ESP RENAULT TWINGO RS 2009 2.G General Vehicle Information Workshop Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 46

Page 7 of 46

01C-3

VEHICLE BODYWORK SPECIFICATIONS

Vehicle panel gaps: Adjustment value

01C

All values are given in millimetres.Section 1

(X1) = 3.5 ±± ± ±

1.5

120453

WARNING

The clearance values are given for information pur-

poses.

When adjusting clearances, certain rules have to be

followed:

-maintain symmetry with respect to the opposite

side,

-ensure the flush fitting is correct,

-check correct operation of the opening, and water/

air-tightness.

120385

Page 15 of 46

01D-2

MECHANICAL INTRODUCTION

Vehicle: Precautions for the repair

01D

4 - Safety

Operations on certain equipment and certain parts (for

instance: spring-shock absorber assembly, automatic

transmission, brake system, ABS, airbag, common rail

diesel injection, LPG, etc.) require particular attention

to be paid to safety, cleanliness and care.

The safety symbol used in this manual indicates that

special attention must be paid to the procedure or the

tightening torque values.

Working safely:

-use suitable tools which are in good condition (use of

« multi-purpose » tools, such as adjustable pliers,

etc., should be avoided wherever possible),

-use supports and adopt a correct posture when per-

forming heavy work or raising loads,

-make sure that the procedure used is not dangerous,

-Do not wear any jewellery or other small objects dur-

ing an operation,

-use personal protection (gloves, safety glasses, work

shoes, masks, skin barrier creams, etc.),

-always follow the safety instructions associated with

the operation to be performed,

-do not smoke when working on vehicles,

-use smoke extractors (welding, exhaust gases, etc.),

-do not use harmful products in unventilated rooms,

-do not overstrain yourself or attempt inappropriate

work operations,

-use axle stands when working under a vehicle raised

on a jack,

-do not ingest any chemicals (brake fluid, coolant,

etc.),

-do not open the cooling circuit when it is hot and pres-

surised,

-take care with components that are liable to start up

suddenly (engine cooling fan, etc.).

Respecting the environment:

-do not allow waste refrigerants to escape into the at-

mosphere,

-do not dispose of waste vehicle fluids (oil, brake fluid,

etc.) in drains,

-do not burn discarded products (tyres, etc.).5 - Conclusion

The procedures contained in this document merit your

attention. Please read them carefully in order to reduce

the risk of injury, and avoid using incorrect procedures

that could damage the vehicle or make it dangerous in

use.

Following the recommended procedures will help you

to provide a quality of service which will ensure the ve-

hicles achieve the highest levels of performance and

reliability.

Maintenance and repair operations must be carried out

under the proper conditions to ensure that our vehicles

run safely and reliably.

Page 17 of 46

01D-4

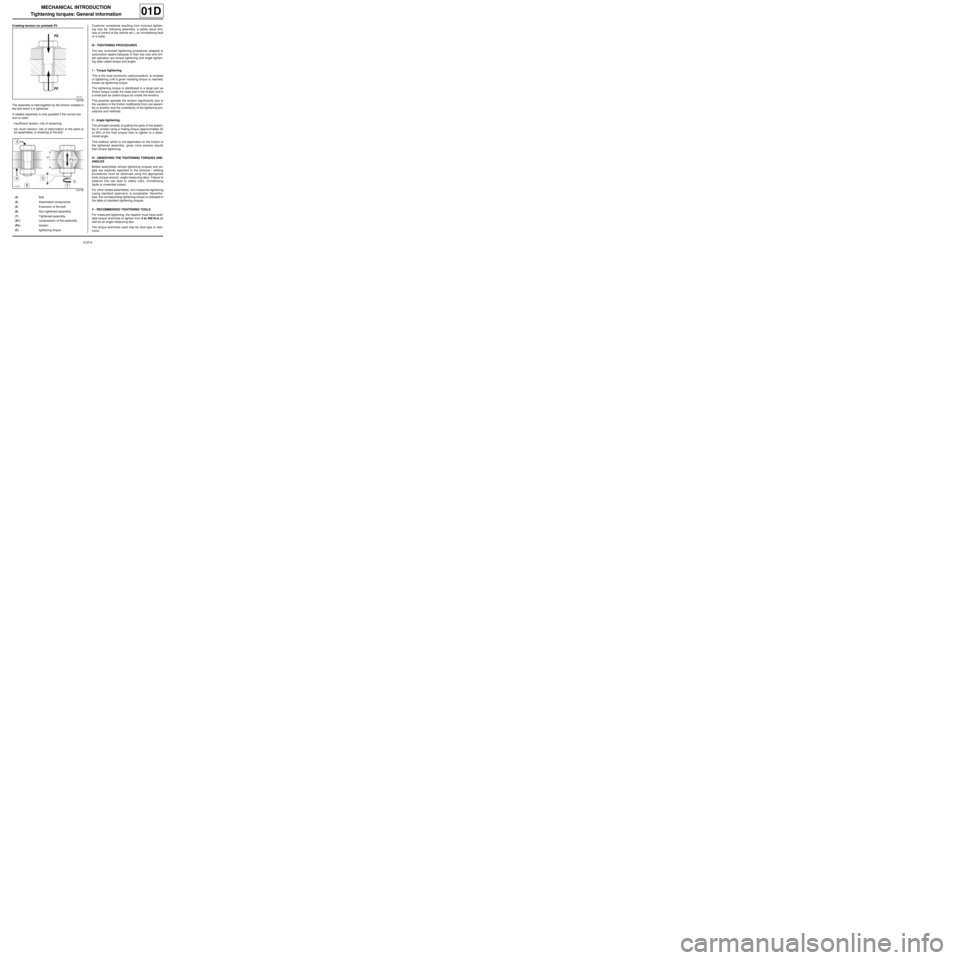

MECHANICAL INTRODUCTION

Tightening torques: General information

01D

Creating tension (or preload) F0

The assembly is held together by the tension created in

the bolt when it is tightened.

A reliable assembly is only possible if the correct ten-

sion is used:

-insufficient tension: risk of loosening,

-too much tension: risk of deformation of the parts to

be assembled, or shearing of the bolt.Customer complaints resulting from incorrect tighten-

ing may be, following assembly, a safety issue (fire,

loss of control of the vehicle etc.), an immobilising fault

or a noise.

III - TIGHTENING PROCEDURES

The two controlled tightening procedures adapted to

automotive repairs because of their low cost and sim-

ple operation are torque tightening and angle tighten-

ing (also called torque and angle).

1 - Torque tightening

This is the most commonly used procedure. Is consists

of tightening until a given resisting torque is reached,

known as tightening torque.

The tightening torque is distributed in a large part as

friction torque (under the head and in the thread) and in

a small part as useful torque (to create the tension).

This practise spreads the tension significantly due to

the variation in the friction coefficients from one assem-

bly to another and the uncertainty of the tightening pro-

cedures and methods.

2 - Angle tightening

The principle consists of putting the parts of the assem-

bly in contact using a mating torque (approximately 25

to 30% of the final torque) then to tighten to a deter-

mined angle.

This method, which is not dependent on the friction of

the tightened assembly, gives more precise results

than torque tightening.

IV - OBSERVING THE TIGHTENING TORQUES AND

ANGLES

Bolted assemblies whose tightening torques and an-

gles are explicitly specified in the removal / refitting

procedures must be observed using the appropriate

tools (torque wrench, angle measuring disc). Failure to

observe this can lead to safety risks, immobilising

faults or unwanted noises.

For other bolted assemblies, non-measured tightening

(using standard spanners) is acceptable. Neverthe-

less, the corresponding tightening torque is indicated in

the table of standard tightening torques.

V - RECOMMENDED TIGHTENING TOOLS

For measured tightening, the repairer must have avail-

able torque wrenches to tighten from 4 to 400 N.m as

well as an angle measuring disc.

The torque wrenches used may be click type or elec-

tronic.

120738

120739

(3) Bolt

(4) Assembled components

(5) Extension of the bolt

(6) Non-tightened assembly

(7) Tightened assembly

(X1) compression of the assembly

(Fo) tension

(C) tightening torque

Page 38 of 46

04B-3

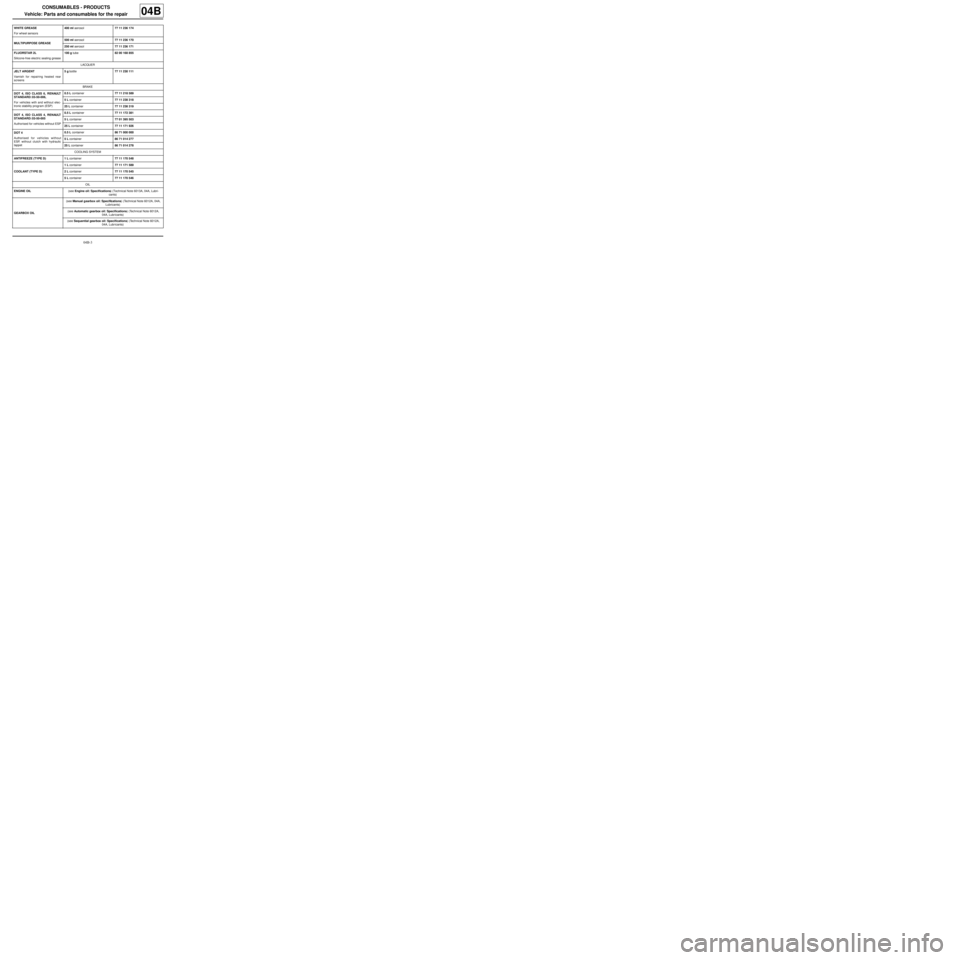

CONSUMABLES - PRODUCTS

Vehicle: Parts and consumables for the repair

04B

WHITE GREASE

For wheel sensors400 ml aerosol77 11 236 174

MULTIPURPOSE GREASE500 ml aerosol77 11 236 170

250 ml aerosol77 11 236 171

FLUORSTAR 2L

Silicone-free electric sealing grease100 g tube82 00 168 855

LACQUER

JELT ARGENT

Varnish for repairing heated rear

screens5 g bottle77 11 230 111

BRAKE

DOT 4, ISO CLASS 6, RENAULT

STANDARD: 03-50-006,

For vehicles with and without elec-

tronic stability program (ESP)0.5 L container77 11 218 589

5 L container77 11 238 318

25 L container77 11 238 319

DOT 4, ISO CLASS 4, RENAULT

STANDARD: 03-50-005

Authorised for vehicles without ESP0.5 L container77 11 172 381

5 L container77 01 395 503

25 L container77 11 171 926

DOT 4

Authorised for vehicles without

ESP, without clutch with hydraulic

tappet0.5 L container86 71 000 000

5 L container86 71 014 277

25 L container86 71 014 278

COOLING SYSTEM

ANTIFREEZE (TYPE D) 1 L container77 11 170 548

COOLANT (TYPE D)1 L container77 11 171 589

2 L container77 11 170 545

5 L container77 11 170 546

OIL

ENGINE OIL (see Engine oil: Specifications) (Technical Note 6013A, 04A, Lubri-

cants)

GEARBOX OIL (see Manual g earbox oil: Specifications) (Technical Note 6012A, 04A,

Lubricants)

(see Automatic gearbox oil: Specifications) (Technical Note 6012A,

04A, Lubr icants)

(see Sequential gearbox oil: Specifications) (Technical Note 6012A,

04A, Lubr icants)