battery RENAULT TWINGO RS 2009 2.G Engine And Peripherals Manual Online

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 652

Page 258 of 652

11A-141

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aPosition the vehicle on a two-post lift (see Vehicle:

Towing and lifting) (02A, Lifting equipment).

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the engine undertray,

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the crankshaft accessories pulley (see 11A, Top

and front of engine, Crankshaft accessories

pulley: Removal - Refitting, page 11A-20) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) .

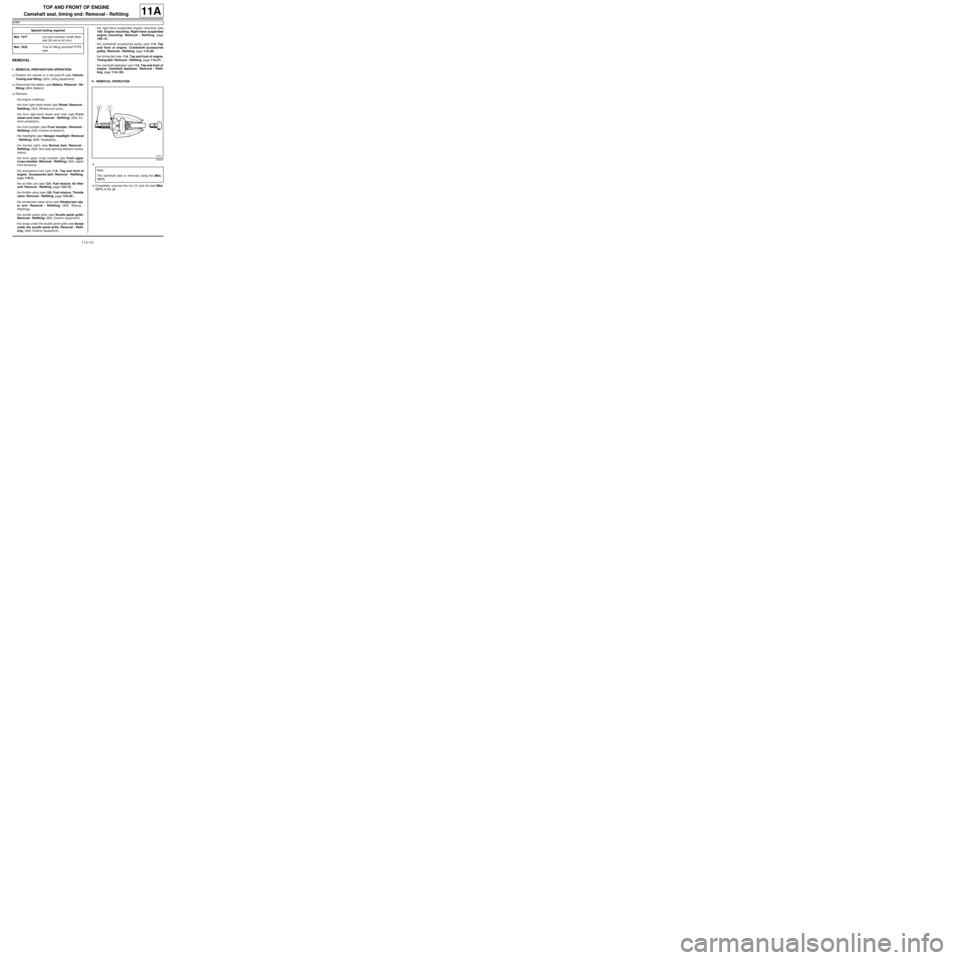

II - REMOVAL OPERATION

a

aCompletely unscrew the nut (1) and the bolt (Mot.

1577) of the (2) . Special tooling required

Mot. 1577Lip seal e xtractor (shaft diam-

eter 28 mm to 42 mm).

Mot. 1632Tool for fitting camshaft PTFE

seal

105257

Note:

The camshaft seal is removed using the (Mot.

1577).

Page 262 of 652

11A-145

TOP AND FRONT OF ENGINE

Camshaft seal, timing end: Removal - Refitting

K4M

11A

aFit the cover (13) and the collar nut (14) of the (Mot.

1632).

aScrew on the collar nut until the cover touches the

cylinder head.

aRemove:

-the collar nut from the (Mot. 1632),

-the cover from the (Mot. 1632),

-the stud from the (Mot. 1632).

III - FINAL OPERATION

aRefit:

-the camshaft dephaser (see 11A, Top and front of

engine, Camshaft dephaser: Removal - Refit-

ting, page 11A-135) ,

-the timing belt (see 11A, Top and front of engine,

Timing belt: Removal - Refitting, page 11A-27) ,

-the right-hand suspended engine mounting (see

19D, Engine mounting, Right-hand suspended

engine mounting: Removal - Refitting, page

19D-13) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),-the throttle valve (see 12A, Fuel mixture, Throttle

valve: Removal - Refitting, page 12A-20) ,

-the air filter unit (see 12A, Fuel mixture, Air filter

unit: Removal - Refitting, page 12A-13) ,

-the accessories belt (see 11A, Top and front of

engine, Accessories belt: Removal - Refitting,

page 11A-3) ,

-the front upper cross member (see Front upper

cross member: Removal - Refitting) (42A, Upper

front structure),

-the bonnet catch (see Bonnet lock: Removal -

Refitting) (52A, Non-side opening element mecha-

nisms),

-the headlights (see Halogen headlight: Removal

- Refitting) (80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (55A, Exterior protection),

-the front right-hand wheel arch liner (see Front

wheel arch liner: Removal - Refitting) (55A, Ex-

terior protection),

-the front right-hand wheel (see Wheel: Removal -

Refitting) (35A, Wheels and tyres),

-the engine undertray.

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

126222

Page 264 of 652

11A-147

TOP AND FRONT OF ENGINE

Oil decanter: Removal - Refitting

K4M

11A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) .

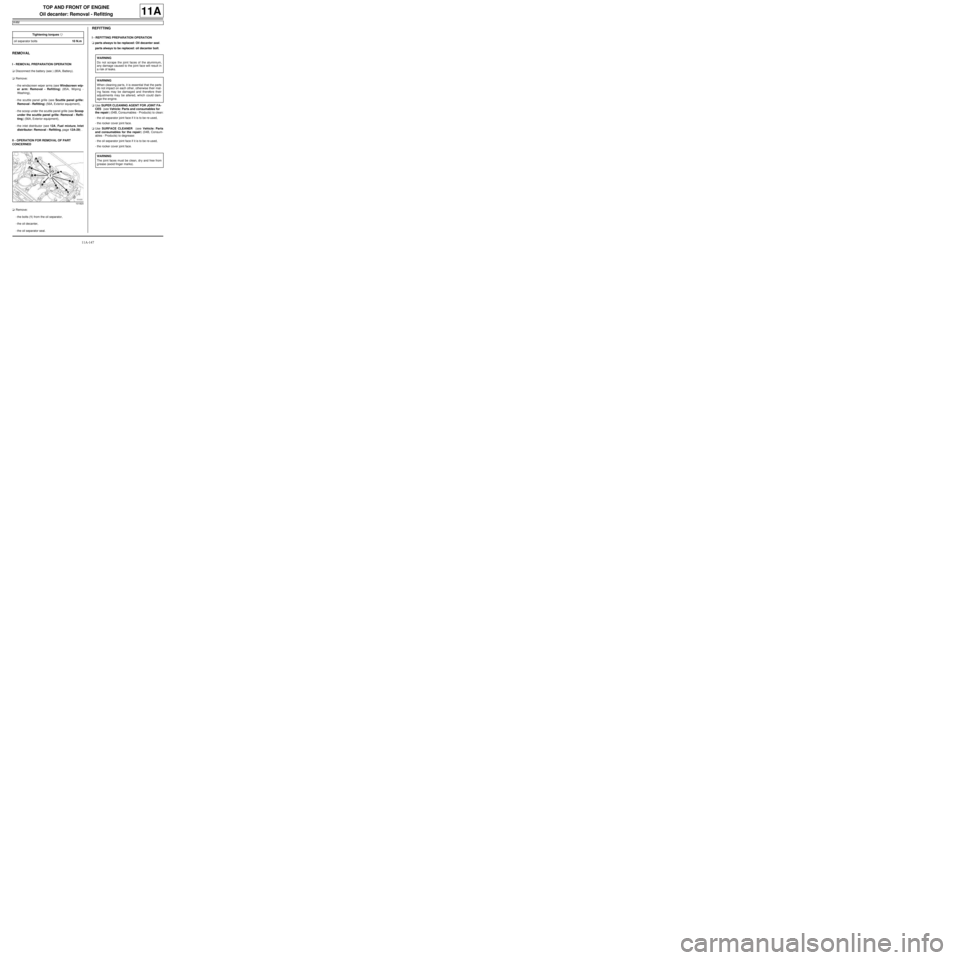

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (1) from the oil separator,

-the oil decanter,

-the oil separator seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Oil decanter seal.

parts always to be replaced: oil decanter bolt.

aUse SUPER CLEANING AGENT FOR JOINT FA-

CES (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) to clean:

-the oil separator joint face if it is to be re-used,

-the rocker cover joint face.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consum-

ables - Products) to degrease:

-the oil separator joint face if it is to be re-used,

-the rocker cover joint face. Tightening torquesm

oil separator bolts10 N.m

101820

WARNING

Do not scrape the joint faces of the aluminium,

any damage caused to the joint face will result in

a risk of leaks.

WARNING

When cleaning par ts, it is essential that the parts

do not impact on each other, otherwise their mat-

ing faces may be damaged and therefore their

adjustments may be altered, which could dam-

age the engine.

WARNING

The joint faces must be clean, dr y and free from

grease (avoid finger marks).

Page 265 of 652

11A-148

TOP AND FRONT OF ENGINE

Oil decanter: Removal - Refitting

K4M

11A

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the oil separator,

-the oil decanter.

aTighten to torque and in order the oil separator

bolts (10 N.m).

III - FINAL OPERATION

aRefit:

-the inlet distributor (see 12A, Fuel mixture, Inlet

distributor: Removal - Refitting, page 12A-29) ,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see ) (80A, Battery).

101820

Page 285 of 652

12A-20

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 772

12A

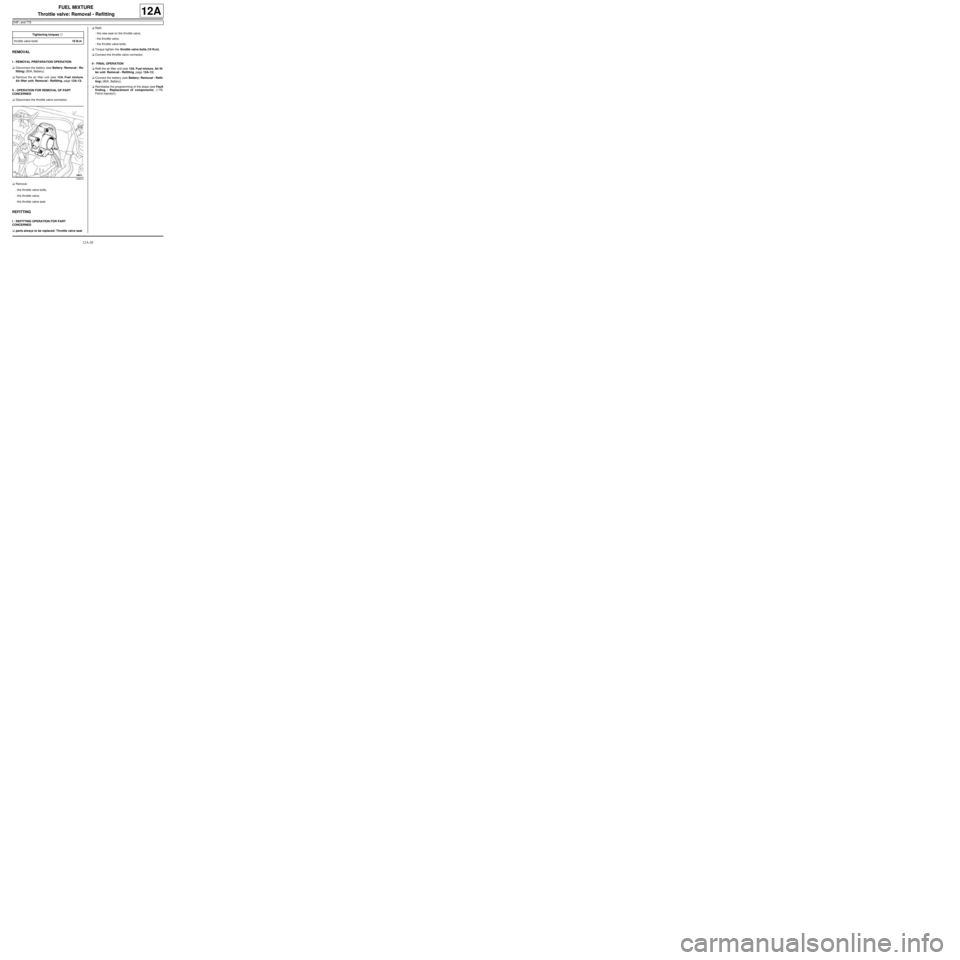

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove the air filter unit (see 12A, Fuel mixture,

Air filter unit: Removal - Refitting, page 12A-13) .

II - OPERATION FOR REMOVAL OF PART

CONCERNED

aDisconnect the throttle valve connector.

aRemove:

-the throttle valve bolts,

-the throttle valve,

-the throttle valve seal.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aparts always to be replaced: Throttle valve seal.aRefit:

-the new seal on the throttle valve,

-the throttle valve,

-the throttle valve bolts.

aTorque tighten the throttle valve bolts (10 N.m).

aConnect the throttle valve connector.

II - FINAL OPERATION

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

aReinitialise the programming of the stops (see Fault

finding - Replacement of components) (17B,

Petrol injection). Tightening torquesm

throttle valve bolts10 N.m

108810

Page 286 of 652

12A-21

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 780 or 782

12A

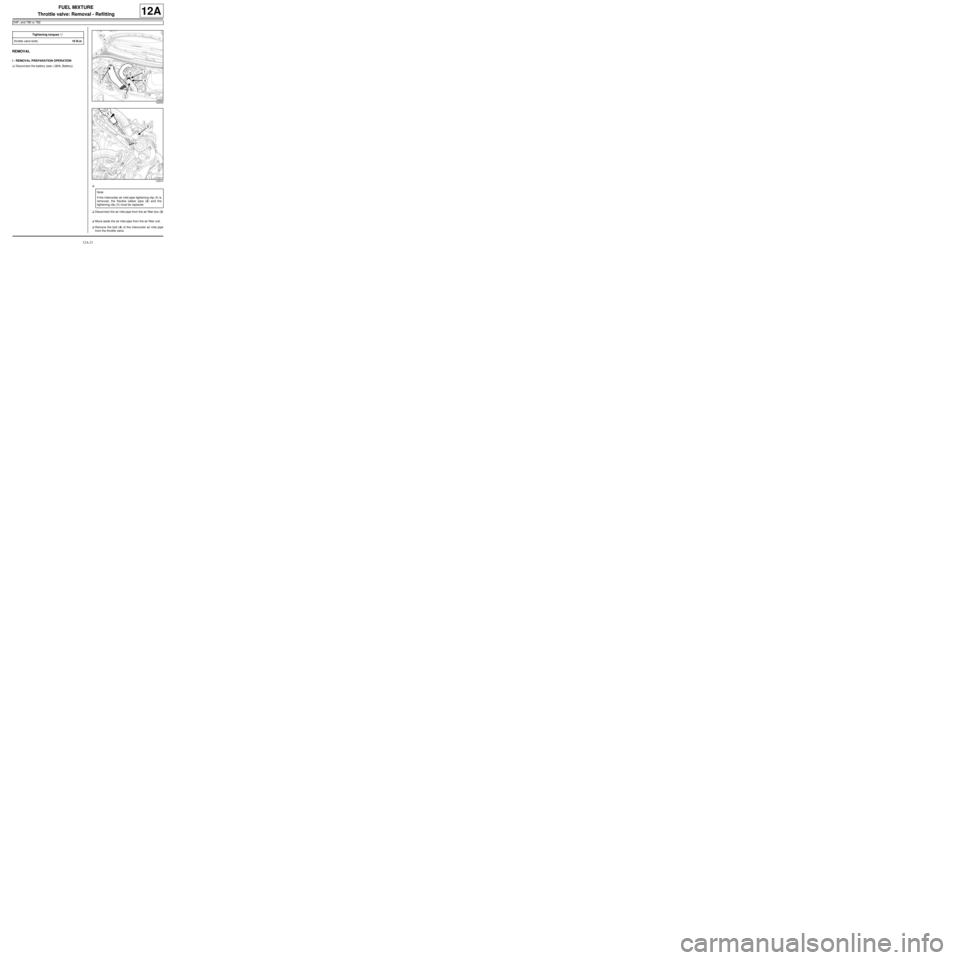

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see ) (80A, Battery).

a

aDisconnect the air inlet pipe from the air filter box (3)

.

aMove aside the air inlet pipe from the air filter unit.

aRemove the bolt (4) of the intercooler air inlet pipe

from the throttle valve. Tightening torquesm

throttle valve bolts10 N.m

122833

122673

Note:

If the intercooler air inlet pipe tightening clip (1) is

removed, the flexible rubber pipe (2) and the

tightening clip (1) must be replaced.

Page 288 of 652

12A-23

FUEL MIXTURE

Throttle valve: Removal - Refitting

D4F, and 780 or 782

12A

-the throttle valve,

-the throttle valve seal.

REFITTING

I - REFITTING PREPARATION OPERATION

aparts always to be replaced: Throttle valve seal.

aUse SURFACE CLEANER (see Vehicle: Parts

and consumables for the repair) (04B, Consuma-

bles - Products) to clean the bearing faces:

-on the inlet distributor,

-on the throttle valve if it is to be reused.

II - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-a new seal on the throttle valve,

-the throttle valve,

-the throttle valve bolts.

aTorque tighten the throttle valve bolts (10 N.m).

aConnect the throttle valve connector.

aClip the wiring onto the throttle valve.

III - FINAL OPERATION

aRefit:

-the intercooler air outlet pipe on the throttle valve,

-the intercooler air outlet pipe bolts.

aTighten the intercooler air outlet pipe bolts.

aConnect the vacuum pipe onto the turbocharger dis-

charge solenoid valve.aPush the intercooler air inlet pipe clip in the direction

of the arrow (11) .

aFit the intercooler air inlet pipe.

aConnect the intercooler air inlet pipe on the turbo-

charger.

aRefit the intercooler air inlet pipe bolt on the throttle

valve.

aFit the air filter box air inlet pipe.

aConnect:

-the air filter unit air inlet pipe,

-the battery (see ) (80A, Battery).

aProgram the throttle valve (see Fault finding - Re-

placement of components) (17B, Petrol injection).

122666

Page 301 of 652

12A-36

FUEL MIXTURE

Inlet distributor: Removal - Refitting

D4F, and 772

12A

III - FINAL OPERATION

aIt is essential to apply a bead of FLUOSTAR 2L

grease (see Vehicle: Parts and consumables for

the repair) (04B, Consumables - Products) 2 mm in

diameter on the inner edge of the high tension caps.

aConnect:

-the high voltage wiring harnesses to the spark

plugs,

-the fuel supply pipe union on the injector rail,

-the motorised throttle valve connector,

-the injector connectors,

-the air inlet temperature sensor connector,

-the non-return valve pipe on the brake servo,

-the petrol vapour rebreather pipe.

aRefit the dipstick.

aClip the engine wiring onto the inlet distributor.

aRefit the air filter unit (see 12A, Fuel mixture, Air fil-

ter unit: Removal - Refitting, page 12A-13) .

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).

106640

Page 305 of 652

12A-40

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

REMOVAL

I - REMOVAL PREPARATION OPERATION

aDisconnect the battery (see Battery: Removal - Re-

fitting) (80A, Battery).

aRemove:

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing),-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the dipstick.

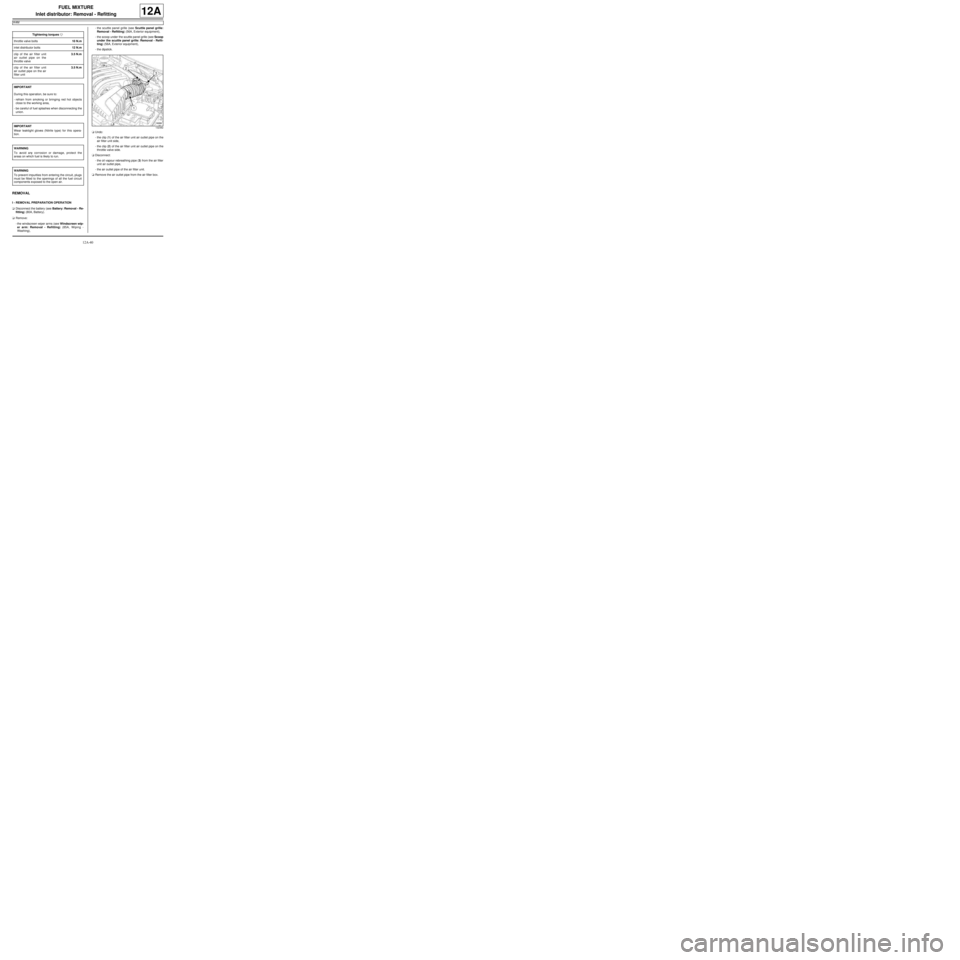

aUndo:

-the clip (1) of the air filter unit air outlet pipe on the

air filter unit side,

-the clip (2) of the air filter unit air outlet pipe on the

throttle valve side.

aDisconnect:

-the oil vapour rebreathing pipe (3) from the air filter

unit air outlet pipe,

-the air outlet pipe of the air filter unit.

aRemove the air outlet pipe from the air filter box. Tightening torquesm

throttle valve bolts10 N.m

inlet distributor bolts12 N.m

clip of the air filter unit

air outlet pipe on the

throttle valve3.5 N.m

clip of the air filter unit

air outlet pipe on the air

filter unit3.5 N.m

IMPORTANT

During this oper ation, be sure to:

-refrain from smoking or bringing red hot objects

close to the working area,

-be careful of fuel splashes when disconnecting the

union.

IMPORTANT

Wear leaktight gloves (Nitrile type) for this opera-

tion.

WARNING

To avoid any corrosion or damage, protect the

areas on which fuel is likely to run.

WARNING

To prevent impurities from entering the circuit, plugs

must be fitted to the openings of all the fuel circuit

components exposed to the open air.

132382

Page 309 of 652

12A-44

FUEL MIXTURE

Inlet distributor: Removal - Refitting

K4M

12A

aTorque tighten:

-the clip of the air filter unit air outlet pipe on the

throttle valve (3.5 N.m),

-the clip of the air filter unit air outlet pipe on the

air filter unit (3.5 N.m).

aRefit:

-the dipstick,

-the scoop under the scuttle panel grille (see Scoop

under the scuttle panel grille: Removal - Refit-

ting) (56A, Exterior equipment),

-the scuttle panel grille (see Scuttle panel grille:

Removal - Refitting) (56A, Exterior equipment),

-the windscreen wiper arms (see Windscreen wip-

er arm: Removal - Refitting) (85A, Wiping -

Washing).

aConnect the battery (see Battery: Removal - Refit-

ting) (80A, Battery).