warning RENAULT TWINGO RS 2009 2.G Chasiss Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 281

Page 158 of 281

36A-7

STEERING ASSEMBLY

Steering column: Removal - Refitting

LEFT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

aLock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags - Pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aSet the wheels straight ahead.

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

- Pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) ,-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Steering column switch

assembly),

-the immobiliser antenna/transponder ring (see

Transponder ring: Removal - Refitting) (MR

411, 82A, Immobiliser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser).

II - REMOVAL OPERATION FOR PART

CONCERNED

aRemove the cover from the universal joint (1) (do not

keep).

aRemove:

-the universal joint bolt (2) (do not keep),

-the universal joint nut (do not keep). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steering column to the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

119544

Page 162 of 281

36A-11

STEERING ASSEMBLY

Steering column: Removal - Refitting

RIGHT-HAND DRIVE

36A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aUnlock the steering column.

a

Lock the airbag computer using the Diagnostic tool

(see Fault finding - Replacement of components)

(MR 413, 88C, Airbags and seat belt pretensioners).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (MR 411, 80A, Battery).

aRemove:

-the driver's front airbag (see Driver's frontal air-

bag: Removal - Refitting) (MR 411, 88C, Airbags

and pretensioners),

-the steering wheel (see 36A, Steering assembly,

Steering wheel: Removal - Refitting, page 36A-

23) .aRemove the rev counter (see Rev counter: Remov-

al - Refitting) (MR 411, 83A, Instrument panel).

aRemove:

-the dashboard lower cover (1) ,

-the bolts (2) from the steering wheel lower cover,

-the steering wheel lower cover (3) ,

-the steering wheel upper cover (4) ,

-the steering column switch assembly (see Steer-

ing column switch assembly: Removal - Refit-

ting) (MR 411, 84A, Control - Signals),

-the antenna/transponder ring (see Transponder

ring: Removal - Refitting) (MR 411, 82A, Immobi-

liser),

-the ignition switch if the steering column is replaced

(see Ignition switch: Removal - Refitting) (MR

411, 82A, Immobiliser). Equipment required

Diagnostic tool

Tightening torquesm

bolt connecting the

steer ing column and the

inter mediate shaft30 Nm

steer ing column bolts21 Nm

universal joint bolt24 Nm

IMPORTANT

To avoid any risk of triggering when working on

or near a pyrotechnic component (airbags or pre-

tensioners), lock the airbag computer using the

diagnostic tool.

When this function is activated, all the trigger

lines are inhibited and the airbag warning light on

the instrument panel lights up continuously (igni-

tion on).

IMPORTANT

Never handle the pyrotechnic systems (preten-

sioners or airbags) near to a source of heat or

naked flame - they may be triggered.

ENGINE REV COUNTER

123870

Page 174 of 281

36A-23

STEERING ASSEMBLY

Steering wheel: Removal - Refitting

36A

REMOVAL

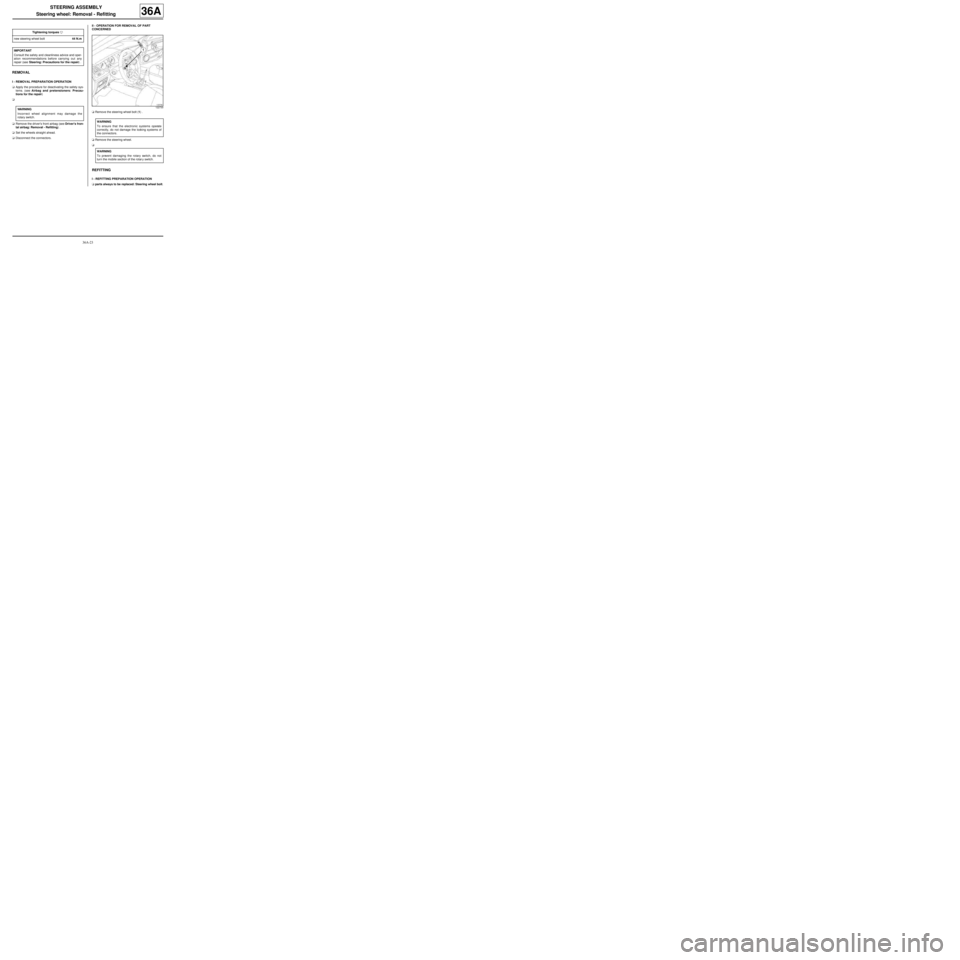

I - REMOVAL PREPARATION OPERATION

aApply the procedure for deactivating the safety sys-

tems. (see Airbag and pretensioners: Precau-

tions for the repair)

a

aRemove the driver's front airbag (see Driver's fron-

tal airbag: Removal - Refitting) .

aSet the wheels straight ahead.

aDisconnect the connectors.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the steering wheel bolt (1) .

aRemove the steering wheel.

a

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Steering wheel bolt. Tightening torquesm

new steering wheel bolt44 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see Steering: Precautions for the repair) .

WARNING

Incorrect wheel alignment may damage the

rotary switch.

122730

WARNING

To ensure that the electronic systems operate

correctly, do not damage the locking systems of

the connectors.

WARNING

To prevent damaging the rotary switch, do not

turn the mobile section of the rotar y switch.

Page 175 of 281

36A-24

STEERING ASSEMBLY

Steering wheel: Removal - Refitting

36A

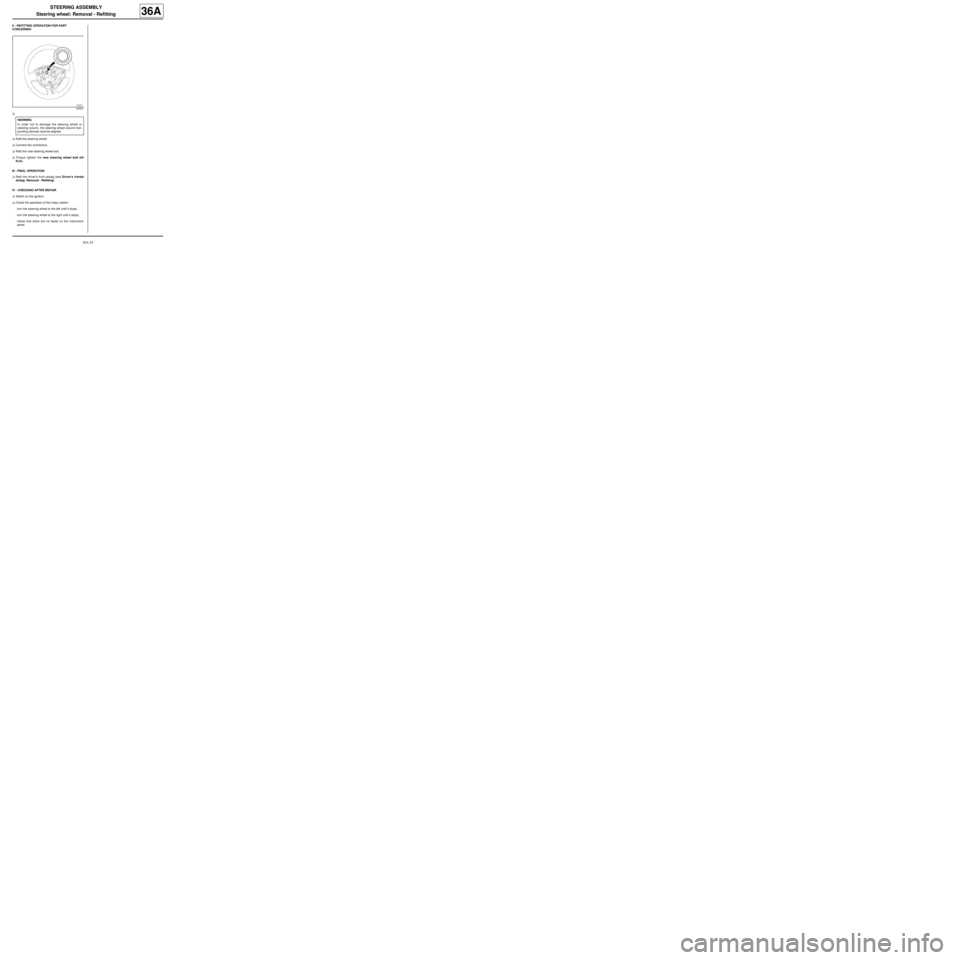

II - REFITTING OPERATION FOR PART

CONCERNED

a

aRefit the steering wheel.

aConnect the connectors.

aRefit the new steering wheel bolt.

aTorque tighten the new steering wheel bolt (44

N.m).

III - FINAL OPERATION

aRefit the driver's front airbag (see Driver's frontal

airbag: Removal - Refitting) .

IV - CHECKING AFTER REPAIR

aSwitch on the ignition.

aCheck the operation of the rotary switch:

-turn the steering wheel to the left until it stops,

-turn the steering wheel to the right until it stops,

-check that there are no faults on the instrument

panel.

105327

WARNING

In order not to damage the steering wheel or

steering column, the steering wheel-column fool-

proofing devices must be aligned.

Page 180 of 281

37A-1

MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal - Refitting

JB1 or JH1 or JH3 or JR5

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the battery (see Battery: Removal - Refitting)

(80A, Battery)

-the battery tray (see Battery tray: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the injection computer (see Petrol injection com-

puter: Removal - Refitting) (17B, Petrol injection),

-the injection computer support.II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the fuel filler cap from the brake fluid reser-

voir (1) .

aDisconnect the brake fluid level sensor connector (2)

.

aDrain the brake fluid reservoir with a syringe. Tightening torquesm

brake fluid reservoir bolt4 Nm

master cylinder nuts on

the brake servo25 Nm

rigid brake pipe unions

on the master cylinder15 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

K4M

121344

Page 184 of 281

37A-5

MECHANICAL COMPONENT CONTROLS

Master cylinder: Removal - Refitting

RIGHT-HAND DRIVE

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).aRemove:

-the fuel vapour recirculation solenoid valve pipes

(1) ,

-the fuel vapour recirculation solenoid valve con-

nector (2) ,

-the fuel vapour recirculation solenoid valve (3) ,

-the fuel vapour recirculation solenoid valve support

nut (4) ,

-the fuel vapour recirculation solenoid valve support

(5) . Tightening torquesm

brake fluid reservoir bolt4 Nm

master cylinder bolts on

the brake servo25 Nm

rigid brake pipe unions

on the master cylinder15 Nm

WARNING

Prepare for the flow of fluid, and protect the sur-

rounding components.

D4F or D7F or K4M

123852

Page 204 of 281

37A-25

MECHANICAL COMPONENT CONTROLS

Vacuum pump: Removal - Refitting

K9K

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the engine cover,

-the air filter unit (see Air filter unit: Removal - Re-

fitting) (MR 411, 12A, Fuel mixture).

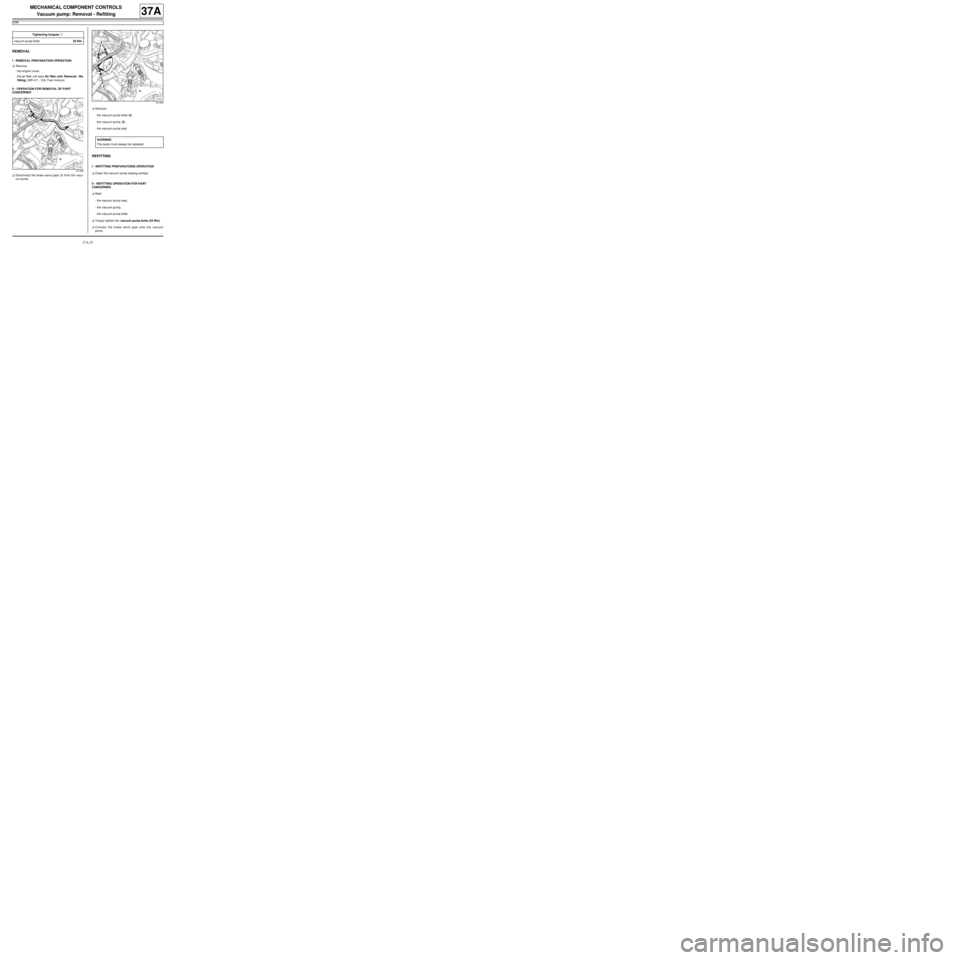

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake servo pipe (1) from the vacu-

um pump.aRemove:

-the vacuum pump bolts (2) ,

-the vacuum pump (3) ,

-the vacuum pump seal.

REFITTING

I - REFITTING PREPARATIONS OPERATION

aClean the vacuum pump sealing surface.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the vacuum pump seal,

-the vacuum pump,

-the vacuum pump bolts.

aTorque tighten the vacuum pump bolts (25 Nm).

aConnect the brake servo pipe onto the vacuum

pump. Tightening torquesm

vacuum pump bolts25 Nm

121356

121355

WARNING

The seals m ust always be replaced.

Page 221 of 281

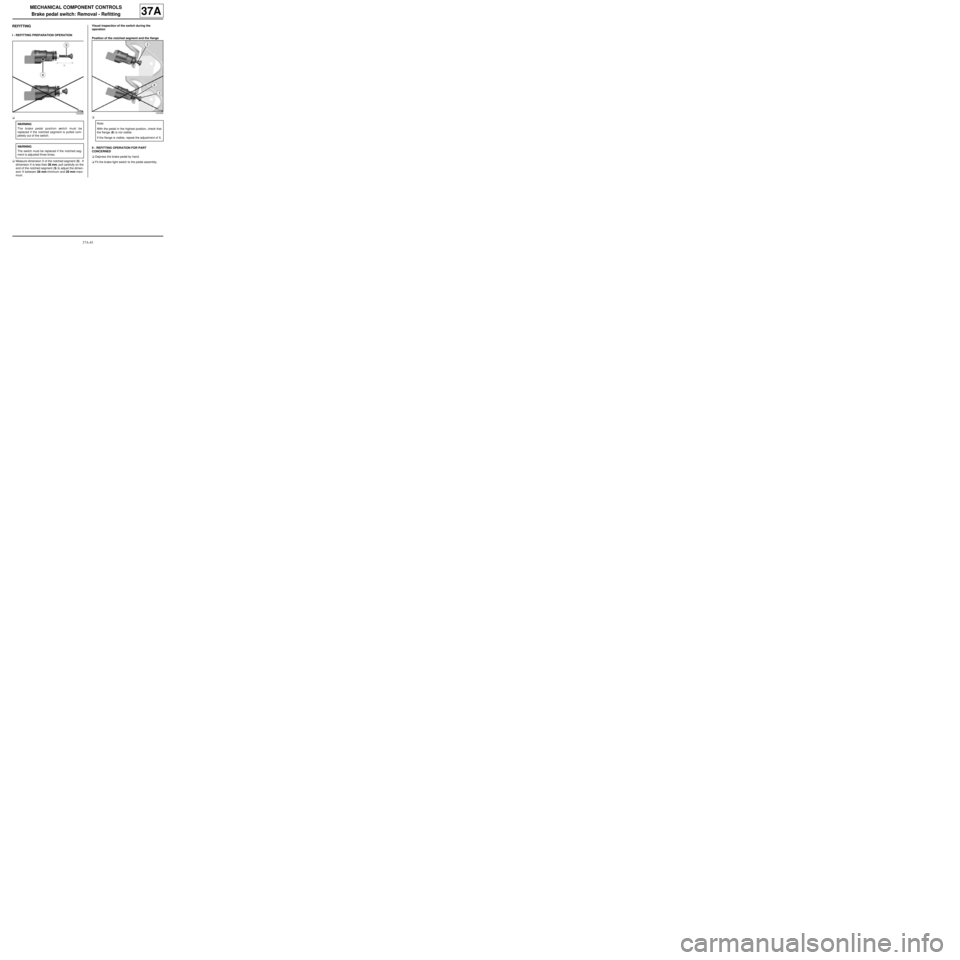

37A-42

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

REMOVAL

I - REMOVAL PREPARATION OPERATION

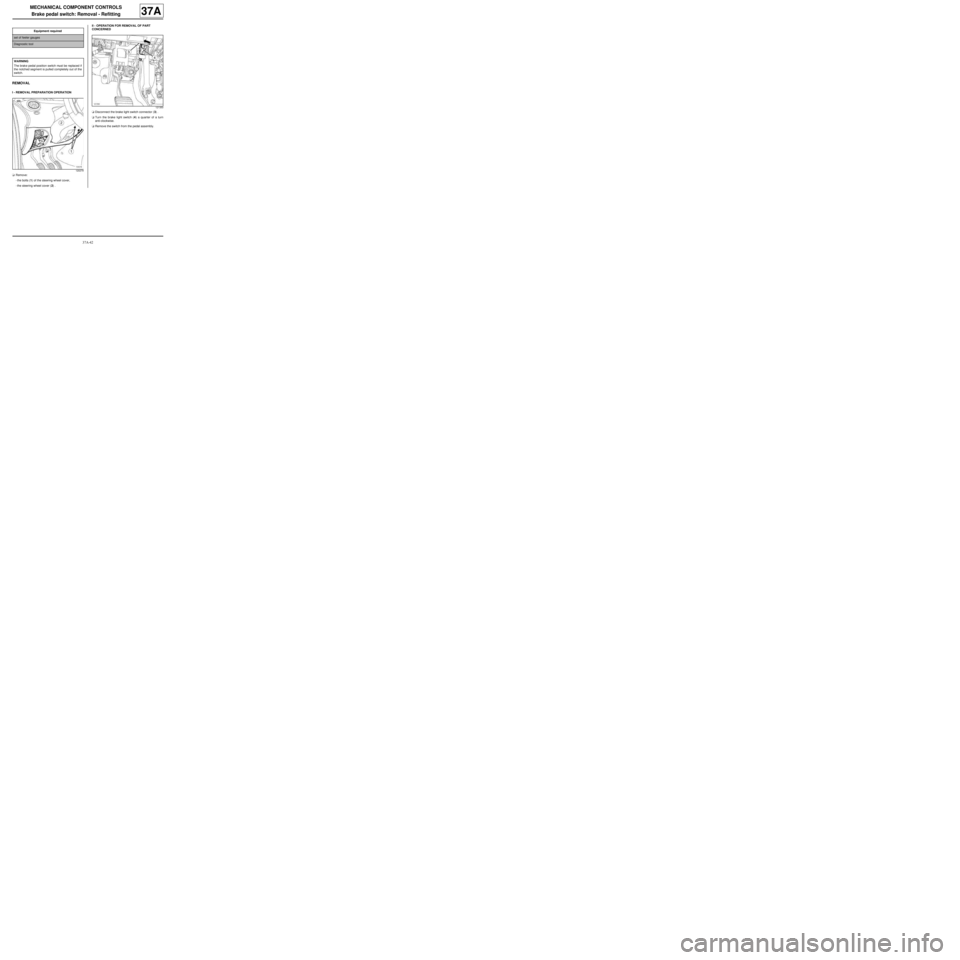

aRemove:

-the bolts (1) of the steering wheel cover,

-the steering wheel cover (2) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the brake light switch connector (3) .

aTurn the brake light switch (4) a quarter of a turn

anti-clockwise.

aRemove the switch from the pedal assembly. Equipment required

set of feeler gauges

Diagnostic tool

WARNING

The brake pedal position switch must be replaced if

the notched segment is pulled completely out of the

switch.

120279

121350

Page 222 of 281

37A-43

MECHANICAL COMPONENT CONTROLS

Brake pedal switch: Removal - Refitting

37A

REFITTING

I - REFITTING PREPARATION OPERATION

a

aMeasure dimension X of the notched segment (5) . If

dimension X is less than 28 mm, pull carefully on the

end of the notched segment (5) to adjust the dimen-

sion X between 28 mm minimum and 29 mm maxi-

mum.Visual inspection of the switch during the

operation

Position of the notched segment and the flange

a

II - REFITTING OPERATION FOR PART

CONCERNED

aDepress the brake pedal by hand.

aFit the brake light switch to the pedal assembly.

134304

WARNING

The brake pedal position switch must be

replaced if the notched segment is pulled com-

pletely out of the switch.

WARNING

The switch must be replaced if the notched seg-

ment is adjusted three times.

134305

Note:

With the pedal in the highest position, check that

the flange (8) is not visible.

If the flange is visible, repeat the adjustment of X.

Page 232 of 281

37A-53

MECHANICAL COMPONENT CONTROLS

Clutch pedal switch: Removal - Refitting

CRUISE CONTROL, and 5-SPEED MANUAL GEARBOX

37A

REFITTING

I - REFITTING PREPARATIONS OPERATION

a

aMeasure dimension of the piston (4) . If the dimen-

sion (x) is less than 15 mm, carefully pull the end of

the piston (4) to adjust the dimension to between 15

mm minimum and 17 mm maximum.

II - REFITTING OPERATION FOR PART

CONCERNED

aDepress the clutch pedal by hand.

aFit the clutch pedal switch to the pedal.

aLock the clutch pedal switch by turning it a quarter of

a turn clockwise.

aAt the same time, carefully return the clutch pedal.

III - FINAL OPERATION.

aConnect the clutch pedal switch connector.aBe sure to carry out a repair check using Diagnostic

tool.

aRefit the dashboard glovebox.

108436

WARNING

Whenever the clutch pedal switch piston is com-

pletely removed, the switch must be replaced.

WARNING

The switch must be replaced if handling of the

piston results in three adjustments being made.

Note:

The clutch pedal switch has an automatic adjust-

ment feature, adapting to the pedal position.

The automatic adjustment makes a clicking noise

when in operation.