Crankshaft pulley RENAULT TWINGO RS 2009 2.G Engine And Peripherals User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 135 of 652

11A-18

TOP AND FRONT OF ENGINE

Accessories belt: Removal - Refitting

K4M

11A

II - REMOVAL OPERATION

aTurn the accessories belt tensioning roller clockwise

using a 16 mm spanner (5) .

aRemove the accessories belt.

aRemove:

-the tensioning roller bolt (6) ,

-the tensioning roller.REFITTING

I - REFITTING PREPARATION OPERATION

aUse a brush to remove any deposits from the crank-

shaft pulley V-grooves.

aparts always to be replaced: Accessories belt.

aparts always to be replaced: Accessories belt

tensioning roller.

II - REFITTING OPERATION

aRefit a new tensioning roller.

aTorque tighten the tensioning roller (40 N.m).

aTurn the accessories belt tensioning roller clockwise

using a 16 mm spanner.

aRefit a new accessories belt.

aGently release the tensioning roller.

aRotate the crankshaft clockwise twice to balance the

accessories belt tension on all pulleys.

III - FINAL OPERATION

aRefit the right-hand headlight carrier panel.

aClip:

-the air conditioning pipe on the right-hand headlight

carrier panel,

-the screen washer bottle filler neck,

-the wiring.

aRefit:

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

132377

132376

Page 137 of 652

11A-20

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

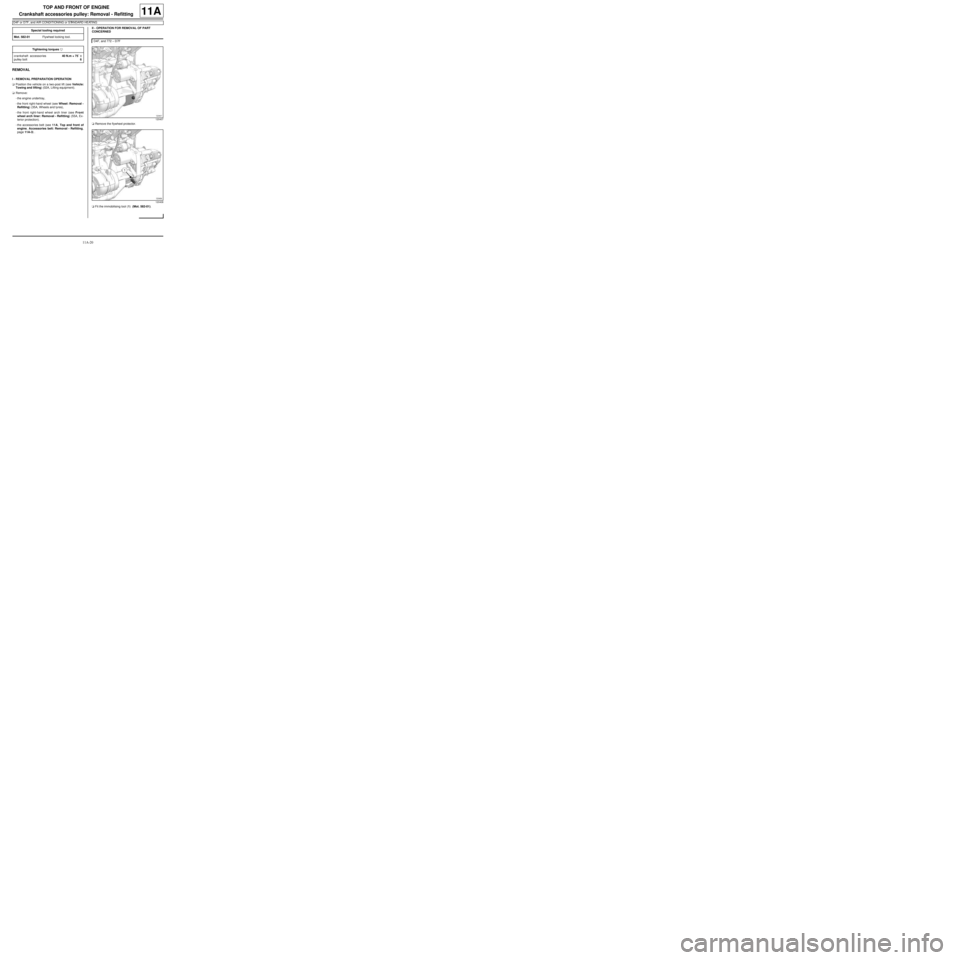

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection).

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove the flywheel protector.

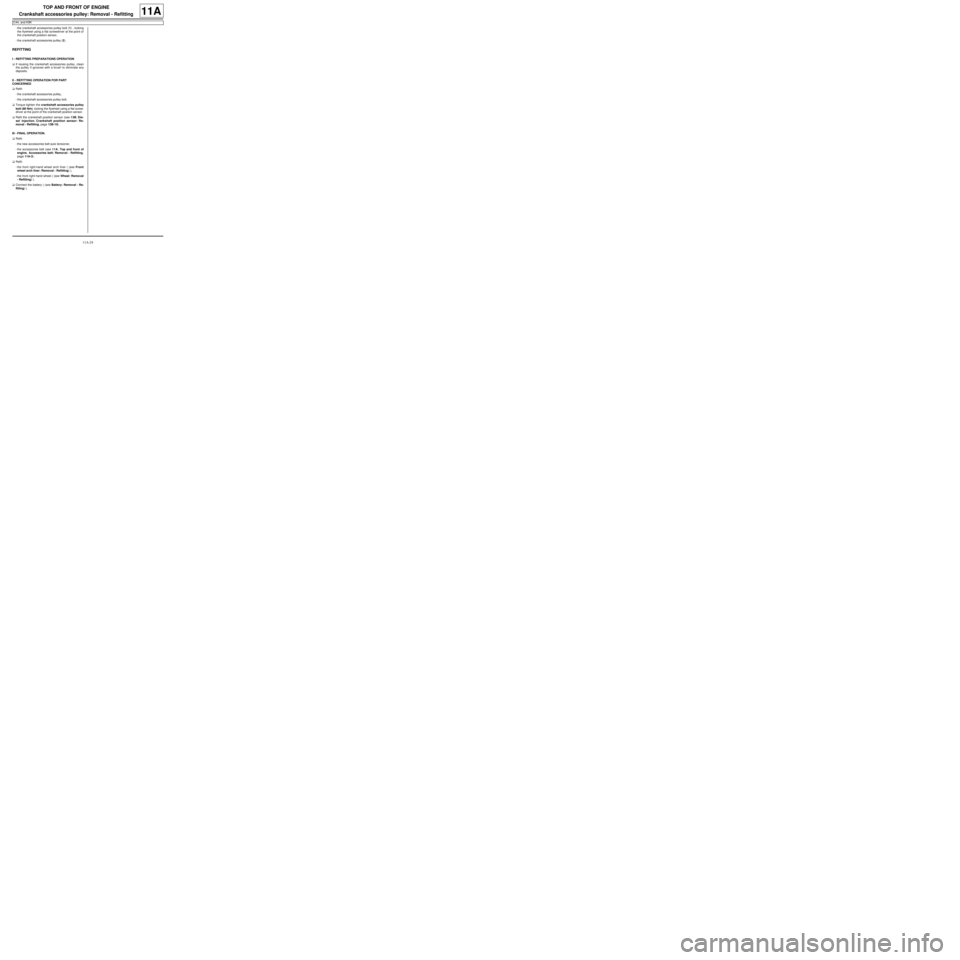

aFit the immobilising tool (1) (Mot. 582-01). Special tooling required

Mot. 582-01Flywheel locking tool.

Tightening torquesm

crankshaft accessories

pulley bolt40 N.m + 75˚ ±± ± ±

6

D4F, and 772 – D7F

120407

120408

Page 138 of 652

11A-21

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

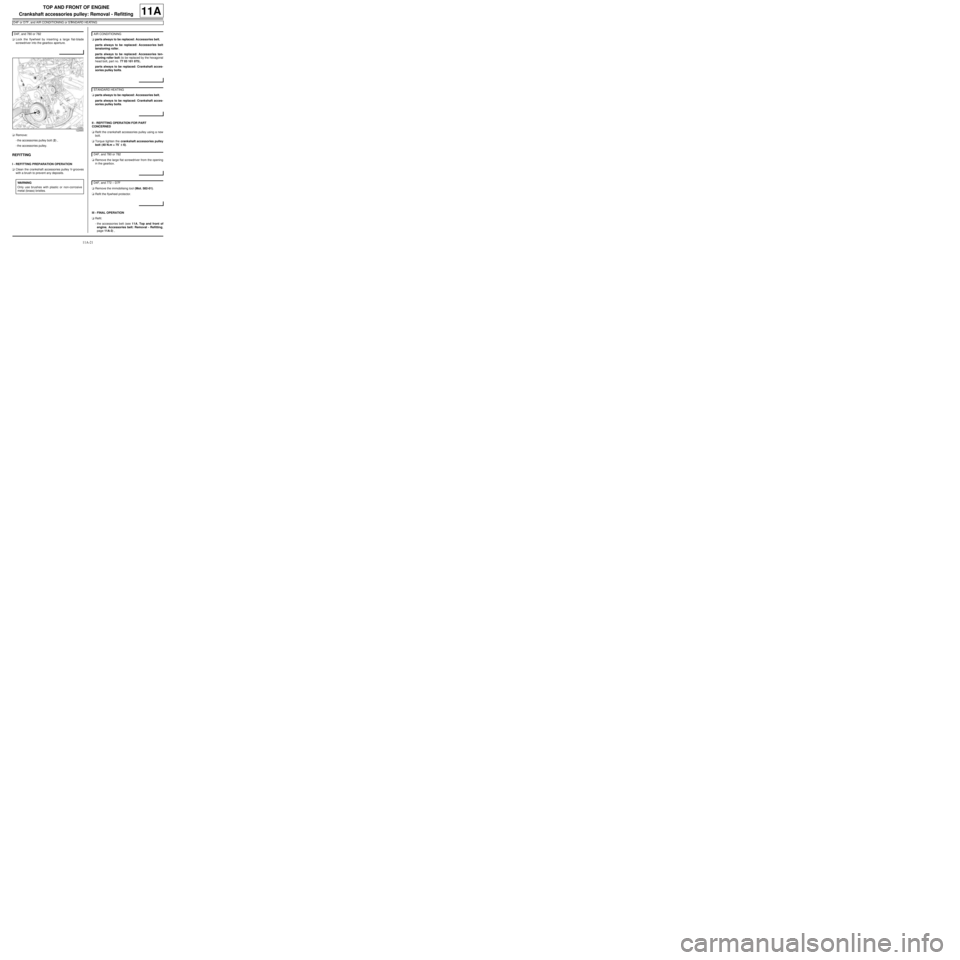

aLock the flywheel by inserting a large flat-blade

screwdriver into the gearbox aperture.

aRemove:

-the accessories pulley bolt (2) ,

-the accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aClean the crankshaft accessories pulley V-grooves

with a brush to prevent any deposits.aparts always to be replaced: Accessories belt,

parts always to be replaced: Accessories belt

tensioning roller,

parts always to be replaced: Accessories ten-

sioning roller bolt (to be replaced by the hexagonal

head bolt, part no. 77 03 101 075),

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

aparts always to be replaced: Accessories belt,

parts always to be replaced: Crankshaft acces-

sories pulley bolts.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit the crankshaft accessories pulley using a new

bolt.

aTorque tighten the crankshaft accessories pulley

bolt (40 N.m + 75˚ ±± ± ±

6).

aRemove the large flat screwdriver from the opening

in the gearbox.

aRemove the immobilising tool (Mot. 582-01).

aRefit the flywheel protector.

III - FINAL OPERATION

aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) , D4F, and 780 or 782

122665

WARNING

Only use brushes with plastic or non-corrosive

metal (brass) bristles.

AIR CONDITIONING

STANDARD HEATING

D4F, and 780 or 782

D4F, and 772 – D7F

Page 139 of 652

11A-22

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

D4F or D7F, and AIR CONDITIONING or STANDARD HEATING

11A

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

Page 140 of 652

11A-23

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

C44, and K9K

11A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-accessories belt,

-accessories belt auto tensioner,

-accessories belt auto tensioner bolt.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift ( (see Vehicle:

Towing and lifting) ).aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the front right-hand wheel ( (see Wheel: Removal

- Refitting) ),

-the front right-hand wheel arch liner ( (see Front

wheel arch liner: Removal - Refitting) ),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the accessories belt auto tensioner.

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the crankshaft position sensor (see 13B, Diesel in-

jection, Crankshaft position sensor: Removal -Refitting, page 13B-15) , Tightening torquesm

crankshaft accessories

pulley bolt80 Nm

19656

Page 141 of 652

11A-24

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

C44, and K9K

11A

-the crankshaft accessories pulley bolt (1) , locking

the flywheel using a flat screwdriver at the point of

the crankshaft position sensor,

-the crankshaft accessories pulley (2) .

REFITTING

I - REFITTING PREPARATIONS OPERATION

aIf reusing the crankshaft accessories pulley, clean

the pulley V-grooves with a brush to eliminate any

deposits.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the crankshaft accessories pulley,

-the crankshaft accessories pulley bolt.

aTorque tighten the crankshaft accessories pulley

bolt (80 Nm), locking the flywheel using a flat screw-

driver at the point of the crankshaft position sensor.

aRefit the crankshaft position sensor (see 13B, Die-

sel injection, Crankshaft position sensor: Re-

moval - Refitting, page 13B-15) .

III - FINAL OPERATION.

aRefit:

-the new accessories belt auto tensioner,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

aRefit:

-the front right-hand wheel arch liner ( (see Front

wheel arch liner: Removal - Refitting) ),

-the front right-hand wheel ( (see Wheel: Removal

- Refitting) ).

aConnect the battery ( (see Battery: Removal - Re-

fitting) ).

Page 142 of 652

11A-25

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray,

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .II - REMOVAL OPERATION

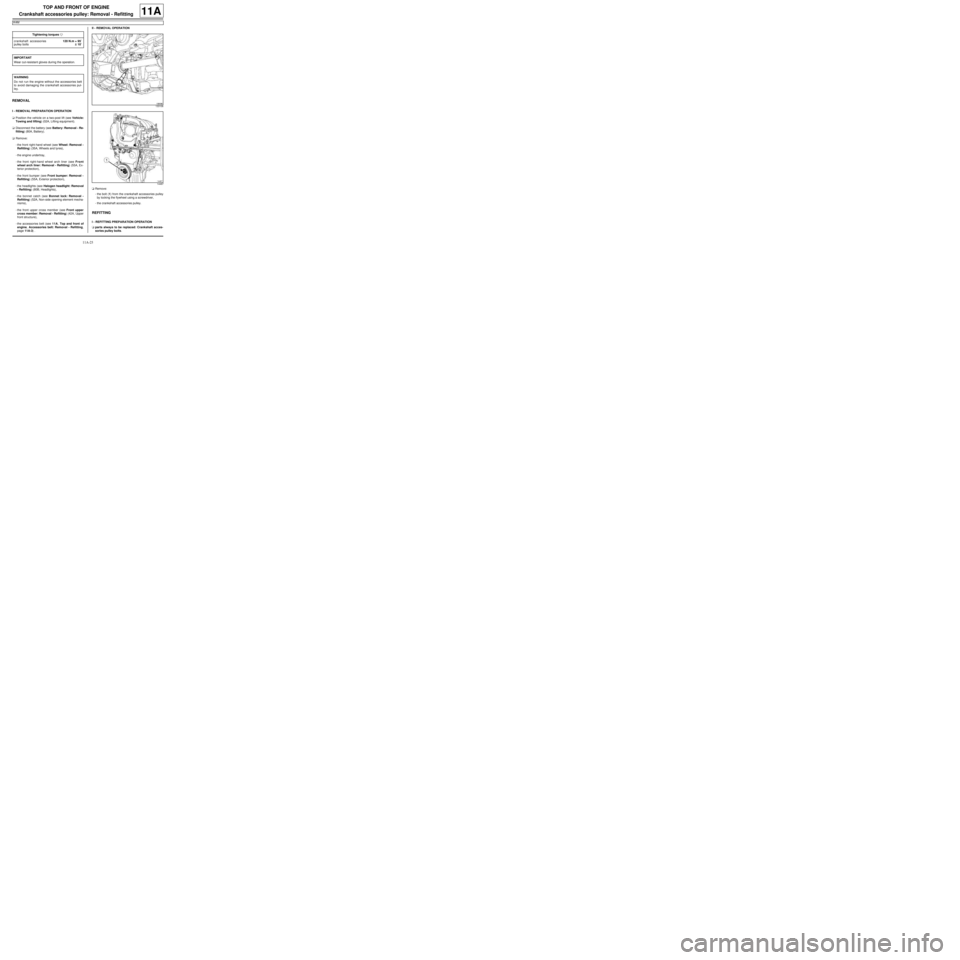

aRemove:

-the bolt (1) from the crankshaft accessories pulley

by locking the flywheel using a screwdriver,

-the crankshaft accessories pulley.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Crankshaft acces-

sories pulley bolts. Tightening torquesm

crankshaft accessories

pulley bolts120 N.m + 95˚

±± ± ±

10˚

IMPORTANT

Wear cut-resistant gloves during the operation.

WARNING

Do not r un the engine without the accessories belt

to avoid damaging the crankshaft accessories pul-

ley.

133106

14487

Page 143 of 652

11A-26

TOP AND FRONT OF ENGINE

Crankshaft accessories pulley: Removal - Refitting

K4M

11A

aUse a brush to remove any deposits from the crank-

shaft accessories pulley V grooves.

II - REFITTING OPERATION

aRefit the crankshaft accessories pulley.

aTighten to torque and angle the crankshaft acces-

sories pulley bolts (120 N.m + 95˚ ±± ± ±

10˚) by locking

the engine flywheel using a flat-blade screwdriver.

III - FINAL OPERATION

aRefit:

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) .

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

Page 144 of 652

11A-27

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D7F, and 800

11A

PARTS AND CONSUMABLES FOR THE

REPAIR WORK

aParts always to be replaced:

-the timing belt,

-the tensioning roller,

-the accessories pulley bolt.

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) .

aDisconnect the battery ( (see Battery: Removal -

Refitting) ).

aRemove:

-the front right-hand wheel arch liner (see) (see ) ,

-the front right-hand wheel ( (see Wheel: Removal

- Refitting) ),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,-the accessories pulley (see 11A, Top and front of

engine, Crankshaft accessories pulley: Remov-

al - Refitting, page 11A-20) ,

-the rear suspended engine mounting (see 19D,

Engine mounting, Lower engine tie-bar: Re-

moval - Refitting, page 19D-18) .

aSet up the engine support tool (Mot. 1379) (1) .

aTighten the bolt (2) to pre-stress the engine stand.

aRemove the right-hand suspended engine mounting

(see 19D, Engine mounting, Right-hand sus-

pended engine mounting: Removal - Refitting,

page 19D-13) . Special tooling required

Mot. 1379Engine suppor t tool for cylin-

der head oper ations.

Mot. 1054TDC setting pin.

Mot. 1386Tool for pre-tensioning the

timing belt.

Mot. 1135-01Timing belt tensioner.

Mot. 1715Belt tension checking tool

(frequency indicator).

Mot. 1505Belt tension setting tool (fre-

quency meter)

Equipment required

torque wrench

Tightening torquesm

tensioning roller nut50 N.m

upper timing cover bolts33 N.m

10267

Page 146 of 652

11A-29

TOP AND FRONT OF ENGINE

Timing belt: Removal - Refitting

D7F, and 800

11A

aPosition the spacer (7) of the timing belt pre-tension-

ing tool (Mot. 1386).

aPosition the timing belt tensioner (Mot. 1135-01) at

(8) on the tensioning roller.

aTurn the tensioning roller anti-clockwise until a belt

tension of 139 ±± ± ±

3 Hz is obtained with frequency

meter (Mot. 1715) (9) or (Mot. 1505).

aTighten the tensioning roller nut.aPosition the (Mot. 1386) (10) .

aApply a pretensioning torque to the timing belt sec-

tion (11) using a torque wrench set to 10 Nm.

aMake sure that the timing belt tension is 139 ±± ± ±

3 Hz

using the frequency meter (Mot. 1715) or (Mot.

1505) : otherwise, adjust it using the (Mot. 1135-01).

aTorque tighten the tensioning roller nut (50 N.m).

aTurn the crankshaft through four revolutions.

aSet the timing using the TDC setting pin (Mot. 1054).

aApply a pretensioning torque to the timing belt sec-

tion (11) using a torque wrench set to 10 Nm.

aMake sure that the timing belt tension is 139 ±± ± ±

3 Hz

using the frequency meter (Mot. 1715) or (Mot.

1505) : otherwise, adjust it using the (Mot. 1135-01).

II - FINAL OPERATION

aRefit the timing covers.

aTorque tighten clockwise the upper timing cover

bolts (33 N.m).

aRefit:

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the accessories pulley (see 11A, Top and front of

engine, Crankshaft accessories pulley: Remov-

al - Refitting, page 11A-20) ,

10881

1629410881