid valves while

depressing the brake pedal and check for locking/unlocking cycles on the wheel concerned (see Dealing with

command modes).

If the cycles are not detected on the wheel tested (wheel remains locked), check if they occur on another wheel

(confirmation of a reversal after a repair, see MR 411, Mechanical, 38C, Hydraulic braking unit, List and

location of components).

If the cycles are not detected on a wheel and the pipes have not been inverted, replace component 1094

(see MR 411, Mechanical, 38C, Hydraulic braking unit, Removal- Refitting).

Check that the sensor holder does not rotate (depending on fitting).

Check the quality of the mounting of the wheel speed sensors (correct clipping for the front wheels).

Check the conformity of the targets: the condition and the number of teeth= 48 (using the command SC001

"Check target teeth").

Replace if necessary.

If the fault is still present after these checks, replace component 1094 (see MR 411, Mechanical, 38C, Hydraulic

braking unit, Removal- Refitting).

ESP_V05_ALP2