RENAULT TWINGO RS 2009 2.G Panelwork Workshop Manual

Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 209

Page 201 of 209

48A-2

NON-SIDE OPENING ELEMENTS

Bonnet: Removal - Refitting

48A

2 - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the bolts (4) ,

-the bonnet.

IV - REFITTING BY MEANS OF THE BONNET

HINGE BOLTS

1 - OPERATION FOR REFITTING PART

CONCERNED

aRefit:

-the bonnet,

-the bolts (4) .

aAdjust the opening clearances and flush fitting (see

48A, Non-side opening elements, Bonnet: Remo-

val - Refitting, page 48A-1) .

2 - FINAL OPERATION

aClip on the pipe at (2) .

aConnect the pipe at (1) .

aRefit:

-the front wing (see 42A, Front upper structure,

Front wing: Removal - Refitting, page 42A-3) ,

-the halogen headlights (see Halogen headlight:

Removal - Refitting) (MR 411, 80B, Headlights),

-the front bumper (see Front bumper: Removal -

Refitting) (MR 412, 55A, Exterior protection),-the front wheel arch liner (see Front wheel arch

liner: Removal - Refitting) (MR 412, 55A, Exterior

protection).

121519

Page 202 of 209

48A-3

NON-SIDE OPENING ELEMENTS

Bonnet: Stripping - Rebuilding

48A

STRIPPING

STRIPPING OPERATION FOR PART CONCERNED

aDisconnect the pipe at (1) .

aUnclip:

-the pipe at (2) ,

-the jets.

aRemove the different blanking covers from the bon-

net.

REBUILDING

REBUILDING OPERATION FOR PART

CONCERNED

aRefit the different blanking covers on the bonnet.

aClip:

-the jets,

-the pipe at (2) .

aConnect the pipe at (1) .

112036

Page 203 of 209

48A-4

NON-SIDE OPENING ELEMENTS

Bonnet: Adjustment

48A

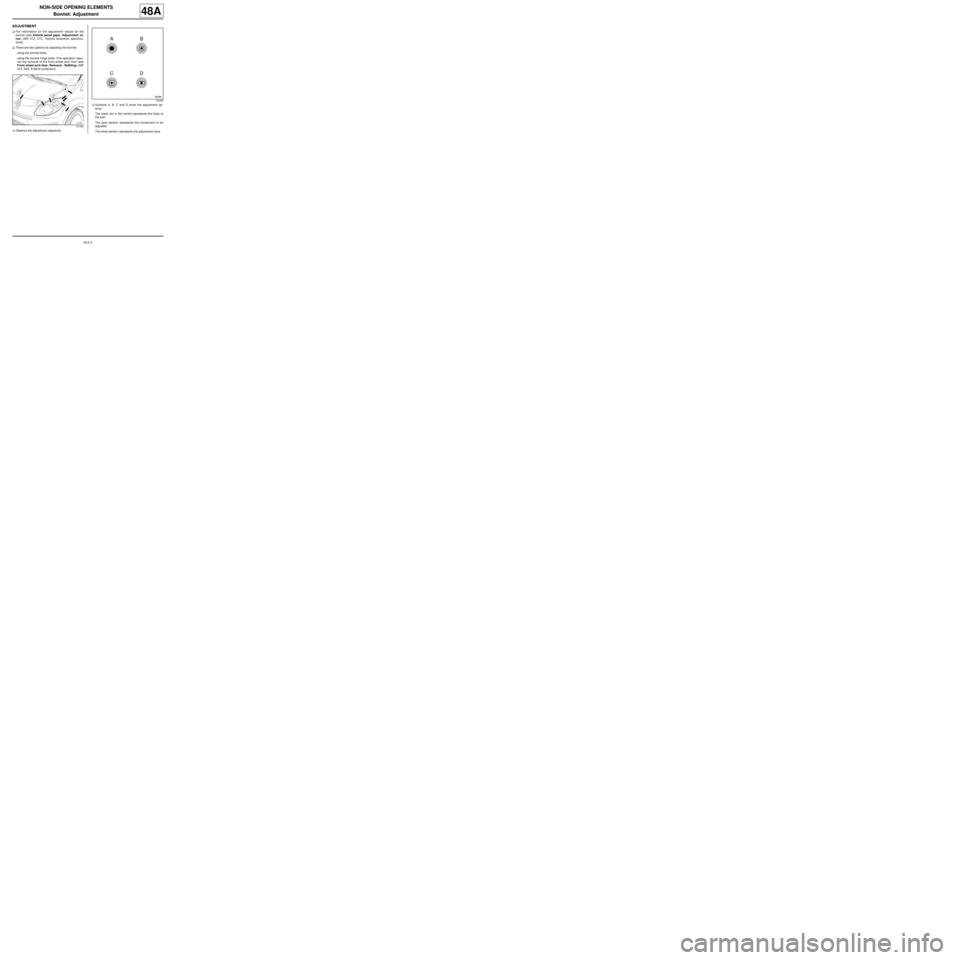

ADJUSTMENT

aFor information on the adjustment values for the

bonnet (see Vehicle panel gaps: Adjustment va-

lue) (MR 412, 01C, Vehicle bodywork specifica-

tions).

aThere are two options for adjusting the bonnet:

-using the bonnet bolts,

-using the bonnet hinge bolts. This operation requi-

res the removal of the front wheel arch liner (see

Front wheel arch liner: Removal - Refitting) (MR

412, 55A, Exterior protection).

aObserve the adjustment sequence.aSymbols A, B, C and D show the adjustment op-

tions.

The black dot in the centre represents the body of

the bolt.

The grey section represents the component to be

adjusted.

The white section represents the adjustment area.

121253

109496

Page 204 of 209

48A-5

NON-SIDE OPENING ELEMENTS

Bonnet: Adjustment

48A

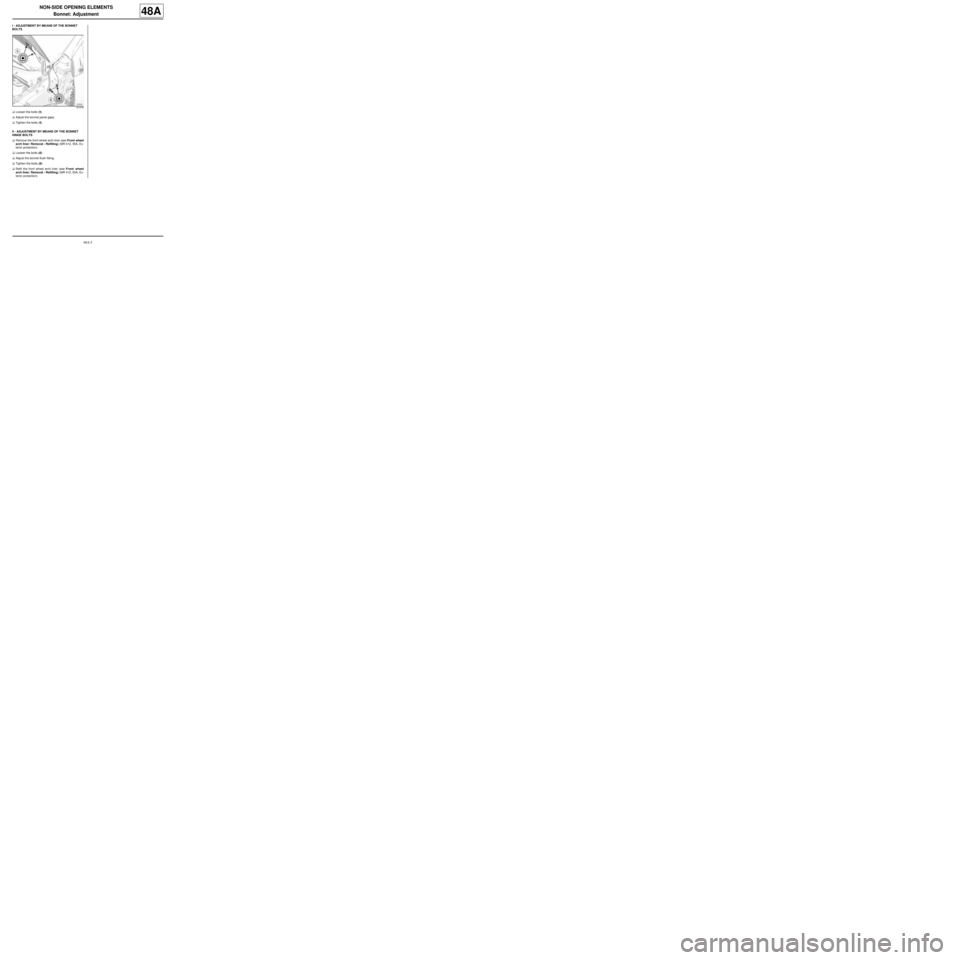

I - ADJUSTMENT BY MEANS OF THE BONNET

BOLTS

aLoosen the bolts (5) .

aAdjust the bonnet panel gaps.

aTighten the bolts (5) .

II - ADJUSTMENT BY MEANS OF THE BONNET

HINGE BOLTS

aRemove the front wheel arch liner (see Front wheel

arch liner: Removal - Refitting) (MR 412, 55A, Ex-

terior protection).

aLoosen the bolts (6) .

aAdjust the bonnet flush fitting.

aTighten the bolts (6) .

aRefit the front wheel arch liner (see Front wheel

arch liner: Removal - Refitting) (MR 412, 55A, Ex-

terior protection).

121818

Page 205 of 209

48A-6

NON-SIDE OPENING ELEMENTS

Tailgate: Removal - Refitting

48A

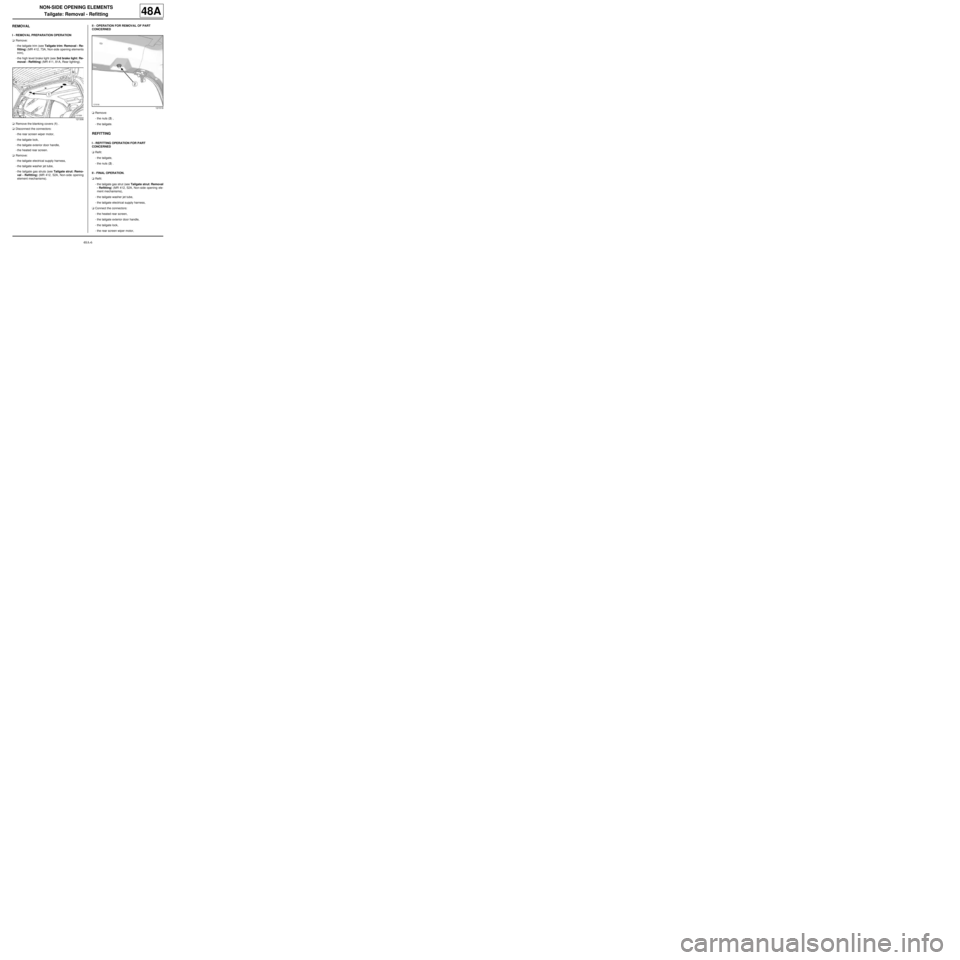

REMOVAL

I - REMOVAL PREPARATION OPERATION

aRemove:

-the tailgate trim (see Tailgate trim: Removal - Re-

fitting) (MR 412, 73A, Non-side opening elements

trim),

-the high level brake light (see 3rd brake light: Re-

moval - Refitting) (MR 411, 81A, Rear lighting).

aRemove the blanking covers (1) .

aDisconnect the connectors:

-the rear screen wiper motor,

-the tailgate lock,

-the tailgate exterior door handle,

-the heated rear screen.

aRemove:

-the tailgate electrical supply harness,

-the tailgate washer jet tube,

-the tailgate gas struts (see Tailgate strut: Remo-

val - Refitting) (MR 412, 52A, Non-side opening

element mechanisms).II - OPERATION FOR REMOVAL OF PART

CONCERNED

aRemove:

-the nuts (2) ,

-the tailgate.

REFITTING

I - REFITTING OPERATION FOR PART

CONCERNED

aRefit:

-the tailgate,

-the nuts (2) .

II - FINAL OPERATION.

aRefit:

-the tailgate gas strut (see Tailgate strut: Removal

- Refitting) (MR 412, 52A, Non-side opening ele-

ment mechanisms),

-the tailgate washer jet tube,

-the tailgate electrical supply harness,

aConnect the connectors:

-the heated rear screen,

-the tailgate exterior door handle,

-the tailgate lock,

-the rear screen wiper motor,

121306

121518

Page 206 of 209

48A-7

NON-SIDE OPENING ELEMENTS

Tailgate: Removal - Refitting

48A

aRefit:

-the blanking covers (1) ,

-the high level brake light (see 3rd brake light: Re-

moval - Refitting) (MR 411, 81A, Rear lighting),

-the tailgate trim (see Tailgate trim: Removal - Re-

fitting) (MR 412, 73A, Non-side opening elements

trim).

Page 207 of 209

48A-8

NON-SIDE OPENING ELEMENTS

Tailgate: Stripping - Rebuilding

48A

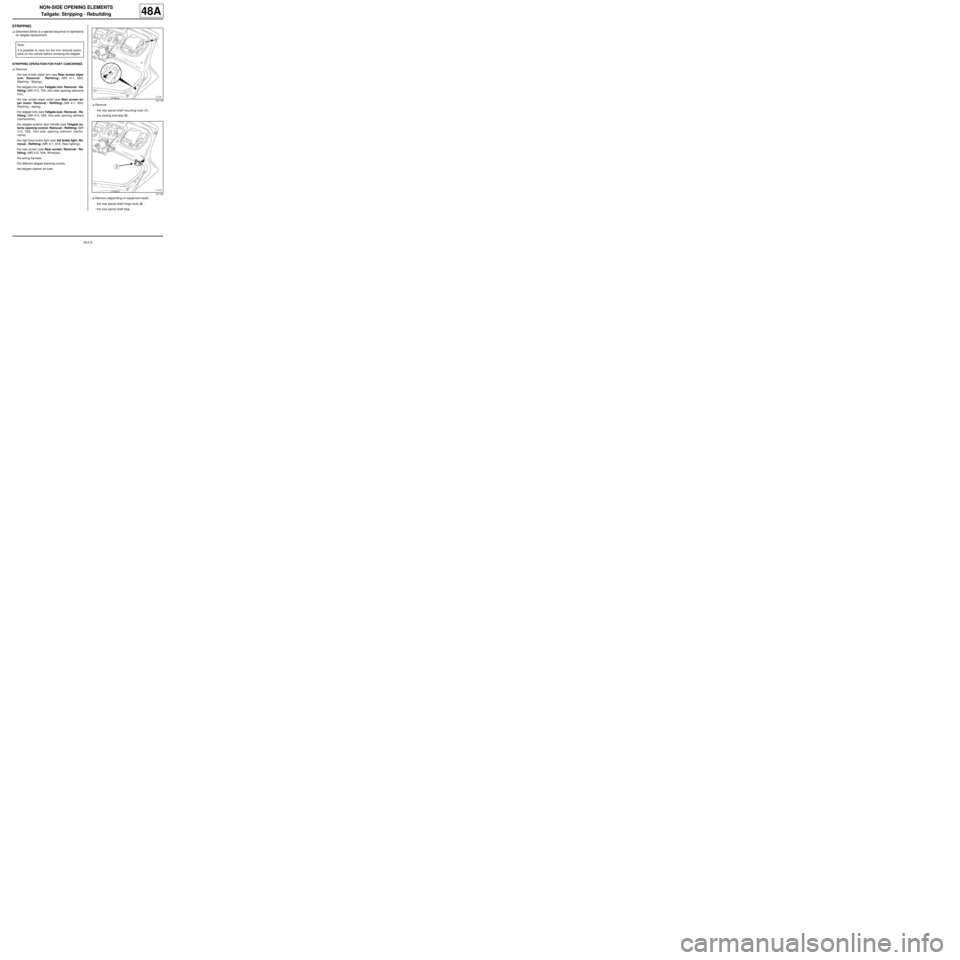

STRIPPING

aDescribed below is a special sequence of operations

for tailgate replacement.

STRIPPING OPERATION FOR PART CONCERNED

aRemove:

-the rear screen wiper arm (see Rear screen wiper

arm: Removal - Refitting) (MR 411, 85A,

Washing - Wiping),

-the tailgate trim (see Tailgate trim: Removal - Re-

fitting) (MR 412, 73A, Non-side opening elements

trim),

-the rear screen wiper motor (see Rear screen wi-

per motor: Removal - Refitting) (MR 411, 85A,

Washing - wiping),

-the tailgate lock (see Tailgate lock: Removal - Re-

fitting) (MR 412, 52A, Non-side opening element

mechanisms),

-the tailgate exterior door handle (see Tailgate ex-

terior opening control: Removal - Refitting) (MR

412, 52A, Non-side opening element mecha-

nisms),

-the high level brake light (see 3rd brake light: Re-

moval - Refitting) (MR 411, 81A, Rear lighting),

-the rear screen (see Rear screen: Removal - Re-

fitting) (MR 412, 54A, Windows),

-the wiring harness,

-the different tailgate blanking covers,

-the tailgate washer jet tube.aRemove:

-the rear parcel shelf mounting hook (1) ,

-the closing end stop (2) .

aRemove (depending on equipment level):

-the rear parcel shelf hinge hook (3) ,

-the rear parcel shelf stop. Note:

It is possible to carry out the trim removal opera-

tions on the vehicle before removing the tailgate.

121149

121148

Page 208 of 209

48A-9

NON-SIDE OPENING ELEMENTS

Tailgate: Stripping - Rebuilding

48A

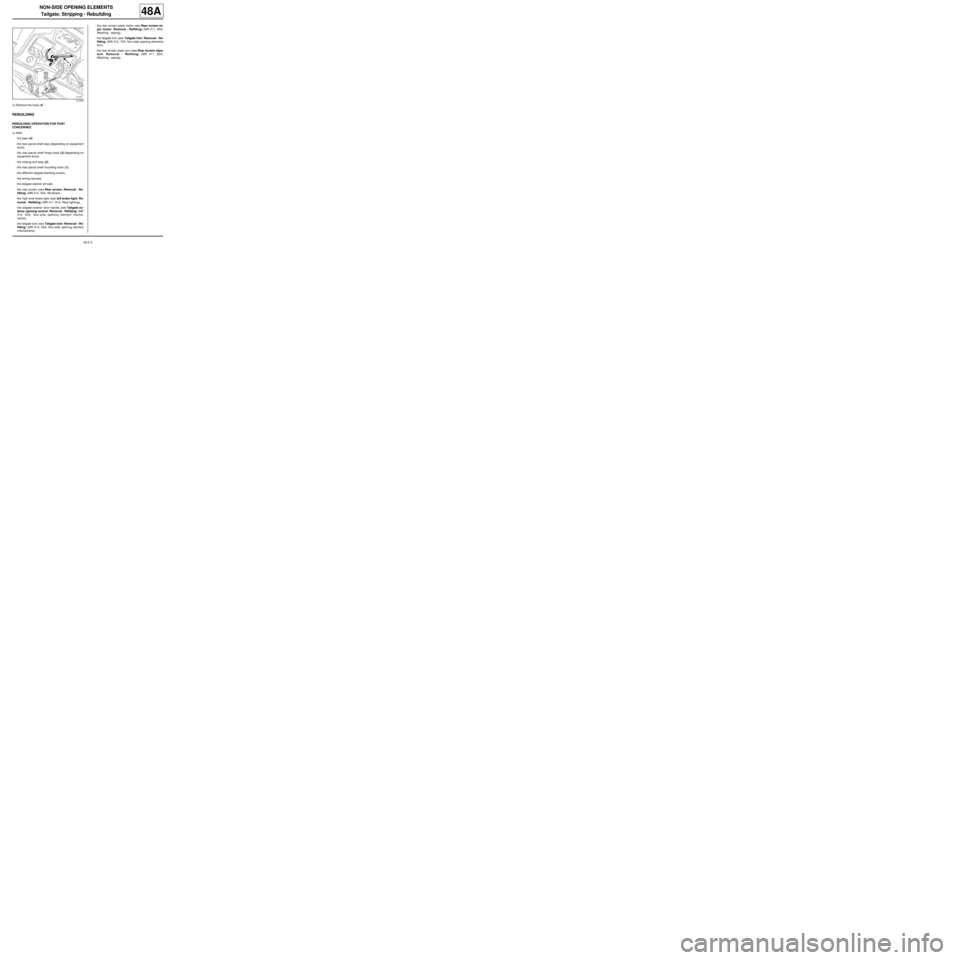

aRemove the hose (4) .

REBUILDING

REBUILDING OPERATION FOR PART

CONCERNED

aRefit:

-the pipe (4) ,

-the rear parcel shelf stop (depending on equipment

level),

-the rear parcel shelf hinge hook (3) (depending on

equipment level),

-the closing end stop (2) ,

-the rear parcel shelf mounting hook (1) ,

-the different tailgate blanking covers,

-the wiring harness,

-the tailgate washer jet tube,

-the rear screen (see Rear screen: Removal - Re-

fitting) (MR 412, 54A, Windows),

-the high level brake light (see 3rd brake light: Re-

moval - Refitting) (MR 411, 81A, Rear lighting),

-the tailgate exterior door handle (see Tailgate ex-

terior opening control: Removal - Refitting) (MR

412, 52A, Non-side opening element mecha-

nisms),

-the tailgate lock (see Tailgate lock: Removal - Re-

fitting) (MR 412, 52A, Non-side opening element

mechanisms),-the rear screen wiper motor (see Rear screen wi-

per motor: Removal - Refitting) (MR 411, 85A,

Washing - wiping),

-the tailgate trim (see Tailgate trim: Removal - Re-

fitting) (MR 412, 73A, Non-side opening elements

trim),

-the rear screen wiper arm (see Rear screen wiper

arm: Removal - Refitting) (MR 411, 85A,

Washing - wiping).

121220

Page 209 of 209

48A-10

NON-SIDE OPENING ELEMENTS

Tailgate: Adjustment

48A

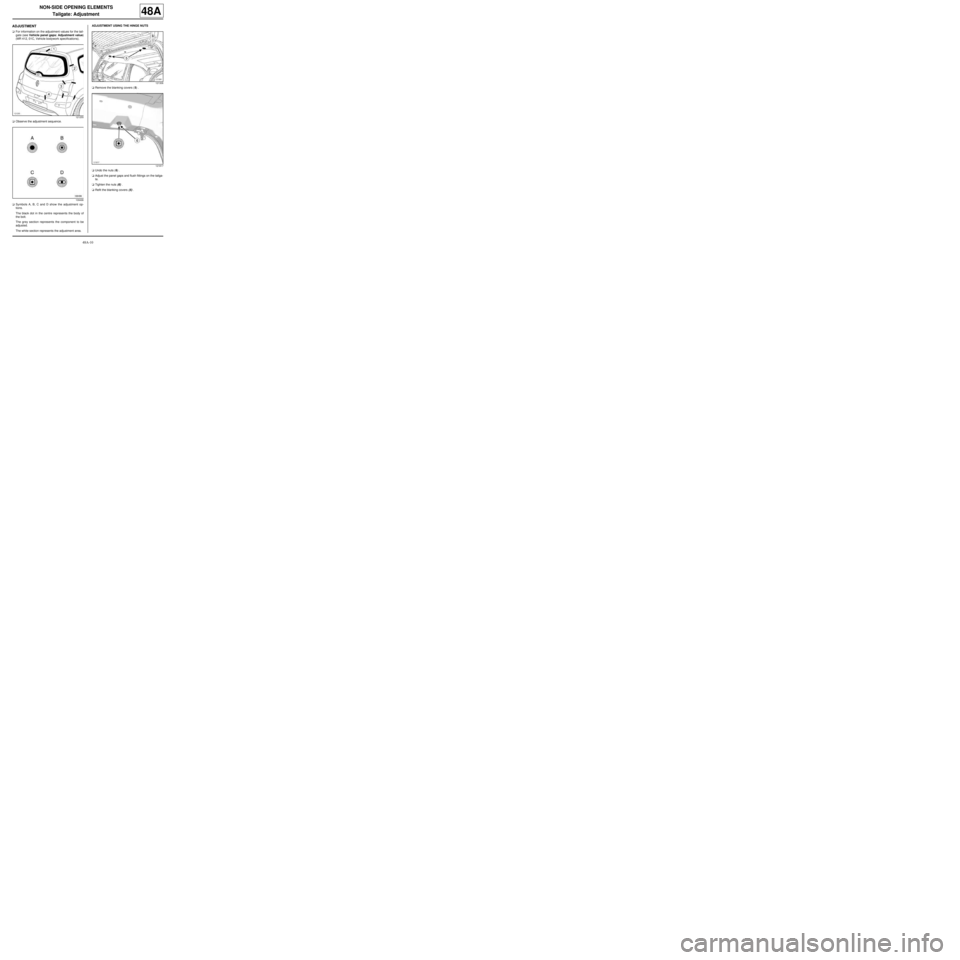

ADJUSTMENT

aFor information on the adjustment values for the tail-

gate (see Vehicle panel gaps: Adjustment value)

(MR 412, 01C, Vehicle bodywork specifications).

aObserve the adjustment sequence.

aSymbols A, B, C and D show the adjustment op-

tions.

The black dot in the centre represents the body of

the bolt.

The grey section represents the component to be

adjusted.

The white section represents the adjustment area.ADJUSTMENT USING THE HINGE NUTS

aRemove the blanking covers (5) .

aUndo the nuts (6) .

aAdjust the panel gaps and flush fittings on the tailga-

te.

aTighten the nuts (6) .

aRefit the blanking covers (5) .

121255

109496

121306

121817