battery RENAULT TWINGO RS 2009 2.G Engine And Peripherals Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 333 of 652

12B-8

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the engine undertray.

aDrain the manual gearbox (see Manual gearbox

oils: Draining - Filling) (21A, Manual gearbox).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the turbocharger oil return pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) .

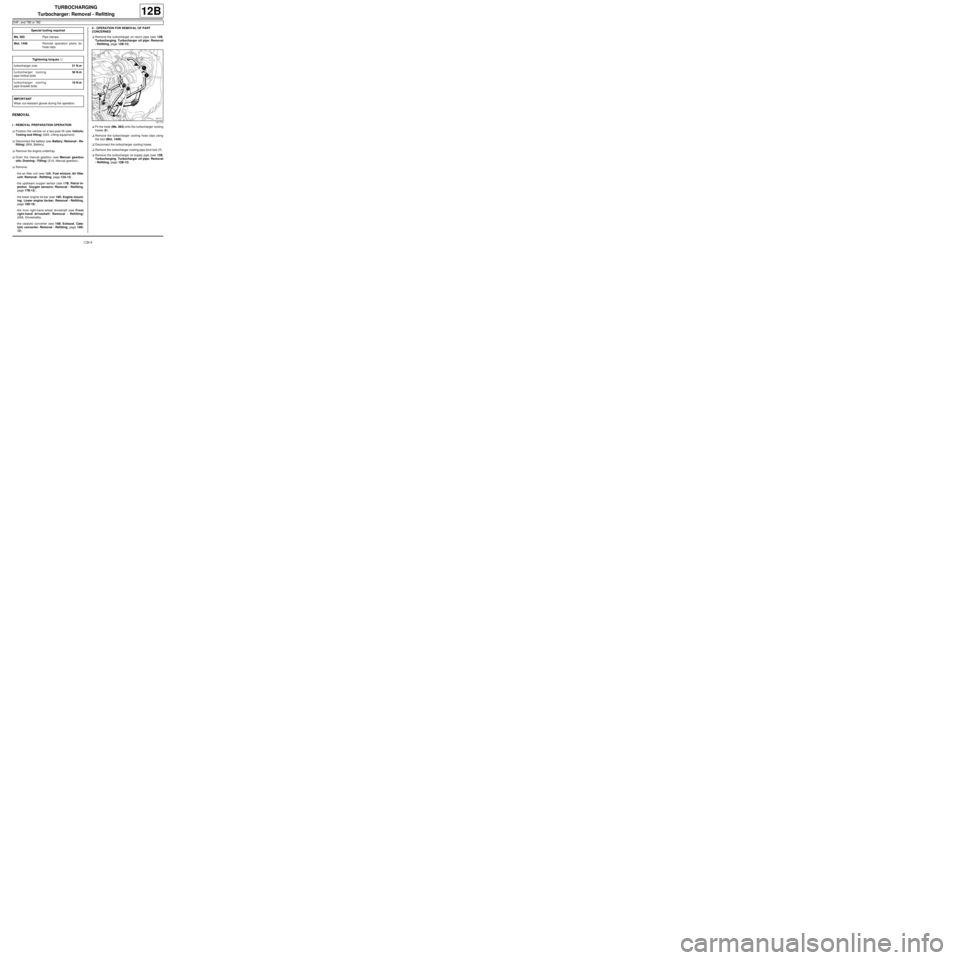

aFit the tools (Ms. 583) onto the turbocharger cooling

hoses (6) .

aRemove the turbocharger cooling hose clips using

the tool (Mot. 1448).

aDisconnect the turbocharger cooling hoses.

aRemove the turbocharger cooling pipe strut bolt (7) .

aRemove the turbocharger oil supply pipe (see 12B,

Turbocharging, Turbocharger oil pipe: Removal

- Refitting, page 12B-12) . Special tooling required

Ms. 583Pipe clamps .

Mot. 1448Remote operation pliers for

hose clips .

Tightening torquesm

turbocharger nuts21 N.m

turbocharger cooling

pipe hollow bolts30 N.m

turbocharger cooling

pipe bracket bolts10 N.m

IMPORTANT

Wear cut-resistant gloves during the operation.121773

Page 336 of 652

12B-11

TURBOCHARGING

Turbocharger: Removal - Refitting

D4F, and 780 or 782

12B

III - FINAL OPERATION

aRefit:

-the catalytic converter (see 19B, Exhaust, Cata-

lytic converter: Removal - Refitting, page 19B-

12) ,

-the front right-hand wheel driveshaft (see Front

right-hand driveshaft: Removal - Refitting)

(29A, Driveshafts),

-the lower engine tie-bar (see 19D, Engine mount-

ing, Lower engine tie-bar: Removal - Refitting,

page 19D-18) ,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRefill:

-and bleed the cooling system (see 19A, Cooling,

Cooling system: Draining - Refilling, page 19A-

9) ,

-the manual gearbox (see Manual gearbox oils:

Draining - Filling) (21A, Manual gearbox).

aRefit the engine undertray.

Page 337 of 652

12B-12

TURBOCHARGING

Turbocharger oil pipe: Removal - Refitting

D4F, and 780 or 782

12B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the air filter box strut bolt,

-the air filter box strut,

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) . Tightening torquesm

turbocharger oil return

pipe bolts10 N.m

turbocharger oil supply

pipe bolt on the cylinder

block19 N.m

turbocharger oil supply

pipe bolt on the turbo-

charger19 N.m

turbocharger oil supply

pipe bolt10 N.m

Page 340 of 652

12B-15

TURBOCHARGING

Turbocharger oil pipe: Removal - Refitting

D4F, and 780 or 782

12B

aRefit:

-the upstream oxygen sensor (see 17B, Petrol in-

jection, Oxygen sensors: Removal - Refitting,

page 17B-13) ,

-the air filter box strut,

-the air filter box strut bolt,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 341 of 652

12B-16

TURBOCHARGING

Turbocharger oil pipe: Removal - Refitting

C44, and K9K

12B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

1 - Turbocharger oil supply pipe

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the exhaust gas recirculation solenoid valve (see

14A, Antipollution, Exhaust gas recirculation

solenoid valve: Removal - Refitting, page 14A-

10) .

2 - turbocharger oil return pipe

aRemove the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

1 - Turbocharger oil supply pipe

aRemove the bolt (1) of the turbocharger oil supply

pipe from the turbocharger.

aUndo the nut (2) of the turbocharger oil supply pipe

on the cylinder head.

aRemove the nut of the turbocharger oil supply pipe

on the cylinder head.

aRemove the turbocharger oil supply pipe. Special tooling required

Mot. 1746Offset wrench for tightening

High Pressure pump pipes.

Tightening torquesm

nut of the oil supply pipe

on the cylinder head35 Nm

bolt of the turbocharger

oil supply pipe on the

turbocharger14 Nm

turbocharger oil return

pipe bolts12 N.m

127900

127898

Page 342 of 652

12B-17

TURBOCHARGING

Turbocharger oil pipe: Removal - Refitting

C44, and K9K

12B

2 - Oil return pipe

aRemove the bolts (3) of the oil return pipe from the

turbocharger.

aIn the direction of the arrows, rotate the oil return

pipe of the turbocharger to facilitate its removal.

aRemove the turbocharger oil pipe from the cylinder

block.

REFITTING

I - REMOVAL PREPARATION OPERATION

aAlways replace:

-the turbocharger oil supply pipe,

-the flat seal of the oil return pip on the turbocharg-

er,

-the O-ring of the oil return pip on the turbocharger.

aLubricate the O-ring of the oil return pipe on the tur-

bocharger with engine oil.

II - REFITTING OPERATION FOR PART

CONCERNED

1 - Turbocharger oil supply pipe

aFit the turbocharger oil supply pipe.

aRefit:

-the turbocharger oil supply pipe nut on the cylinder

head,-the bolt of the turbocharger oil supply pipe onto the

turbocharger.

aTorque tighten:

-the nut of the oil supply pipe on the cylinder

head ( 35 Nm) using the (Mot. 1746),

-the bolt of the turbocharger oil supply pipe on

the turbocharger (14 Nm).

2 - turbocharger oil return pipe

aFit the oil return pipe on the cylinder block.

aRefit the turbocharger oil return pipe bolts.

aTorque tighten the turbocharger oil return pipe

bolts (12 N.m).

III - FINAL OPERATION.

1 - Turbocharger oil supply pipe

aRefit:

-the exhaust gas recirculation solenoid valve (see

14A, Antipollution, Exhaust gas recirculation

solenoid valve: Removal - Refitting, page 14A-

10) ,

-the air filter box (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

2 - turbocharger oil return pipe

aRefit the catalytic converter (see 19B, Exhaust,

Catalytic converter: Removal - Refitting, page

19B-12) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aRefit the engine cover.

127899

Page 374 of 652

13B-13

DIESEL INJECTION

Diesel injection computer: Removal - Refitting

K9K

13B

To configure the diesel injection computer (see MR

413 Fault finding, 13B, Diesel injection, Fault find-

ing - Replacement of components).

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove the front engine cover.

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the injection computer connectors (1) .

aRemove the nuts (2) from the computer on the bat-

tery tray.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aPosition the new injection computer making sure the

positioning lug is engaged, then fit the computer

onto the studs.

aRefit the computer nuts on the battery tray.aTorque tighten the computer nuts (4 Nm).

aConnect the injection computer.

II - FINAL OPERATION.

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

aRefit the engine cover. Tightening torquesm

computer nuts4 Nm

120322

Page 377 of 652

13B-16

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove the front engine cover.

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment).

aRemove:

-the dipstick,

-the oil level dipstick nut (1) ,

-the oil level dipstick guide.

aPlug the oil level dipstick guide inlet opening on the

cylinder block.

aDisconnect the following connectors :

-the heater plugs,

-of the injectors,

-the flow actuator,

-the diesel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1672Low er engine support.

Mot. 1430Set of 5 crankshaft and cam-

shaft pulley timing pins.

Mot. 1606High pressure pump pulley

support tool.

Mot. 1525Gear extractor for tapered

hub injection pump.

Mot. 1525-02Adapter claws for Mot. 1525.

Equipment required

Diagnostic tool

Tightening torquesm

high pressure pump

bolts on the cylinder

head23 N.m

high pressure pump pul-

ley nut70 N.m

cylinder head sus-

pended mounting bolts25 N.m

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527

Page 385 of 652

13B-24

DIESEL INJECTION

High pressure pump: Removal - Refitting

K9K

13B

aRefit the lower timing cover.

aRefit the accessories belt (see 11A, Top and front

of engine, Accessories belt: Removal - Refitting,

page 11A-3)

aRefit:

-the upper timing cover,

-the camshaft position sensor (see 13B, Diesel in-

jection, Camshaft position sensor: Removal -

Refitting, page 13B-14) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) .

aRemove the blanking plugs.

aRefit a high pressure pipe between the pump and

the rail (see 13B, Diesel injection, High pressure

pipe between pump and rail: Removal - Refitting,

page 13B-35) .

aConnect the diesel return pipe to the venturi fitted to

the high pressure pump.aRefit:

-the fuel filter mounting,

-the fuel filter (see 13A, Fuel supply, Fuel filter:

Removal - Refitting, page 13A-4) .

aRefit:

-the engine tie-bar (see 19D, Engine mounting,

Lower engine tie-bar: Removal - Refitting, page

19D-18) ,

-the engine harness channel.

aFit the engine wiring on the engine wiring channel.

aClip on the engine wiring channel.

aConnect to the high pressure pump:

-the diesel supply pipe,

-the diesel return pipe to the diesel filter.

aClip on the high pressure pump pipes.

aRemove the protection on the alternator to prevent

fuel flowing out.

aConnect the connectors of:

-the diesel temperature sensor,

-the flow actuator,

-the injectors,

-the heater plugs.

aRemove the blanking cover which protects the oil

level dipstick guide inlet opening on the cylinder

block.

aRefit:

-the dipstick guide,

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aPrime the fuel circuit with a manual priming pump

until the disconnected pipes are filled with fuel; if

necessary, bleed the fuel filter (see 13A, Fuel sup-

ply, Fuel filter: Removal - Refitting, page 13A-4) .

aCheck that there are no fuel leaks.

aConnect the battery (see ) (80A, Battery). K9K, and 740

19659

Note:

Make sure that the tab (23) is positioned oppo-

site the mark (24) .

Page 387 of 652

13B-26

DIESEL INJECTION

Flow actuator: Removal - Refitting

K9K

13B

PIECES ET INGREDIENTS POUR LA REPARATION

Pièces à remplacer systématiquement :

-the high pressure pipe between the rail and injector

number 4,

-the clip between high pressure pipes number 3 and 4.

Ingrédients :

-cleaning cloths,

-set of K9K blanking plugs (injection DELPHI).

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (MR 411, 80A, Bat-

tery).

aRemove the front engine cover.aRemove:

-the dipstick,

-the dipstick guide nut (1) ,

-the oil level dipstick guide.

aBlock the dipstick guide inlet opening on the cylinder

block.

aDisconnect the connectors:

-the heater plugs,

-the injectors,

-the flow actuator,

-diesel fuel temperature sensor.

aProtect the alternator from fuel outflow. Special tooling required

Mot. 1746Offset wrench for tightening

High Pressure pump pipes.

Equipment required

Diagnostic tool

Tightening torquesm

fuel flow actuator bolts

on the high pressure

pump6 Nm

high pressure pipe

unions between the rail

and injector number 4

(yellow)24 Nm

high pressure pipe

unions between the rail

and injector number 4

(silver)28 Nm

IMPORTANT

Consult the safety and cleanliness advice and oper-

ation recommendations before carrying out any

repair (see 13B, Diesel injection, Diesel injec-

tion: Precautions for the repair, page 13B-1) .

114527