warning RENAULT TWINGO RS 2009 2.G Chasiss Owner's Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 107 of 281

33A-9

REAR AXLE COMPONENTS

Rear brake calliper mounting: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRelease the parking brake.

aRemove:

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

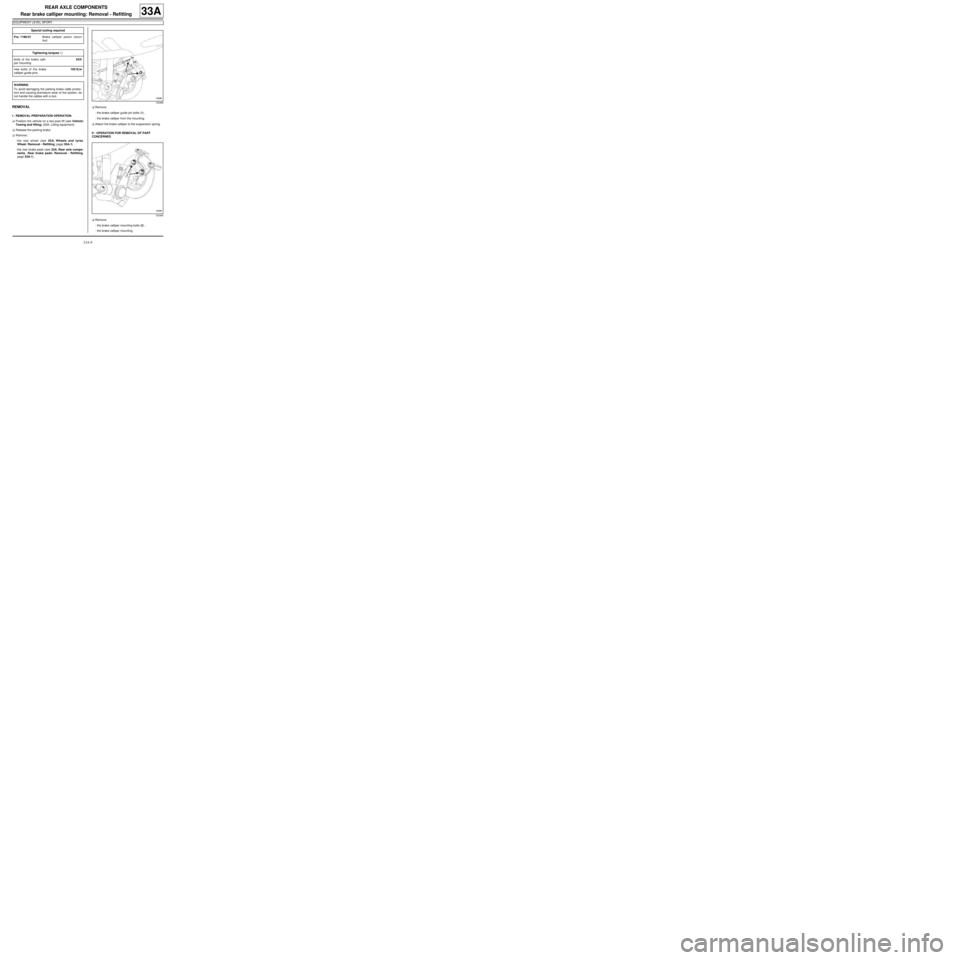

page 33A-1) .aRemove:

-the brake calliper guide pin bolts (1) ,

-the brake calliper from the mounting.

aAttach the brake calliper to the suspension spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the brake calliper mounting bolts (2) ,

-the brake calliper mounting. Special tooling required

Fre. 1190-01Brake calliper piston return

tool.

Tightening torquesm

bolts of the brake calli-

per mountingXXX

new bolts of the brake

calliper guide pins105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

132465

Page 109 of 281

33A-11

REAR AXLE COMPONENTS

Rear brake disc: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

Brake discs cannot be reground. If there is excessive

scoring or wear, they will need to be replaced (see

30A, General information, Brake: Specifications,

page 30A-19) .

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the rear wheels (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) ,

-the rear brake pads (see 33A, Rear axle compo-

nents, Rear brake pads: Removal - Refitting,

page 33A-1) .aRemove:

-the brake calliper mounting bolts (1) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "calliper mounting - brake calliper" to the

shock absorber spring.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the hub's nut cover (2) . Equipment required

par ts washer

Tightening torquesm

new hub nut175 N.m

brake calliper mounting

bolts105 N.m

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132467

132456

Page 120 of 281

33A-22

REAR AXLE COMPONENTS

Rigid brake pipe: Removal - Refitting

C44

33A

The pipes have a rigid section and a flexible section.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).

aFit the pedal press tool to the brake pedal to limit

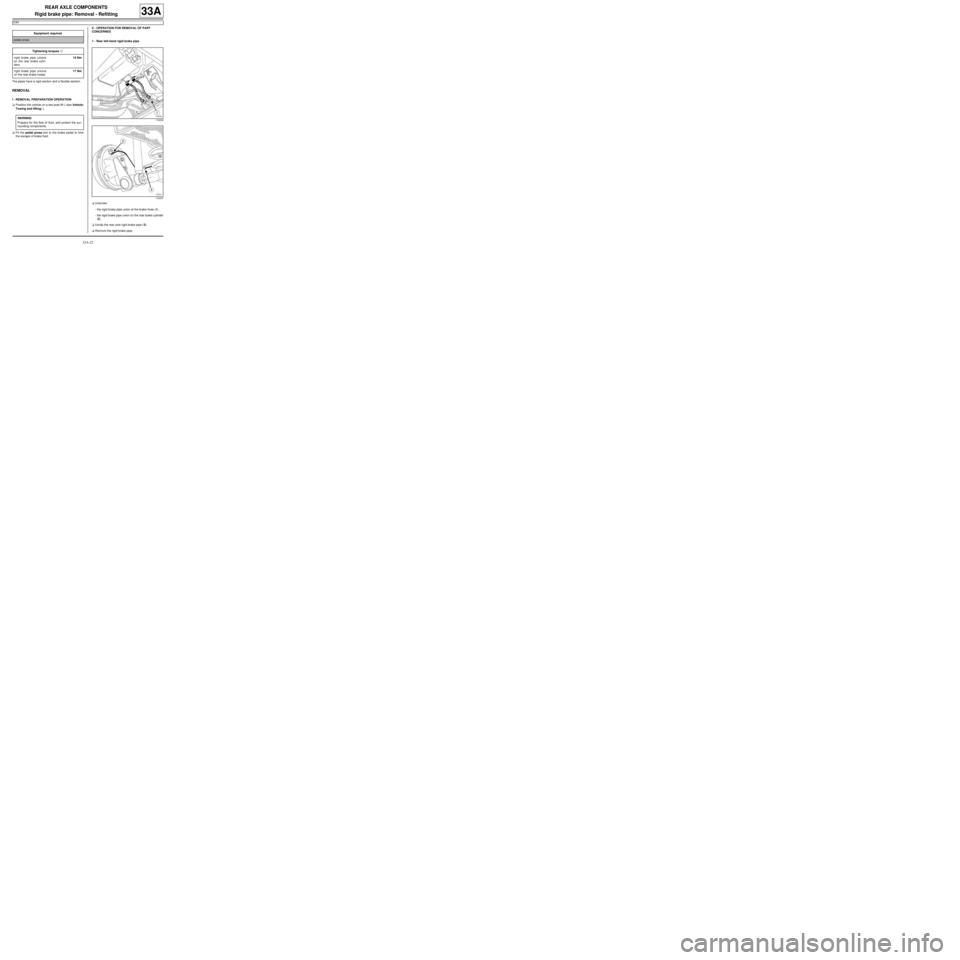

the escape of brake fluid.II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Rear left-hand rigid brake pipe

aUnscrew:

-the rigid brake pipe union at the brake hose (1) .

-the rigid brake pipe union on the rear brake cylinder

(2) .

aUnclip the rear axle rigid brake pipe (3) .

aRemove the rigid brake pipe. Equipment required

pedal press

Tightening torquesm

rigid brake pipe unions

on the rear brake cylin-

ders15 Nm

rigid brake pipe unions

on the rear brake hoses17 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

119339

119337

Page 121 of 281

33A-23

REAR AXLE COMPONENTS

Rigid brake pipe: Removal - Refitting

C44

33A

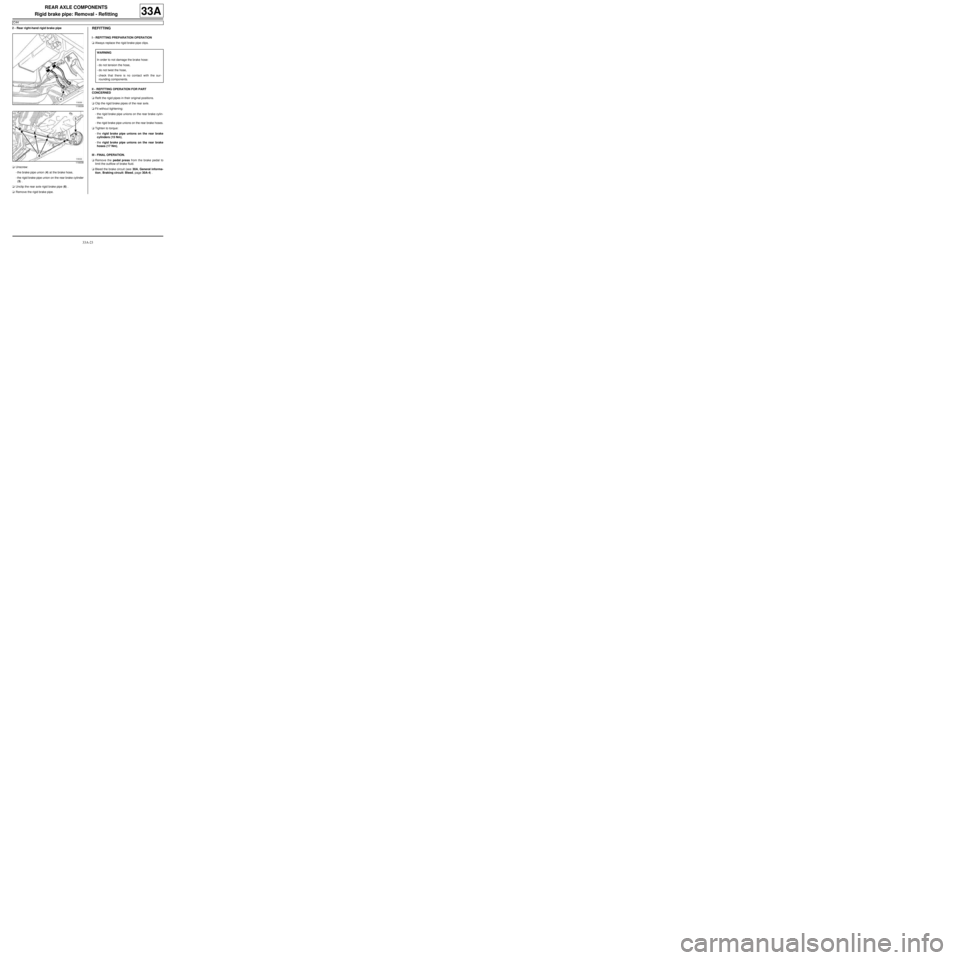

2 - Rear right-hand rigid brake pipe

aUnscrew:

-the brake pipe union (4) at the brake hose,

-the rigid brake pipe union on the rear brake cylinder

(5) .

aUnclip the rear axle rigid brake pipe (6) .

aRemove the rigid brake pipe.REFITTING

I - REFITTING PREPARATION OPERATION

aAlways replace the rigid brake pipe clips.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the rigid pipes in their original positions.

aClip the rigid brake pipes of the rear axle.

aFit without tightening:

-the rigid brake pipe unions on the rear brake cylin-

ders.

-the rigid brake pipe unions on the rear brake hoses.

aTighten to torque:

-the rigid brake pipe unions on the rear brake

cylinders (15 Nm),

-the rigid brake pipe unions on the rear brake

hoses (17 Nm),

III - FINAL OPERATION.

aRemove the pedal press from the brake pedal to

limit the outflow of brake fluid.

aBleed the brake circuit (see 30A, General informa-

tion, Braking circuit: Bleed, page 30A-4) .

119339

119338

WARNING

In order to not damage the brake hose:

-do not tension the hose,

-do not twist the hose,

-check that there is no contact with the sur-

rounding components.

Page 122 of 281

33A-24

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

33A

If a shock absorber is replaced, the shock absorber on

the opposite side must also be replaced.

REMOVAL

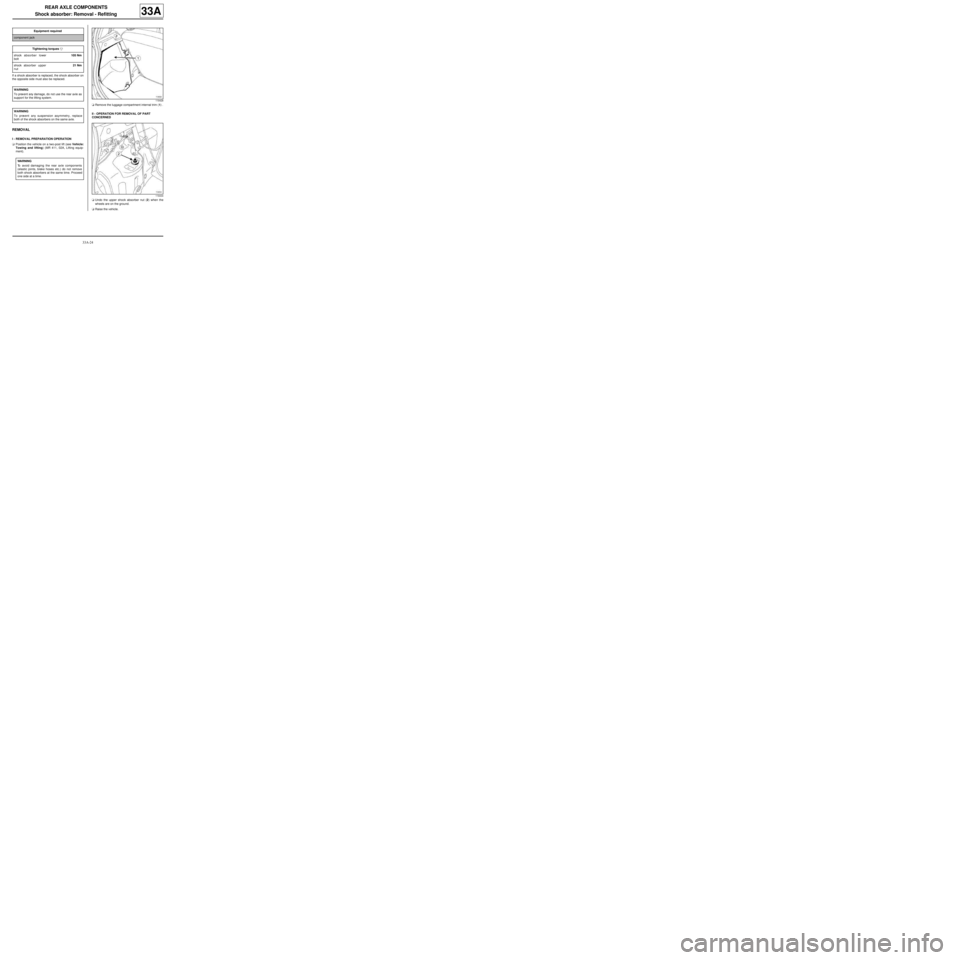

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).aRemove the luggage compartment internal trim (1) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the upper shock absorber nut (2) when the

wheels are on the ground.

aRaise the vehicle. Equipment required

component jack

Tightening torquesm

shock absorber lower

bolt105 Nm

shock absorber upper

nut21 Nm

WARNING

To prevent any damage, do not use the rear axle as

support for the lifting system.

WARNING

To prevent any suspension asymmetry, replace

both of the shock absorbers on the same axle.

WARNING

To avoid damaging the rear axle components

(elastic joints, brake hoses etc.) do not remove

both shock absorbers at the same time. Proceed

one side at a time.

119428

119434

Page 124 of 281

33A-26

REAR AXLE COMPONENTS

Shock absorber: Removal - Refitting

G44

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (MR 411, 02A, Lifting equip-

ment).

aRemove the luggage compartment interior trim (see

Rear loading trim: Removal - Refitting) (MR 412,

71A, Body internal trim).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aUndo the upper shock absorber nut (1) when the

wheels are on the ground.

aRaise the vehicle. Equipment required

component jack

Tightening torquesm

lower shock absorber

bolt105 Nm

shock absorber upper

nut21 Nm

WARNING

To prevent any damage, do not use the rear axle as

support for the lifting system.

WARNING

To prevent any suspension asymmetry, replace

both of the shock absorbers on the same axle.

WARNING

To avoid damaging the rear axle components

(elastic joints, brake hoses etc.) do not remove

both shock absorbers at the same time. Proceed

one side at a time.

119434

Page 129 of 281

33A-31

REAR AXLE COMPONENTS

Rear drum bearing: Removal - Refitting

33A

REFITTING

I - REFITTING PREPARATIONS OPERATION

aClean:

-the internal and external surfaces of the new bear-

ing in contact with the drum,

-the drum surfaces in contact with the new bearing.

aIt is essential to check the condition of the surface of

the bore of the drum before refitting the bearing. It is

essential to replace the stub axle carrier if it is faulty.a

II - REFITTING OPERATION FOR PART

CONCERNED

aFit the bearing until it presses the shoulder using a

tube with a diameter between 51 mm and 54 mm

and using a hydraulic press.

aRefit the rubber ring.

III - FINAL OPERATION.

aRefit:

-the rear brake drum (see 33A, Rear axle compo-

nents, Rear brake drum: Removal - Refitting,

page 33A-19) ,

-the rear wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) .

117348

WARNING

Do not press the bearing's inner bush so as to

avoid damaging the bearing (very high shrink-fit-

ting force).

121332

Note:

Take care not to press the ABS target (4) when

refitting the bear ing.

Page 132 of 281

33A-34

REAR AXLE COMPONENTS

Rear stub axle carrier: Removal - Refitting

EQ UIPMENT LEVEL SPORT

33A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the rear wheel (see 35A, Wheels and ty-

res, Wheel: Removal - Refitting, page 35A-1) .aUnclip the parking brake cable from the calliper at

(1) .

aRemove:

-the brake calliper mounting bolts (2) ,

-the "brake calliper mounting - brake calliper" as-

sembly.

aAttach the "brake calliper mounting - brake calliper"

assembly to the suspension spring.

aRemove the rear brake disc (see 33A, Rear axle

components, Rear brake disc: Removal - Refit-

ting, page 33A-11) . Equipment required

component jack

Tightening torquesm

new bolts of the rear

stub axle carrier53 N.m

lower bolt of the rear

shock absorber105 N.m

new bolts of the brake

calliper mounting105 Nm

WARNING

To avoid damaging the parking brake cable protec-

tors and causing premature wear of the system, do

not handle the cables with a tool.

132468

Page 146 of 281

35A-6

WHEELS AND TYRES

Wheel: Balancing

35A

aEnter the specific wheel parameters when starting

the wheel balancer.

aStart the wheel balancer and check the wheel bal-

ance, which should be 0 g on each plane of the

wheel.

aIf this is not the case, remove the old wheel balanc-

ing weights and repeat the wheel balancing proce-

dure, checking that the wheel balance equals 0 on

each wheel plane.

IV - FINAL OPERATION

aRefit the wheel (see 35A, Wheels and tyres,

Wheel: Removal - Refitting, page 35A-1) . WARNING

To avoid detachment of the balance weights, use

only weights which correspond to the vehicle

wheel rims.

Page 150 of 281

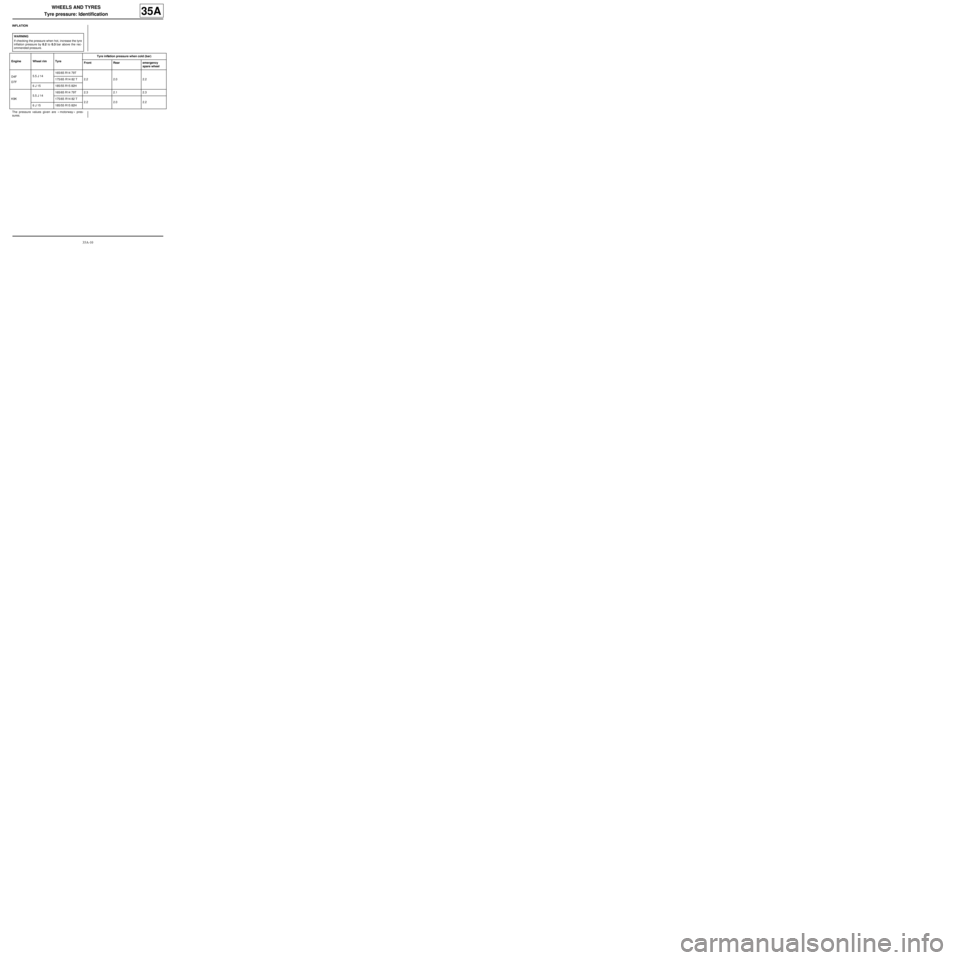

35A-10

WHEELS AND TYRES

Tyre pressure: Identification

35A

INFLATION

The pressure values given are « motorway » pres-

sures.WARNING

If checking the pressure when hot, increase the tyre

inflation pressure by 0.2 to 0.3 bar above the rec-

ommended pressure.

Engine Wheel rim TyreTyre inflation pressure when cold (bar)

Front Rear emergency

spare wheel

D4F

D7F5.5 J 14165/65 R14 79T

2.2 2.0 2.2 175/65 R14 82 T

6 J 15 185/55 R15 82H

K9K5.5 J 14165/65 R14 79T 2.3 2.1 2.3

175/65 R14 82 T

2.2 2.0 2.2

6 J 15 185/55 R15 82H