Seat Alhambra 2016 Manual Online

Manufacturer: SEAT, Model Year: 2016, Model line: Alhambra, Model: Seat Alhambra 2016Pages: 324, PDF Size: 5.93 MB

Page 81 of 324

Transporting children safely

●

All

modifications to the integrated child

seat must be carried out by a specialised

workshop.

● Replace the child seat or any seat compo-

nents d

amaged or involved in an accident. WARNING

Loose objects could fly uncontrollably around

the vehic

le interior and cause injuries in the

event of an accident or sudden braking.

● Do not leave toys or other hard, loose ob-

jects

on the child seat or on the seat while

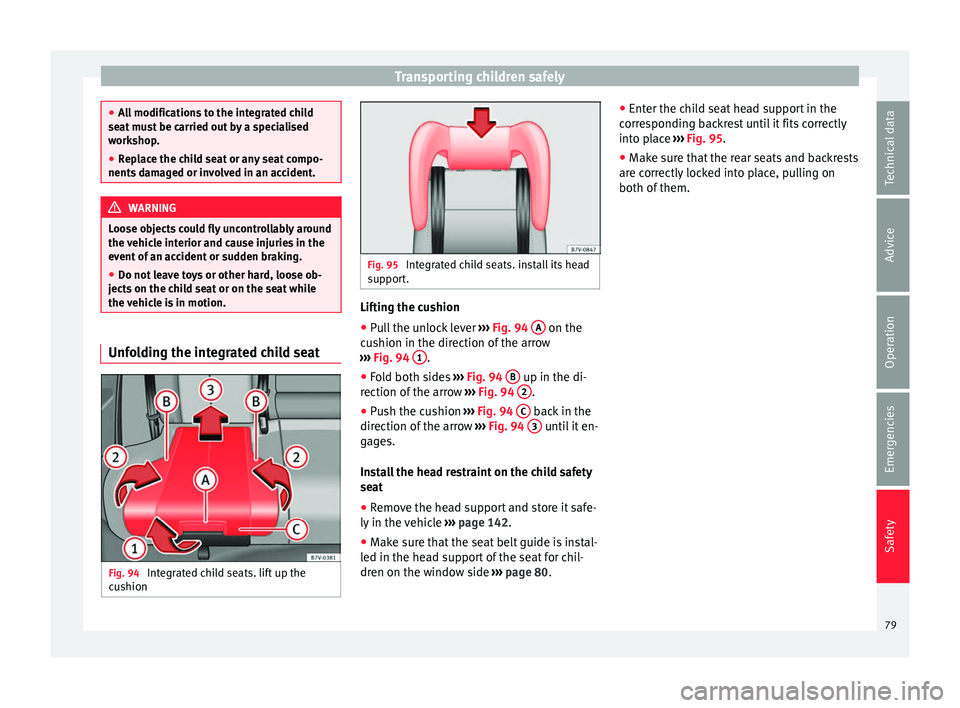

the vehicle is in motion. Unfolding the integrated child seat

Fig. 94

Integrated child seats. lift up the

c u

shion Fig. 95

Integrated child seats. install its head

sup por

t. Lifting the cushion

●

Pull the unlock lever ››

›

Fig. 94 A on the

c u

shion in the dir

ection of the arrow

››› Fig. 94 1 .

● Fold both sides ››

›

Fig. 94 B up in the di-

r ection of

the arr

ow ››› Fig. 94 2 .

● Push the cushion ››

›

Fig. 94 C back in the

dir ection of

the arr

ow ››› Fig. 94 3 until it en-

g ag

e

s.

Install the head restraint on the child safety

seat

● Remove the head support and store it safe-

ly in the v

ehicle ››› page 142.

● Make sure that the seat belt guide is instal-

led in the hea

d support of the seat for chil-

dren on the window side ››› page 80. ●

Enter the chi

ld seat head support in the

corresponding backrest until it fits correctly

into place ››› Fig. 95.

● Make sure that the rear seats and backrests

are corr

ectly locked into place, pulling on

both of them.

79

Technical data

Advice

Operation

Emergencies

Safety

Page 82 of 324

Safety

Seat belt routing on the integrated

c hi

l

d seat Fig. 96

Integrated child seats. adjusting the

se at

belt

. Fig. 97

Integrated child seats. seat belt rout-

in g w

ith guide h

andle Using the guide handle

››

›

Fig. 97, position

the seat belt so that the shoulder part of the

belt lies on the centre of the child's shoulder.

Seat belt guide handle

● Secure the seat belt guide handle to the

side hea

d restraint on the window side. The

guide handle is secured by a button.

● Open the upper button on the seat belt

guide handle and p

ass the belt webbing be-

low the side head restraint and through the

guide handle.

● Close the button again.

Adjustin

g the seat belt

● Guide the automatic three-point seat belt

below the side he

ad restraint.

● Pull the latch plate and slowly place the

belt we

bbing across the child's chest and

lap.

● Insert the latch plate into the buckle for the

appropri

ate seat and push it down until it is

securely locked with an audible click.

● Pull the belt to ensure that the latch plate is

securely

engaged in the buckle. WARNING

The seat belt only offers maximum protection

from sev er

e or fatal injuries when it is cor-

rectly positioned. ●

Chil dr

en must assume the proper sitting

position and be properly belted in while trav-

elling.

● The shoulder belt must be positioned

agains

t the middle of the shoulder.

● The seat belt must lie flat and fit comforta-

bly.

● A

llow the belt to retract until it fits tightly

over the c

hild's seat.

● The lap part of the seat belt must lie across

the pelvis, nev

er across the stomach.

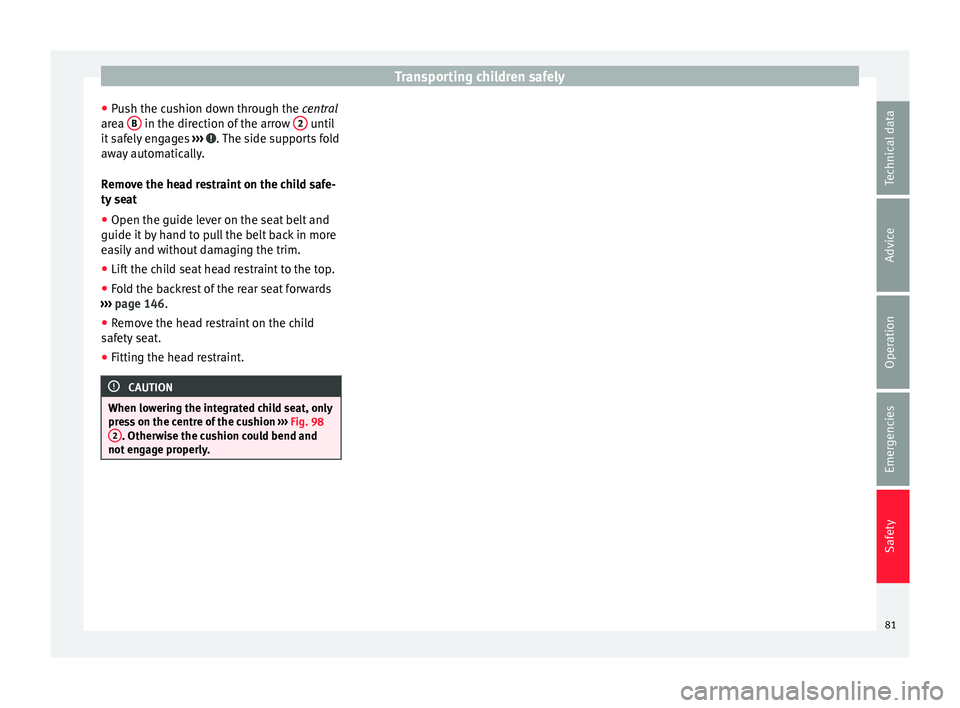

● Only one child may occupy a child seat. Removing the child seat

Fig. 98

Integrated child seats. lowering the

c u

shion Lowering the cushion

● Pull the unlock lever ››

›

Fig. 98 A on the

c u

shion in the dir

ection of the arrow 1 .

80

Page 83 of 324

Transporting children safely

● Pu

sh the c

ushion down through the central

area B in the direction of the arrow

2 until

it s

af

ely engages ››› . The side supports fold

a w

a

y automatically.

Remove the head restraint on the child safe-

ty seat

● Open the guide lever on the seat belt and

guide it by

hand to pull the belt back in more

easily and without damaging the trim.

● Lift the child seat head restraint to the top.

● Fold the backrest of the rear seat forwards

›››

page 146.

● Remove the head restraint on the child

safety

seat.

● Fitting the head restraint. CAUTION

When lowering the integrated child seat, only

pre s

s on the centre of the cushion ››› Fig. 98

2 . Otherwise the cushion could bend and

not en g

age properly. 81

Technical data

Advice

Operation

Emergencies

Safety

Page 84 of 324

Emergencies

Emergencies

Self -help

In c a

se of emergency

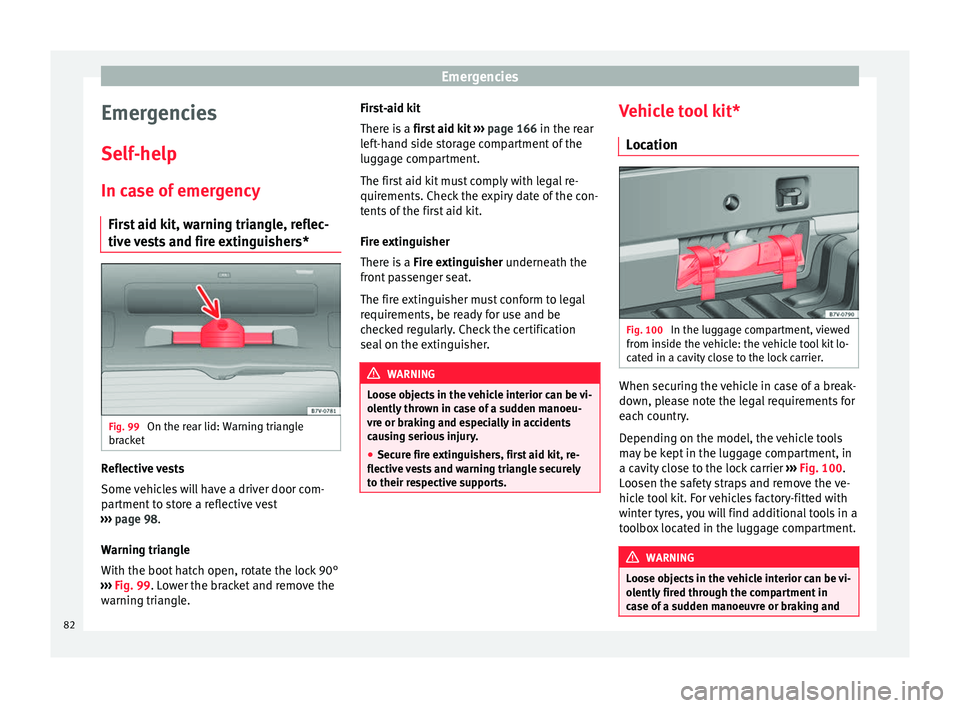

First aid kit, warning triangle, reflec-

tive vests and fire extinguishers* Fig. 99

On the rear lid: Warning triangle

br ac

k

et Reflective vests

Some

v

ehic

les will have a driver door com-

partment to store a reflective vest

››› page 98.

Warning triangle

With the boot hatch open, rotate the lock 90°

››› Fig. 99. Lower the bracket and remove the

warning triangle. First-aid kit

There is

a first aid kit ››› page 166 in the rear

left-hand side storage compartment of the

luggage compartment.

The first aid kit must comply with legal re-

quirements. Check the expiry date of the con-

tents of the first aid kit.

Fire extinguisher

There is a Fire extinguisher underneath the

front passenger seat.

The fire extinguisher must conform to legal

requirements, be ready for use and be

checked regularly. Check the certification

seal on the extinguisher. WARNING

Loose objects in the vehicle interior can be vi-

ol ently

thrown in case of a sudden manoeu-

vre or braking and especially in accidents

causing serious injury.

● Secure fire extinguishers, first aid kit, re-

flective

vests and warning triangle securely

to their respective supports. Vehicle tool kit*

Loc

ation Fig. 100

In the luggage compartment, viewed

fr om in

s

ide the vehicle: the vehicle tool kit lo-

cated in a cavity close to the lock carrier. When securing the vehicle in case of a break-

do

wn, p

l

ease note the legal requirements for

each country.

Depending on the model, the vehicle tools

may be kept in the luggage compartment, in

a cavity close to the lock carrier ››› Fig. 100.

Loosen the safety straps and remove the ve-

hicle tool kit. For vehicles factory-fitted with

winter tyres, you will find additional tools in a

toolbox located in the luggage compartment. WARNING

Loose objects in the vehicle interior can be vi-

ol ently

fired through the compartment in

case of a sudden manoeuvre or braking and 82

Page 85 of 324

Self-help

especially in accidents causing serious in-

jury

.

● M

ake sure that the vehicle tools are stored

safely

in the luggage compartment. WARNING

Unsuitable or damaged vehicle tools can

c au se injur

y or accidents.

● Never work with inappropriate or damaged

tool

s. Note

After use, return the jack to its initial position

us in

g the handle in order to securely store it

in the vehicle. Components

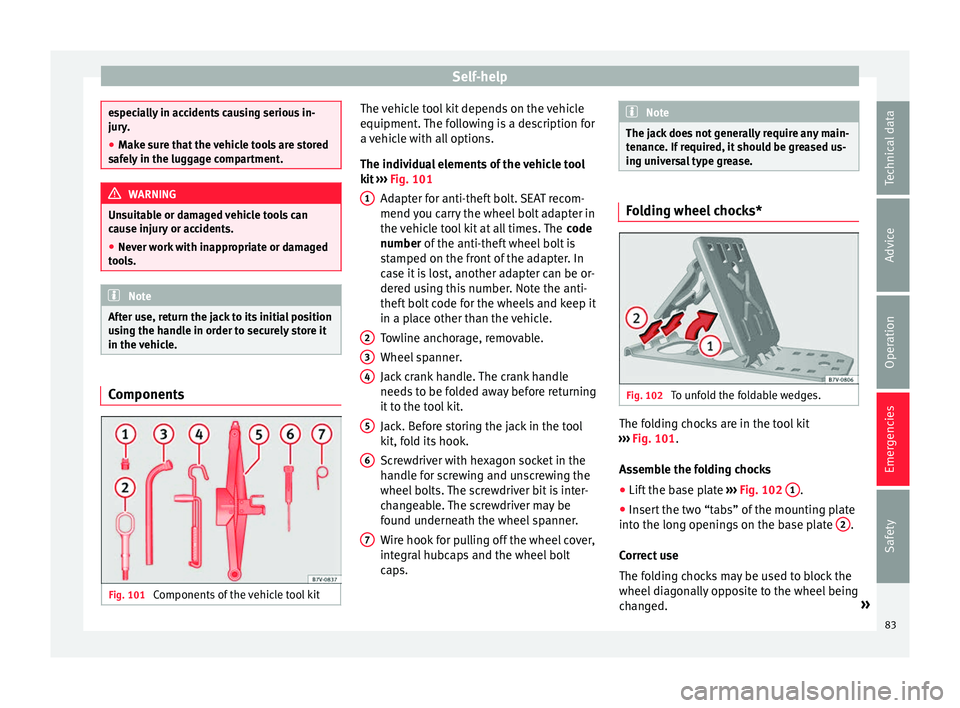

Fig. 101

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment

.

The f

ollowing is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit ››› Fig. 101

Adapter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The code

number of the anti-theft wheel bolt is

stamped on the front of the adapter. In

case it is lost, another adapter can be or-

dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wheel spanner.

Jack crank handle. The crank handle

needs to be folded away before returning

it to the tool kit.

Jack. Before storing the jack in the tool

kit, fold its hook.

Screwdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

changeable. The screwdriver may be

found underneath the wheel spanner.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

1

2

3

4

5

6

7 Note

The jack does not generally require any main-

ten anc

e. If required, it should be greased us-

ing universal type grease. Folding wheel chocks*

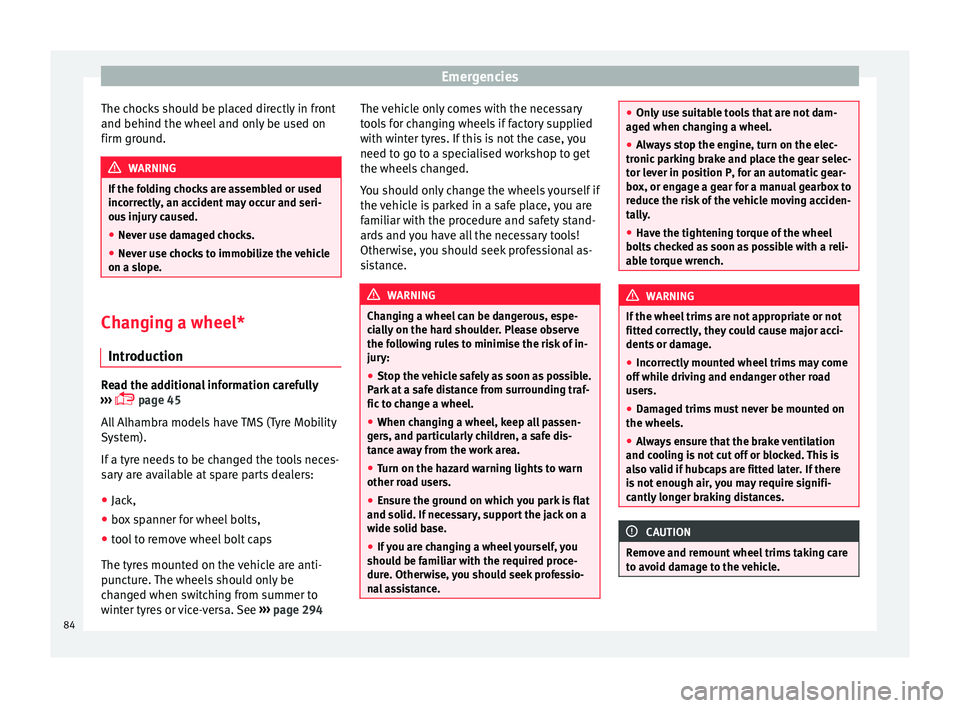

Fig. 102

To unfold the foldable wedges. The folding chocks are in the tool kit

› ›

›

Fig. 101.

Assemble the folding chocks

● Lift the base plate ›››

Fig. 102 1 .

● Insert the two “tabs” of the mounting plate

int o the lon

g openin

gs on the base plate 2 .

C orr

ect

use

The folding chocks may be used to block the

wheel diagonally opposite to the wheel being

changed. »

83

Technical data

Advice

Operation

Emergencies

Safety

Page 86 of 324

Emergencies

The chocks should be placed directly in front

and behind the wheel and on

ly

be used on

firm ground. WARNING

If the folding chocks are assembled or used

incorr ectly

, an accident may occur and seri-

ous injury caused.

● Never use damaged chocks.

● Never use chocks to immobilize the vehicle

on a slope. Changing a wheel*

Intr oduction Read the additional information carefully

› ›

›

page 45

All Alhambra models have TMS (Tyre Mobility

System).

If a tyre needs to be changed the tools neces-

sary are available at spare parts dealers:

● Jack,

● box spanner for wheel bolts,

● tool to remove wheel bolt caps

The tyre

s mounted on the vehicle are anti-

puncture. The wheels should only be

changed when switching from summer to

winter tyres or vice-versa. See ›››

page 294 The vehicle only comes with the necessary

tool

s for changing wheels if factory supplied

with winter tyres. If this is not the case, you

need to go to a specialised workshop to get

the wheels changed.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance. WARNING

Changing a wheel can be dangerous, espe-

ci a

lly on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at

a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and p

articularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Ensure the ground on which you park is flat

and solid. If nec

essary, support the jack on a

wide solid base.

● If you are changing a wheel yourself, you

should be f

amiliar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance. ●

Only u

se suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, turn on the elec-

tronic p

arking brake and place the gear selec-

tor lever in position P, for an automatic gear-

box, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving acciden-

tally.

● Have the tightening torque of the wheel

bolts

checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted c orr

ectly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off whil

e driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Alw

ays ensure that the brake ventilation

and coolin

g is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to av oid d

amage to the vehicle.84

Page 87 of 324

Self-help

Tyre repair TM S

(T

yre Mobility System)* Read the additional information carefully

›› ›

page 44

The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm in diameter. Do not remove foreign ob-

jects, e.g. screws or nails, from the tyre.

Once the sealant is in the tyre, make sure to

check the pressure after 10 minutes driving.

If the vehicle has more than one damaged

tyre, seek professional assistance. The tyre

mobility system is designed for filling one

tyre.

Only use the tyre mobility system if the vehi-

cle is properly parked, you know how to do it

and the necessary safety measures, and if

you have the right kit! Otherwise, you should

seek professional assistance.

The tyre sealant should not be used in the

following cases:

● If the wheel is damaged.

● The outside temperature is lower than

-20°C (-4°F).

● If the t

ear or puncture on the tyre is over 4

mm wide. ●

If y

ou have driven with very low pressure or

a flat tyre.

● If the expiry date on the bottle of tyre seal-

ant ha

s passed. WARNING

Using the tyre mobility system can be dan-

ger ou

s, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it

at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground is flat and firm.

● All occupants, and especially children,

should a

lways be at a safe distance outside

the work area.

● Turn on the hazard warning lights to warn

other roa

d users.

● Use the tyre mobility system only if you are

famili

ar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● Only use the tyre mobility system in the

event of

an emergency to get to the nearest

workshop.

● Replace the repaired tyre with the tyre mo-

bility

set as soon as possible.

● The sealant is hazardous for your health

and if it t

ouches your skin, it must be imme-

diately washed off. ●

Keep c hi

ldren away from the tyre mobility

system.

● Never use a jack even if it is approved for

the vehic

le.

● To reduce the risk of the vehicle possibly

movin

g on its own, always turn off the en-

gine, set the electronic parking brake and put

the selector lever in position P or put into

gear if the gearbox is a manual. WARNING

A tyre filled with sealant does not have the

s ame per f

ormance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fas

t cornering.

● Drive for only 10 minutes at a maximum

speed of 80

km/h (50 mph) and then check

the tyre. For the sake of the environment

Once used or expired, dispose of the sealant

acc or

ding to legal provisions. Note

● Sea l

ant bottles can be purchased from

SEAT dealers.

● Observe the usage instructions provided by

the snow c

hain manufacturer. 85

Technical data

Advice

Operation

Emergencies

Safety

Page 88 of 324

Emergencies

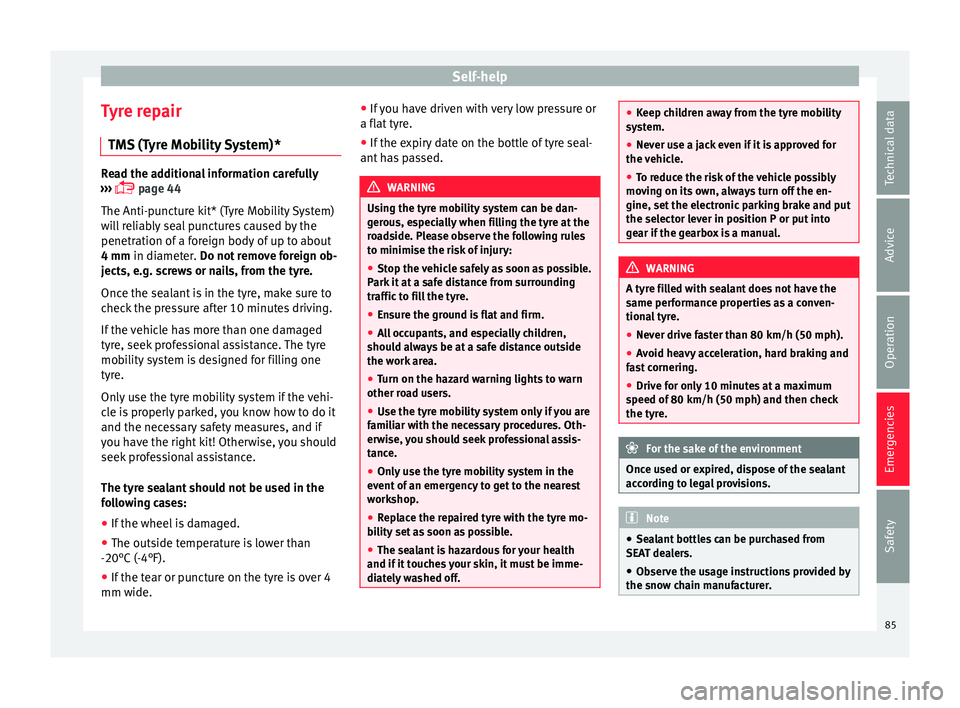

Contents of the tyre mobility system* Fig. 103

Standard representation: Contents

of the ty

r

e mobility system. The tyre mobility system is located under-

ne

ath the floor c

o

vering in the boot. It in-

cludes the following components ››› Fig. 103:

Tyre valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

ON/OFF switch

Air bleed screw 1)

Tyre pressure monitoring 1)

1 2

3

4

5

6

7 Tube for inflating tyres

12

v

o

lt connector

Bottle of sealant

Spare insert for valve

The valve insert remover 1 has a gap at the

lo w

er end f

or a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the tyre, the air compressor

and the inflat or t

ube may become hot.

● Protect hands and skin from hot parts.

● Do not place the air compressor or inflator

tube onto fl

ammable materials while they are

hot.

● Before storing the equipment, let it cool.

● If a minimum pressure of 2.0 bar

(29 psi / 200 kP

a) cannot be reached, the tyre

is badly damaged. In this instance, the seal-

ant will not be able to seal the tyre. Do not

continue driving. Seek specialist assistance. CAUTION

The air compressor should be turned off after

a max imum of

8 minutes since otherwise it

will overheat. Before switching it on again, let

it cool for a few minutes. 8

9

10

11 Check after 10 minutes of driving

Screw the inflator tube

›››

Fig. 103 8 again

and chec k

the tyre pressure on the gauge 7 .

Equa l

to or below 1.3 bar (19 psi/130 kPa):

● Stop driving! The tyre c

ould not be suffi-

ciently sealed with the tyre mobility system.

● You should obtain professional assistance

›››

.

Equa l

to or above 1.4 bar (20 psi/140 kPa):

● Correct the tyre pressure until the correct

lev el

is reached ››› page 288.

● Carefully head to the nearest specialised

workshop at

a maximum speed of 80 km/h

(50 mph).

● Ask the workshop to change the damaged

tyre. WARNING

Driving with a tyre that cannot be sealed is

dan g

erous and may lead to accidents and se-

rious injury.

● Do not continue driving if the tyre pressure

is 1.3

bar (19 psi / 130 kPa) or lower.

● Seek specialist assistance. 1)

An inflator tube may also be included.

86

Page 89 of 324

Self-help

Changing the windscreen wiper

b l

a

des

Changing the windscreen and rear

window wiper blades Read the additional information carefully

›› ›

page 54.

The windscreen wiper blades are supplied as

standard with a layer of graphite. This layer is

responsible for ensuring that the wipe is si-

lent. If the graphite layer is damaged, the

noise of the water as it is wiped across the

windscreen will be louder.

Check the condition of the wiper blades regu-

larly. If the wipers scrape across the glass

they should be changed if they are damaged,

or cleaned if they are dirty ››› .

Dam ag

ed w

iper blades should be replaced

immediately. These are available from quali-

fied workshops. WARNING

Worn or dirty wiper blades reduce visibility

and incr e

ase the risk of accident and serious

injury.

● Always replace damaged or worn blades or

bla

des which do not clean the windscreen

correctly. CAUTION

● Damag ed or dir

ty windscreen wipers could

scratch the glass.

● If products containing solvents, rough

spong

es or sharp objects are used to clean

the blades, the graphite layer will be dam-

aged.

● Never use fuel, nail varnish remover, paint

thinner or simil

ar products to clean the win-

dows.

● In icy conditions, always check that the

wiper bl

ades are not frozen to the glass be-

fore using the wipers. In cold weather, it may

help to leave the vehicle parked with the wip-

ers in service position ›››

page 54.

● To prevent damage to the bonnet and the

wiper arms, only

leave them in the service

position.

● Before driving, always lower the wiper

arms. Tow-starting and towing

Intr oduction Read the additional information carefully

› ›

›

page 50

When towing, always respect legal require-

ments.

For technical reasons, it is not possible to

tow a vehicle if the battery is flat. If the vehicle comes with the Keyless Access

syst

em, towing is only allowed with the igni-

tion on!

The vehicle battery drains if the vehicle is

towed with the engine switched off and the

ignition connected. Depending on the battery

charge status, the drop in voltage may be so

large, even after just a few minutes, that no

electrical device in the vehicle may work e.g.

the hazard warning lights. In vehicles with

the Keyless Access system, the steering

wheel could lock ››› .

WARNING

A vehicle with a flat battery should never be

to w

ed.

● Never remove the key from the ignition

lock. Otherw

ise, the steering wheel lock

could suddenly lock. The vehicle would not

be controlled and a serious accident could

ensue. WARNING

When towing the vehicle, the handling and

brak in

g efficiency change considerably.

Please observe the following instructions to

minimise the risk of serious accidents and in-

jury:

● As the driver of the vehicle being towed:

– The brake mu

st be depressed must hard-

er as the brake servo does not operate. » 87

Technical data

Advice

Operation

Emergencies

Safety

Page 90 of 324

Emergencies

Always remain aware to avoid collision

with the t

o

wing vehicle.

– More strength is required at the steering

wheel as the power steering does not op-

erate when the engine is switched off.

● As the driver of the towing vehicle:

– Acc

elerate gently and carefully.

– Avoid sudden braking and manoeuvres.

– Brake well in advance than usual and

brake gently. CAUTION

● Car ef

ully fit and remove the towline anchor-

age and its cover to avoid damage to the ve-

hicle (e.g. paintwork).

● When towing, fuel could enter the catalytic

conv

erter and cause damage! Note

● The v ehic

le can only be towed if the elec-

tronic parking brake and steering lock are de-

activated. If the vehicle has no power supply

or there is an electric system fault, the en-

gine must be started using jump leads to de-

activate the electronic parking brake and

electronic steering lock.

● Vehicles with the Keyless Access locking

and ignition syst

em should only be towed

with the ignition connected since, otherwise,

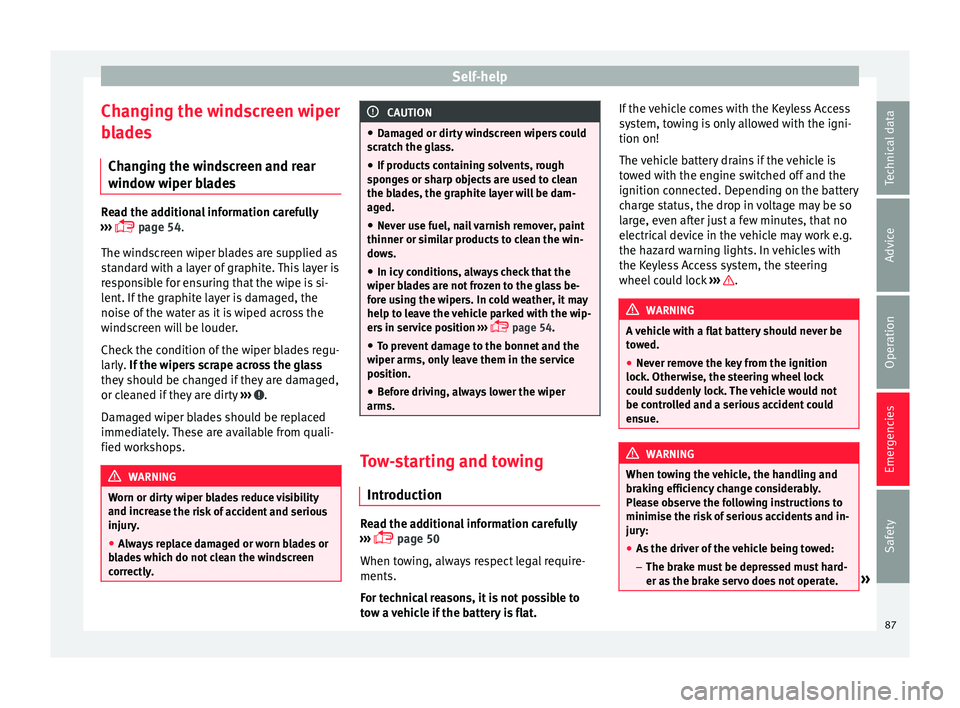

the electronic steering lock will not unlock. Fitting the front towline anchorage

Fig. 104

On the right-hand side of the front

b umper:

Sc

rew in the towline anchorage. The location for the removable towline an-

c

hor

ag

e is on the right-hand side of the front

bumper ››› Fig. 104.

The towline anchorage should always be kept

in the vehicle.

Note the instructions for towing

››› page 50.

To fit the towline anchorage

● Take the towline anchorage from the vehi-

cle t

ool kit ››› page 82.

● Press on the upper cover and carefully re-

move it

forwards. Allow the cover to hang.

● Screw in the towline anchorage into its po-

sition antic

lockwise as far as it will go

››› Fig. 104 ››› . Use a suitable tool to firmly

tight en the t o

wline anchorage in its location. ●

After t

owing, remove the towline anchorage

by turning it clockwise and put the cover

back in place. CAUTION

The towline anchorage must always be com-

pl et

ely and firmly tightened. Otherwise, it

could be released while towing and tow-start-

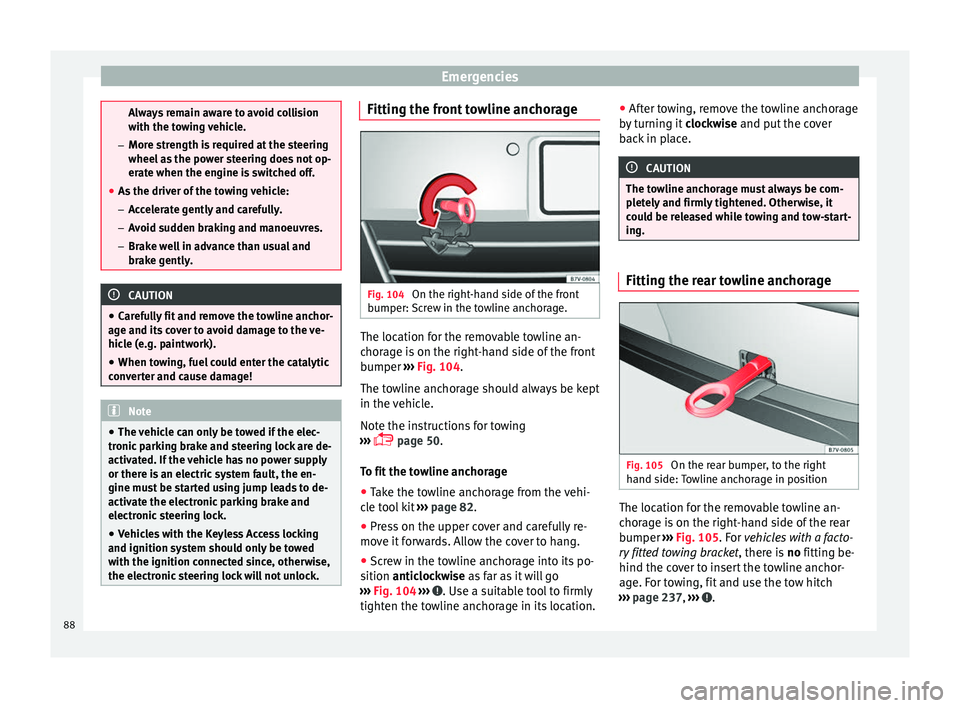

ing. Fitting the rear towline anchorage

Fig. 105

On the rear bumper, to the right

h and s ide:

Towline anchorage in position The location for the removable towline an-

c

hor

ag

e is on the right-hand side of the rear

bumper ››› Fig. 105. For vehicles with a facto-

ry fitted towing bracket , there is no fitting be-

hind the cover to insert the towline anchor-

age. For towing, fit and use the tow hitch

››› page 237, ››› .

88