maintenance Seat Alhambra 2007 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Alhambra, Model: Seat Alhambra 2007Pages: 291, PDF Size: 9.13 MB

Page 235 of 291

If and when233

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

If you are driving without the spare wheel, the cable should be rolled up

and the bracket fastened to the floor of the luggage compartment.

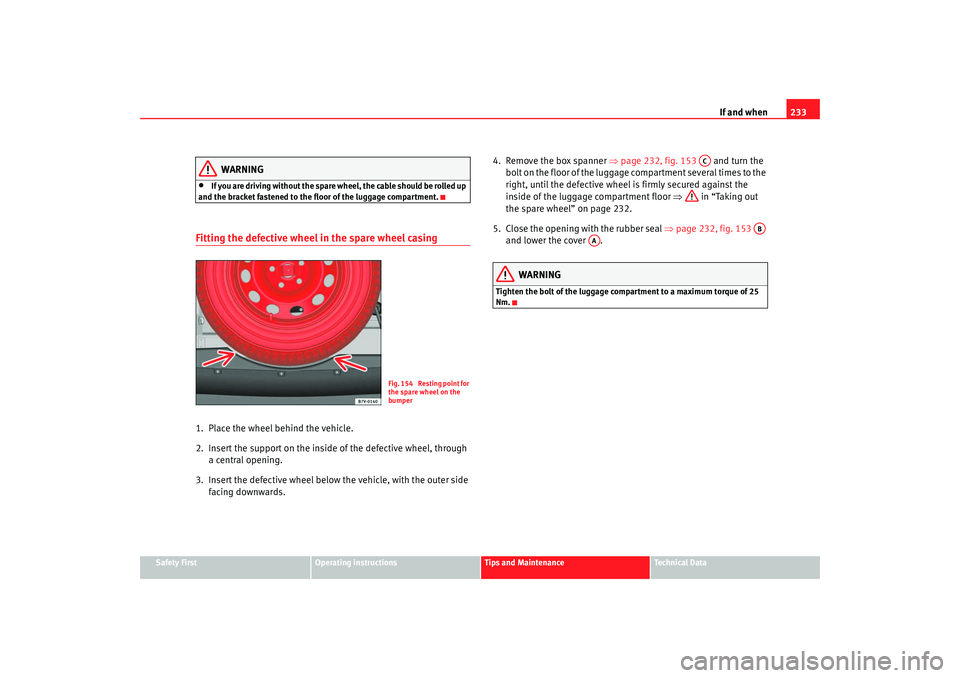

Fitting the defective wheel in the spare wheel casing1. Place the wheel behind the vehicle.

2. Insert the support on the inside of the defective wheel, through a central opening.

3. Insert the defective wheel below the vehicle, with the outer side facing downwards. 4. Remove the box spanner

⇒page 232, fig. 153 and turn the

bolt on the floor of the luggage compartment several times to the

right, until the defective wheel is firmly secured against the

inside of the luggage compartment floor ⇒ in “Taking out

the spare wheel” on page 232.

5. Close the opening with the rubber seal ⇒page 232, fig. 153

and lower the cover .

WARNING

Tighten the bolt of the luggage compartment to a maximum torque of 25

Nm.

Fig. 154 Resting point for

the spare wheel on the

bumper

AC

AB

AA

alhambra ingles.book Seite 233 Donnerstag, 19. April 2007 4:04 16

Page 237 of 291

If and when235

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– Use the enclosed extractor ⇒page 234, fig. 155 to unscrew

the valve insert. Place the valve insert on a clean surface.

– Vigorously shake the sealant bottle ⇒page 234, fig. 155 for

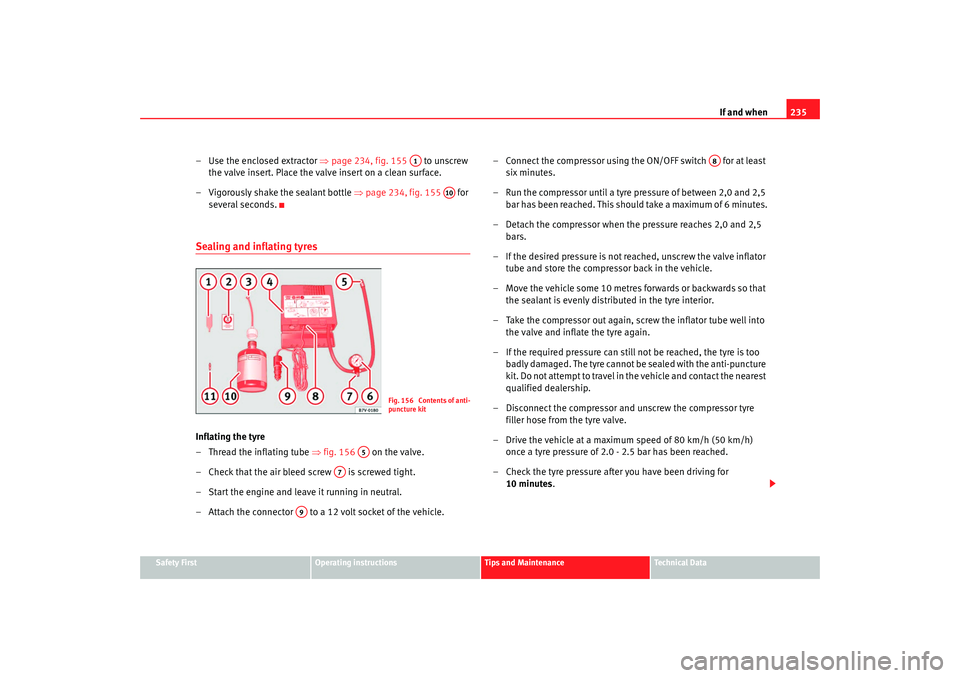

several seconds.Sealing and inflating tyresInflating the tyre

– Thread the inflating tube ⇒fig. 156 on the valve.

– Check that the air bleed screw is screwed tight.

– Start the engine and leave it running in neutral.

– Attach the connector to a 12 volt socket of the vehicle. – Connect the compressor using the ON/OFF switch for at least

six minutes.

– Run the compressor until a tyre pressure of between 2,0 and 2,5 bar has been reached. This should take a maximum of 6 minutes.

– Detach the compressor when th e pressure reaches 2,0 and 2,5

bars.

– If the desired pressure is not reached, unscrew the valve inflator tube and store the compressor back in the vehicle.

– Move the vehicle some 10 metres forwards or backwards so that the sealant is evenly distributed in the tyre interior.

– Take the compressor out again, screw the inflator tube well into the valve and inflate the tyre again.

– If the required pressure can still not be reached, the tyre is too badly damaged. The tyre cannot be sealed with the anti-puncture

kit. Do not attempt to travel in the vehicle and contact the nearest

qualified dealership.

– Disconnect the compressor and unscrew the compressor tyre filler hose from the tyre valve.

– Drive the vehicle at a maximum speed of 80 km/h (50 km/h) once a tyre pressure of 2.0 - 2.5 bar has been reached.

– Check the tyre pressure afte r you have been driving for

10 minutes .

A1

A10

Fig. 156 Contents of anti-

puncture kit

A5

A7

A9

A8

alhambra ingles.book Seite 235 Donnerstag, 19. April 2007 4:04 16

Page 239 of 291

If and when237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

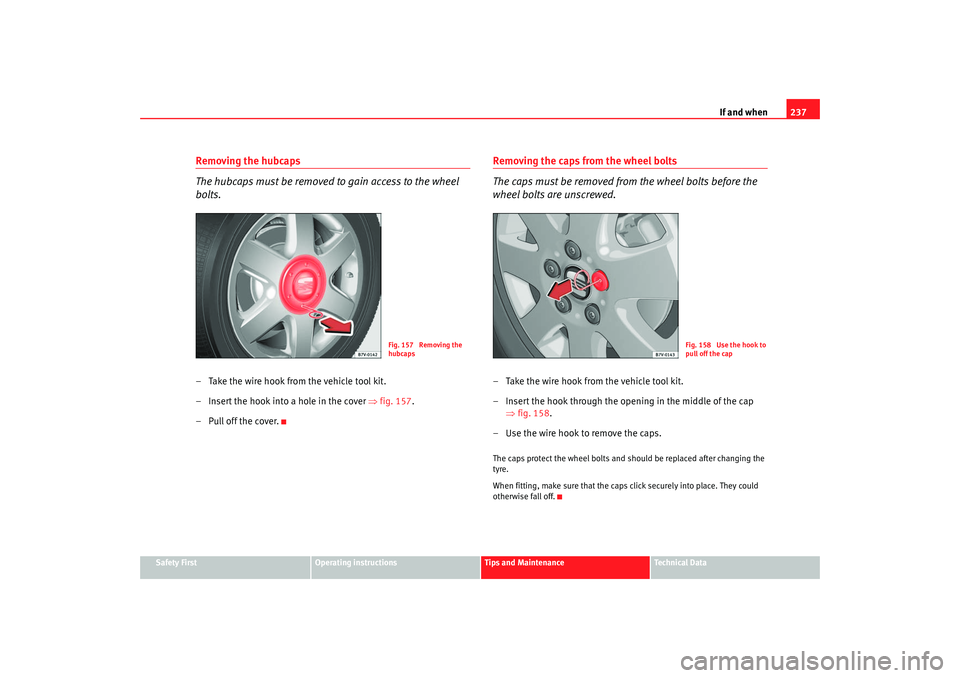

Removing the hubcaps

The hubcaps must be removed to gain access to the wheel

bolts.– Take the wire hook from the vehicle tool kit.

– Insert the hook into a hole in the cover ⇒fig. 157 .

– Pull off the cover.

Removing the caps from the wheel bolts

The caps must be removed from the wheel bolts before the

wheel bolts are unscrewed.– Take the wire hook from the vehicle tool kit.

– Insert the hook through the opening in the middle of the cap ⇒fig. 158.

– Use the wire hook to remove the caps.The caps protect the wheel bolts and should be replaced after changing the

tyre.

When fitting, make sure that the caps click securely into place. They could

otherwise fall off.

Fig. 157 Removing the

hubcaps

Fig. 158 Use the hook to

pull off the cap

alhambra ingles.book Seite 237 Donnerstag, 19. April 2007 4:04 16

Page 241 of 291

If and when239

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

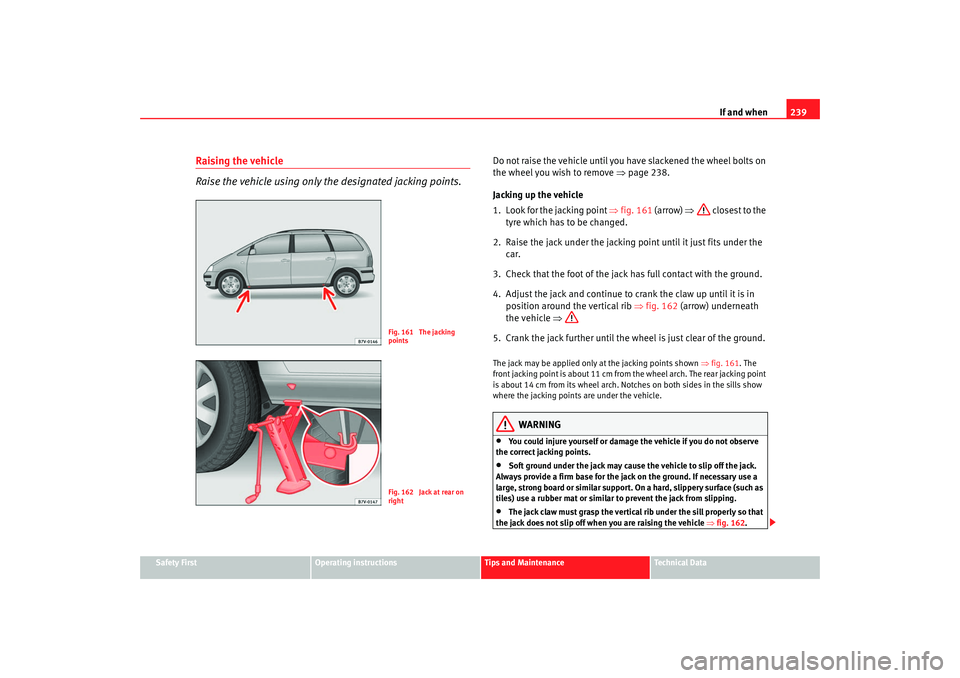

Raising the vehicle

Raise the vehicle using only the designated jacking points.

Do not raise the vehicle until you have slackened the wheel bolts on

the wheel you wish to remove ⇒page 238.

Jacking up the vehicle

1. Look for the jacking point ⇒fig. 161 (arrow) ⇒ closest to the

tyre which has to be changed.

2. Raise the jack under the jacking point until it just fits under the car.

3. Check that the foot of the jack has full contact with the ground.

4. Adjust the jack and continue to crank the claw up until it is in position around the vertical rib ⇒fig. 162 (arrow) underneath

the vehicle ⇒

5. Crank the jack further until the wheel is just clear of the ground.The jack may be applied only at the jacking points shown ⇒fig. 161 . The

front jacking point is about 11 cm from the wheel arch. The rear jacking point

is about 14 cm from its wheel arch. Notches on both sides in the sills show

where the jacking points are under the vehicle.

WARNING

•

You could injure yourself or damage the vehicle if you do not observe

the correct jacking points.

•

Soft ground under the jack may cause the vehicle to slip off the jack.

Always provide a firm base for the jack on the ground. If necessary use a

large, strong board or similar support. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

•

The jack claw must grasp the vertical rib under the sill properly so that

the jack does not slip off when you are raising the vehicle ⇒fig. 162.

Fig. 161 The jacking

pointsFig. 162 Jack at rear on

right

alhambra ingles.book Seite 239 Donnerstag, 19. April 2007 4:04 16

Page 243 of 291

If and when241

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

If the prescribed torque of the wheel bolts is too low, they could loosen

whilst the vehicle is in motion. Risk of accident! If the tightening torque is

too high, the wheel bolts and threads could be damaged.Caution

The stipulated torque for the wheel bolts on steel wheels and alloy wheels is

170 Nm with a tolerance of ± 10 Nm. You should visit a specialised workshop

as soon as possible to check the torque with a torque wrench.

Note

•

The wheel bolts should be clean and turn easily. Do not grease or oil them.

•

The hexagonal socket in the screwdriver handle should be used only for

turning wheel bolts which have been slackened off. Do not use it to loosen or

tighten the wheel bolts.

•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before you have the tightening

torque checked.

•

If the spare tyre is not the same as the tyres that are mounted on the car -

for example with winter tyres - you should only use the spare tyre for a short

period of time and drive with extra care. Refit the normal road wheel as soon

as possible.

•

Have the flat tyre replaced as quickly as possible.

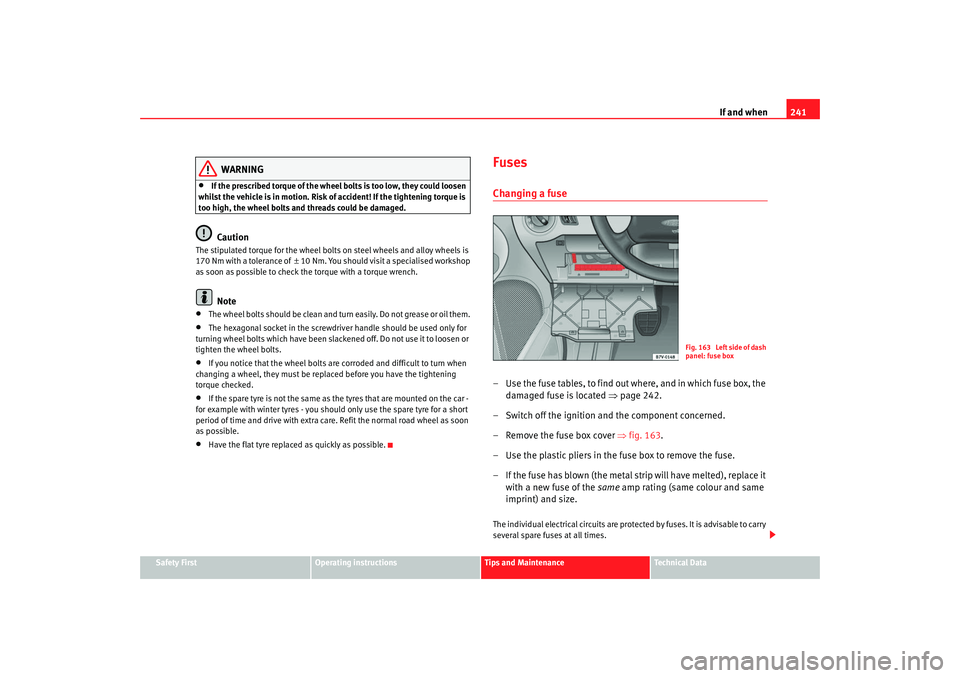

FusesChanging a fuse– Use the fuse tables, to find out where, and in which fuse box, the damaged fuse is located ⇒page 242.

– Switch off the ignition and the component concerned.

– Remove the fuse box cover ⇒fig. 163 .

– Use the plastic pliers in the fuse box to remove the fuse.

– If the fuse has blown (the metal strip will have melted), replace it with a new fuse of the same amp rating (same colour and same

imprint) and size.The individual electrical circuits are protected by fuses. It is advisable to carry

several spare fuses at all times.

Fig. 163 Left side of dash

panel: fuse box

alhambra ingles.book Seite 241 Donnerstag, 19. April 2007 4:04 16

Page 245 of 291

If and when243

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

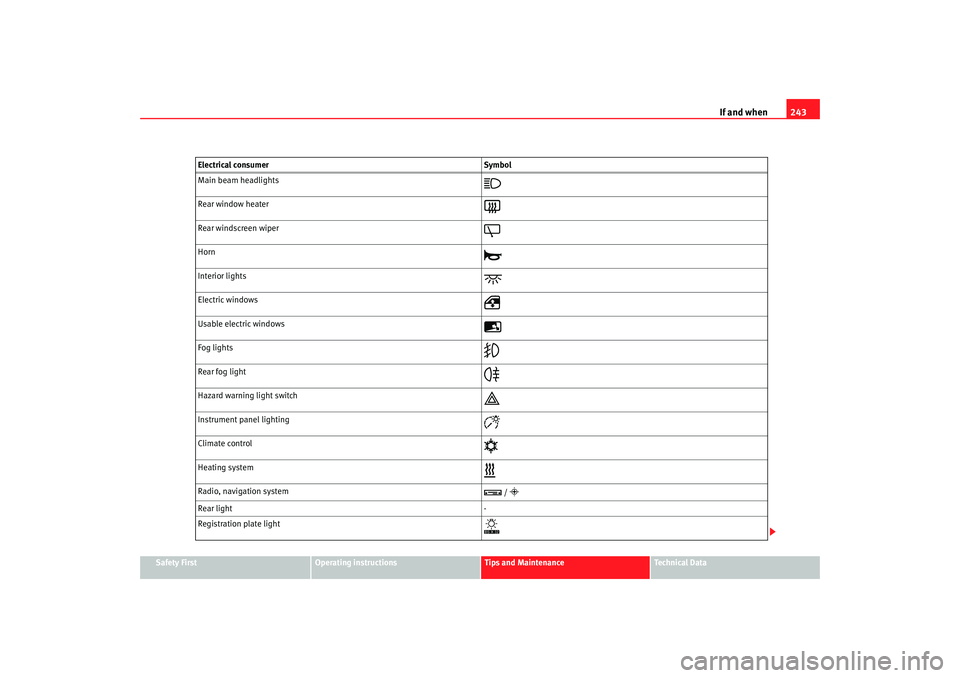

Main beam headlights

Rear window heater

Rear windscreen wiper

Horn

Interior lights

Electric windows

Usable electric windows

Fog lights

Rear fog light

Hazard warning light switch

Instrument pa

nel lighting

Climate control

Heating system

Radio, navigation system

/

Rear light -

Registration plate light

Electrical consumer Symbol

alhambra ingles.book Seite 243 Donnerstag, 19. April 2007 4:04 16

Page 247 of 291

If and when245

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

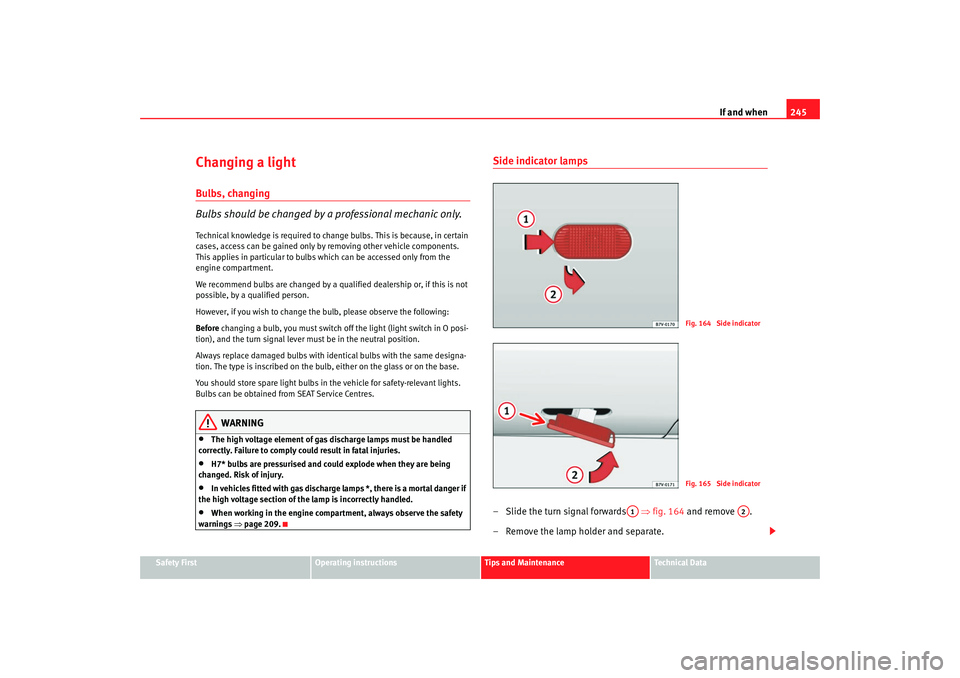

Changing a lightBulbs, changing

Bulbs should be changed by a professional mechanic only.Technical knowledge is required to change bulbs. This is because, in certain

cases, access can be gained only by removing other vehicle components.

This applies in particular to bulbs which can be accessed only from the

engine compartment.

We recommend bulbs are changed by a qualified dealership or, if this is not

possible, by a qualified person.

However, if you wish to change the bulb, please observe the following:

Before changing a bulb, you must switch off the light (light switch in O posi-

tion), and the turn signal lever mu st be in the neutral position.

Always replace damaged bulbs with identical bulbs with the same designa-

tion. The type is inscribed on the bulb, either on the glass or on the base.

You should store spare light bulbs in the vehicle for safety-relevant lights.

Bulbs can be obtained from SEAT Service Centres.

WARNING

•

The high voltage element of gas discharge lamps must be handled

correctly. Failure to comply could result in fatal injuries.

•

H7* bulbs are pressurised and could explode when they are being

changed. Risk of injury.

•

In vehicles fitted with gas discharge lamps *, there is a mortal danger if

the high voltage section of th e lamp is incorrectly handled.

•

When working in the engine compartment, always observe the safety

warnings ⇒ page 209.

Side indicator lamps– Slide the turn signal forwards ⇒fig. 164 and remove .

– Remove the lamp holder and separate.

Fig. 164 Side indicatorFig. 165 Side indicator

A1

A2

alhambra ingles.book Seite 245 Donnerstag, 19. April 2007 4:04 16

Page 249 of 291

If and when247

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

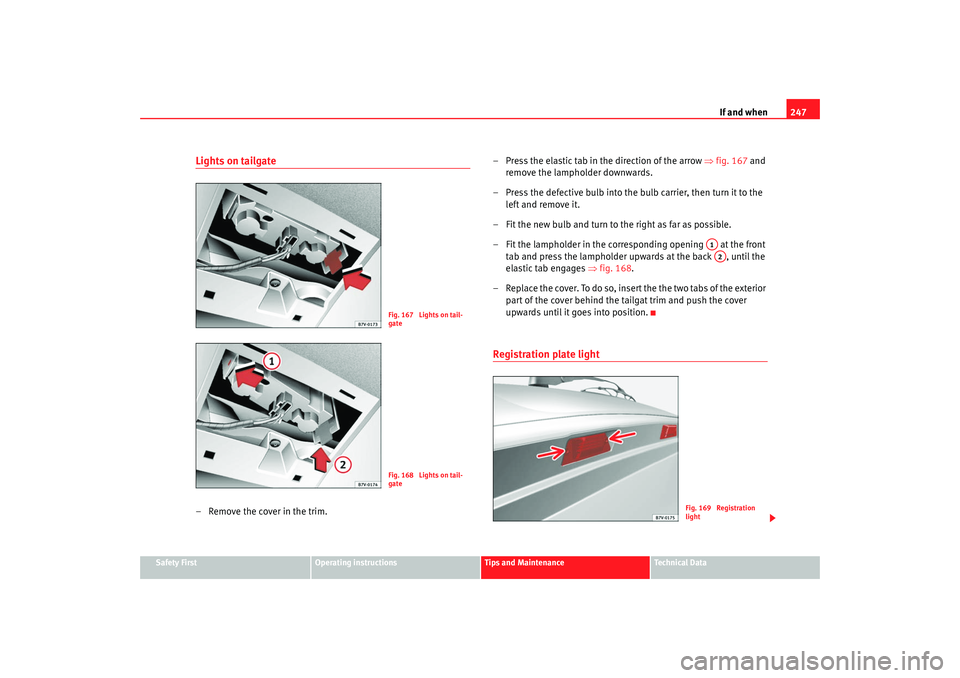

Lights on tailgate– Remove the cover in the trim. – Press the elastic tab in the direction of the arrow

⇒fig. 167 and

remove the lampholder downwards.

– Press the defective bulb into the bulb carrier, then turn it to the left and remove it.

– Fit the new bulb and turn to the right as far as possible.

– Fit the lampholder in the corresponding opening at the front tab and press the lampholder upwards at the back , until the

elastic tab engages ⇒fig. 168.

– Replace the cover. To do so, insert the the two tabs of the exterior part of the cover behind the tailgat trim and push the cover

upwards until it goes into position.

Registration plate light

Fig. 167 Lights on tail-

gateFig. 168 Lights on tail-

gate

A1A2

Fig. 169 Registration

light

alhambra ingles.book Seite 247 Donnerstag, 19. April 2007 4:04 16

Page 251 of 291

If and when249

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

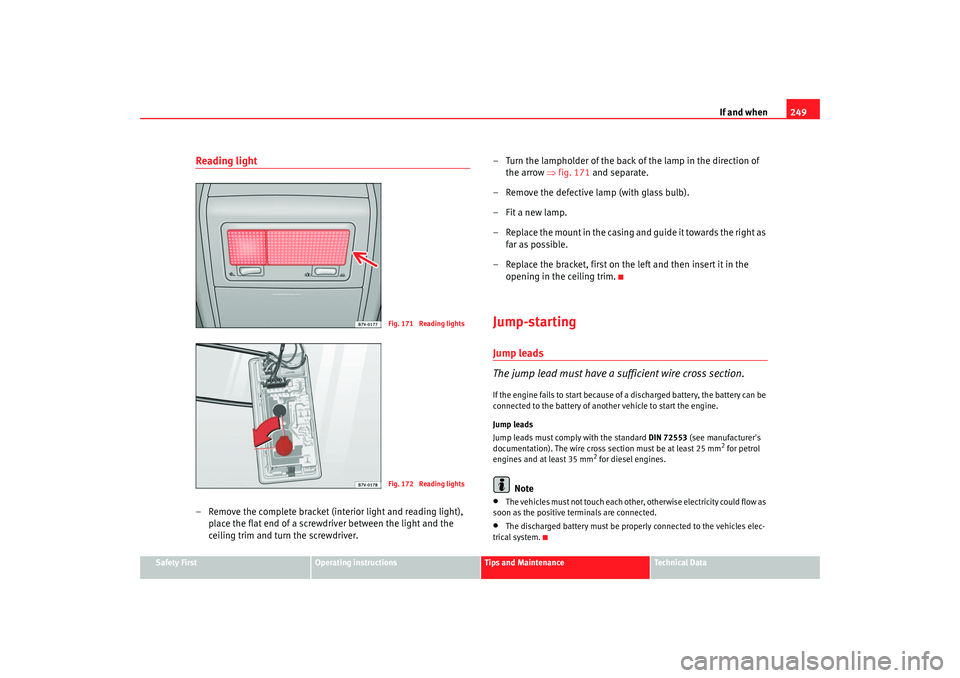

Reading light – Remove the complete bracket (interior light and reading light),

place the flat end of a screwdriver between the light and the

ceiling trim and turn the screwdriver. – Turn the lampholder of the back of the lamp in the direction of

the arrow ⇒fig. 171 and separate.

– Remove the defective lamp (with glass bulb).

–Fit a new lamp.

– Replace the mount in the casing and guide it towards the right as far as possible.

– Replace the bracket, first on the left and then insert it in the opening in the ceiling trim.

Jump-startingJump leads

The jump lead must have a sufficient wire cross section.If the engine fails to start because of a discharged battery, the battery can be

connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with the standard DIN 72553 (see manufacturer's

documentation). The wire cross section must be at least 25 mm

2 for petrol

engines and at least 35 mm

2 for diesel engines.

Note

•

The vehicles must not touch each othe r, otherwise electricity could flow as

soon as the positive terminals are connected.

•

The discharged battery must be properly connected to the vehicles elec-

trical system.

Fig. 171 Reading lightsFig. 172 Reading lights

alhambra ingles.book Seite 249 Donnerstag, 19. April 2007 4:04 16

Page 253 of 291

If and when251

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

Please note the safety warnings referring to working in the engine

compartment ⇒page 209, “Working in the engine compartment”.

•

The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

•

Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

•

Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.

•

Observe the instructions provided by the manufacturer of the jump

leads.

•

Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.

•

Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

•

The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

•

Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

•

Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

alhambra ingles.book Seite 251 Donnerstag, 19. April 2007 4:04 16