RENAULT TWINGO RS 2009 2.G Panelwork User Guide

TWINGO RS 2009 2.G

RENAULT

RENAULT

https://www.carmanualsonline.info/img/7/1724/w960_1724-0.png

RENAULT TWINGO RS 2009 2.G Panelwork User Guide

Page 160 of 209

44A-5

REAR UPPER STRUCTURE

Rear lights mounting: General description

44A

DESIGN OF THE STRUCTURAL COMPONENT

This is a basic part; its only function is that of a rear li-

ghts mounting.

If there are other issues regarding access to mating fa-

ces, the various replacement options are described in

the basic instructions for structural bodywork repair

(see MR 400, 40A, General Information). WARNING

The information contained in the following descri-

bes the general repair procedure for all vehicles

having the same design for this part.

Before reading the following general information,

make sure that there are no special notes associa-

ted with the vehicle. These special notes are speci-

fied if necessary in other par ts of the sub-section

dealing with the component.

Note:

For a detailed description of a particular connec-

tion, see MR 400, 40A, General Information.

109669

Page 161 of 209

44A-6

REAR UPPER STRUCTURE

Rear lights mounting: Description

C44

44A

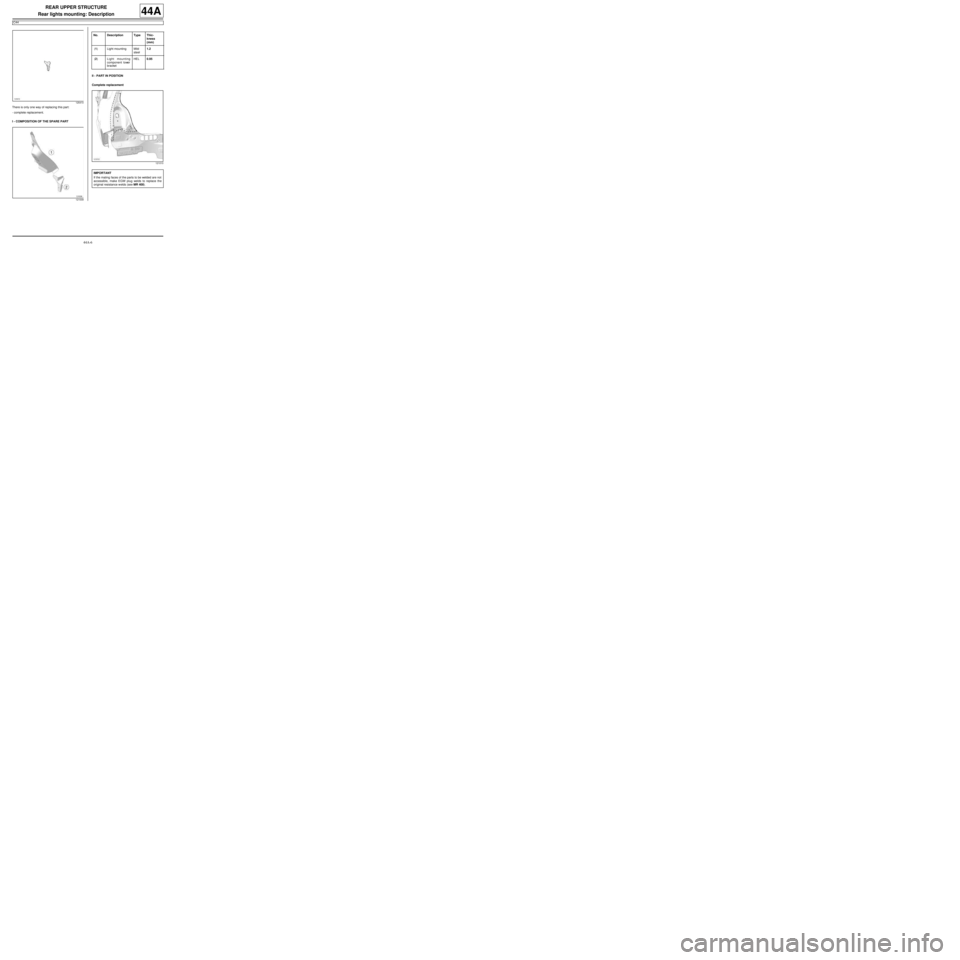

There is only one way of replacing this part:

-complete replacement.

I - COMPOSITION OF THE SPARE PARTII - PART IN POSITION

Complete replacement

125410

121009

No. Description Type Thic-

kness

(mm)

(1) Light mounting Mild

steel1.2

(2) Light mounting

component lower

bracketHEL0.95

121010

IMPORTANT

If the mating faces of the parts to be welded are not

accessible, make EGW plug welds to replace the

original resistance welds (see MR 400).

Page 162 of 209

44A-7

REAR UPPER STRUCTURE

Rear lights mounting: Description

C44

44A

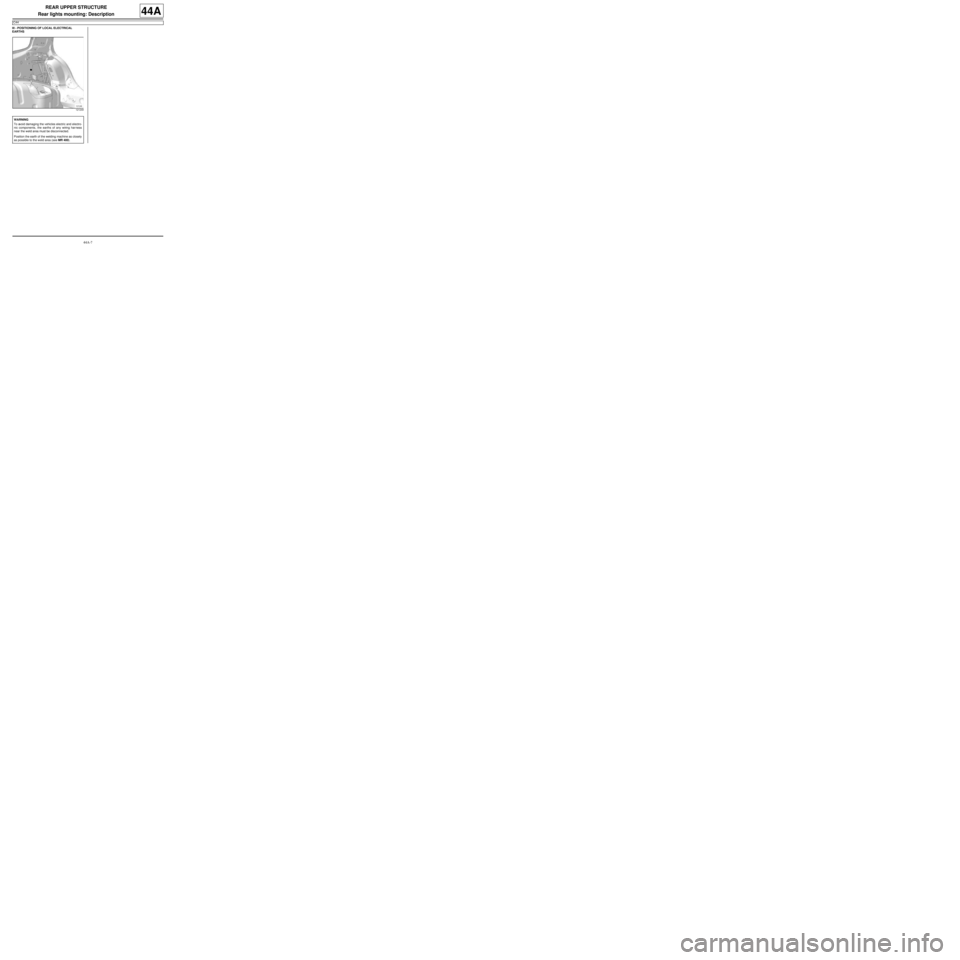

III - POSITIONING OF LOCAL ELECTRICAL

EARTHS

121249

WARNING

To avoid damaging the vehicles electric and electro-

nic components, the earths of any wiring harness

near the weld area must be disconnected.

Position the earth of the welding machine as closely

as possible to the weld area (see MR 400).

Page 200 of 209

48A-1

NON-SIDE OPENING ELEMENTS

Bonnet: Removal - Refitting

48A

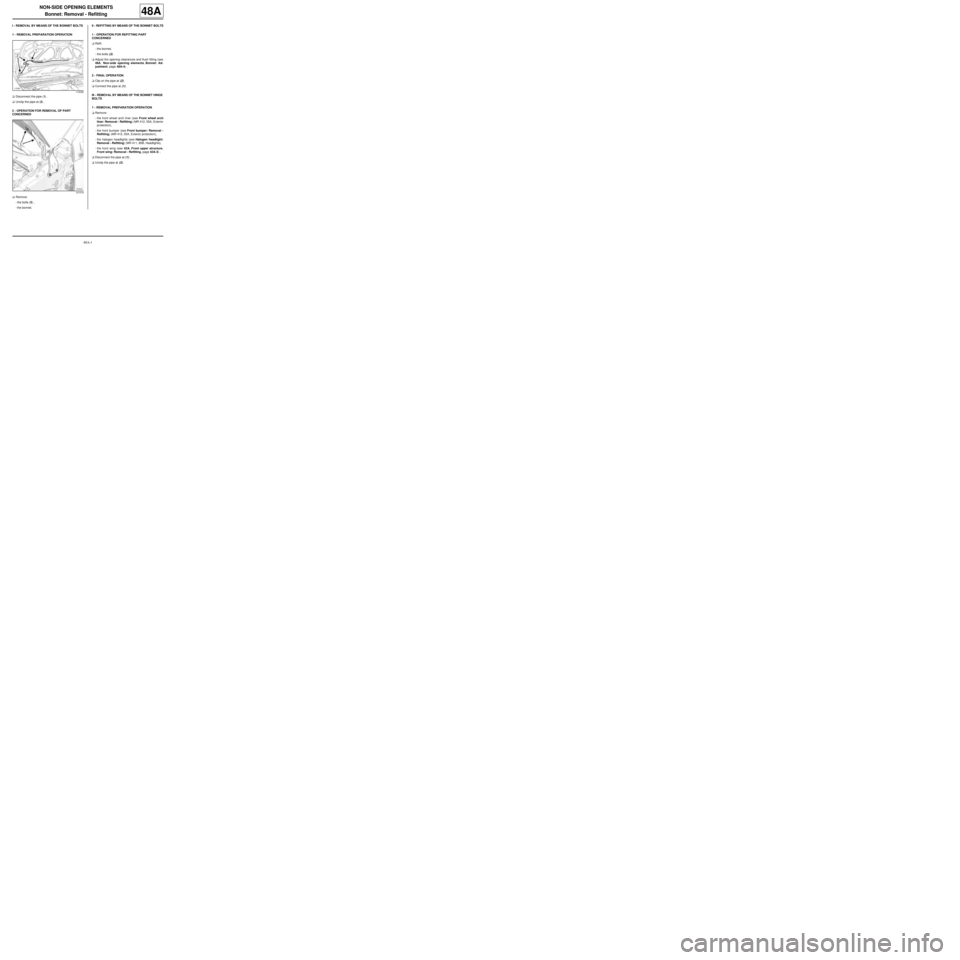

I - REMOVAL BY MEANS OF THE BONNET BOLTS

1 - REMOVAL PREPARATION OPERATION

aDisconnect the pipe (1) .

aUnclip the pipe at (2) .

2 - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (3) ,

-the bonnet.II - REFITTING BY MEANS OF THE BONNET BOLTS

1 - OPERATION FOR REFITTING PART

CONCERNED

aRefit:

-the bonnet,

-the bolts (3) .

aAdjust the opening clearances and flush fitting (see

48A, Non-side opening elements, Bonnet: Ad-

justment, page 48A-4) .

2 - FINAL OPERATION

aClip on the pipe at (2) .

aConnect the pipe at (1) .

III - REMOVAL BY MEANS OF THE BONNET HINGE

BOLTS

1 - REMOVAL PREPARATION OPERATION

aRemove:

-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (MR 411, 80B, Headlights),

-the front wing (see 42A, Front upper structure,

Front wing: Removal - Refitting, page 42A-3) ,

aDisconnect the pipe at (1) .

aUnclip the pipe at (2) .

112036

121519

Page 201 of 209

48A-2

NON-SIDE OPENING ELEMENTS

Bonnet: Removal - Refitting

48A

2 - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (4) ,

-the bonnet.

IV - REFITTING BY MEANS OF THE BONNET

HINGE BOLTS

1 - OPERATION FOR REFITTING PART

CONCERNED

aRefit:

-the bonnet,

-the bolts (4) .

aAdjust the opening clearances and flush fitting (see

48A, Non-side opening elements, Bonnet: Remo-

val - Refitting, page 48A-1) .

2 - FINAL OPERATION

aClip on the pipe at (2) .

aConnect the pipe at (1) .

aRefit:

-the front wing (see 42A, Front upper structure,

Front wing: Removal - Refitting, page 42A-3) ,

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (MR 411, 80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection).

121519