RENAULT TWINGO RS 2009 2.G Chasiss Owner's Manual

TWINGO RS 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1719/w960_1719-0.png

RENAULT TWINGO RS 2009 2.G Chasiss Owner's Manual

Page 231 of 281

37A-52

MECHANICAL COMPONENT CONTROLS

Clutch pedal switch: Removal - Refitting

CRUISE CONTROL, and 5-SPEED MANUAL GEARBOX

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the dashboard glovebox.

aDisconnect the connector (2) from the clutch pedal

switch.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aTurn the clutch pedal switch (3) a quarter of a turn

anti-clockwise

aRemove the clutch pedal switch from the pedal. Equipment required

Diagnostic tool

119506

119507

121349

Page 232 of 281

37A-53

MECHANICAL COMPONENT CONTROLS

Clutch pedal switch: Removal - Refitting

CRUISE CONTROL, and 5-SPEED MANUAL GEARBOX

37A

REFITTING

I - REFITTING PREPARATIONS OPERATION

a

aMeasure dimension of the piston (4) . If the dimen-

sion (x) is less than 15 mm, carefully pull the end of

the piston (4) to adjust the dimension to between 15

mm minimum and 17 mm maximum.

II - REFITTING OPERATION FOR PART

CONCERNED

aDepress the clutch pedal by hand.

aFit the clutch pedal switch to the pedal.

aLock the clutch pedal switch by turning it a quarter of

a turn clockwise.

aAt the same time, carefully return the clutch pedal.

III - FINAL OPERATION.

aConnect the clutch pedal switch connector.aBe sure to carry out a repair check using Diagnostic

tool.

aRefit the dashboard glovebox.

108436

WARNING

Whenever the clutch pedal switch piston is com-

pletely removed, the switch must be replaced.

WARNING

The switch must be replaced if handling of the

piston results in three adjustments being made.

Note:

The clutch pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in operation.

Page 247 of 281

37A-68

MECHANICAL COMPONENT CONTROLS

Gear control unit: Removal - Refitting

JH3 or JR5

37A

aRemove:

-the nuts (8) ,

-the gear control unit (9) by passing it between the

exhaust system and the tunnel.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit the gear control unit by passing it between the

exhaust pipe and the tunnel

aTorque tighten the gear control unit nuts (12 Nm).

aAttach the sleeve stops of the control cable and gear

selection cable by clipping them to the gearbox.

aAttach the cables to the ball joints.

II - FINAL OPERATION.

aTorque tighten the exhaust clip (21 Nm).

aRefit:

-the heat shields,

-the central console (see Centre console: Remov-

al - Refitting) (57A, Interior equipment).

Note:

It is not necessary to adjust the control cable and

gear selection cable.

Page 250 of 281

37A-71

MECHANICAL COMPONENT CONTROLS

Gear control unit: Adjustment

JB1

37A

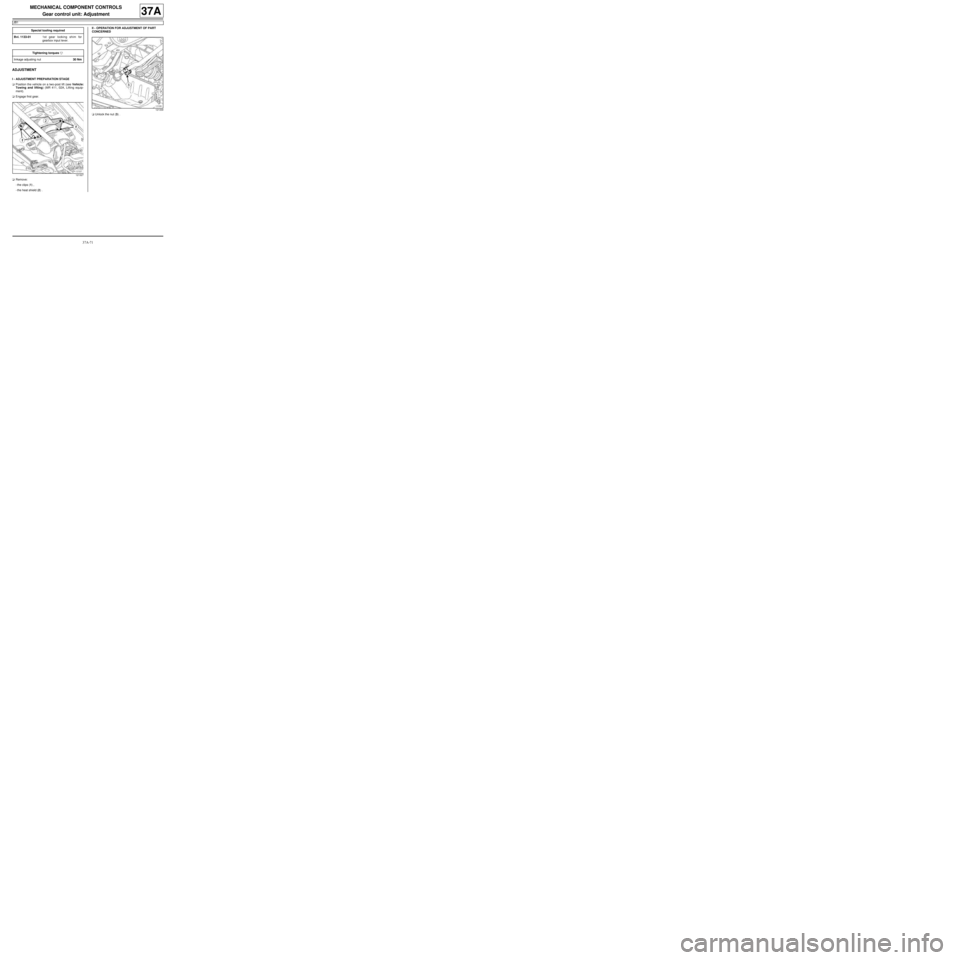

ADJUSTMENT

I - ADJUSTMENT PREPARATION STAGE

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aEngage first gear.

aRemove:

-the clips (1) ,

-the heat shield (2) .II - OPERATION FOR ADJUSTMENT OF PART

CONCERNED

aUnlock the nut (3) . Special tooling required

Bvi. 1133-011st gear locking shim for

gearbox input lever.

Tightening torquesm

linkage adjusting nut30 Nm

121327

121339

Page 251 of 281

37A-72

MECHANICAL COMPONENT CONTROLS

Gear control unit: Adjustment

JB1

37A

aPosition the (Bvi. 1133-01) between the control le-

ver (4) and the gearbox casing.aPosition a 5 mm thick adjustment shim between the

gear lever lower thrust bearing and the lower rail on

the unit.

aHold the gear control lever against the shim.

aTorque tighten the linkage adjusting nut (30 Nm).

aCheck the adjustment value.

aClearance noted at the bottom of the lever (Y) (in

mm):

-first gear engaged = Y1 ,

-second gear engaged = Y2,

Yaverage = (Y1+Y2)/2

5 ≤≤ ≤ ≤

Y

average≤≤ ≤ ≤

8

-adjustment shim = 5 mm.

aRemove the shim.

CHECK

I - CHECKING OPERATION FOR PART

CONCERNED

aCheck gear changes.

18728

18727

121338

Note:

It is preferable to be closer to the maxim um value

of the adjustment inter val.