wiring RENAULT TWINGO RS 2009 2.G Sequential Transmission Service Manual

[x] Cancel search | Manufacturer: RENAULT, Model Year: 2009, Model line: TWINGO RS, Model: RENAULT TWINGO RS 2009 2.GPages: 138

Page 81 of 138

21B-81

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

ET003

ET004

CONTINUED

Check the condition and correct connection of component 119.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity of connection 65A between components 119 and 160.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

wiring: precautions for repair), repair the wiring, otherwise replace it.

Check the insulation to + 12 V of the following connections:

●Connection code 65A between components 160 and 119.

●Connection code 65A between components 160 and 645.

●Connection code 65A between components 160 and 172.

●Connection code 65A between components 160 and 173.

●Connection code 65A between components 160 and 639.

●Connection code 65A between components 160 and 1094.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, perform fault finding of the following computers:

●The UCH (see 87B, Passenger compartment connection unit).

●The injection computer (see 17B, Petrol injection).

●The ABS computer (see 38C, Anti-lock braking system).

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

Page 84 of 138

21B-84

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

ET027

DRIVER'S DOOR OPEN

STATUS

DEFINITIONStatus ET027 indicates the position of the opening elements by the specifications

"CLOSED " and "OPEN".

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

Engine stopped, ignition on

CLOSED: Driver's door closed

OPEN: Driver's door open

In the event of a fault, refer to the fault finding procedure below.

Electrical check of the sensor

Check the connection and condition of the connectors of components 140, 1016 and 119 as well as the driver's

door intermediate connector.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check the continuity and insulation of connection H24 between components 119, 1016 and 140.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

wiring: precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, carry out fault finding on the UCH (see 87B, Passenger compartment connection

unit).

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_ET027

Page 85 of 138

21B-85

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

ET028

HANDBRAKE

STATUS

DEFINITION"Engaged": the handbrake lever is raised.

"Released": the handbrake lever is in rest position.

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

Engine stopped, ignition on

Status ET028 indicates the position of the handbrake lever:

●"Engaged": the handbrake lever is raised.

●"Released": the handbrake lever is in rest position.

If status ET028 is incorrect, apply the procedure below.

Electrical check of the sensor

Run a multiplex network test (see 88B, multiplex).

Check the condition of the connections of component 156 and check that they are correctly connected.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Remove the handbrake switch.

Press the handbrake switch and check the insulation between connection 27A and earth.

If there is resistance, replace the handbrake switch.

Release the handbrake switch and check the continuity between the same connections.

If there is no continuity, replace the handbrake switch.

Check the condition of the connections of component 247 and check that they are correctly connected.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Check the continuity and the earth insulation on connection 27A between components 247 and 156.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

wiring: precautions for repair), repair the wiring, otherwise replace it.

If the fault is still present, perform a fault finding of the instrument panel (see 83A, Instrument panel).

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_ET028

Page 86 of 138

21B-86

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

ET030

ACCELERATOR PEDAL POSITION

STATUS

DEFINITION"PL": the accelerator pedal is in the "no load" position.

"Intermediate": the accelerator pedal is in the intermediate position.

"PF": the accelerator pedal is in the "full load" position.

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

Engine stopped, ignition on

Status ET030 is a multiplexed signal supplied by the injection computer.

This status ET030 indicates the position of the accelerator pedal, check the conformity of the status by depressing

the accelerator pedal:

●PL: pedal in rest position

●Intermediate: pedal in an intermediate position

●PF: pedal in full load position

If status ET030 is incorrect, apply the procedure below.

Electrical check of the sensor

Check the positioning of the accelerator pedal potentiometer on the accelerator pedal.

Check that nothing inhibits the movement of the pedal (floor carpet etc.).

Check the condition of the connections of component 921 and check that they are correctly connected.

If the connector is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the connector, otherwise replace the wiring.

Run fault finding on the injection system (see 17B, Petrol injection).

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_ET030

Page 87 of 138

21B-87

MR-413-X44-21B000$649.mif

V2

SEQUENTIAL GEARBOX

Fault finding - Interpretation of statuses

Vdiag No: 04

21B

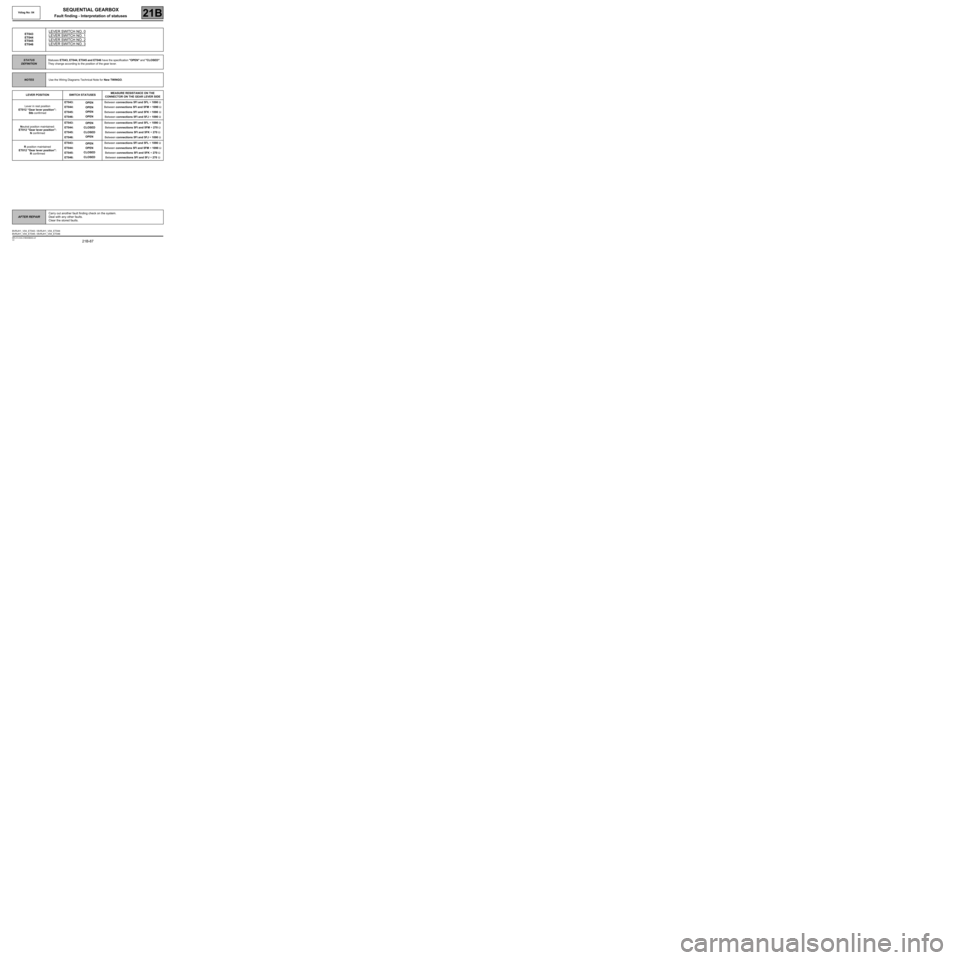

ET043

ET044

ET045

ET046LEVER SWITCH NO. 0

LEVER SWITCH NO. 1

LEVER SWITCH NO. 2

LEVER SWITCH NO. 3

STATUS

DEFINITIONStatuses ET043, ET044, ET045 and ET046 have the specification "OPEN" and "CLOSED".

They change according to the position of the gear lever.

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

LEVER POSITION SWITCH STATUSESMEASURE RESISTANCE ON THE

CONNECTOR ON THE GEAR LEVER SIDE

Lever in rest position

ET012 “Gear lever position”:

Stb confirmedET043:

ET044:

ET045:

ET046:OPEN

OPEN

OPEN

OPENBetween connections 5FI and 5FL = 1090 Ω

Between connections 5FI and 5FM = 1090 Ω

Between connections 5FI and 5FK = 1090 Ω

Between connections 5FI and 5FJ = 1090 Ω

Neutral position maintained:

ET012 "Gear lever position":

N confirmedET043:

ET044:

ET045:

ET046:OPEN

CLOSED

CLOSED

OPENBetween connections 5FI and 5FL = 1090 Ω

Between connections 5FI and 5FM = 270 Ω

Between connections 5FI and 5FK = 270 Ω

Between connections 5FI and 5FJ = 1090 Ω

R position maintained

ET012 "Gear lever position":

R confirmedET043:

ET044:

ET045:

ET046:OPEN

OPEN

CLOSED

CLOSEDBetween connections 5FI and 5FL = 1090 Ω

Between connections 5FI and 5FM = 1090 Ω

Between connections 5FI and 5FK = 270 Ω

Between connections 5FI and 5FJ = 270 Ω

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_ET043 / BVRJH1_V04_ET044

BVRJH1_V04_ET045 / BVRJH1_V04_ET046

Page 107 of 138

21B -107

MR-413-X44-21B000$767.mif

V2

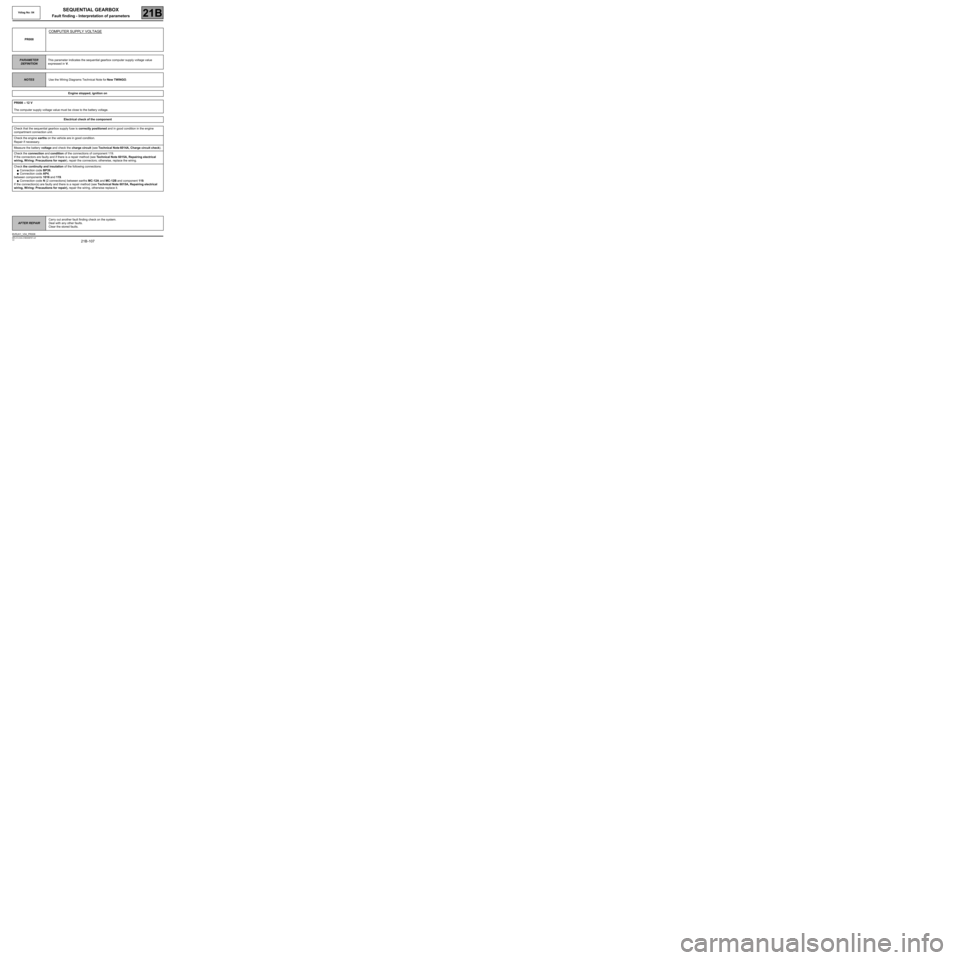

SEQUENTIAL GEARBOX

Fault finding - Interpretation of parameters

Vdiag No: 04

21B

PR008

COMPUTER SUPPLY VOLTAGE

PARAMETER

DEFINITIONThis parameter indicates the sequential gearbox computer supply voltage value

expressed in V.

NOTESUse the Wiring Diagrams Technical Note for New TWINGO.

Engine stopped, ignition on

PR008 ≈ 12 V

The computer supply voltage value must be close to the battery voltage.

Electrical check of the component

Check that the sequential gearbox supply fuse is correctly positioned and in good condition in the engine

compartment connection unit.

Check the engine earths on the vehicle are in good condition.

Repair if necessary.

Measure the battery voltage and check the charge circuit (see Technical Note 6014A, Charge circuit check).

Check the connection and condition of the connections of component 119.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check the continuity and insulation of the following connections:

●Connection code BP39,

●Connection code AP4,

between components 1016 and 119.

●Connection code N (2 connections) between earths MC-12A and MC-12B and component 119.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRCarry out another fault finding check on the system.

Deal with any other faults.

Clear the stored faults.

BVRJH1_V04_PR008

Page 126 of 138

21B -126

MR-413-X44-21B000$944.mif

V2

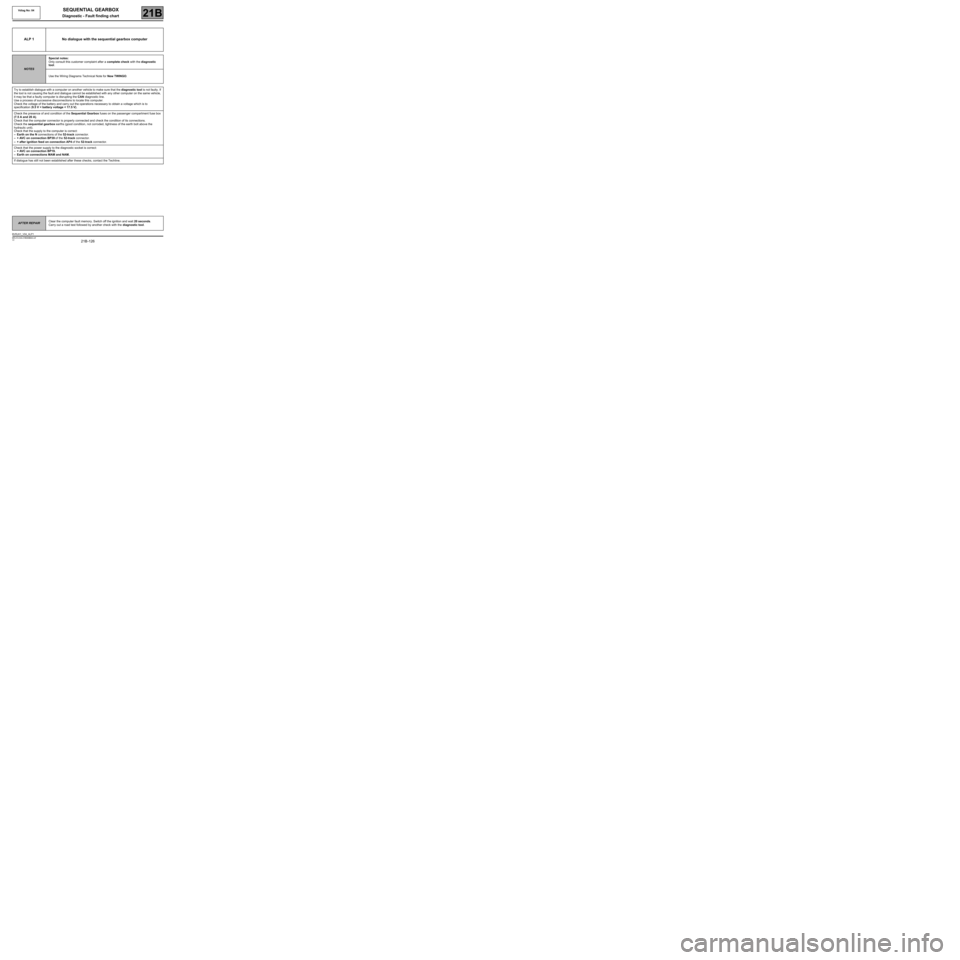

21B

SEQUENTIAL GEARBOX

Diagnostic - Fault finding chart

ALP 1 No dialogue with the sequential gearbox computer

NOTESSpecial notes:

Only consult this customer complaint after a complete check with the diagnostic

tool.

Use the Wiring Diagrams Technical Note for New TWINGO.

Try to establish dialogue with a computer on another vehicle to make sure that the diagnostic tool is not faulty. If

the tool is not causing the fault and dialogue cannot be established with any other computer on the same vehicle,

it may be that a faulty computer is disrupting the CAN diagnostic line.

Use a process of successive disconnections to locate this computer.

Check the voltage of the battery and carry out the operations necessary to obtain a voltage which is to

specification (9.5 V < battery voltage < 17.5 V).

Check the presence of and condition of the Sequential Gearbox fuses on the passenger compartment fuse box

(7.5 A and 20 A).

Check that the computer connector is properly connected and check the condition of its connections.

Check the sequential gearbox earths (good condition, not corroded, tightness of the earth bolt above the

hydraulic unit).

Check that the supply to the computer is correct:

–Earth on the N connections of the 52-track connector.

–+ AVC on connection BP39 of the 52-track connector.

–+ after ignition feed on connection AP4 of the 52-track connector.

Check that the power supply to the diagnostic socket is correct:

–+ AVC on connection BP19.

–Earth on connections MAM and NAM.

If dialogue has still not been established after these checks, contact the Techline.

AFTER REPAIRClear the computer fault memory. Switch off the ignition and wait 20 seconds.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_ALP1

MR-413-X44-21B000$944.mif

Vdiag No: 04

Page 127 of 138

21B -127

MR-413-X44-21B000$944.mif

V2

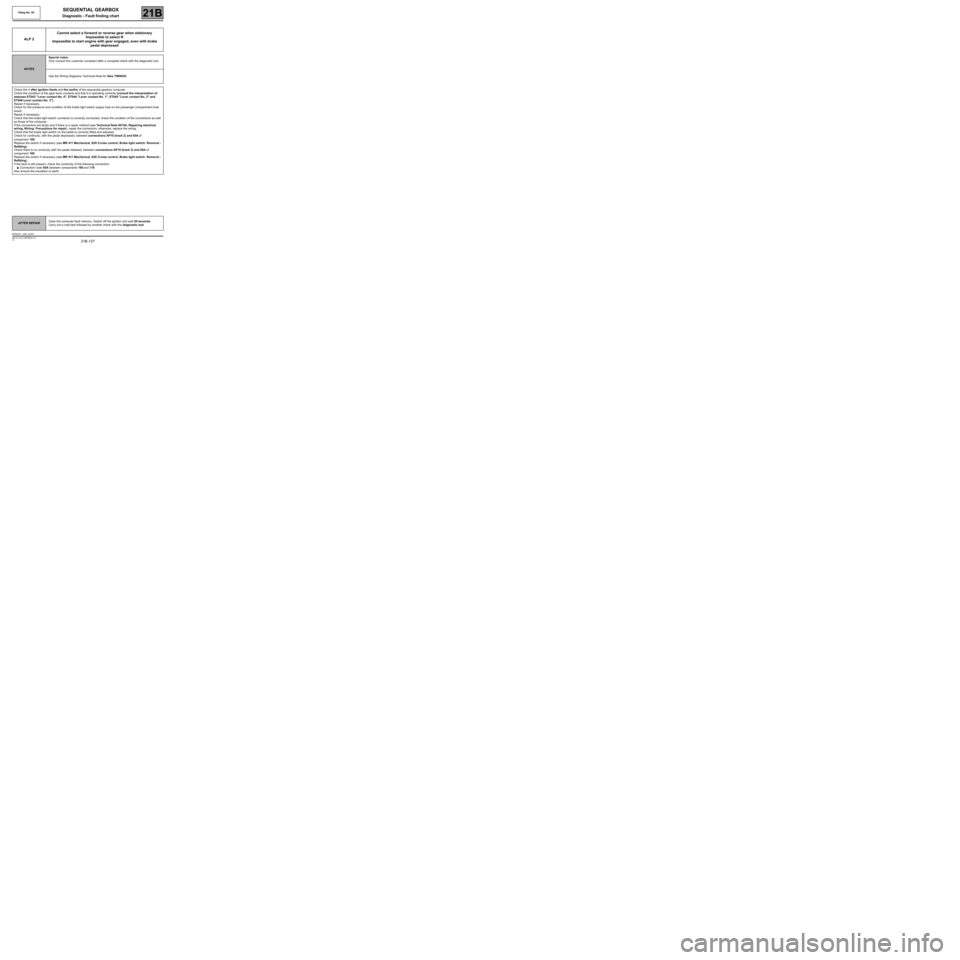

SEQUENTIAL GEARBOX

Diagnostic - Fault finding chart

Vdiag No: 04

21B

ALP 2Cannot select a forward or reverse gear when stationary

Impossible to select N

Impossible to start engine with gear engaged, even with brake

pedal depressed

NOTESSpecial notes:

Only consult this customer complaint after a complete check with the diagnostic tool.

Use the Wiring Diagrams Technical Note for New TWINGO.

Check the + after ignition feeds and the earths of the sequential gearbox computer.

Check the condition of the gear lever contacts and that it is operating correctly (consult the interpretation of

statuses ET043 "Lever contact No. 0", ET044 "Lever contact No. 1", ET045 "Lever contact No. 2" and

ET046 Lever contact No. 3").

Repair if necessary.

Check for the presence and condition of the brake light switch supply fuse on the passenger compartment fuse

board.

Repair if necessary.

Check that the brake light switch connector is correctly connected, check the condition of the connections as well

as those of the computer.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Check that the brake light switch on the pedal is correctly fitted and adjusted.

Check for continuity, with the pedal depressed, between connections AP10 (track 2) and 65A of

component 160.

Replace the switch if necessary (see MR 411 Mechanical, 83D Cruise control, Brake light switch: Removal -

Refitting).

Check there is no continuity with the pedal released, between connections AP10 (track 2) and 65A of

component 160.

Replace the switch if necessary (see MR 411 Mechanical, 83D Cruise control, Brake light switch: Removal -

Refitting).

If the fault is still present, check the continuity of the following connection:

●Connection code 65A between components 160 and 119.

Also ensure the insulation to earth.

AFTER REPAIRClear the computer fault memory. Switch off the ignition and wait 20 seconds.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_ALP2

Page 129 of 138

21B -129

MR-413-X44-21B000$944.mif

V2

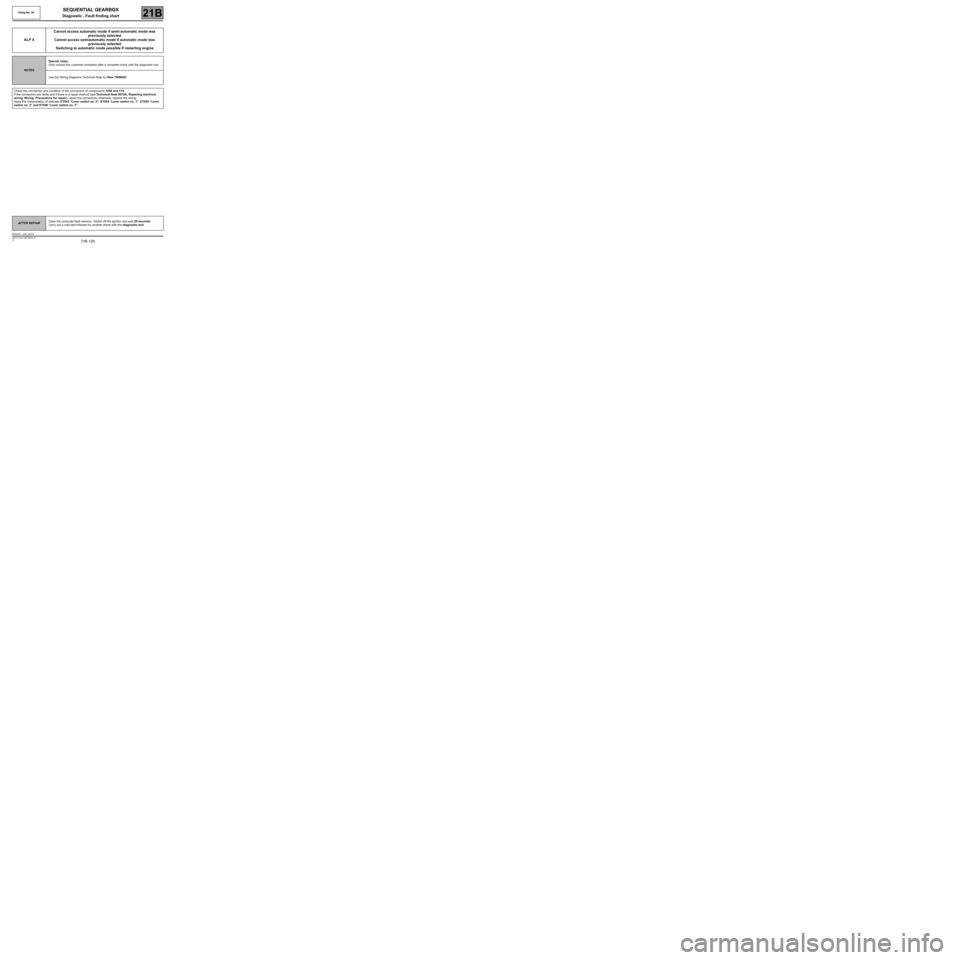

SEQUENTIAL GEARBOX

Diagnostic - Fault finding chart

Vdiag No: 04

21B

ALP 4Cannot access automatic mode if semi-automatic mode was

previously selected

Cannot access semiautomatic mode if automatic mode was

previously selected

Switching to automatic mode possible if restarting engine

NOTESSpecial notes:

Only consult this customer complaint after a complete check with the diagnostic tool.

Use the Wiring Diagrams Technical Note for New TWINGO.

Check the connection and condition of the connectors of components 1058 and 119.

If the connectors are faulty and if there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the connectors; otherwise, replace the wiring.

Apply the interpretation of statuses ET043 “Lever switch no. 0”, ET044 “Lever switch no. 1”, ET045 “Lever

switch no. 2” and ET046 “Lever switch no. 3”.

AFTER REPAIRClear the computer fault memory. Switch off the ignition and wait 20 seconds.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_ALP4

Page 130 of 138

21B -130

MR-413-X44-21B000$944.mif

V2

SEQUENTIAL GEARBOX

Diagnostic - Fault finding chart

Vdiag No: 04

21B

ALP 5 No reversing lights

NOTESSpecial notes:

Only consult this customer complaint after a complete check with the diagnostic tool.

Use the Wiring Diagrams Technical Note for New TWINGO.

Check the condition of the bulbs for the reversing lights.

Replace if not correct.

Check the conformity of the supply fuse of the reversing light switch (15 A) located on the passenger

compartment fuse box.

Replace the fuse if not correct.

If, following replacement of the fuse and switching on the ignition, the fuse is not correct, check the insulation to

earth of connection AP3 between components 1016 and 155.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

Wiring: Precautions for repair), repair the wiring, otherwise replace it.

Replace the faulty fuse.

If the fuse is correct, check the presence of + 12 V on connection AP3 of component 155.

If there is no + 12 V, check the continuity of connection AP3 between components 1016 and 155.

If the connection is faulty and there is a repair procedure (see Technical Note 6015A, Electrical wiring repair,

wiring: precautions for repair), repair the wiring, otherwise replace it.

Check the conformity of the reversing lights switch:

●Switch in rest position: insulation between connections AP3 and H66P of component 155.

●Switch depressed: continuity between connections AP3 and H66P of component 155.

Replace the reversing lights switch if not correct.

Check for the earth of the reversing light on the following connection(s):

●Left-hand drive: connection MF of component 172.

●Right-hand drive: connection MG of component 173.

If the connection(s) are faulty and there is a repair method (see Technical Note 6015A, Repairing electrical

wiring, W iring: Precautions for repair), repair the wiring, otherwise replace it.

AFTER REPAIRClear the computer fault memory. Switch off the ignition and wait 20 seconds.

Carry out a road test followed by another check with the diagnostic tool.

BVRJH1_V04_ALP5