battery RENAULT TWINGO RS 2009 2.G Electrical Equipment - Petrol Injection Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 348

Page 7 of 348

17B-7V7 MR-413-X44-17B000$010.mif

PETROL INJECTION

Fault finding – Introduction17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

5. FAULT FINDING LOG

You will always be asked for this log:

●when requesting technical assistance from Techline,

●for approval requests when replacing parts for which approval is mandatory,

●to be attached to monitored parts for which reimbursement is requested. The log is needed for warranty

reimbursement, and enables better analysis of the parts removed.

6. SAFETY INSTRUCTIONS

Safety rules must be observed during any work on a component to prevent any material damage or personal injury:

–check the battery voltage to avoid incorrect operation of computer functions,

–use the proper tools. IMPORTANT!IMPORTANT

Any fault on a complex system requires thorough fault finding with the appropriate tools.

The FAULT FINDING LOG, which should be completed during the fault finding procedure,

ensures a record is kept of the procedure carried out. It is an essential document when

consulting the manufacturer.

IT IS THEREFORE ESSENTIAL THAT THE FAULT FINDING LOG IS FILLED OUT EVERY TIME IT IS

REQUESTED BY TECHLINE OR THE WARRANTY RETURNS DEPARTMENT.

Page 13 of 348

17B-13V7 MR-413-X44-17B000$030.mif

PETROL INJECTION

Fault finding – System operation17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Idle speed

The idle speed setpoint is dependent on:

–the coolant temperature,

–the emission control programs,

–air conditioning requirements,

–the position of the gear lever,

–any power-assisted steering operation,

–the passenger compartment heating resistors,

–the oil temperature (engine protection),

–and lastly, the electric power balance (engine speed is increased by a maximum of 160 rpm if the battery voltage

remains below 12.7 V).

Ignition

Advance is calculated for each cylinder, and is limited between - 23˚ to + 72˚, and includes possible corrections due

to pinking.

Anti-pinking correction is the maximum advance value taken from the advance of one of the cylinders. If none of the

cylinders is pinking, this correction is zero.

Richness

For the catalytic converter to operate correctly, adjust around richness 1.

The richness regulation controlled by the upstream sensor which ensures a richness of around 1.

The upstream sensor supplies a voltage according to the image of the average engine richness: the voltage supplied

to the computer represents a Rich-Lean signal.

For the upstream sensor to be operational very rapidly, it is heated. The heating works only when the engine is

running. It is deactivated at speeds above 84 mph (140 km/h) or when the engine is under load.

The downstream sensor is also heated. The command does not activate immediately after starting the engine. It is

activated when the engine is running and has reached its operating temperature. The downstream heating sensor is

deactivated at speeds above 84 mph (140 km/h) or when the engine is under load.

Torque management

The torque structure is the system for managing engine torque. It is required for certain functions such as the

electronic stability program (ESP), automatic transmission (BVA) or sequential gearbox (BVR).

Each computer (ESP, sequential gearbox, automatic transmission) sends a request for torque via the multiplex

network to the injection computer. This intervenes between the torque requests received and the driver's requests

(made via the pedal or the cruise control/speed limiter function). The result of this intervention is the torque setpoint

to be applied. Using the torque setpoint, the structure calculates the throttle position setpoint, the ignition advance

and if the turbocharging function is present, the turbocharging solenoid valve setpoint.

Page 16 of 348

17B-16V7 MR-413-X44-17B000$030.mif

PETROL INJECTION

Fault finding – System operation17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

–DF089 Inlet manifold pressure sensor fault 1.DEF: Signal inconsistency.

Or 2. DEF: Open circuit or short circuit.

Or 3. DEF: Non-compliance with emission control standards.

–DF091 Vehicle speed signal in 1.DEF: No multiplex signals or invalid values.

Or 2. DEF: Non-compliance with emission control standards.

–DF001 Coolant temperature sensor circuit in 1.DEF: Signal inconsistency.

Or 2. DEF: Open circuit or short circuit.

Or 3. DEF: Non-compliance with emission control standards.

–DF002 Air temperature circuit in 1. DEF: Open circuit or short circuit.

Or 2. DEF: Non-compliance with emission control standards.

–DF330 Pinking sensor circuit in 1.DEF: Open circuit or short circuit.

Or 2. DEF: Non-compliance with emission control standards.

–DF893 Controlled coolant thermostat circuit in CO: Open circuit.

Or CC.0: Short circuit to earth.

Or CC.1: Short circuit to + 12 volts.

Or 1. DEF: Non-compliance with emission control standards.

Engine torque limitation is activated.

If the fault is directly linked to the controlled thermostat (DF893 Controlled coolant thermostat circuit), the

thermostat is no longer controlled. It operates continuously, either in low temperature mode (instance of short circuit to

earth) or in high temperature mode (instance of open circuit or short circuit to the battery). The engine torque is limited

to limit heating and also to protect the engine by preventing overheating.

c. Functions affected by the presence of a controlled thermostat:

–Coolant temperature: 108˚C nominal, between 70˚C and 90˚C in defect mode or on loaded points.

–Coolant temperature fault finding: the fault finding setting for coolant temperature consistency has been adapted.

–Consumption: The function improves fuel consumption. Consequence: a fault with the function may lead to

inefficient consumption.

–Bleeding the circuit: A new procedure adapted to this innovation is described in MR 392 and 385, Mechanical

systems, CLIO III and MODUS, 19A Cooling, Cooling circuit: Bleeding.

–Coolant temperature display and illumination of the warning light on the instrument panel: During nominal

operation there is no impact as the temperature reference value is taken into account as well as the warning light

illumination thresholds. In the event of malfunction, see the summary table below.

–Fan unit and air conditioning: the fan unit activation threshold and the high temperature air conditioning

deactivation threshold are adapted in accordance with the temperature setpoint.

–Fault finding of controlled thermostat: Electrical fault finding is used. No operational fault finding:

A mechanical fault (such as jamming) will not be detected by the system.

–Performance: In the event of a fault, there is the option to switch the engine to reduced performance mode (see

Description of operation: Operation in defect mode). Note:

If a fault on the coolant temperature sensor is detected, fan assembly 1 is requested to operate permanently,

regardless of the management mode of the engine coolant temperature.

Page 19 of 348

17B-19V7 MR-413-X44-17B000$040.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Injection computer:

This is located on the right-hand side of the engine compartment on the battery mounting.

Fuel vapour recirculation solenoid valve:

This is located on the left-hand side of the engine compartment, behind the engine mounting.

Upstream oxygen sensor:

This is located on the exhaust pipe, downstream of the turbocharger.

Downstream oxygen sensor:

This is located on the exhaust pipe, upstream of the catalytic converter.

Pinking sensor:

The sensor is located underneath the inlet manifold behind the oil dipstick.

Oil pressure sensor:

This is located under the exhaust manifold to the left of the engine compartment.

Turbocharger:

The turbocharger is located after the exhaust manifold.

Turbocharger pressure sensor:

The turbocharger pressure sensor is fitted to the air circuit between the turbocharger and the motorised throttle

valve.

Ignition coil:

This is located on the right-hand side of the rocker cover.

Motorised throttle valve:

The damper valve is located to the right of the inlet manifold.

TDC sensor:

This sensor is located on the flywheel.

Refrigerant pressure sensor:

This sensor is located on the coolant circuit.

Engine coolant temperature sensor:

This sensor is located on the cylinder head near the engine thermostat housing.

PETROL INJECTION

Fault finding – List and location of components

Page 24 of 348

17B-24V7 MR-413-X44-17B000$060.mif

PETROL INJECTION

Fault finding – Features17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Air supply

The idle speed regulator performs all of the calculations that allow the idle speed actuator, the motorised throttle, to

be controlled physically. The functional component of the regulator is adaptive (variation programming and ageing).

If the idle speed regulation conditions are met, the status ET054 Idle speed regulation is "Active", and the idle

speed regulator continually positions the motorised throttle to maintain the engine speed at its idle reference value.

The motorised throttle opening ratio necessary to comply with the speed setpoint is then given by parameter PR091

Idle speed regulation theoretical OCR*.

The PR090 Idle speed regulation programming value is a stored parameter designed to program engine

variations and engine wear and tear for the idle speed regulator. The programming is carried out only when the

engine is idle and warm, and no electrical consumer (air conditioning, fan assembly, power assisted steering) is

operating. Therefore it adjusts slowly.

Idle speed

The idle speed setpoint is dependent on:

–the coolant temperature,

–the emission control programs,

–air conditioning requirements,

–the position of the gear lever,

–any power-assisted steering operation,

–the passenger compartment heating resistors,

–the oil temperature (engine protection),

–the electric power balance (engine speed is increased by 160 rpm maximum if the battery voltage remains below

12.7 V).

Ignition

Advance is calculated for each cylinder, and is limited between - 23˚ to + 72˚, and includes possible corrections due

to pinking.

Anti-pinking correction is the maximum advance value taken from the advance of one of the cylinders. If none of the

cylinders is pinking, this correction is zero.

Page 30 of 348

17B-30V7 MR-413-X44-17B000$070.mif

PETROL INJECTION

Fault finding – Role of components17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

Injection computer:

The injection computer manages the entire system.

Its role is to define the engine optimum operating mode and to inform the driver (via the instrument panel, information

display, and buzzer) and to communicate with the other computers.

Fuel vapour recirculation solenoid valve:

The fuel vapour absorber works like a ''sponge'' for petrol vapours and enables gases coming from the tank to be

collected.

Upstream oxygen sensor:

This sensor measures the amount of oxygen in the exhaust gas.

The voltage supplied to the computer by the sensor indicates the amount of oxygen in the exhaust gas - a rich

mixture or a lean mixture - and a program is adopted accordingly.

Downstream oxygen sensor:

This sensor measures the amount of oxygen in the exhaust gas.

The voltage supplied to the computer by the sensor indicates the amount of oxygen in the exhaust gas - a rich

mixture or a lean mixture - and a program is adopted accordingly.

Pinking sensor:

The sensor detects engine knocking and sends its electrical signal to the injection computer.

Oil pressure sensor:

This sensor measures the engine oil pressure.

Turbocharger:

The turbocharger is used to supply the engine with more air.

Turbocharger pressure sensor:

This sensor indicates the pressure at the turbocharger air cooler outlet before the damper valve.

Ignition coil:

This acts both as an energy storage battery and a transformer. It generates high voltage ignition pulses and the

energy required to ignite the mixture.

Motorised throttle valve:

The motorised throttle valve supplies the engine with varying mixtures of fuel and air according to the load required.

This electronic control detects the position of the accelerator using a sensor (potentiometer) to inject the mixture.

Page 34 of 348

17B-34V7 MR-413-X44-17B000$080.mif

PETROL INJECTION

Fault finding – Defect modes17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

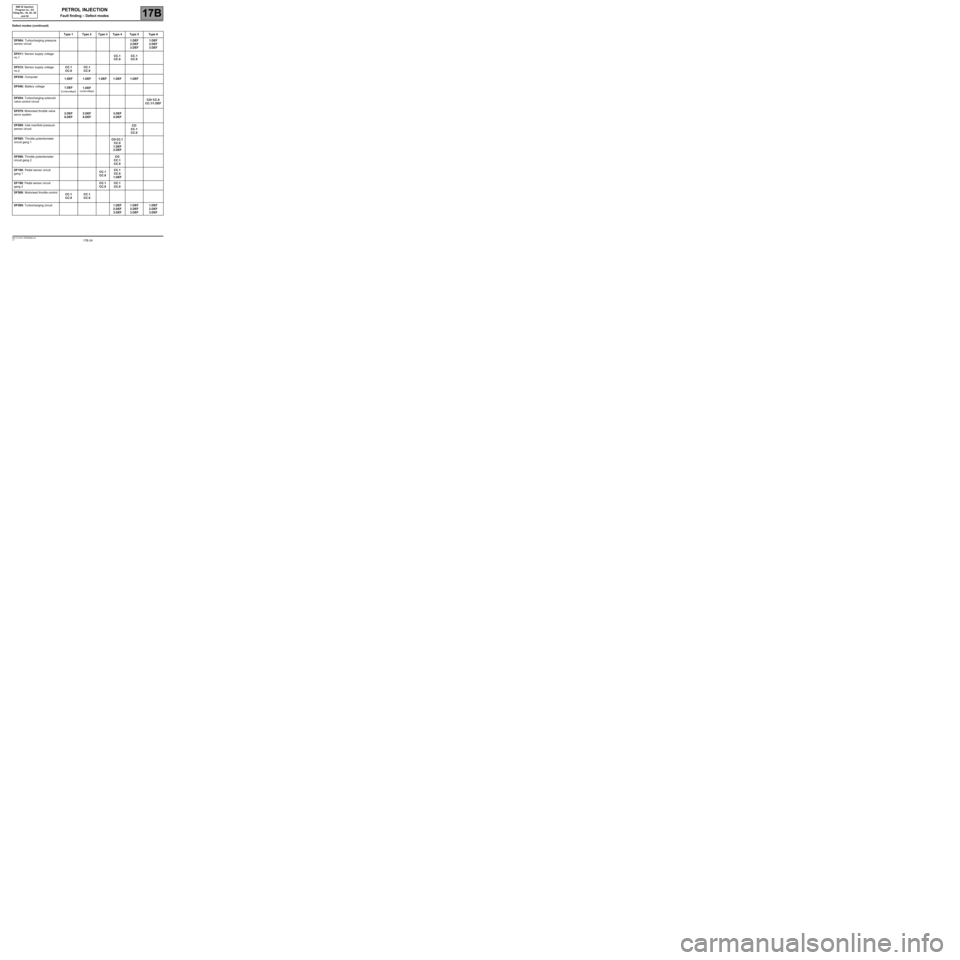

Defect modes (continued)

Type 1Type 2Type 3Type 4Type 5Type 6

DF004: Turbocharging pressure

sensor circuit1.DEF

2.DEF

3.DEF1.DEF

2.DEF

3.DEF

DF011: Sensor supply voltage

no.1CC.1

CC.0CC.1

CC.0

DF012: Sensor supply voltage

no.2CC.1

CC.0CC.1

CC.0

DF038: Computer1.DEF1.DEF1.DEF1.DEF1.DEF

DF046: Battery voltage1.DEF

(

undervoltage)

1.DEF

(undervoltage)

DF054: Turbocharging solenoid

valve control circuit CO/ CC.0

CC.1/1.DEF

DF079: Motorised throttle valve

servo system2.DEF

6.DEF2.DEF

6.DEF3.DEF

4.DEF

DF089: Inlet manifold pressure

sensor circuitCO

CC.1

CC.0

DF095: Throttle potentiometer

circuit gang 1CO CC.1

CC.0

1.DEF

2.DEF

DF096: Throttle potentiometer

circuit gang 2CO

CC.1

CC.0

DF196: Pedal sensor circuit

gang 1CC.1

CC.0CC.1

CC.0

1.DEF

DF198: Pedal sensor circuit

gang 2CC.1

CC.0CC.1

CC.0

DF508: Motorised throttle controlCC.1

CC.0CC.1

CC.0

DF569: Turbocharging circuit1.DEF

2.DEF

3.DEF1.DEF

2.DEF

3.DEF1.DEF

2.DEF

3.DEF

Page 35 of 348

17B-35V7 MR-413-X44-17B000$090.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

1. COMPUTER REPLACEMENT OR REPROGRAMMING OPERATIONS

Computer replacement or reprogramming for engines with the OCS (customised oil change interval)

function.

For Vdiag 44 and 4C, commands SC001 and SC003 are not accessible.

The system can be programmed via the diagnostic socket using the RENAULT CLIP diagnostic tool (refer to

Technical Note 3585A, COMPUTER PROGRAMMING AND REPROGRAMMING PROCEDURE or follow the

instructions given by the diagnostic tool). Only in Vdiag 54 and certain engines in Vdiag 50:

For Vdiag 50, the procedure below should be followed only if ET840 Customised Oil Change Interval is ACTIVE.

Certain variables linked to the O.C.S and the details of the last four oil services are saved by the computer.

However, all data saved is cleared during a reprogramming operation. When replacing or reprogramming the

computer, it is necessary to save the data from the old computer so it can be written to the new computer

(or reprogrammed). To do this before changing (or reprogramming) the computer, it is necessary to run the request

SC003 Save computer data, and after it has been changed (or reprogrammed), it is necessary to run the request

SC001 Write saved data.

For Vdiag 50, if ET840 Customised Oil Change Interval is INACTIVE, commands SC001 and SC003 should

not be used.

Operations to check before reprogramming the injection computer:

Before reprogramming the injection computer, move the main Cruise control/Speed limiter switch to the rest

position. The information about the cruise control or the speed limiter displayed on the instrument panel

disappears.

Otherwise, if the main switch remains in the cruise control or speed limiter position during and after reprogramming,

the Cruise control/Speed limiter function will not be operational.

The procedure for resetting the function is as follows:

Ignition switched on and main switch in rest position (the computer detects rest position at that moment).

Switch in Cruise control position to activate the Cruise control function.

Switch in Speed limiter position to activate the Speed limiter function.

IMPORTANT:

–Switch on the diagnostic tool (mains or cigarette lighter supply).

–Connect a battery charger.

–Switch off all electrical consumers (lights, interior lighting, air conditioning, radio, etc.).

–Wait for the engine to cool (engine coolant temperature below 60˚C and air temperature below 50˚C).

PETROL INJECTION

Fault finding – Replacement of components

Page 36 of 348

17B-36V7 MR-413-X44-17B000$090.mif

PETROL INJECTION

Fault finding – Replacement of components17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

PROCEDURE:

Before any computer programming, only Vdiag 54 and 50 (see previous page):

–Run the command SC003 'Save computer data.

Any time the computer has been programmed

–Switch the ignition off and then on again.

–Select the UCH domain using the diagnostic tool.

–In repair mode, run the command SC017 "Programming the injection immobiliser code" and follow the

instructions given by the diagnostic tool.

–Switch the ignition off and then on again.

–Select the INJECTION subgroup and check status ET341 Immobiliser code programmed.

–Run the command SC001 ''Write saved data" Vdiag 54 only.

IF ET341 = YES

–Start and then stop the engine (to initialise the computer) and wait 30 seconds.

–Switch the ignition back on and use the diagnostic tool to carry out the following steps:

–Run the command VP010 Write VIN.

–After injection system programming, stored faults may appear on other computers. Clear the memory of

these computers.

IF ET341: NO

–Re-run command SC017 and follow the instructions given by the diagnostic tool.

2. COMPUTER REPROGRAMMING OPERATIONS

When replacing or removing the TDC sensor, program the engine flywheel ring (see Configurations and

programming).

3. REPLACING THE MOTORISED THROTTLE VALVE

When replacing the throttle valve, program the throttle stops (see Configurations and programming).

4. REPLACING THE MOTORISED THROTTLE VALVE

When replacing the throttle valve, program the throttle stops (see Configurations and programming). IMPORTANT:

AFTER A PROGRAMMING OPERATION, DO NOT DISCONNECT THE BATTERY FOR AT LEAST

30 MINUTES (to carry out other work on the vehicle).

IMPORTANT:

Never drive the vehicle without having programmed the throttle stops.

Page 40 of 348

17B-40V7 MR-413-X44-17B000$120.mif

17B

SIM 32 Injection

Program no.: D3

Vdiag No.: 44, 4C, 50

and 54

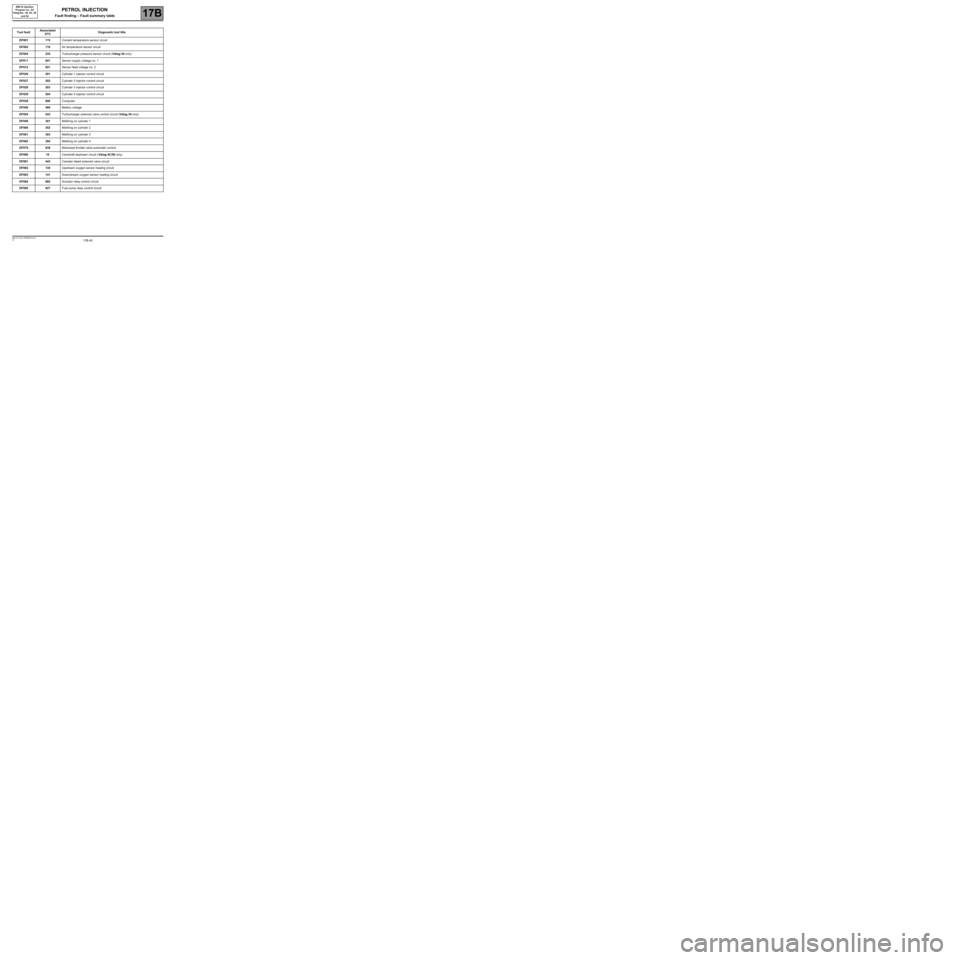

Tool faultAssociated

DTCDiagnostic tool title

DF001115Coolant temperature sensor circuit

DF002110Air temperature sensor circuit

DF004235Turbocharger pressure sensor circuit (Vdiag 54 only)

DF011641Sensor supply voltage no. 1

DF012651Sensor feed voltage no. 2

DF026201Cylinder 1 injector control circuit

DF027202Cylinder 2 injector control circuit

DF028203Cylinder 3 injector control circuit

DF029204Cylinder 4 injector control circuit

DF038606Computer

DF046560Battery voltage

DF054243Turbocharger solenoid valve control circuit (Vdiag 54 only)

DF059301Misfiring on cylinder 1

DF060302Misfiring on cylinder 2

DF061303Misfiring on cylinder 3

DF062304Misfiring on cylinder 4

DF079638Motorised throttle valve automatic control

DF08010Camshaft dephaser circuit (Vdiag 4C/50 only)

DF081443Canister bleed solenoid valve circuit

DF082135Upstream oxygen sensor heating circuit

DF083141Downstream oxygen sensor heating circuit

DF084685Actuator relay control circuit

DF085627Fuel pump relay control circuit

PETROL INJECTION

Fault finding – Fault summary table