Seat Exeo ST 2009 Owner's manual

Manufacturer: SEAT, Model Year: 2009, Model line: Exeo ST, Model: Seat Exeo ST 2009Pages: 316, PDF Size: 8.83 MB

Page 261 of 316

If and when259

Safety First

Controls and equipment

Practical tips

Technical Data

Tyre repair* (Tyre-Mobility-System)General information and safety notes

Repaired tyres are only suitable for temporary use over a

short period.Your vehicle is equipped with a tyre repair kit: the Ty re Mo bil it y Syste m.

In the event of a puncture you will find the TMS, which consists of a sealing

compound and a compressor, located under the floor panel in the luggage

compartment.

The Ty re Mo bil i t y Syste m will reliably seal tyres damaged by foreign bodies,

provided that the cuts or punctures are no larger than approx. 4 mm in diam-

eter.

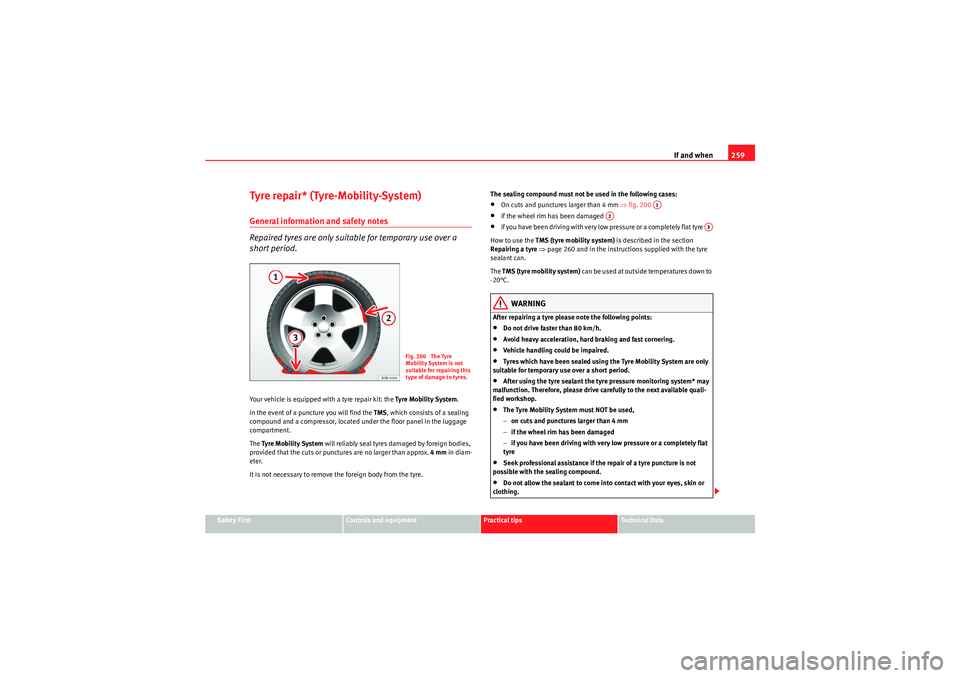

It is not necessary to remove the foreign body from the tyre. The sealing compound must not be used in the following cases:

•On cuts and punctures larger than 4 mm

⇒fig. 200 •if the wheel rim has been damaged •i f yo u ha ve b e en d r iving wit h v e r y low pre ssu re o r a com ple te ly fla t tyre

How to use the TMS (tyre mobility system) is described in the section

Repairing a tyre ⇒ page 260 and in the instructions supplied with the tyre

sealant can.

The TMS (tyre mobility system) can be used at outside temperatures down to

-20°C.WARNING

After repairing a tyre please note the following points:•Do not drive faster than 80 km/h.•Avoid heavy acceleration, hard braking and fast cornering.•Vehicle handling could be impaired.•Tyres which have been sealed using the Tyre Mobility System are only

suitable for temporary use over a short period.•After using the tyre sealant the tyre pressure monitoring system* may

malfunction. Therefore, please drive carefully to the next available quali-

fied workshop.•The Tyre Mobility System must NOT be used,

− on cuts and punctures larger than 4 mm

− if the wheel rim has been damaged

− if you have been driving with very low pressure or a completely flat

tyre•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.•Do not allow the sealant to come into contact with your eyes, skin or

clothing.

Fig. 200 The Tyre

Mobility System is not

suitable for repairing this

type of damage to tyres.

A1

A2

A3

ExeoST_EN.book Seite 259 Donnerstag, 3. September 2009 12:24 12

Page 262 of 316

If and when

260•If you do come into contact with the sealant immediately rinse the eyes

or skin affected with clean water.•Change clothing immediately if it becomes soiled with the tyre sealant.•Make sure you do not breathe in the fumes!•If any of the tyre sealant is accidentally ingested, immediately rinse the

mouth thoroughly and drink lots of water.

−Do not induce vomiting. Seek medical assistance if needed.•If any allergic reactions should occur get medical help immediately.•Keep the sealant away from children.For the sake of the environment

Used bottles of sealing compound can be returned to the Technical Service

for disposal.

Note

•If sealant should leak out, leave it to dry. When it has dried, you can pull

it off like a piece of foil.•Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a qualified workshop.

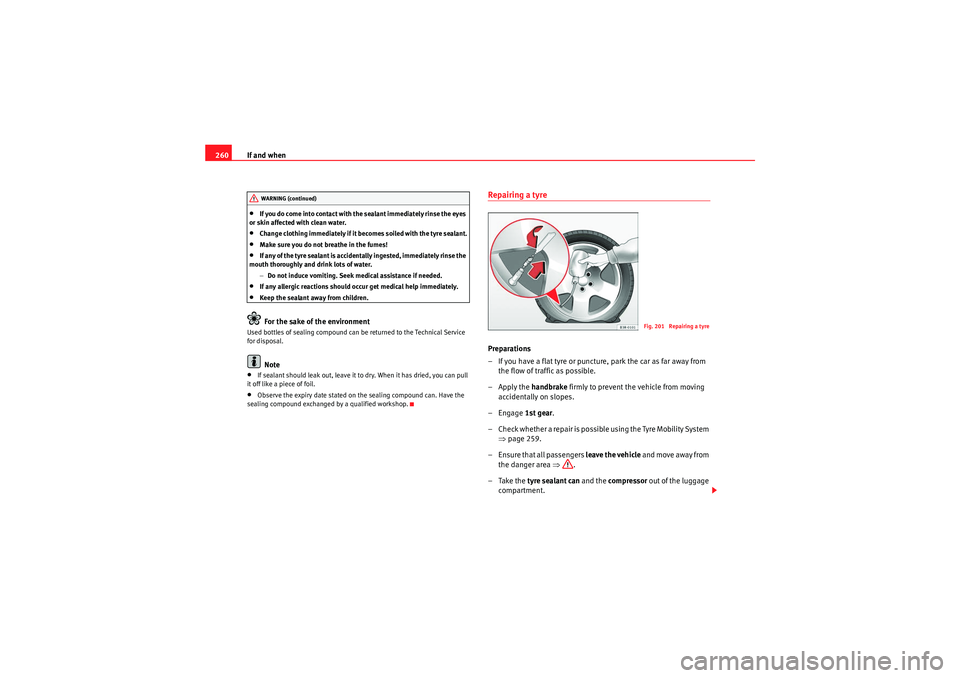

Repairing a tyrePreparations

– If you have a flat tyre or puncture, park the car as far away from the flow of traffic as possible.

–Apply the handbrake firmly to prevent the vehicle from moving

accidentally on slopes.

–Engage 1st gear.

– Check whether a repair is possible using the Tyre Mobility System ⇒page 259.

– Ensure that all passengers leave the vehicle and move away from

the danger area ⇒.

–Take the tyre sealant can and the compressor out of the luggage

compartment.

WARNING (continued)

Fig. 201 Repairing a tyre

ExeoST_EN.book Seite 260 Donnerstag, 3. September 2009 12:24 12

Page 263 of 316

If and when261

Safety First

Controls and equipment

Practical tips

Technical Data

– Stick the “max. 80 km/h” adhesive, which is included with the

tyre sealant can, onto the instrument panel where the driver will

see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it will go. This will automatically pierce the foil sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve insert tool to unscrew the valve insert ⇒page 260, fig. 201 .

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back into the tyre valve.

Inflating the tyre

– Screw the compressor filling hose onto the tyre valve and plug the connector into the cigarette lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure shown on the pressure gauge. – If the tyre pressure remains lower than the value specified above

drive the vehicle approx. 10 metres forwards or backwards, so

that the sealant can spread evenly in the tyre. If the pressure is

still lower than the specification the tyre is too badly damaged

and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly damaged. Do not drive on! You should obtain professional

assistance.

WARNING

•If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.•Make sure your pass engers wait in a safe place ( for instance behind t he

roadside crash barrier).•Please observe the manufacturers' safety notes on the compressor and

the instructions supplied with the tyre sealant can.•If it was not possible to build up a tyre pressure of 2.0 bar within 6

minutes this means that the tyre is too badly damaged. Do not drive on!•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.•If tyre pressure is less than 1.3 bar after driving about 10 minutes, the

tyre is too badly damaged. Do not drive on! Obtain technical assistance.Caution

Take special care if you have to repair a tyre on a slope.

ExeoST_EN.book Seite 261 Donnerstag, 3. September 2009 12:24 12

Page 264 of 316

If and when

262

Note•Do not use the compressor for longer than 6 minutes. Otherwise, it might

overheat. When the compressor has cooled down, you can use it again.•If tyre sealant should leak out, leave it to dry and then pull it off like foil.•After carrying out a tyre repair remember to buy a new tyre sealant can at

a qualified workshop. This will ensure that the Tyre Mobility System is opera-

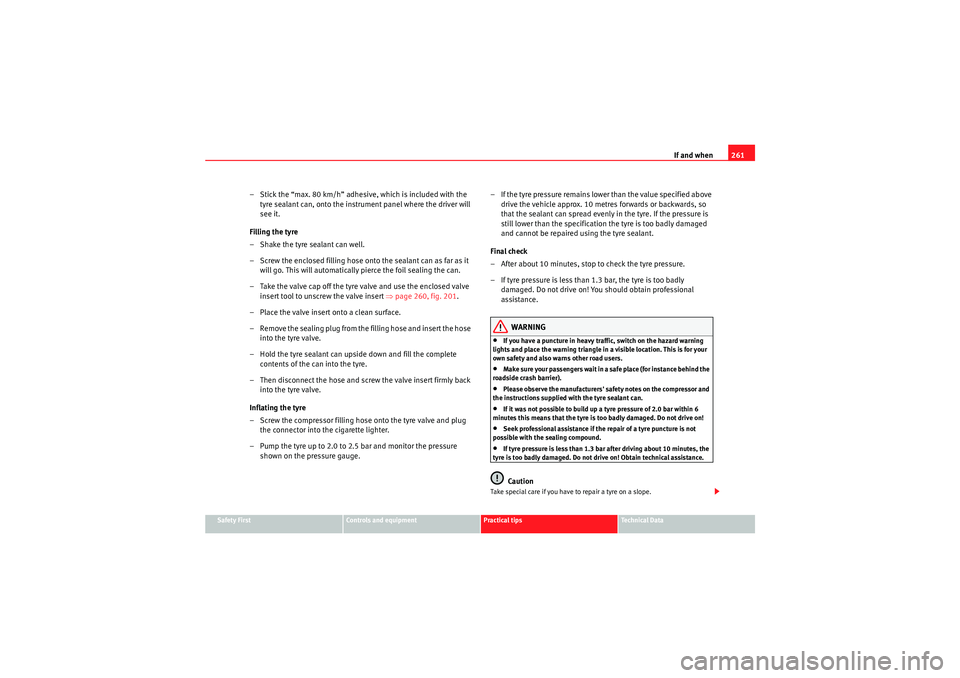

tive again.•Please observe legal requirements when doing so.FusesChanging fuses

If a fuse has blown, it must be replaced.

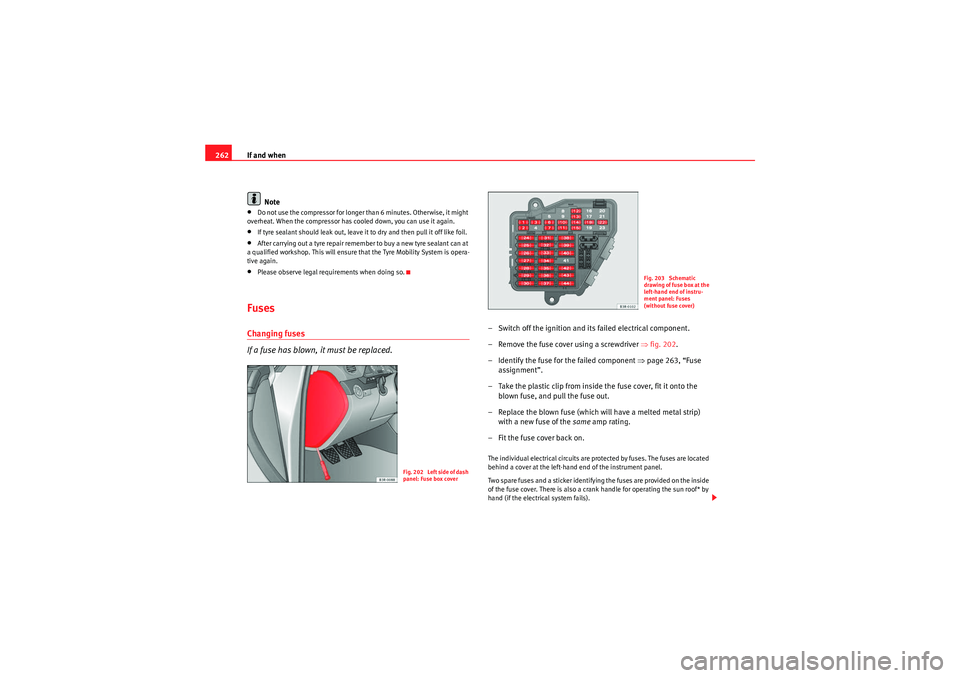

– Switch off the ignition and its failed electrical component.

– Remove the fuse cover using a screwdriver ⇒fig. 202 .

– Identify the fuse for the failed component ⇒ page 263, “Fuse

assignment”.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse, and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same amp rating.

–Fit the fuse cover back on.The individual electrical circuits are protected by fuses. The fuses are located

behind a cover at the left-hand end of the instrument panel.

Two spare fuses and a sticker identifying the fuses are provided on the inside

of the fuse cover. There is also a crank handle for operating the sun roof* by

hand (if the electrical system fails).

Fig. 202 Left side of dash

panel: Fuse box cover

Fig. 203 Schematic

drawing of fuse box at the

left-hand end of instru-

ment panel: Fuses

(without fuse cover)

ExeoST_EN.book Seite 262 Donnerstag, 3. September 2009 12:24 12

Page 265 of 316

If and when263

Safety First

Controls and equipment

Practical tips

Technical Data

Caution

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. It could also cause

damage to other parts of the electrical system.

Note

If a newly replaced fuse blows again after a short time, the electrical system

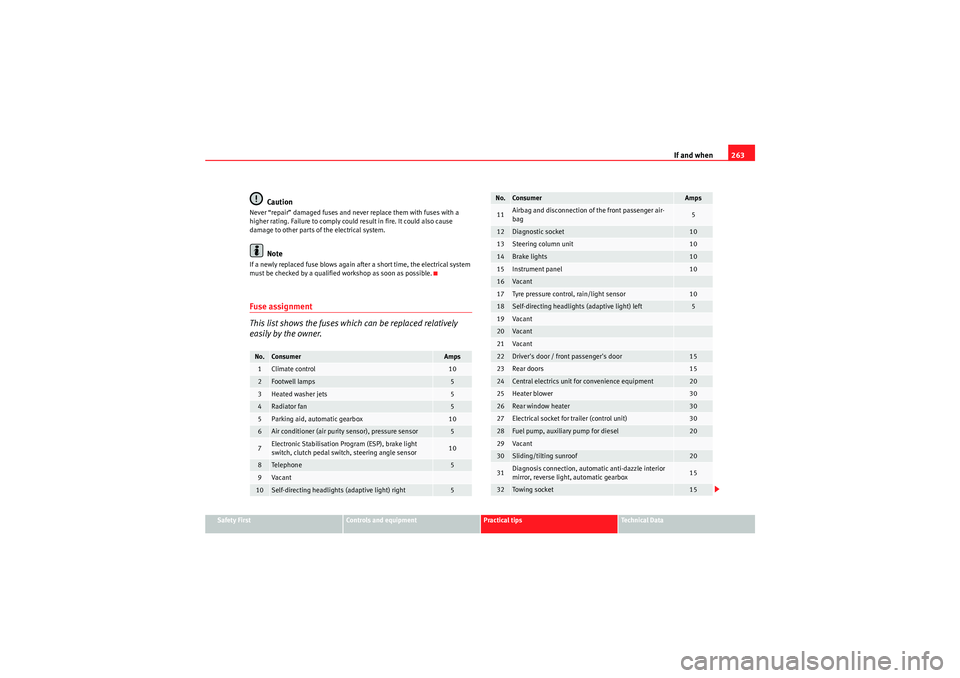

must be checked by a qualified workshop as soon as possible.Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.No.

Consumer

Amps

1

Climate control

10

2

Footwell lamps

5

3

Heated washer jets

5

4

Radiator fan

5

5

Parking aid, automatic gearbox

10

6

Air conditioner (air purity sensor), pressure sensor

5

7

Electronic Stabilisation Program (ESP), brake light

switch, clutch pedal switch, steering angle sensor

10

8

Te le p hon e

5

9

Va can t

10

Self-directing headlights (adaptive light) right

5

11

Airbag and disconnection of the front passenger air-

bag

5

12

Diagnostic socket

10

13

Steering column unit

10

14

Brake lights

10

15

Instrument panel

10

16

Va can t

17

Tyre pressure control, rain/light sensor

10

18

Self-directing headlights (adaptive light) left

5

19

Va can t

20

Va can t

21

Va can t

22

Driver's door / front passenger's door

15

23

Rear doors

15

24

Central electrics unit for convenience equipment

20

25

Heater blower

30

26

Rear window heater

30

27

Electrical socket for trailer (control unit)

30

28

Fuel pump, auxiliary pump for diesel

20

29

Va can t

30

Sliding/tilting sunroof

20

31

Diagnosis connection, automatic anti-dazzle interior

mirror, reverse light, automatic gearbox

15

32

Towi ng s ocke t

15

No.

Consumer

Amps

ExeoST_EN.book Seite 263 Donnerstag, 3. September 2009 12:24 12

Page 266 of 316

If and when

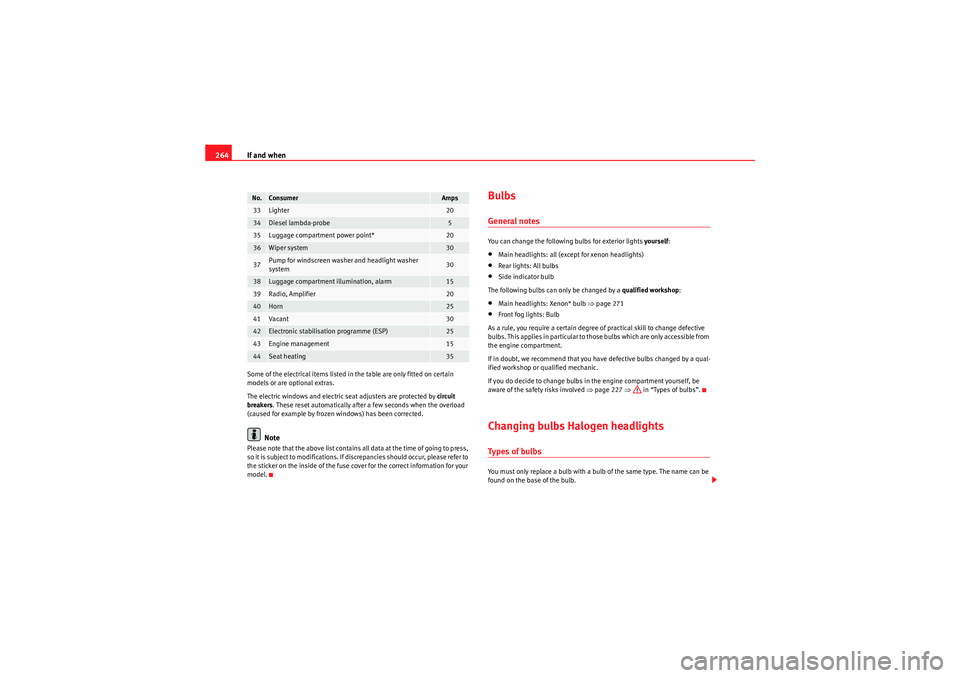

264Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

The electric windows and electric seat adjusters are protected by circuit

breakers . These reset automatically after a few seconds when the overload

(caused for example by frozen windows) has been corrected.

Note

Please note that the above list contains all data at the time of going to press,

so it is subject to modifications. If discrepancies should occur, please refer to

the sticker on the inside of the fuse cover for the correct information for your

model.

BulbsGeneral notesYou can change the following bulbs for exterior lights yourself:•Main headlights: all (except for xenon headlights)•Rear lights: All bulbs•Side indicator bulb

The following bulbs can only be changed by a qualified workshop:•Main headlights: Xenon* bulb ⇒page 271•Front fog lights: Bulb

As a rule, you require a certain degree of practical skill to change defective

bulbs. This applies in particular to those bulbs which are only accessible from

the engine compartment.

If in doubt, we recommend that you have defective bulbs changed by a qual-

ified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment yourself, be

aware of the safety risks involved ⇒page 227 ⇒ in “Types of bulbs”.Changing bulbs Halogen headlightsTypes of bulbsYou must only replace a bulb with a bulb of the same type. The name can be

found on the base of the bulb.

33

Lighter

20

34

Diesel lambda-probe

5

35

Luggage compartment power point*

20

36

Wiper system

30

37

Pump for windscreen washer and headlight washer

system

30

38

Luggage compartment illumination, alarm

15

39

Radio, Amplifier

20

40

Horn

25

41

Va can t

30

42

Electronic stabilisation programme (ESP)

25

43

Engine management

15

44

Seat heating

35

No.

Consumer

Amps

ExeoST_EN.book Seite 264 Donnerstag, 3. September 2009 12:24 12

Page 267 of 316

If and when265

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

•Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!•Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.•The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.•When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•Remove the ignition key before working on the electric system. If not, a

short circuit could occur.•Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicators may be temporarily misted. This does not affect the useful life of the lighting system. By switching on the lights, the

area through which the beam of light is projected will quickly be demisted.

However, the edges may continue to be misted.

•Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.•Before changing a bulb, make sure you have the correct new bulb.•Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will

vaporise as a result of the heat generated by the bulb, be deposited on the

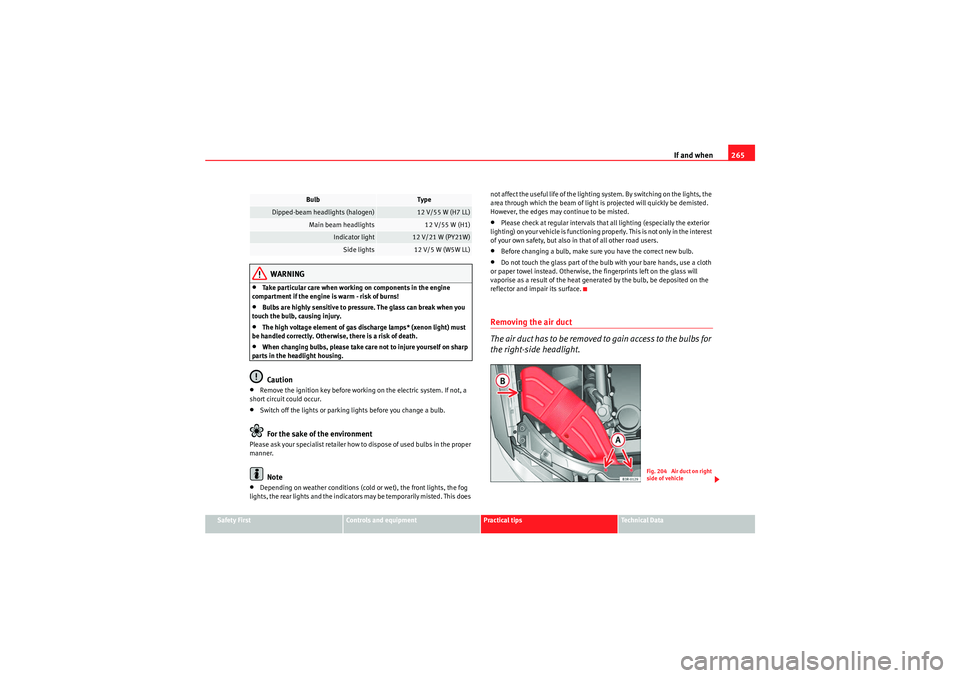

reflector and impair its surface.Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.

Bulb

Type

Dipped-beam headlights (halogen)

12 V/55 W (H7 LL)

Main beam headlights

12 V/55 W (H1)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W LL)

Fig. 204 Air duct on right

side of vehicle

ExeoST_EN.book Seite 265 Donnerstag, 3. September 2009 12:24 12

Page 268 of 316

If and when

266

–Unscrew bolts ⇒page 265, fig. 204 .

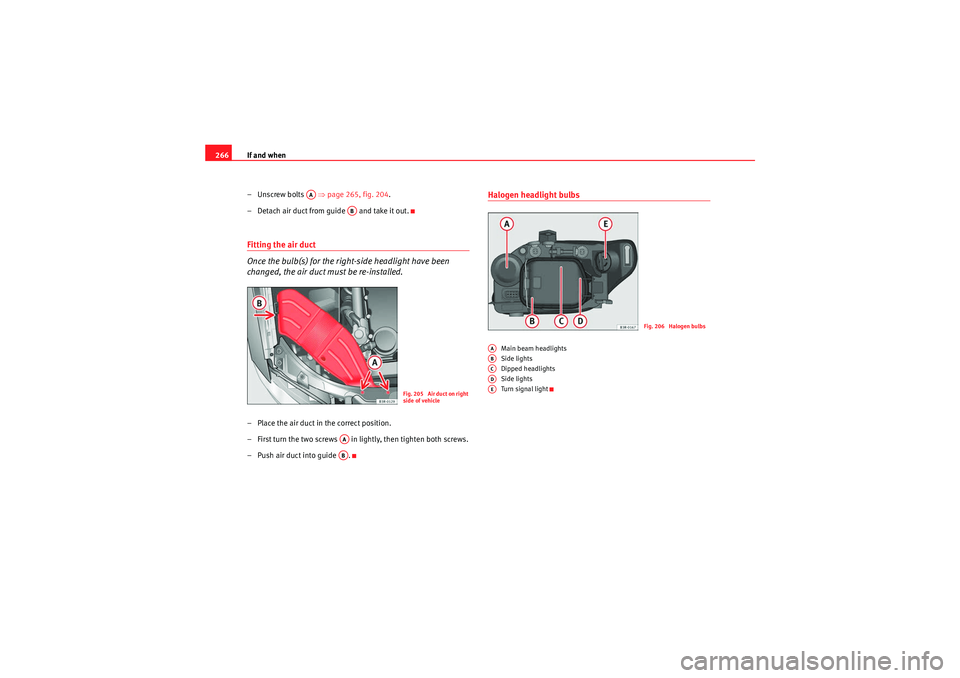

– Detach air duct from guide and take it out.Fitting the air duct

Once the bulb(s) for the right-side headlight have been

changed, the air duct must be re-installed.– Place the air duct in the correct position.

– First turn the two screws in lightly, then tighten both screws.

– Push air duct into guide .

Halogen headlight bulbs

Main beam headlights

Side lights

Dipped headlights

Side lights

Turn signal light

AA

AB

Fig. 205 Air duct on right

side of vehicle

AAAB

Fig. 206 Halogen bulbs

AAABACADAE

ExeoST_EN.book Seite 266 Donnerstag, 3. September 2009 12:24 12

Page 269 of 316

If and when267

Safety First

Controls and equipment

Practical tips

Technical Data

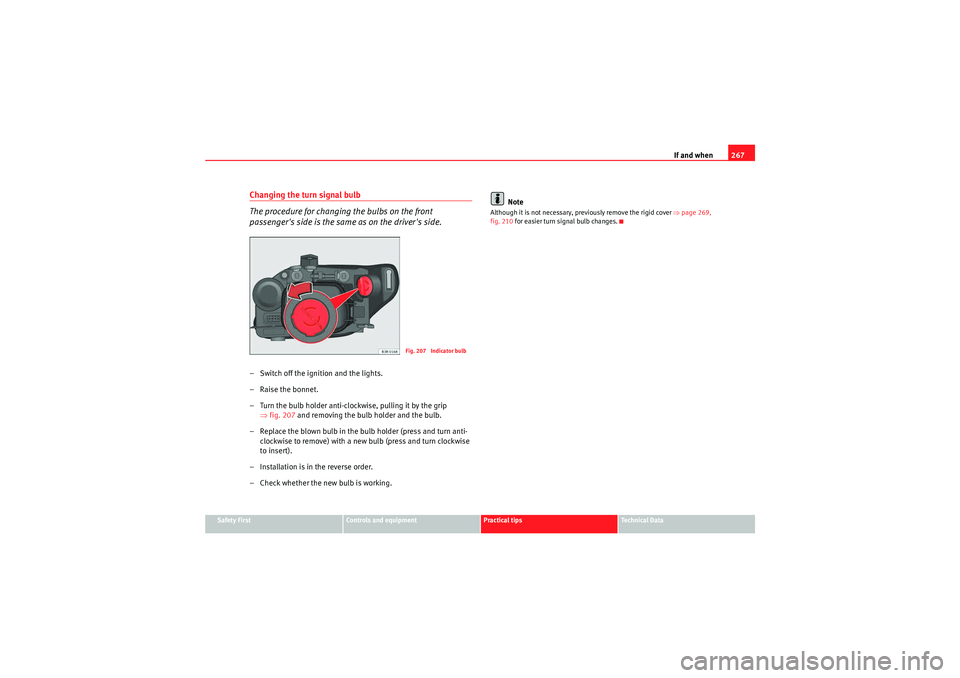

Changing the turn signal bulb

The procedure for changing the bulbs on the front

passenger's side is the same as on the driver's side.– Switch off the ignition and the lights.

– Raise the bonnet.

– Turn the bulb holder anti-clockwise, pulling it by the grip

⇒fig. 207 and removing the bulb holder and the bulb.

– Replace the blown bulb in the bulb holder (press and turn anti- clockwise to remove) with a new bulb (press and turn clockwise

to insert).

– Installation is in the reverse order.

– Check whether the new bulb is working. Note

Although it is not necessary, previously remove the rigid cover

⇒page 269,

fig. 210 for easier turn signal bulb changes.

Fig. 207 Indicator bulb

ExeoST_EN.book Seite 267 Donnerstag, 3. September 2009 12:24 12

Page 270 of 316

If and when

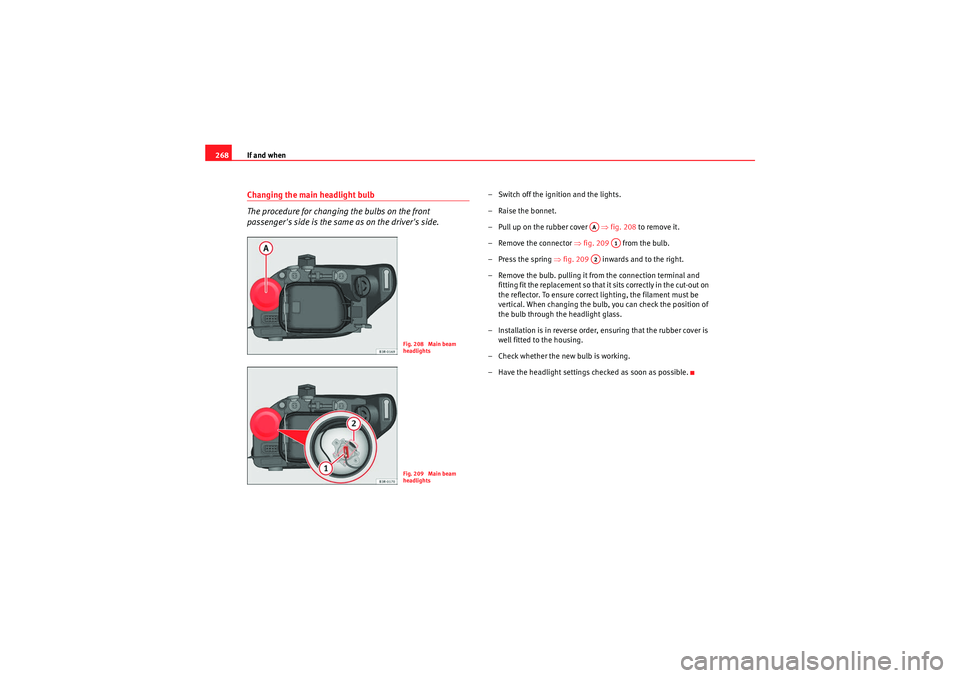

268Changing the main headlight bulb

The procedure for changing the bulbs on the front

passenger's side is the same as on the driver's side.

– Switch off the ignition and the lights.

– Raise the bonnet.

– Pull up on the rubber cover ⇒fig. 208 to remove it.

– Remove the connector ⇒fig. 209 from the bulb.

–Press the spring ⇒fig. 209 inwards and to the right.

– Remove the bulb. pulling it from the connection terminal and fitting fit the replacement so that it sits correctly in the cut-out on

the reflector. To ensure correct lighting, the filament must be

vertical. When changing the bulb, you can check the position of

the bulb through the headlight glass.

– Installation is in reverse order, ensuring that the rubber cover is

well fitted to the housing.

– Check whether the new bulb is working.

– Have the headlight settings checked as soon as possible.

Fig. 208 Main beam

headlightsFig. 209 Main beam

headlights

AA

A1

A2

ExeoST_EN.book Seite 268 Donnerstag, 3. September 2009 12:24 12