wheel bolts Seat Exeo ST 2010 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Exeo ST, Model: Seat Exeo ST 2010Pages: 325, PDF Size: 9.34 MB

Page 254 of 325

Wheels and tyres

252

For the sake of the environmentOld tyres must be disposed of according to the laws in the country concerned.

Note

•For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.•If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒page 223.

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch. ⇒ The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.•Use only wheel bolts which belong to the wheel.•If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Caution

The prescribed tightening torque for wheel bolts for steel and alloy wheels is

120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicle's

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

ExeoST_EN.book Seite 252 Freitag, 3. September 2010 11:41 11

Page 255 of 325

Wheels and tyres253

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code

⇒page 251, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 251, “New tyres and wheels”.

WARNING

The maximum speed for the winter tyres must not be exceeded. Otherwise,

this could lead to tyre damage and risk of accident.

For the sake of the environment

Fit your summer tyres again as soon as possible. They are quieter, do not wear

so quickly and reduce fuel consumption.

Snow chainsSnow chains may be fitted only to the front wheels, and only to certain tyre

sizes ⇒page 300.

Remove wheel hub covers and trim rings before fitting snow chains. For safety

reasons cover caps, available in any Authorised Service Centre, must then be

fitted over the wheel bolts.

WARNING

Observe the fitting instructions provid ed by the snow chain manufacturer.

Caution

You must remove the snow chains to drive on roads which are free of snow.

Otherwise they will impair handling, damage the tyres and wear out very

quickly.

Note

•In some countries, the speed limit for using snow chains is 50 km/h. The

legal requirements of the country should be followed.•We recommend that you ask your Authorised Service Centre for informa-

tion about appropriate wheel, tyre and snow chain size.205/55 R16

15 mm chains

225/45 R17

9 mm chains

225/40 R18

7 mm chains

ExeoST_EN.book Seite 253 Freitag, 3. September 2010 11:41 11

Page 257 of 325

If and when255

Safety First

Operating Instructions

Practical Tips

Technical Specifications

•A hook for removing wheel covers* or hub caps•Box spanner for wheel bolts•A screwdriver with reversible blade•Towing eye•An adapter for the anti-theft wheel bolts*

Before replacing the jack in the storage bin, wind down the arm of the jack as

far as it will go.

Some of the tools listed are only provided in certain models or are optional

extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts, as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.•The factory-supplied jack is only designed for changing wheels on this

model. On no account attempt to use it for lifting heavier vehicles or other

loads. Risk of injury.•Never start the engine when the vehicl e is raised. Failure to do so could

result in an accident.•I f w o r k is t o b e ca r r ie d o u t un d e r n ea t h t h e v e h ic l e , t h is m u s t be s e cu re d

by suitable stands. Otherwise, there is a risk of injury.

Tyre mobility system

The tyre mobility system is stored under the floor panel in the

luggage compartment.– Take hold of the handle and fold back the floor panel in the luggage compartment.

– Take out the tyre mobility system.Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are

included with the sealant can.

Fig. 191 Tyre Mobility

System under floor panel

in luggage compartment

ExeoST_EN.book Seite 255 Freitag, 3. September 2010 11:41 11

Page 259 of 325

If and when257

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Changing a wheelPreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

–All passengers should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

–Apply the handbrake firmly.

– Engage 1st gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 254 out of the

luggage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning lights

and place the warning triangle in a visible location. This is for your own

safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheel

Change the wheel as described below.– Remove the wheel cover.

–Loosen the wheel bolts ⇒page 258.

– Raise the vehicle with the jack ⇒page 259.

– Ta k e o f f the wheel with the flat tyre and then put on the spare

wheel ⇒page 260.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner ⇒page 258.

– Replace the cover.After changing a wheel

After changing the wheel, there are still tasks to complete.– Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment.

ExeoST_EN.book Seite 257 Freitag, 3. September 2010 11:41 11

Page 260 of 325

If and when

258

–The inflation pressure of the newly fitted spare tyre must be

checked as soon as possible.

–Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. It must be 120 Nm (always

when cold)

–Have the flat tyre replaced as quickly as possible.

Note•If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening torque

checked.•For your safety, drive at moderate speeds until the wheel bolt tightening

torque has been checked.

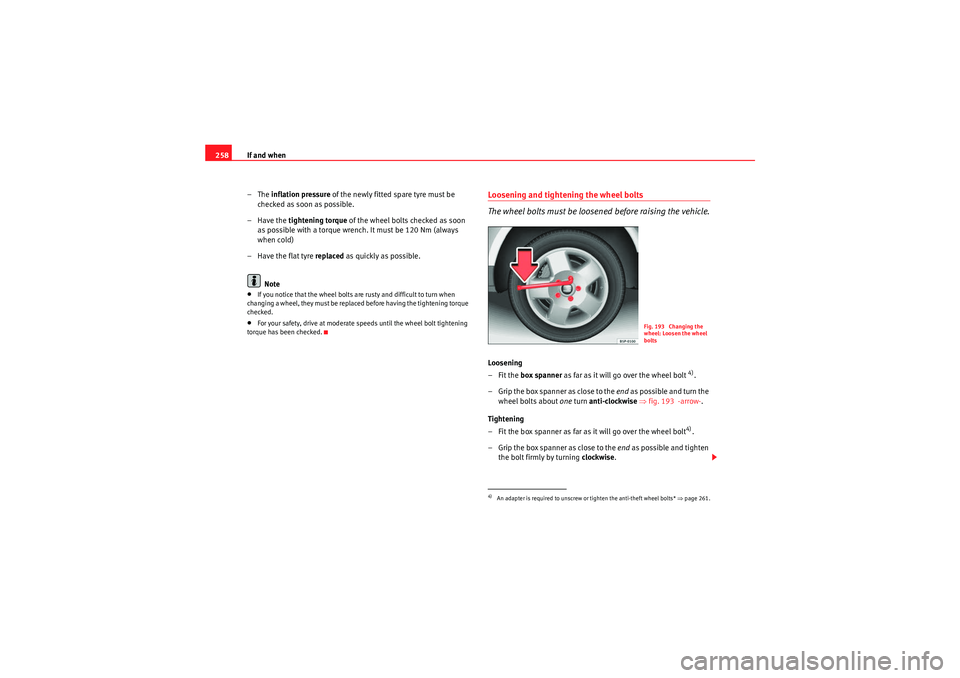

Loosening and tightening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt

4).

– Grip the box spanner as close to the end as po ssible an d turn t he

wheel bolts about one turn anti-clockwise ⇒ fig. 193 -arrow- .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt4).

– Grip the box spanner as close to the end as possible and tighten

the bolt firmly by turning clockwise.

4)An adapter is required to unscrew or tighten the anti-theft wheel bolts* ⇒page 261.

Fig. 193 Changing the

wheel: Loosen the wheel

bolts

ExeoST_EN.book Seite 258 Freitag, 3. September 2010 11:41 11

Page 261 of 325

If and when259

Safety First

Operating Instructions

Practical Tips

Technical Specifications

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack. Failure to do so could result in an accident.

Note

•Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.•If the wheel bolt does not come loose, it may be possible to release it by

pushing down the end of the spanner carefully with your foot. Hold on to the

vehicle for support and take care not to slip.Raising the vehicle

In order to remove the wheel, the vehicle must be raised with

a jack.

– Position the vehicle jack under the door sill at the jacking point

closest to the wheel being changed ⇒fig. 194 -arrows- .

–Wind up the jack under the jacking point until the claw of the jack

is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits on the rib under the door sill ⇒fig. 195 and the movable base plate of the jack

is flat on the ground.

– Raise the vehicle until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒fig. 194 -arrows- . There is only one jacking point for each wheel. Do not fit

the jack anywhere else.

The distance from the jacking points to the wheel arches is approximately 15

cm at the front and 25 cm at the rear.

Fig. 194 Changing the

wheel: Jack position

points

Fig. 195 Changing the

wheel: Jack

AA

AB

ExeoST_EN.book Seite 259 Freitag, 3. September 2010 11:41 11

Page 262 of 325

If and when

260An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

a large, stable base if necessary. On a hard, slippery surface (such as tiles)

use a rubber mat or similar to prevent the jack from slipping.

WARNING

•Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.•The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.

After loosening the wheel bolts and raising the vehicle with the jack,

change the wheel as described below:

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 196 .

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts. The reversible screwdriver blade should be removed when the

tool is used for this purpose.

If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 196 Changing the

wheel: Hexagonal socket

in screwdriver handle to

turn the wheel bolts

ExeoST_EN.book Seite 260 Freitag, 3. September 2010 11:41 11

Page 263 of 325

If and when261

Safety First

Operating Instructions

Practical Tips

Technical Specifications

Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 197.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Code

The code number of the anti-theft wheel bolt is stamped onto the front part of

the adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that they

rotate in the correct direction.A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely carefully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.

Fig. 197 Anti-theft wheel

bolt

ExeoST_EN.book Seite 261 Freitag, 3. September 2010 11:41 11

Page 302 of 325

Description of specifications

300If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), at least 4% of the actual trailer weight is a

legal stipulation for a drawbar load.

WARNING

•For safet y reas ons , d o not excee d the 8 0 k m/h limit . Th is is als o valid in

countries where higher speeds are permitted.•Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced. ⇒

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low, there

is an increased danger of accidents, particularly at high speeds.•If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

ExeoST_EN.book Seite 300 Freitag, 3. September 2010 11:41 11

Page 322 of 325

Index

320Sliding/tilting sunroof . . . . . . . . . . . . . . . . . . . 112

Automatic close function . . . . . . . . . . . . . . 113

Closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Emergency activation . . . . . . . . . . . . . . . . . 114

Manual operation . . . . . . . . . . . . . . . . . . . . 114

Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Snow chains . . . . . . . . . . . . . . . . . . . . . . . 253, 300

Solar sunroof . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Solar-powered blower/sunroof . . . . . . . . . . . . 171

Spare keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Spare wheel Steel rim . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Speed warning . . . . . . . . . . . . . . . . . . . . . . . 81, 82

Speed warning function . . . . . . . . . . . . . . . . . . . 82

Speedometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Steam jets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Steering Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Manual steering wheel adjustment . . . . . . 172

Steering wheel controls . . . . . . . . . . . . . . . . . . . 91

Stopping the engine . . . . . . . . . . . . . . . . . . . . . 175

Sun visors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Switches in the driver door Electric windows . . . . . . . . . . . . . . . . . . . . . 110

Symbols Red symbols in central display . . . . . . . . . . 77

Yellow symbols in central display . . . . . . . . 79

TTailgateCentral locking system . . . . . . . . . . . . . . . . 103

Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

TCS How the system works . . . . . . . . . . . . . . . . 194

Technical modifications . . . . . . . . . . . . . . . . . . 223

The danger of not using the seat belt . . . . . . . . 20

The environment Heated rear window . . . . . . . . . . . . . . . . . . 127

Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Warming up the engine . . . . . . . . . . . . . . . 174

Tightening torque of wheel bolts . . . . . . . . . . . 300

tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . . 183, 189

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Tow starting General notes . . . . . . . . . . . . . . . . . . . . . . . 294

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203, 294 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 205

Notes on towing . . . . . . . . . . . . . . . . . 203, 204

Removable towing bracket . . . . . . . . . . . . . 206

Technical requirements . . . . . . . . . . . . . . . 203

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . 299

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . 212

Towing eye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Towing eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

Traction control system How the system works . . . . . . . . . . . . . . . . 194

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . 299 Trip recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Turn signal lamps

Hazard warning lights . . . . . . . . . . . . . . . . . . 68

Trailer turn signals . . . . . . . . . . . . . . . . . . . . 67

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Tyre Mobility System . . . . . . . . . . . . . . . . . . . . . 262

Tyre mobility system . . . . . . . . . . . . . . . . . . . . . 255

Tyre pressure . . . . . . . . . . . . . . . . . . . . . 66, 90, 245 Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 246

Tyre pressure monitoring system . . . . . . . . . . . . 89

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Tyre repair kit Tyre Mobility System . . . . . . . . . . . . . . . . . . 262

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 251

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 248

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 249

Tyres with directional tread pattern . . . . . . . . . 245

UUnderbody protection . . . . . . . . . . . . . . . . . . . . 219VVehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 298

Vehicle identification data . . . . . . . . . . . . . . . . 298

Vehicle identification number . . . . . . . . . . . . . 298

Vehicle keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

ExeoST_EN.book Seite 320 Freitag, 3. September 2010 11:41 11