ECU Seat Altea XL 2015 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Altea XL, Model: Seat Altea XL 2015Pages: 236, PDF Size: 4.23 MB

Page 105 of 236

Transport and practical equipment

Fastening rings* There can be four fastening rings in the lug-

gage compartment for fastening luggage and

other objects.

–

Always use suitable and undamaged straps

to secure luggage and other objects to the fastening rings ››› in Loading the lug-

gage compartment on page 101.

– Pull up the fastening rings to attach the

straps.

During a collision or an accident, even small

and light objects can build up so much ener-

gy that they can cause very severe injuries.

The amount of “energy” depends on the

speed of the vehicle and the weight of the

object. The most significant factor, however,

is the speed of the vehicle.

Example: An object weighing 4.5 kg is lying

unsecured in the vehicle. During a frontal col-

lision at a speed of 50 km/h (30 mph), this

object generates a force corresponding to 20

times its weight. This means that the effec-

tive weight of the object increases to about

90 kg. Imagine the injuries that may result

from said “object” if it hits any passenger

when flying through the passenger compart-

ment. This increased risk of injury will be fur-

ther increased if a loose object is struck by

an inflating airbag. WARNING

● If pieces of baggage or other objects are se-

cured to the fastening rings with inappropri-

ate or damaged retaining cords, injuries

could result in the event of braking manoeu-

vres or accidents.

● Never secure a child seat on the fastening

rings. Cargo separation net*

3 Applies to the model: ALTEA XL/ALTEA FREETRACK

Fig. 107

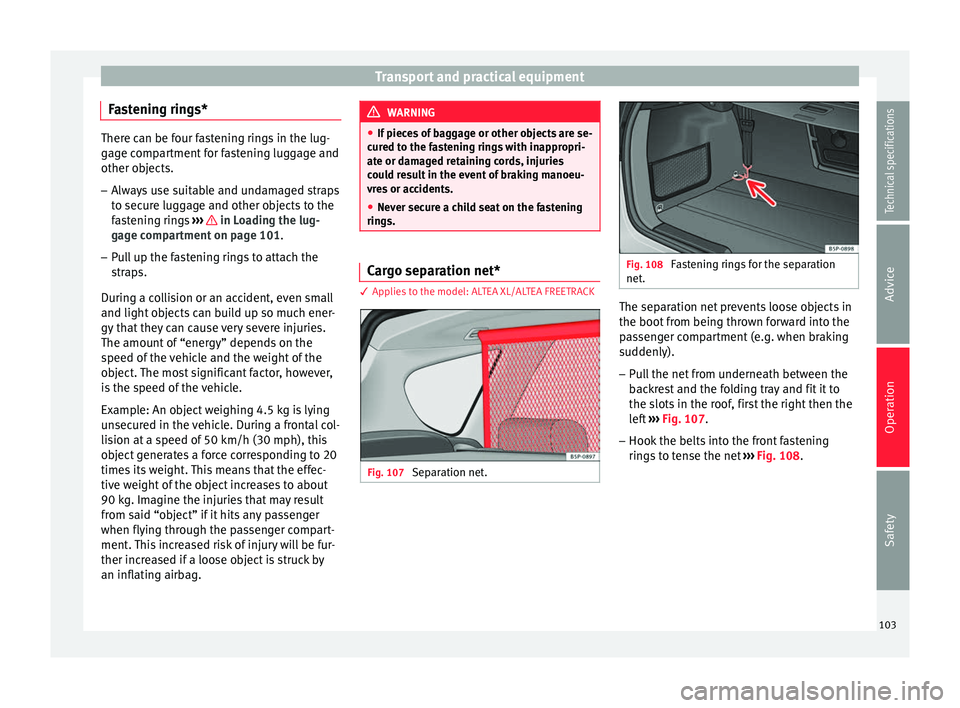

Separation net. Fig. 108

Fastening rings for the separation

net. The separation net prevents loose objects in

the boot from being thrown forward into the

passenger compartment (e.g. when braking

suddenly).

– Pull the net from underneath between the

backrest and the folding tray and fit it to

the slots in the roof, first the right then the

left ››› Fig. 107 .

– Hook the belts

into the front fastening

rings to tense the net ››› Fig. 108

.

103

Technical specifications

Advice

Operation

Safety

Page 106 of 236

Operation

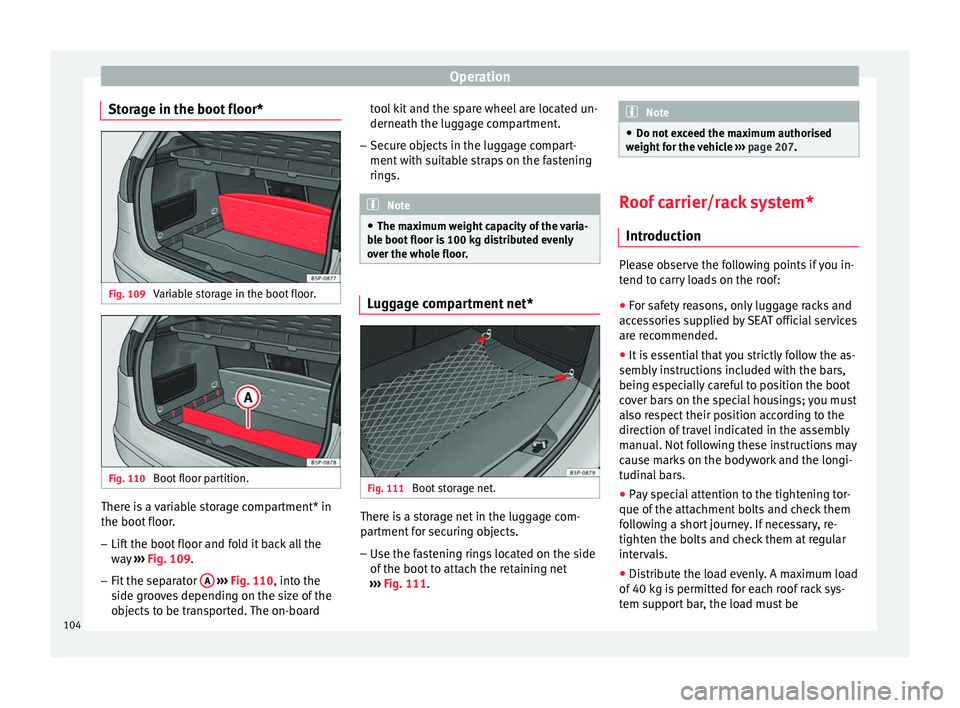

Storage in the boot floor* Fig. 109

Variable storage in the boot floor. Fig. 110

Boot floor partition. There is a variable storage compartment* in

the boot floor.

–

Lift the boot floor and fold it back all the

way ››› Fig. 109 .

– Fit the sep

arator A

››› Fig. 110

, into the

s ide gr

ooves depending on the size of the

objects to be transported. The on-board tool kit and the spare wheel are located un-

derneath the luggage compartment.

– Secure objects in the luggage compart-

ment with suitable straps on the fastening

rings. Note

● The maximum weight capacity of the varia-

ble boot floor is 100 kg distributed evenly

over the whole floor. Luggage compartment net*

Fig. 111

Boot storage net. There is a storage net in the luggage com-

partment for securing objects.

– Use the fastening rings located on the side

of the boot to attach the retaining net

››› Fig. 111 . Note

● Do not exceed the maximum authorised

weight for the vehicle ››› page 207. Roof carrier/rack system*

Introduction Please observe the following points if you in-

tend to carry loads on the roof:

● For safety reasons, only luggage racks and

accessories supplied by SEAT official services

are recommended.

● It is essential that you strictly follow the as-

sembly instructions included with the bars,

being especially careful to position the boot

cover bars on the special housings; you must

also respect their position according to the

direction of travel indicated in the assembly

manual. Not following these instructions may

cause marks on the bodywork and the longi-

tudinal bars.

● Pay special attention to the tightening tor-

que of the attachment bolts and check them

following a short journey. If necessary, re-

tighten the bolts and check them at regular

intervals.

● Distribute the load evenly. A maximum load

of 40 kg is permitted for each roof rack sys-

tem support bar, the load must be

104

Page 107 of 236

Transport and practical equipment

distributed evenly along the entire length.

However, the maximum load permitted for

the entire roof (including the support system)

of 75 kg must not be exceeded nor the total

weight recommended for the entire vehicle.

See the “Technical Data” ››› page 207 sec-

tion.

● When transporting heavy or large objects

on the roof, any change in the normal vehicle

behaviour due to a change in the centre of

gravity or an increased wind resistance must

be taken into account. For this reason, a suit-

able speed and driving style must be used.

● On vehicles fitted with a sliding/tilting sun-

roof*, make sure it does not hit the load on

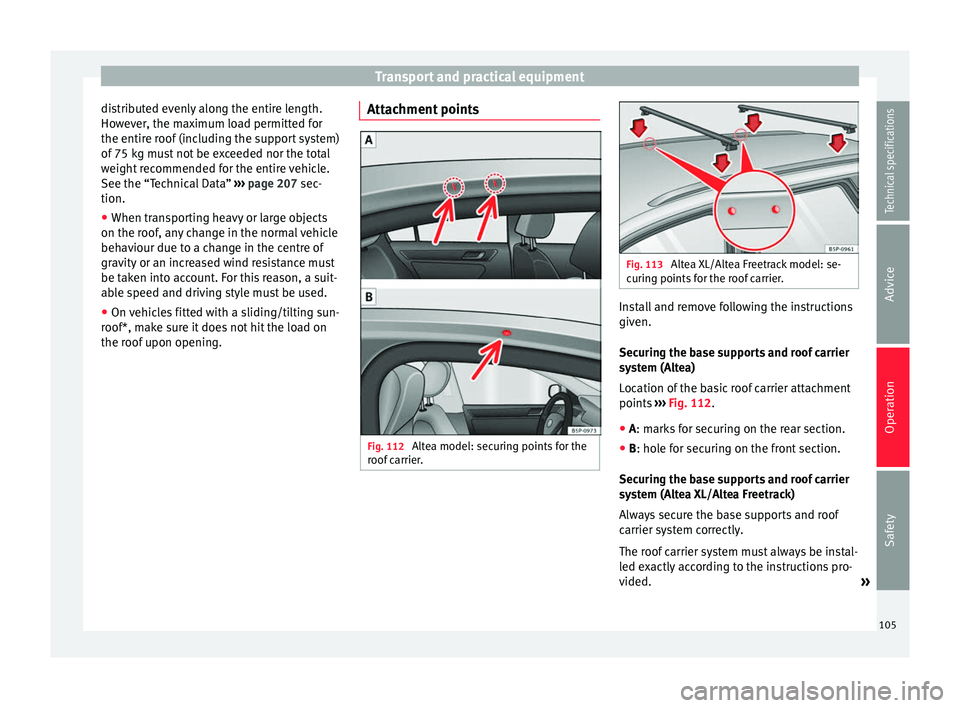

the roof upon opening. Attachment points

Fig. 112

Altea model: securing points for the

roof carrier. Fig. 113

Altea XL/Altea Freetrack model: se-

curing points for the roof carrier. Install and remove following the instructions

given.

Securing the base supports and roof carrier

system (Altea)

Location of the basic roof carrier attachment

points

››› Fig. 112 .

● A: marks for securing on the rear section.

● B: hole for securing on the front section.

Sec uring the base supports and roof carrier

system (Altea XL/Altea Freetrack)

Always secure the base supports and roof

carrier system correctly.

The roof carrier system must always be instal-

led exactly according to the instructions pro-

vided. »

105

Technical specifications

Advice

Operation

Safety

Page 127 of 236

Driving

●

If the handbrake is only partially released,

this will cause the rear brakes to overheat,

which can impair the function of the brake

system and could lead to an accident. This al-

so causes premature wear on the rear brake

pads. CAUTION

Always apply the handbrake before you leave

the vehicle. Put it in 1st gear as well. Parking

The handbrake should always be firmly ap-

plied when the vehicle is parked.

Always note the following points when park-

ing the vehicle:

– Use the brake pedal to stop the vehicle.

– Apply the handbrake.

– Put it in 1st gear.

– Switch the engine off and remove the key

from the ignition. Turn the steering wheel

slightly to engage the steering lock.

– Always take you keys with you when you

leave the vehicle ››› .Additional notes on parking the vehicle on

gradients:

Turn the steering wheel so that the vehicle

rolls against the kerb if it started to roll.

●

If the vehicle is parked facing downhill,

turn the front wheels so that they point to-

wards the kerb .

● If the vehicle is parked facing uphill, turn

the fr ont

wheels so that they point away from

the kerb

.

● Secure the vehicle as usual by applying the

handbrake firmly and putting it in 1st gear. WARNING

● Take measures to reduce the risk of injury

when you leave your vehicle unattended.

● Never park where the hot exhaust system

could ignite inflammable materials, such as

dry grass, low bushes, spilt fuel etc.

● Never allow vehicle occupants to remain in

the vehicle when it is locked. They would be

unable to open the vehicle from the inside,

and could become trapped in the vehicle in

an emergency. In the event of an emergency,

locked doors will delay assistance to vehicle

occupants.

● Never leave children alone in the vehicle.

They could set the vehicle in motion, for ex-

ample, by releasing the handbrake or the

gearbox lever. ●

Depending on weather conditions, it may

become extremely hot or cold inside the vehi-

cle. This can be fatal. Hill driving assistant*

This function is only included in vehicles with

ESC.

The hill driving assistant helps the driver to

move off and upward on a hill without rolling

backward.

The system maintains brake pressure for ap-

proximately 2 seconds after the driver takes

his foot off the brake pedal to prevent the ve-

hicle from rolling backward when starting off.

During these 2 seconds, the driver has

enough time to release the clutch pedal and

accelerate without the vehicle moving and

without having to use the handbrake, making

starting off easier, more comfortable and saf-

er.

These are the basic operation conditions:

● being on a ramp or hill/slope,

● closed doors,

● vehicle completely stationary,

● engine running and foot on the brake,

● besides having a gear engaged or being in

neutral for manual gear change and with the

selector lever at position S,

D

or R for an au-

tomatic gearbox. »

125

Technical specifications

Advice

Operation

Safety

Page 146 of 236

Operation

once on the upper part of the rocker switch RES/+ ››› Fig. 137 A .

Complete system deactivation* Vehicles with a manual gearbox

The system is completely turned off

by mov-

ing the control B

››› Fig. 137 all the way to

the right (OFF

engaged), or when the vehicle

is stationary, by switching off the ignition.

Vehicles with automatic gearbox/DSG

automatic gearbox

To completely disengage the system, the se-

lector lever must be placed in one of the fol-

lowing positions: P ,

N, R or 1 or with the vehi-

cle stopped and the ignition turned off. Towing bracket device

Trailer towing Instructions to follow Your vehicle may be used to tow a trailer

when fitted with the correct equipment.

If the car is supplied with a

factory-fitted tow-

in g br

acket it will already have the necessary

technical modifications and meet the statuto-

ry requirements for towing a trailer. If you

wish to retrofit a towing bracket, consult

›

›› page 146.

Connect

ors

Your vehicle is fitted with a 12-pin connector

for the electrical connection between the

trailer and the vehicle.

If the trailer has a 7-pin plug you will need to

use an a

dapter cable. It is available at any

Technical Service.

Trailer weight/drawbar load

Never exceed the authorised trailer weight. If

you do not load the trailer up to the maxi-

mum permitted trailer weight, you can then

climb correspondingly steeper slopes.

The maximum trailer weights listed are only applicable for altitudes up to 1000 m above

sea l

evel. With increasing altitude the engine power and therefore the vehicle climbing

ability are impaired because of the reduced

air density. The maximum trailer weight has

to be reduced accordingly. The weight of the

vehicle and trailer combination must be re-

duced by 10% for every further 1000 m (or

part thereof). The gross combination weight

is the actual weight of the laden vehicle plus

the actual weight of the laden trailer. When

possible, operate the trailer with the maxi-

mum permitted drawbar load on the ball joint

of the t

owing bracket, but do not exceed the

specified limit.

The figures for trailer weights

and drawbar

loads that are given on the data plate of the

towing bracket are for certification purposes

only. The correct figures for your specific

model, which may be lower than these fig-

ures for the towing bracket, are given in the

vehicle documentation or in ››› chapter Tech-

nical Data .

Distributing the load

Distribute loads in the trailer so that heavy

objects are as near to the axle as possible.

Loads carried in the trailer must be secured

to prevent them moving.

144

Page 147 of 236

Towing bracket device

Tyre pressure

Set tyre pressure to the maximum permissi-

ble pressure shown on the sticker on the in-

side of the fuel tank flap. Set the tyre pres-

sure of the trailer tyres in accordance with the

trailer manufacturer's recommendations.

Exterior mirrors

Check whether you can see enough of the

road behind the trailer with the standard rear

vision mirrors. If this is not the case, you

should have additional exterior mirrors fitted.

Both exterior mirrors should be mounted on

hinged extension brackets. Adjust the mirrors

to give sufficient vision to the rear. WARNING

Never transport people in a trailer. This could

result in fatal accidents. Note

● Towing a trailer places additional demands

on the vehicle. We recommend additional

services between the normal inspection inter-

vals if the vehicle is used frequently for tow-

ing a trailer.

● Find out whether special regulations apply

to towing a trailer in your country. Ball coupling of towing bracket*

Depending on the model version, the spheri-

cal head on the trailer hook may be stored in

the tool box.

The ball coupling is provided with instruc-

tions on fitting and removing the ball cou-

pling of the towing bracket.

WARNING

The towing bracket ball coupling must be

stored securely in the luggage compartment

to prevent them being flung through the vehi-

cle and causing injury. Note

● By law, the ball coupling must be removed

if a trailer is not being towed if it obscures

the number plate. Driving tips

Driving with a trailer always requires extra

care.

Weight distribution

The weight distribution of a loaded trailer

with an unladen vehicle is very unfavourable.

However, if this cannot be avoided, drive ex-

tra slowly to allow for the unbalanced weight

distribution.Speed

The stability of the vehicle and trailer is re-

duced with increasing speed. For this reason,

it is advisable not to drive at the maximum

permissible speed in an unfavourable road,

weather or wind conditions. This applies es-

pecially when driving downhill.

You should always reduce speed immediately

if the trailer shows the slightest sign of

snak-

ing . Never try to stop the “snaking” by in-

c r

easing speed.

Always brake in due course. If the trailer has

an

overrun brake, apply the brakes gently at

first and then, firmly. This will prevent the

jerking that can be caused by locking of trail-

er wheels. Select a low gear in due course

before going down a steep downhill. This en-

ables you to use the engine braking to slow

down the vehicle.

Reheating

At very high temperatures and during pro-

longed slopes, driving in a low gear and high

engine speed, always monitor the coolant

temperature gauge ››› page 31.

Electronic Stability Control*

The ESC* system helps to stabilise the trailer

in case of skidding or rocking.

145

Technical specifications

Advice

Operation

Safety

Page 148 of 236

Operation

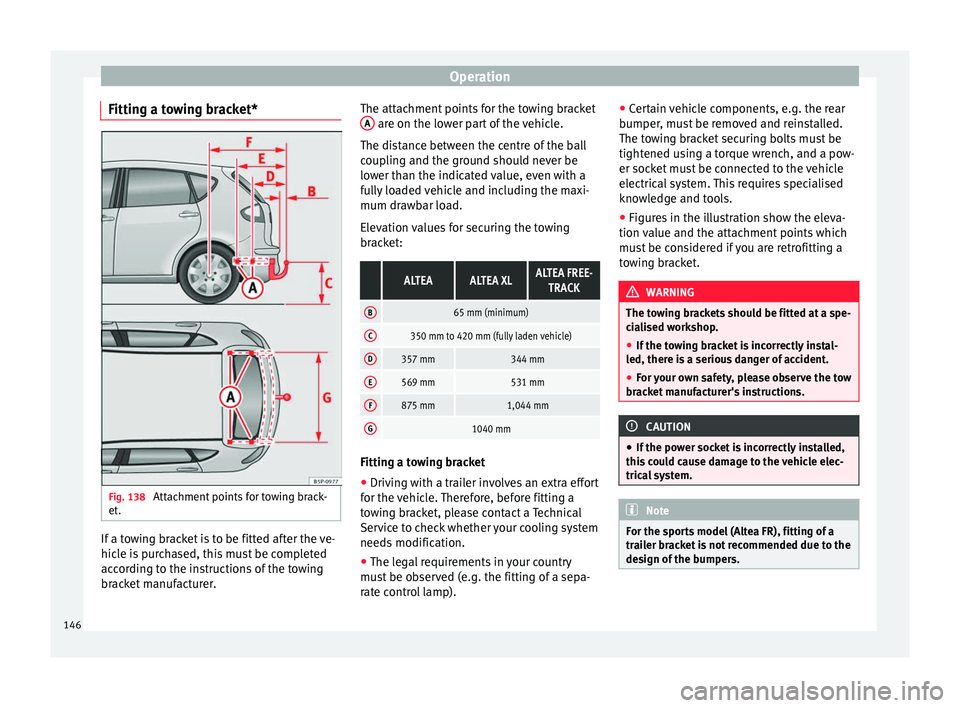

Fitting a towing bracket* Fig. 138

Attachment points for towing brack-

et. If a towing bracket is to be fitted after the ve-

hicle is purchased, this must be completed

according to the instructions of the towing

bracket manufacturer. The attachment points for the towing bracket

A are on the lower part of the vehicle.

The distance between the centre of the ball

coupling and the ground should never be

lower than the indicated value, even with a

fully loaded vehicle and including the maxi-

mum drawbar load.

Elevation values for securing the towing

bracket: ALTEAALTEA XLALTEA FREE- TRACK

B65 mm (minimum)

C350 mm to 420 mm (fully laden vehicle)

D357 mm344 mm

E569 mm531 mm

F875 mm1,044 mm

G1040 mm Fitting a towing bracket

●

Driving with a trailer involves an extra effort

for the vehicle. Therefore, before fitting a

towing bracket, please contact a Technical

Service to check whether your cooling system

needs modification.

● The legal requirements in your country

must be observed (e.g. the fitting of a sepa-

rate control lamp). ●

Certain vehicle components, e.g. the rear

bumper, must be removed and reinstalled.

The towing bracket securing bolts must be

tightened using a torque wrench, and a pow-

er socket must be connected to the vehicle

electrical system. This requires specialised

knowledge and tools.

● Figures in the illustration show the eleva-

tion value and the attachment points which

must be considered if you are retrofitting a

towing bracket. WARNING

The towing brackets should be fitted at a spe-

cialised workshop.

● If the towing bracket is incorrectly instal-

led, there is a serious danger of accident.

● For your own safety, please observe the tow

bracket manufacturer's instructions. CAUTION

● If the power socket is incorrectly installed,

this could cause damage to the vehicle elec-

trical system. Note

For the sports model (Altea FR), fitting of a

trailer bracket is not recommended due to the

design of the bumpers. 146

Page 160 of 236

Advice

Checking and refilling levels

Fuel Refuelling Fig. 139

Tank flap open. The tank flap is released manually and is lo-

cated at the rear of the vehicle on the right.

The tank holds approximately 55 litres. For

all-wheel drive vehicles, the tank capacity is

approximately 60 litres.

Vehicles using LPG have two fuel tanks: one

for LPG and another for petrol

››› page 160.

Opening the fuel tank cap

– Lift the lid.

– Hold the cap firmly with one hand, then in-

sert the key into the lock and rotate 180° to

the left. –

Unscrew the cap, turning it anticlockwise.

Closing the fuel tank cap

– Screw the tank cap to the right until it

“clicks”.

– Turn the key in the lock, without releasing

the cap, clockwise through 180°.

– Remove the key and close the flap until it

clicks into place. The tank cap is secured

with an anti-loss attachment

If the automatic filler nozzle is operated cor-

rectly, it will switch itself off as soon as the

tank is full. Never attempt to fill beyond this

point, as this will fill the expansion chamber.

Fuel may leak out if ambient conditions are

warm.

The correct fuel grade for your vehicle is giv-

en on a sticker on the inside of the fuel tank

flap. Here you will find further information on

fuel. WARNING

● Fuel is highly flammable and can cause se-

rious burns and other injuries.

–Never smoke or come into contact with

sparks when filling the fuel tank of the

vehicle or a spare fuel canister with fuel.

This is an explosion hazard.

– Follow legal requirements for the use of

spare fuel canisters. –

For safety reasons we do not recommend

carrying a spare fuel canister in the vehi-

cle. The canister could be damaged in an

accident and leak.

● If, in exceptional circumstances, you have

to carry a spare fuel canister, please observe

the following:

–Never fill the spare fuel canister inside

the vehicle or on it. An electrostatic

charge could build up during filling, caus-

ing the fuel fumes to ignite. This could

cause an explosion. Always place the

canister on the ground to fill it.

– Insert the fuel nozzle into the mouth of

the canister as far as possible.

– If the spare fuel canister is made of met-

al, the filling nozzle must be in contact

with the canister during filling. This

helps prevent an electrostatic charge

building up.

– Never spill fuel in the vehicle or in the

luggage compartment. Fuel vapours are

explosive. Danger of death. CAUTION

● Fuel spills should be removed from the

paintwork immediately.

● Never run the tank completely dry. Irregular

fuel supply can cause misfiring. As a result,

unburnt fuel could enter the catalytic convert-

er and cause damage. 158

Page 167 of 236

Checking and refilling levels

For the sake of the environment

Service fluids leaks are harmful to the envi-

ronment. For this reason you should make

regular checks on the ground underneath

your vehicle. If you find spots of oil or other

fluids, have your vehicle inspected in a speci-

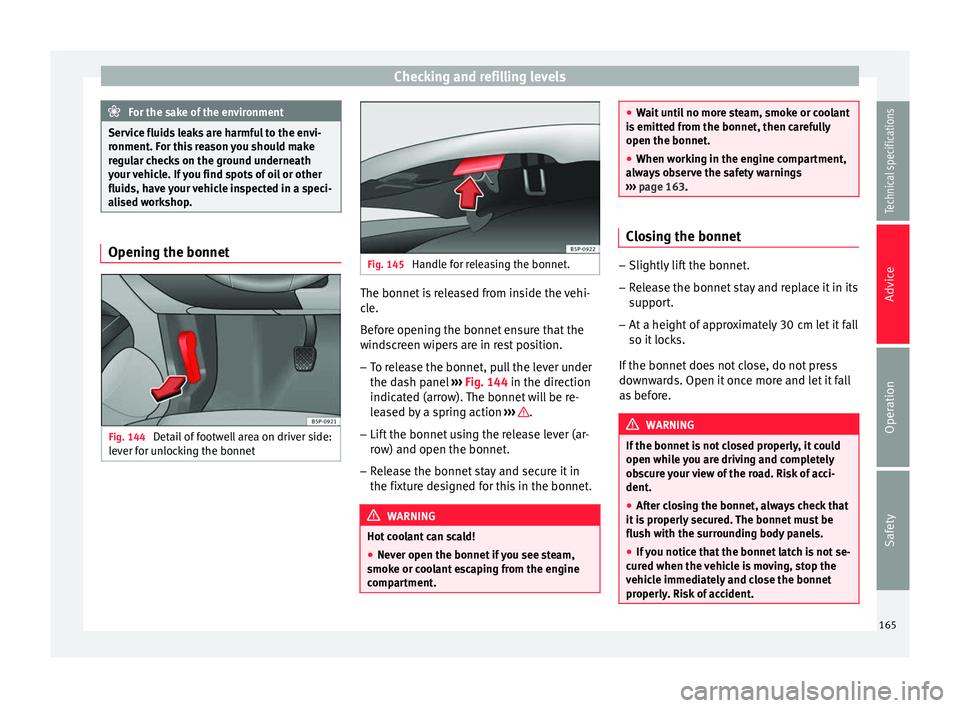

alised workshop. Opening the bonnet

Fig. 144

Detail of footwell area on driver side:

lever for unlocking the bonnet Fig. 145

Handle for releasing the bonnet. The bonnet is released from inside the vehi-

cle.

Before opening the bonnet ensure that the

windscreen wipers are in rest position.

– To release the bonnet, pull the lever under

the dash panel ››› Fig. 144 in the direction

indic at

ed (arrow). The bonnet will be re-

leased by a spring action ››› .

– Lift the bonnet using the release lever (ar-

row) and open the bonnet.

– Release the bonnet stay and secure it in

the fixture designed for this in the bonnet. WARNING

Hot coolant can scald!

● Never open the bonnet if you see steam,

smoke or coolant escaping from the engine

compartment. ●

Wait until no more steam, smoke or coolant

is emitted from the bonnet, then carefully

open the bonnet.

● When working in the engine compartment,

always observe the safety warnings

››› page 163. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay and replace it in its

support.

– At a height of approximately 30 cm let it fall

so it locks.

If the bonnet does not close, do not press

downwards. Open it once more and let it fall

as before. WARNING

If the bonnet is not closed properly, it could

open while you are driving and completely

obscure your view of the road. Risk of acci-

dent.

● After closing the bonnet, always check that

it is properly secured. The bonnet must be

flush with the surrounding body panels.

● If you notice that the bonnet latch is not se-

cured when the vehicle is moving, stop the

vehicle immediately and close the bonnet

properly. Risk of accident. 165

Technical specifications

Advice

Operation

Safety

Page 182 of 236

Advice

For the sake of the environment

Old tyres must be disposed of according to

the laws in the country concerned. Note

● For technical reasons, it is not generally

possible to use the wheels from other vehi-

cles. This can also apply to wheels of the

same model. The use of wheels or tyres

which have not been approved by SEAT for

use with your model may invalidate the vehi-

cle's type approval for use on public roads.

● If the spare tyre is not the same as the

tyres that are mounted on the vehicle (e.g.

winter tyres) you should only use the spare

tyre for a short period of time and drive with

extra care. Refit the normal road wheel as

soon as possible. Wheel bolts

The design of wheel bolts is matched to the

rims. If different wheel rims are fitted, the

correct wheel bolts with the right length and

correctly shaped bolt heads must be used.

This ensures that wheels are fitted securely

and that the brake system functions correctly.

In certain circumstances, you should not use

wheel bolts from a different vehicle, even if it

is the same model

›››

page 147. After the wheels have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench

››› . The tightening torque for steel

and alloy wheels is 120 Nm. WARNING

If the wheel bolts are not tightened correctly,

the wheel could become loose while driving.

Risk of accident.

● The wheel bolts must be clean and turn

easily. Never apply grease or oil to them.

● Use only wheel bolts which belong to the

wheel.

● If the tightening torque of the wheel bolts

is too low, they could loosen whilst the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. CAUTION

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 120 Nm. Winter service

Winter tyres In winter conditions winter tyres will consid-

erably improve the vehicle's handling. Sum-mer tyres (width, rubber compound, tread

pattern) provide less grip on ice and snow.

Winter tyres must be inflated to a

pressure of

0.2 bar (2.9 psi/20 kPa) higher than the pres-

sures specified for summer tyres (see sticker

on fuel tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes

can be found in the vehicle's registration

documentation. Use only radial winter tyres.

All tyre sizes listed in the vehicle documenta-

tion also apply to winter tyres.

Winter tyres lose their effectiveness when the

tread is worn down to a depth of 4 mm.

The speed rating code ››› page 179, New

tyres and wheels determines the following

speed limits for winter tyres:

›

› › max. 160 km/h

max. 180 km/h

max. 190 km/h

max. 210 km/h

In some countries, vehicles which can exceed

the speed rating of the fitted tyre must have

an appropriate sticker in the driver's field of

view. These stickers are available from your

technical service. The legal requirements of

each country must be followed.

Do not have winter tyres fitted for unnecessa-

rily long periods. Vehicles with summer tyres Q

S

T

H

180