coolant RENAULT TWINGO RS 2009 2.G Heating And Air Conditioning - Manual Air Conditioning User Guide

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 63

Page 32 of 63

62C-32

MR-413-X44-62C000$637_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Conformity check62C

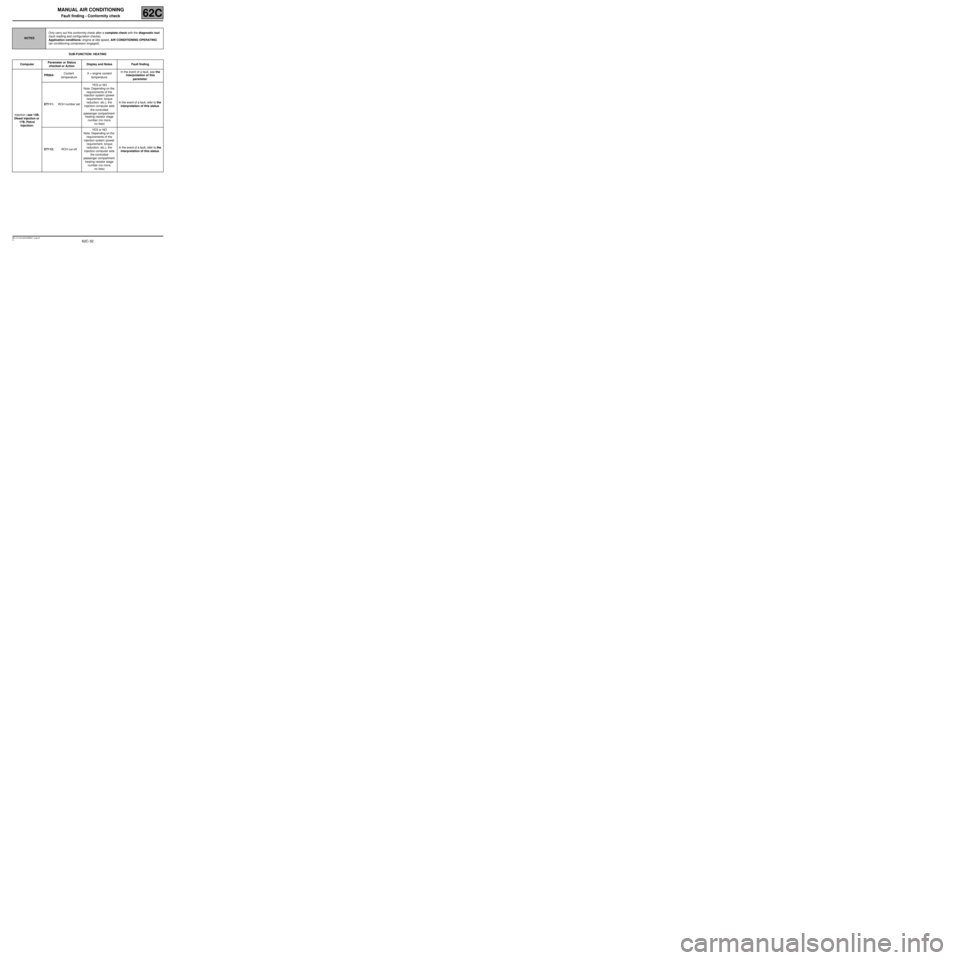

SUB-FUNCTION: HEATING

NOTESOnly carry out this conformity check after a complete check with the diagnostic tool

(fault reading and configuration checks).

Application conditions: engine at idle speed, AIR CONDITIONING OPERATING

(air conditioning compressor engaged).

ComputerParameter or Status

checked or ActionDisplay and Notes Fault finding

Injection (see 13B,

Diesel injection or

17B, Petrol

injection)PR064:Coolant

temperatureX = engine coolant

temperatureIn the event of a fault, see the

interpretation of this

parameter.

ET111:RCH number setYES or NO

Note: Depending on the

requirements of the

injection system (power

requirement, torque

reduction, etc.), the

injection computer sets

the controlled

passenger compartment

heating resistor stage

number (no more,

no less)In the event of a fault, refer to the

interpretation of this status.

ET112:RCH cut-offYES or NO

Note: Depending on the

requirements of the

injection system (power

requirement, torque

reduction, etc.), the

injection computer sets

the controlled

passenger compartment

heating resistor stage

number (no more,

no less)In the event of a fault, refer to the

interpretation of this status.

Page 39 of 63

62C-39

MR-413-X44-62C000$819_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

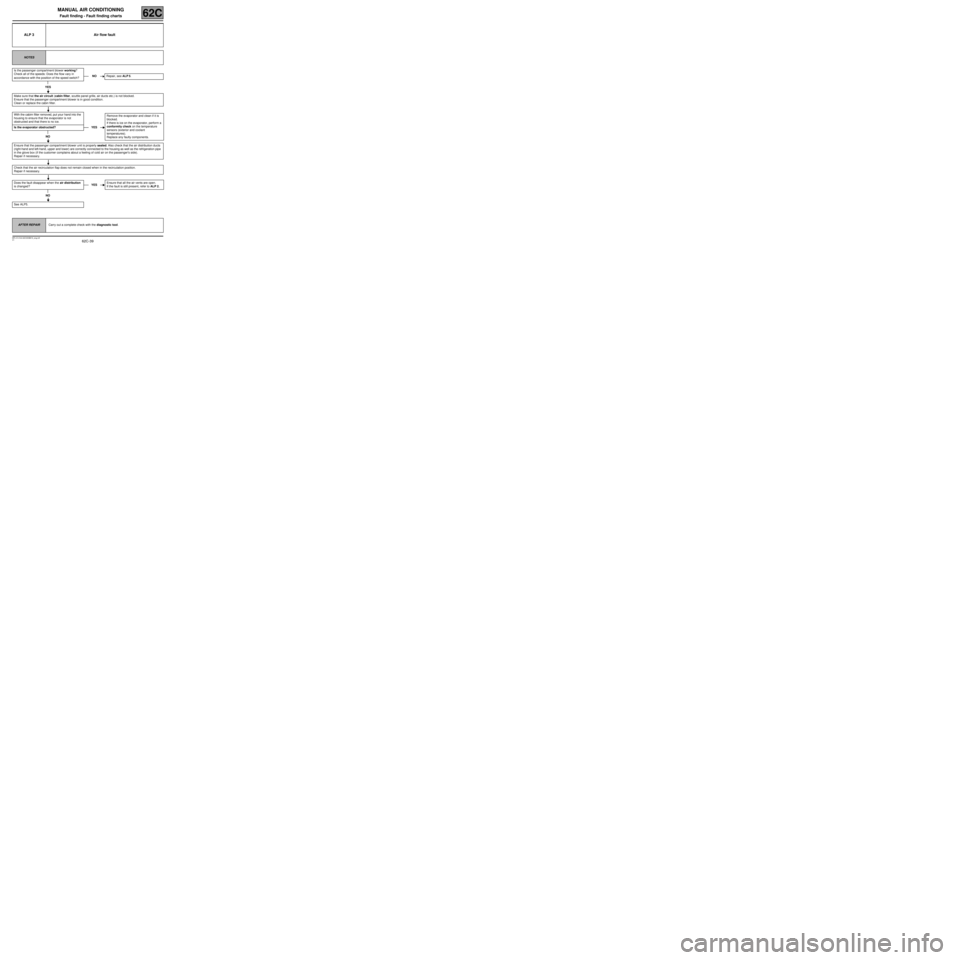

ALP 3 Air flow fault

NOTES

Is the passenger compartment blower working?

Check all of the speeds: Does the flow vary in

accordance with the position of the speed switch?

YES

Make sure that the air circuit (cabin filter, scuttle panel grille, air ducts etc.) is not blocked.

Ensure that the passenger compartment blower is in good condition.

Clean or replace the cabin filter.

With the cabim filter removed, put your hand into the

housing to ensure that the evaporator is not

obstructed and that there is no ice.

Is the evaporator obstructed?

NO

Ensure that the passenger compartment blower unit is properly sealed. Also check that the air distribution ducts

(right-hand and left-hand, upper and lower) are correctly connected to the housing as well as the refrigeration pipe

in the glove box (if the customer complains about a feeling of cold air on the passenger's side).

Repair if necessary.

Check that the air recirculation flap does not remain closed when in the recirculation position.

Repair if necessary.

Does the fault disappear when the air distribution

is changed ?

NO

See ALP5.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

NORepair, see ALP 5.

YESRemove the evaporator and clean if it is

blocked.

If there is ice on the evaporator, perform a

conformity check on the temperature

sensors (exterior and coolant

temperatures).

Replace any faulty components.

YESEnsure that all the air vents are open.

If the fault is still present, refer to ALP 2.

Page 49 of 63

62C-49

MR-413-X44-62C000$819_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

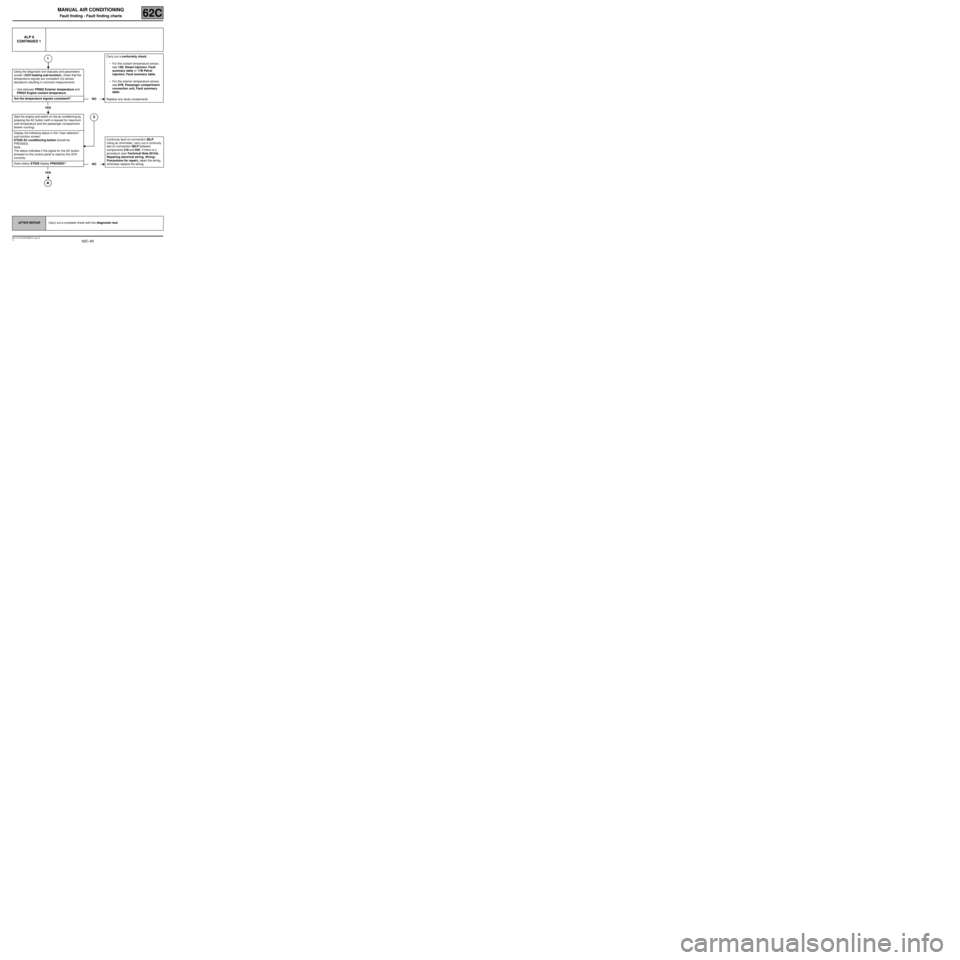

ALP 8

CONTINUED 1

1

Using the diagnostic tool statuses and parameters

screen (UCH heating sub-function), check that the

temperature signals are consistent (no sensor

deviations resulting in incorrect measurement).

–Use statuses PR002 Exterior temperature and

PR024 Engine coolant temperature.

Are the temperature signals consistent?

YES

Start the engine and switch on the air conditioning by

pressing the AC button (with a request for maximum

cold temperature and the passenger compartment

blower running).

2

Display the following status in the “User selection”

sub-function screen:

ET029 Air conditioning button should be

PRESSED.

Note:

The status indicates if the signal for the AC button

pressed on the control panel is read by the UCH

correctly.

Does status ET029 display PRESSED?

YES

NOCarry out a conformity check:

–For the coolant temperature sensor,

see 13B, Diesel injection, Fault

summary table or 17B Petrol

injection, Fault summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary

table.

Replace any faulty components.

NOContinuity fault on connection 38LP.

Using an ohmmeter, carry out a continuity

test on connection 38LP between

components 319 and 645. If there is a

procedure (see Technical Note 6015A,

Repairing electrical wiring, Wiring:

Precautions for repair), repair the wiring,

otherwise replace the wiring.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 57 of 63

62C-57

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

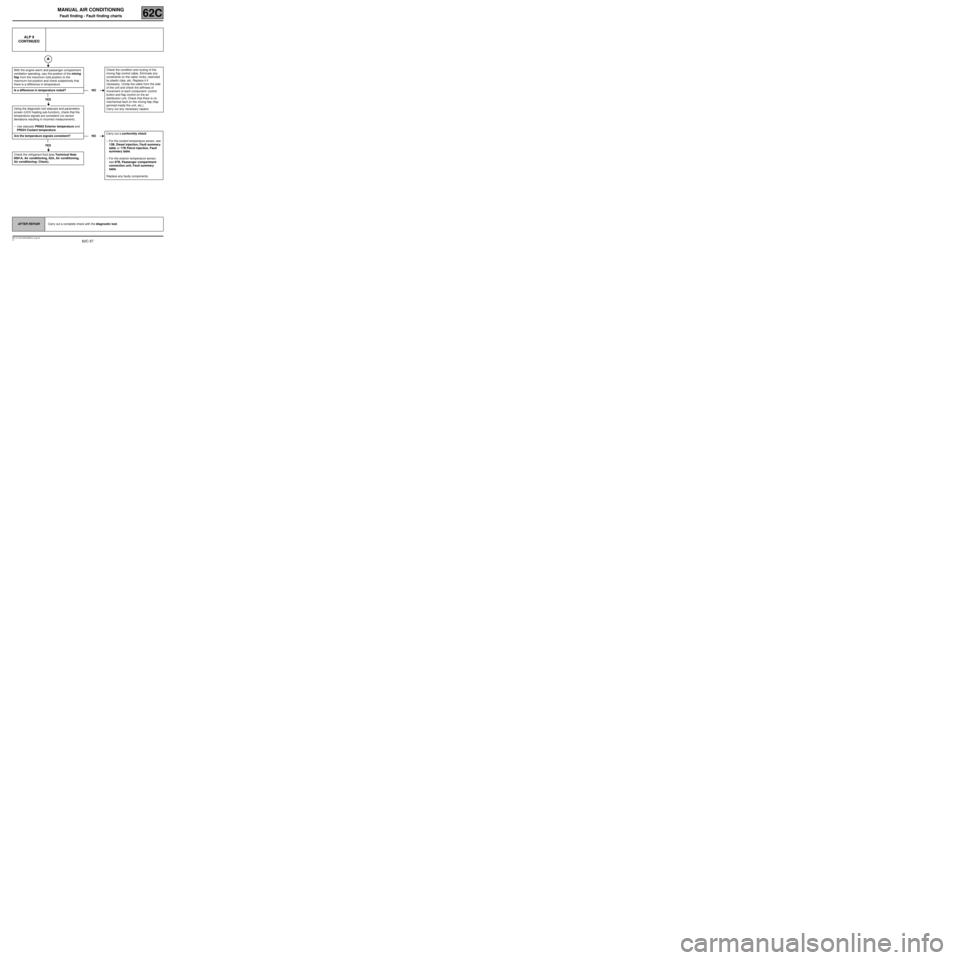

ALP 9

CONTINUED

With the engine warm and passenger compartment

ventilation operating, vary the position of the mixing

flap from the maximum cold position to the

maximum hot position and check subjectively that

there is a difference in temperature.

Is a difference in temperature noted?

YES

Using the diagnostic tool statuses and parameters

screen (UCH heating sub-function), check that the

temperature signals are consistent (no sensor

deviations resulting in incorrect measurement).

–Use statuses PR002 Exterior temperature and

PR024 Coolant temperature.

Are the temperature signals consistent?

YES

Check the refrigerant fluid (see Technical Note

6001A, Air conditioning, 62A, Air conditioning,

Air conditioning: Check).

NOCheck the condition and routing of the

mixing flap control cable. Eliminate any

constraints on the cable: kinks, restricted

by plastic clips, etc. Replace it if

necessary. Unclip the cable from the side

of the unit and check the stiffness of

movement of each component: control

button and flap control on the air

distribution unit. Check that there is no

mechanical fault on the mixing flap (flap

jammed inside the unit, etc.).

Carry out any necessary repairs.

NOCarry out a conformity check:

–For the coolant temperature sensor, see

13B, Diesel injection, Fault summary

table or 17B Petrol injection, Fault

summary table.

–For the exterior temperature sensor,

see 87B, Passenger compartment

connection unit, Fault summary

table.

Replace any faulty components.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 60 of 63

62C-60

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

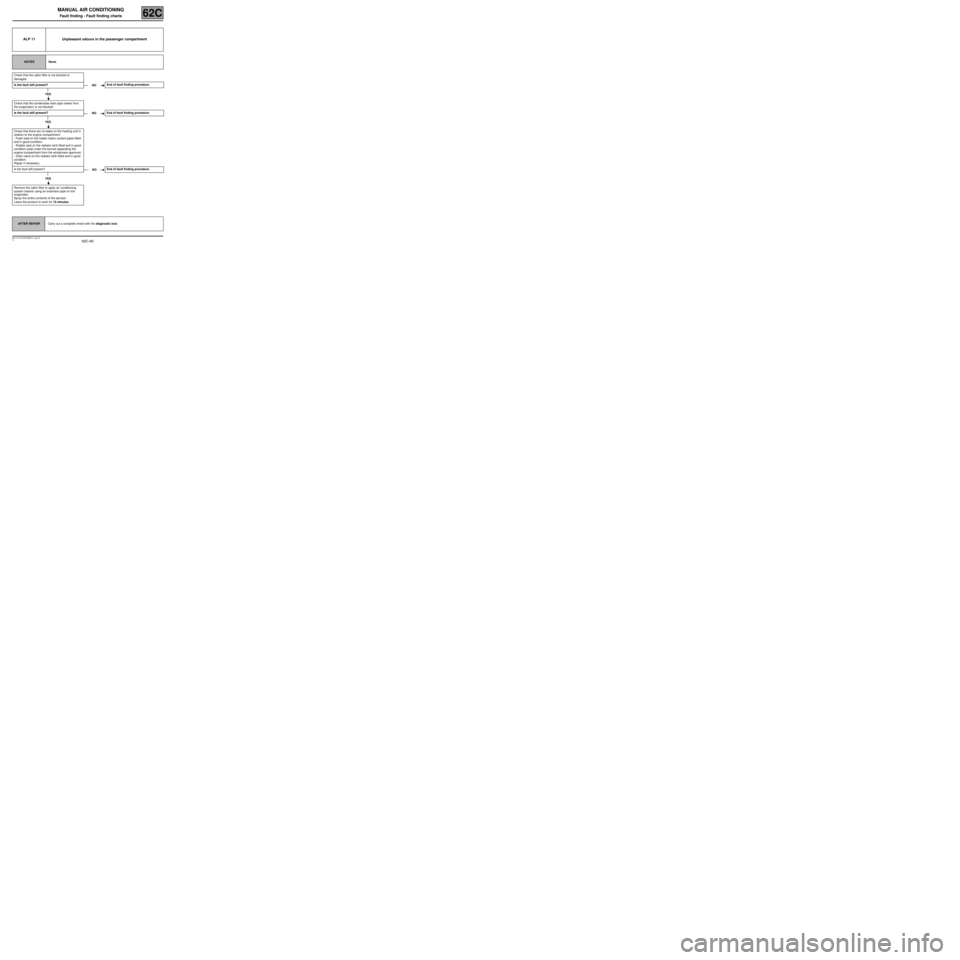

ALP 11 Unpleasant odours in the passenger compartment

NOTESNone.

Check that the cabin filter is not blocked or

damaged.

Is the fault still present?

YES

Check that the condensate drain pipe (water from

the evaporator) is not blocked.

Is the fault still present?

YES

Check that there are no leaks on the heating unit in

relation to the engine compartment:

- Foam seal on the heater matrix coolant pipes fitted

and in good condition.

- Rubber seal on the radiator tank fitted and in good

condition (seal under the bonnet separating the

engine compartment from the windscreen aperture).

- Drain valve on the radiator tank fitted and in good

condition.

Repair if necessary.

Is the fault still present?

YES

Remove the cabin filter to apply air conditioning

system cleaner using an extension pipe on the

evaporator.

Spray the entire contents of the aerosol.

Leave the product to work for 15 minutes.

NOEnd of fault finding procedure.

NOEnd of fault finding procedure.

NOEnd of fault finding procedure.

AFTER REPAIRCarry out a complete check with the diagnostic tool.

Page 61 of 63

62C-61

MR-413-X44-62C000$910_eng.mif

V1

MANUAL AIR CONDITIONING

Fault finding - Fault finding charts62C

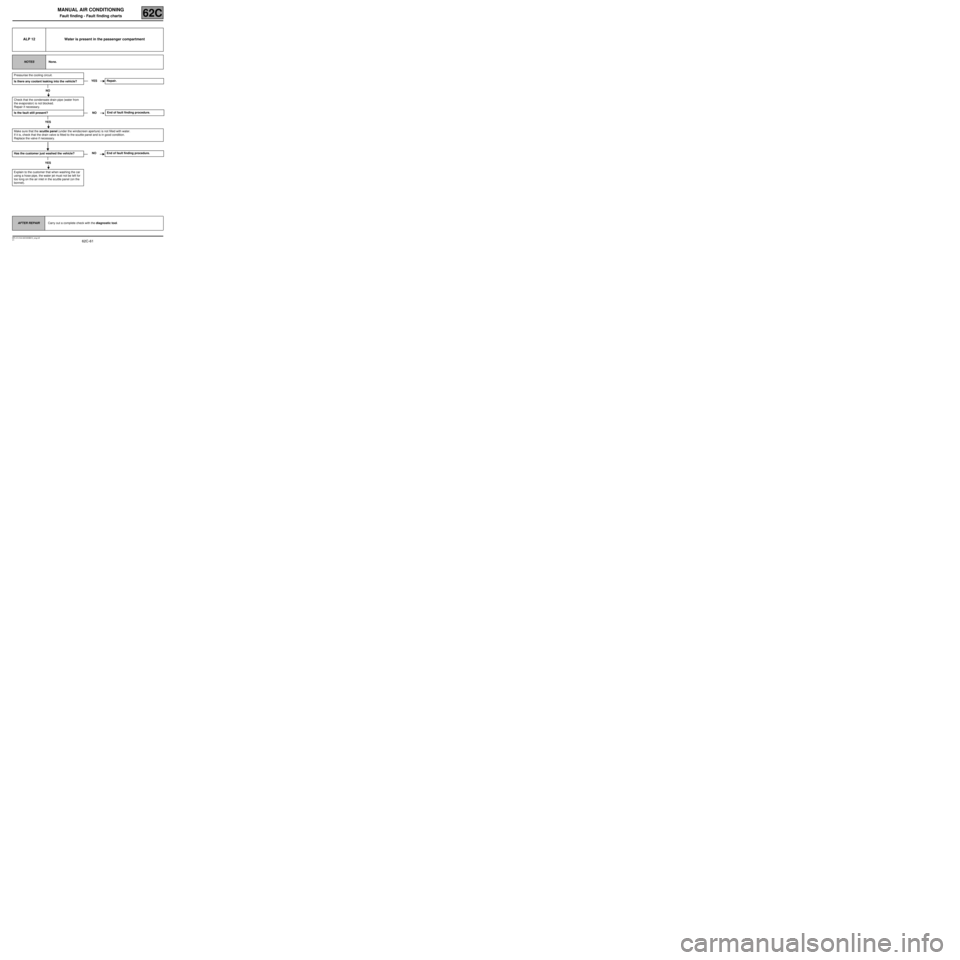

ALP 12 Water is present in the passenger compartment

NOTESNone.

Pressurise the cooling circuit.

Is there any coolant leaking into the vehicle?

NO

Check that the condensate drain pipe (water from

the evaporator) is not blocked.

Repair if necessary.

Is the fault still present?

YES

Make sure that the scuttle panel (under the windscreen aperture) is not filled with water.

If it is, check that the drain valve is fitted to the scuttle panel and is in good condition.

Replace the valve if necessary.

Has the customer just washed the vehicle?

YES

Explain to the customer that when washing the car

using a hose pipe, the water jet must not be left for

too long on the air inlet in the scuttle panel (on the

bonnet).

YES Repair.

NOEnd of fault finding procedure.

NO End of fault finding procedure.

AFTER REPAIRCarry out a complete check with the diagnostic tool.