battery RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 454 of 652

16A-15

STARTING - CHARGING

Starter: Removal - Refitting

K9K

16A

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the starter,

-the starter bolts.

aTighten the starter bolts.

aFit:

-the starter wiring harness,

-the gearbox wiring channel.

aRefit:

-the wiring channel mounting clip on the gearbox,

-the electrical connections on the starter,

-the electrical connection nuts.

aTighten to torque:

-the electrical connection nut (5 N.m) (5) ,

-the electrical connection nut (8 N.m) (6) .

aConnect:

-the accelerometer connector,

-the rail pressure sensor connector.

II - FINAL OPERATION

aRefit the engine cover.

aConnect the battery (see ) (MR 411, 80A, Battery).

121432

Page 455 of 652

16A-16

STARTING - CHARGING

Starter: Removal - Refitting

K4M

16A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

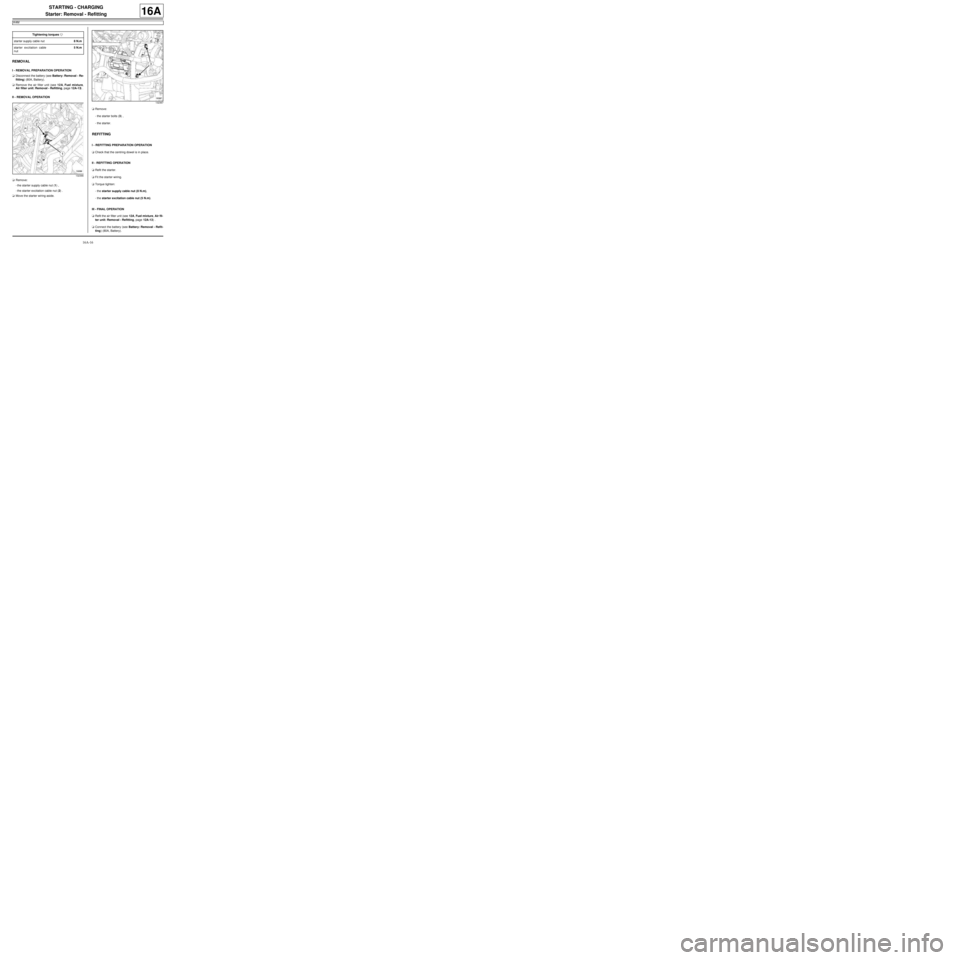

II - REMOVAL OPERATION

aRemove:

-the starter supply cable nut (1) ,

-the starter excitation cable nut (2) .

aMove the starter wiring aside.aRemove:

-the starter bolts (3) ,

-the starter.

REFITTING

I - REFITTING PREPARATION OPERATION

aCheck that the centring dowel is in place.

II - REFITTING OPERATION

aRefit the starter.

aFit the starter wiring.

aTorque tighten:

-the starter supply cable nut (8 N.m),

-the starter excitation cable nut (5 N.m).

III - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery). Tightening torquesm

starter supply cable nut8 N.m

starter excitation cable

nut5 N.m

132366

132367

Page 457 of 652

17A-1

IGNITION

Coils: Removal - Refitting

D7F

17A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-Fluostar 2L.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

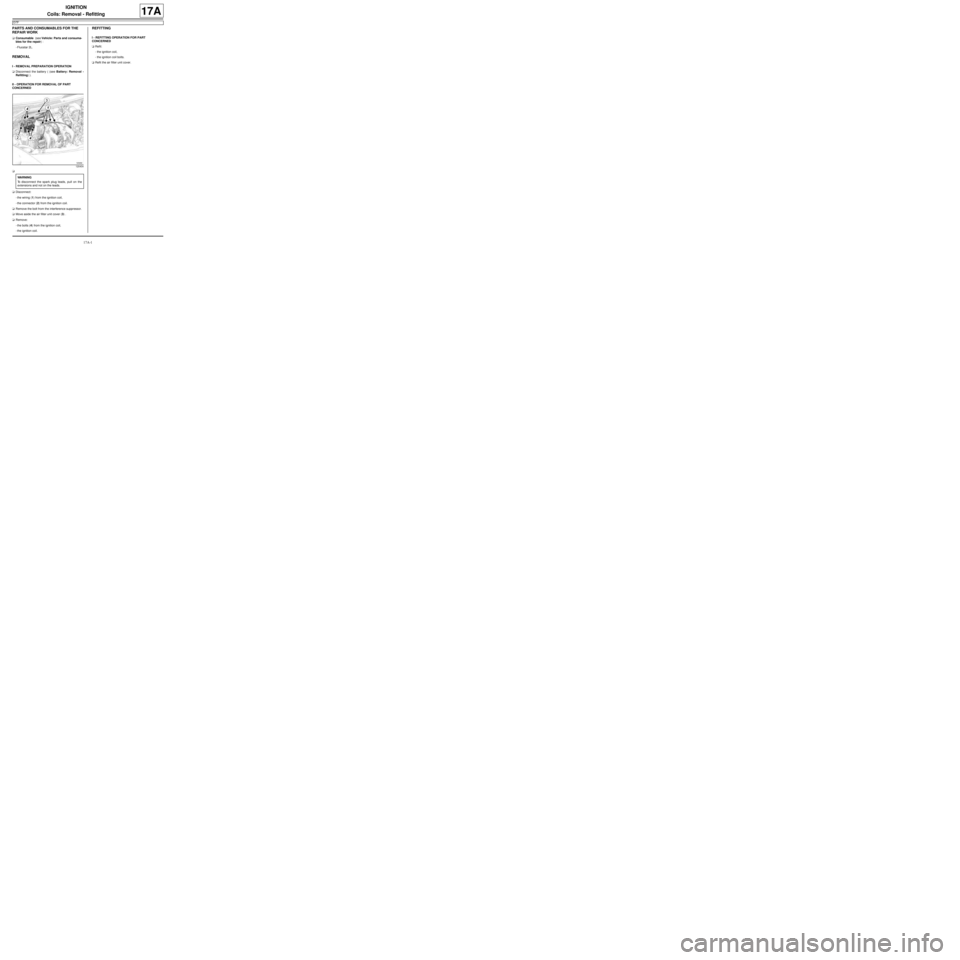

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect:

-the wiring (1) from the ignition coil,

-the connector (2) from the ignition coil.

aRemove the bolt from the interference suppressor.

aMove aside the air filter unit cover (3) .

aRemove:

-the bolts (4) from the ignition coil,

-the ignition coil.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the ignition coil,

-the ignition coil bolts.

aRefit the air filter unit cover.

120404

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

Page 458 of 652

17A-2

IGNITION

Coils: Removal - Refitting

D7F

17A

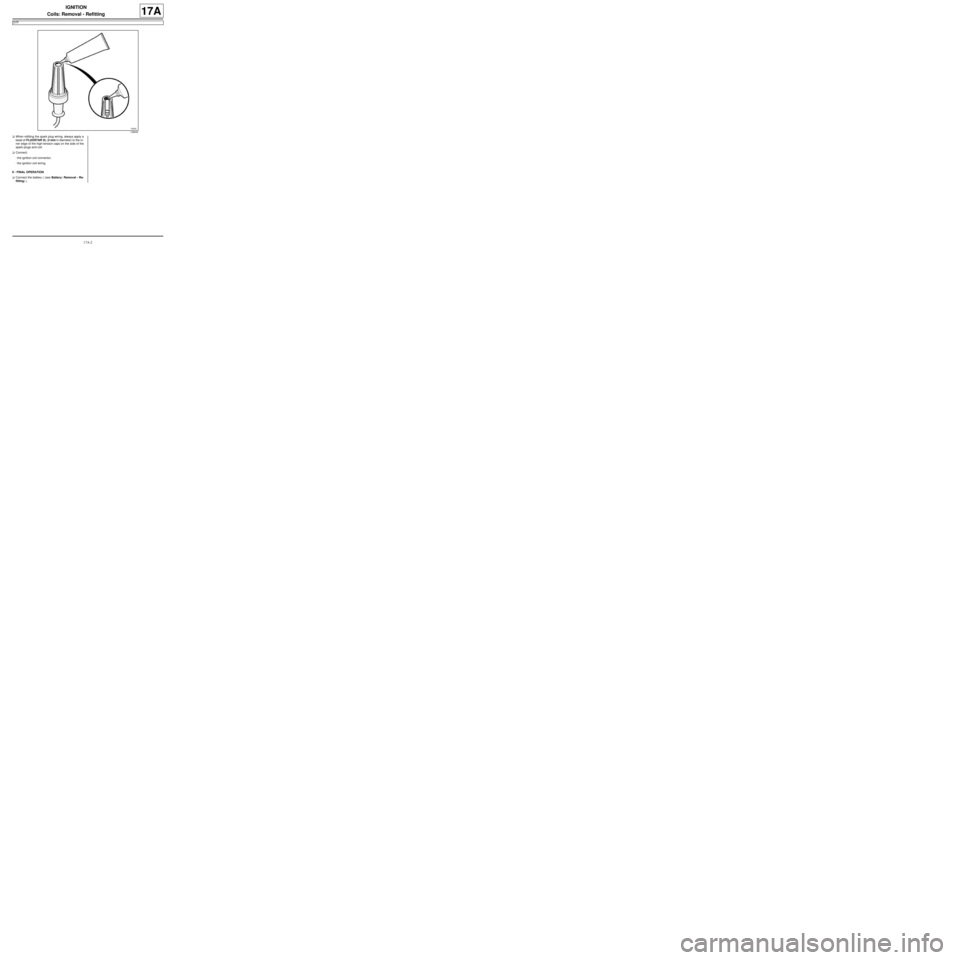

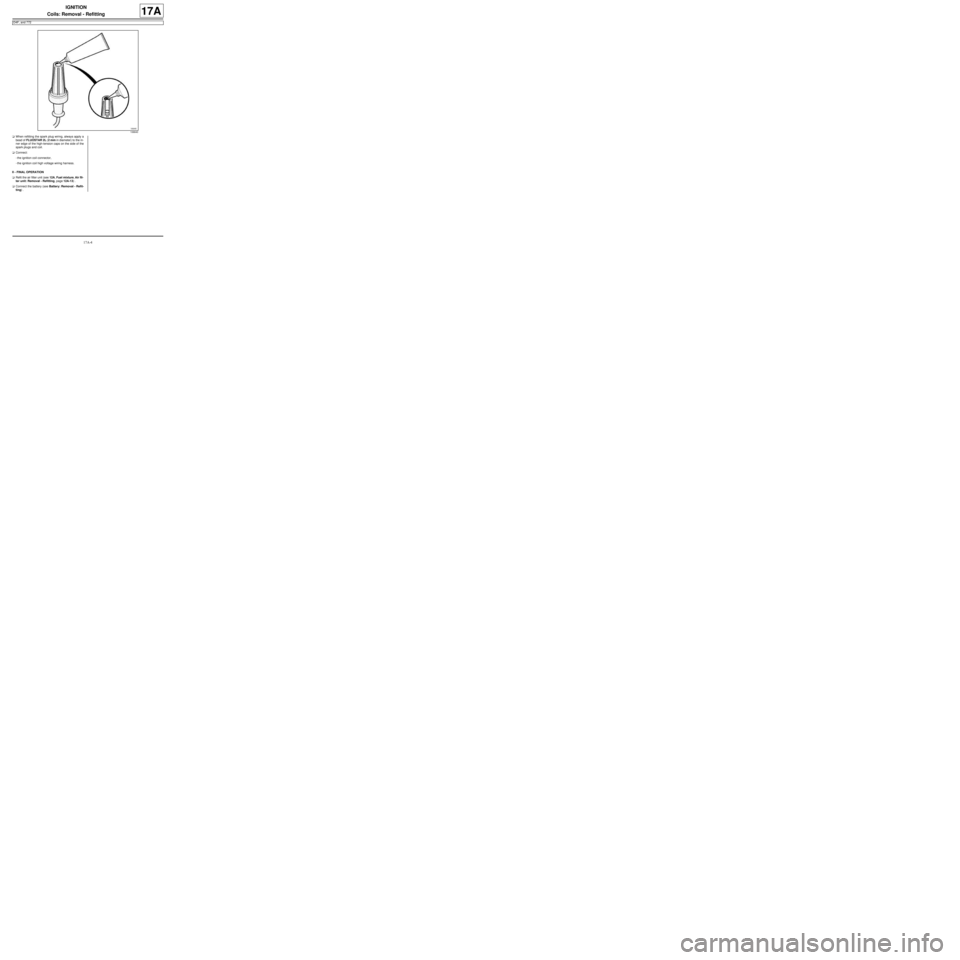

aWhen refitting the spark plug wiring, always apply a

bead of FLUOSTAR 2L (2 mm in diameter) to the in-

ner edge of the high-tension caps on the side of the

spark plugs and coil.

aConnect:

-the ignition coil connector,

-the ignition coil wiring.

II - FINAL OPERATION

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

106640

Page 459 of 652

17A-3

IGNITION

Coils: Removal - Refitting

D4F, and 772

17A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aConsumable (see Vehicle: Parts and consuma-

bles for the repair) :

-Fluostar 2L.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) .

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

a

aDisconnect:

-the ignition coil high voltage wiring harness,

-the ignition coil connector.aRemove:

-the ignition coil bolts ,

-the ignition coil.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the ignition coil,

-the ignition coil bolts.

120300

WARNING

To disconnect the spark plug leads, pull on the

extensions and not on the leads.

113044

Page 460 of 652

17A-4

IGNITION

Coils: Removal - Refitting

D4F, and 772

17A

aWhen refitting the spark plug wiring, always apply a

bead of FLUOSTAR 2L (2 mm in diameter) to the in-

ner edge of the high-tension caps on the side of the

spark plugs and coil.

aConnect:

-the ignition coil connector,

-the ignition coil high voltage wiring harness.

II - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) .

106640

Page 493 of 652

17B-18

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

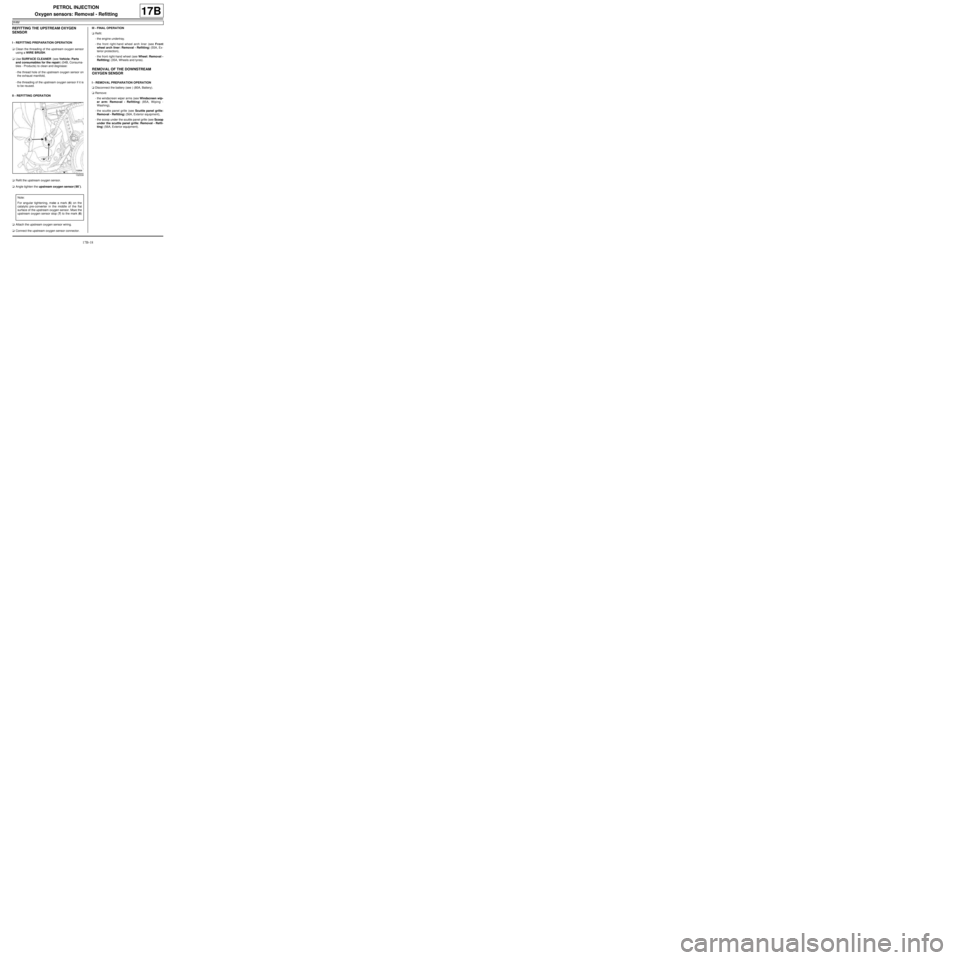

REFITTING THE UPSTREAM OXYGEN

SENSOR

I - REFITTING PREPARATION OPERATION

aClean the threading of the upstream oxygen sensor

using a WIRE BRUSH.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread hole of the upstream oxygen sensor on

the exhaust manifold,

-the threading of the upstream oxygen sensor if it is

to be reused.

II - REFITTING OPERATION

aRefit the upstream oxygen sensor.

aAngle tighten the upstream oxygen sensor ( 90˚).

aAttach the upstream oxygen sensor wiring.

aConnect the upstream oxygen sensor connector.III - FINAL OPERATION

aRefit:

-the engine undertray.

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

REMOVAL OF THE DOWNSTREAM

OXYGEN SENSOR

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

132539

Note:

For angular tightening, make a mark (6) on the

catalytic pre-converter in the middle of the flat

surface of the upstream oxygen sensor. Move the

upstream oxygen sensor stop (7) to the mark (6)

.

Page 494 of 652

17B-19

PETROL INJECTION

Oxygen sensors: Removal - Refitting

K4M

17B

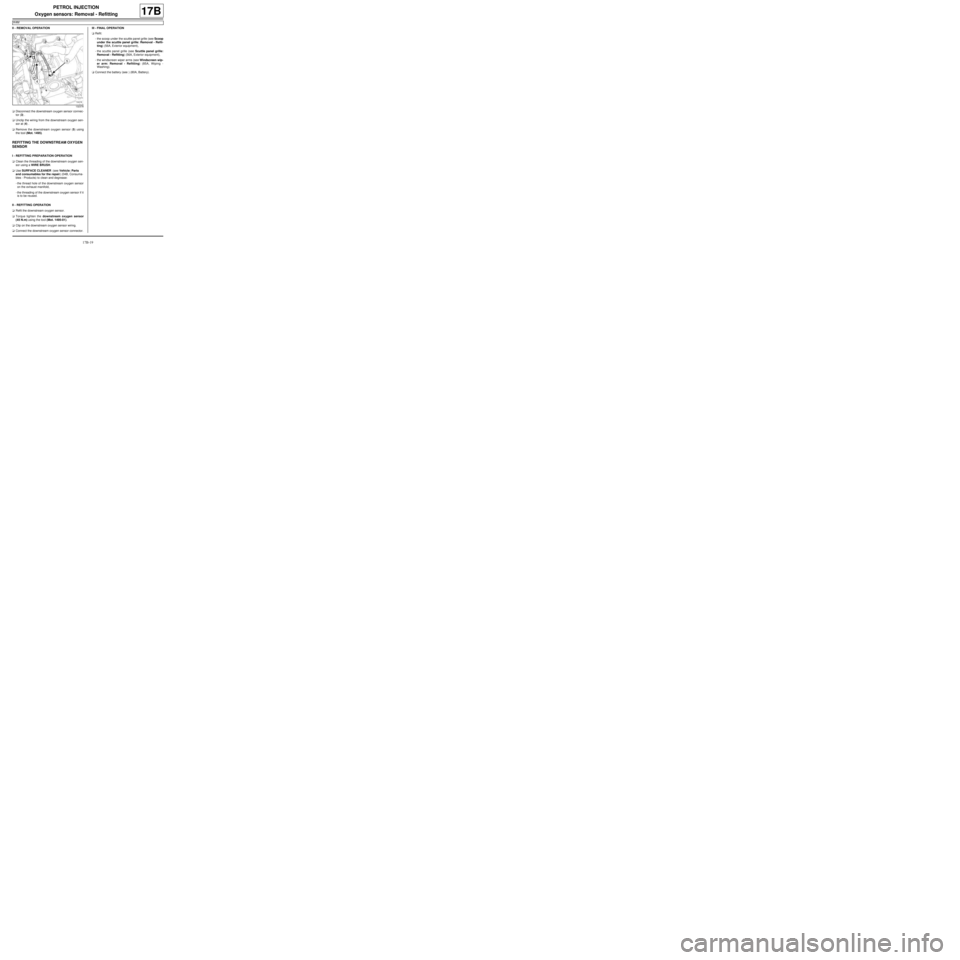

II - REMOVAL OPERATION

aDisconnect the downstream oxygen sensor connec-

tor (3) .

aUnclip the wiring from the downstream oxygen sen-

sor at (4) .

aRemove the downstream oxygen sensor (5) using

the tool (Mot. 1495).

REFITTING THE DOWNSTREAM OXYGEN

SENSOR

I - REFITTING PREPARATION OPERATION

aClean the threading of the downstream oxygen sen-

sor using a WIRE BRUSH.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean and degrease:

-the thread hole of the downstream oxygen sensor

on the exhaust manifold,

-the threading of the downstream oxygen sensor if it

is to be reused.

II - REFITTING OPERATION

aRefit the downstream oxygen sensor.

aTorque tighten the downstream oxygen sensor

(45 N.m) using the tool (Mot. 1495-01).

aClip on the downstream oxygen sensor wiring.

aConnect the downstream oxygen sensor connector.III - FINAL OPERATION

aRefit:

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see ) (80A, Battery).

132378

Page 495 of 652

17B-20

PETROL INJECTION

Petrol injection computer: Removal - Refitting

D4F or D7F

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the injection computer connectors (1) .

aRemove:

-the injection computer nuts (2) ,

-the injection computer.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the injection computer,

-the injection computer nuts.

aTorque tighten the injection computer nuts (8

N.m).

aConnect the injection computer connectors.

II - FINAL OPERATION

aConnect the battery (see ) (MR 411, 80A, Battery).

aCarry out the necessary configurations and/or pro-

gramming, using the Diagnostic tool (see Fault

finding - Replacement of components) (MR 413,

17B, Petrol injection). Equipment required

Diagnostic tool

Tightening torquesm

injection computer nuts8 N.m

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical

Note 6015A, 88A, Wiring).

120779

Page 496 of 652

17B-21

PETROL INJECTION

Petrol injection computer: Removal - Refitting

K4M

17B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the battery (see Battery: Removal - Refit-

ting) (80A, Battery).aRemove:

-the tamperproof bolts (1) using the tool (Mot. 1844)

(2) and a drill,

-the petrol injection computer protector. Special tooling required

Mot. 1844Drill bush for removing the

tamper-proof bolts from the

injection computer protective

cover

Equipment required

drill

Diagnostic tool

WARNING

Do not use any product designed to improve the

electr ical contact in the injection computer and oxy-

gen sensor connectors or on the bodies of the oxy-

gen sensors.

Failure to respect this advice prevents the oxygen

sensor from operating correctly and results in fail-

ure to comply with the emission control standard.

WARNING

If the connections are corroded, repair the wiring

(see Wiring: Precautions for repair) (Technical Note

6015A, 88A, Wiring).

RIGHT-HAND DRIVE

132448