technical specifications Seat Exeo ST 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Exeo ST, Model: Seat Exeo ST 2011Pages: 319, PDF Size: 5.12 MB

Page 281 of 319

279

If and when

– Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Check that all four retaining tabs ⇒ fig. 225 -arrows- have en-

gaged.

– Re-install the tail light unit ⇒ page 279.

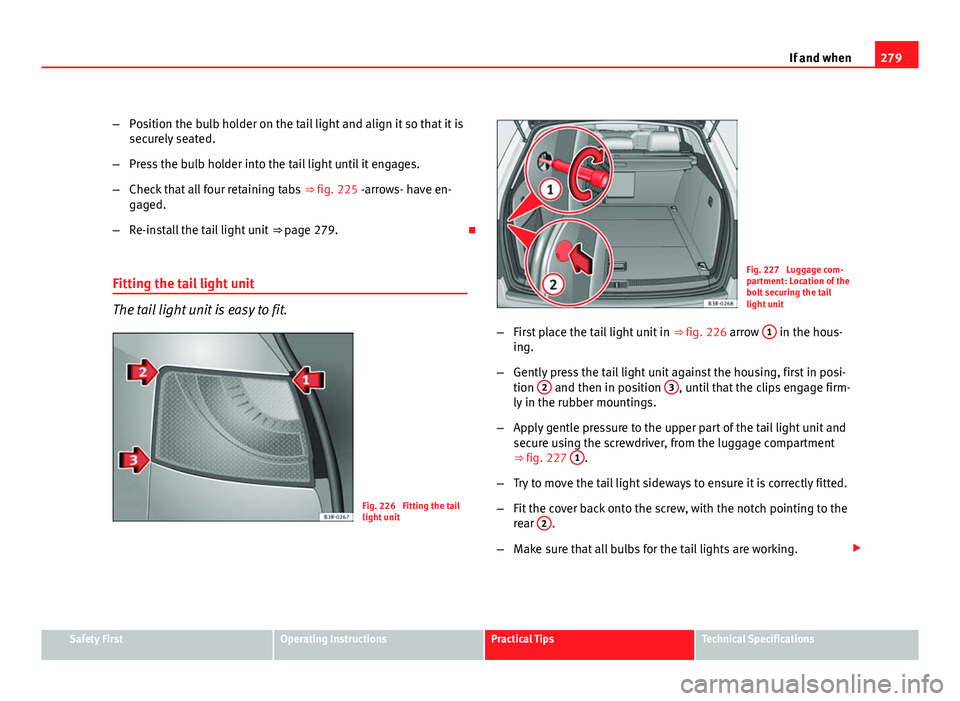

Fitting the tail light unit

The tail light unit is easy to fit.

Fig. 226 Fitting the tail

light unit

Fig. 227 Luggage com-

partment: Location of the

bolt securing the tail

light unit

– First place the tail light unit in ⇒ fig. 226 arrow 1

in the hous-

ing.

– Gently press the tail light unit against the housing, first in posi-

tion 2

and then in position 3, until that the clips engage firm-

ly in the rubber mountings.

– Apply gentle pressure to the upper part of the tail light unit and

secure using the screwdriver, from the luggage compartment

⇒ fig. 227 1

.

– Try to move the tail light sideways to ensure it is correctly fitted.

– Fit the cover back onto the screw, with the notch pointing to the

rear 2

.

– Make sure that all bulbs for the tail lights are working.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 283 of 319

281

If and when

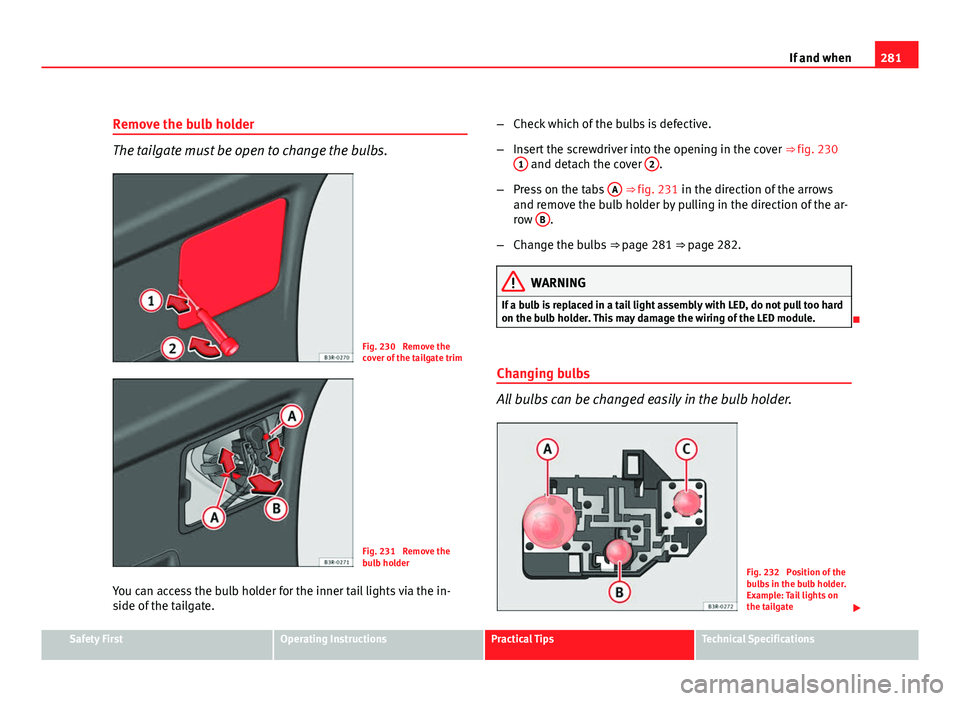

Remove the bulb holder

The tailgate must be open to change the bulbs.

Fig. 230 Remove the

cover of the tailgate trim

Fig. 231 Remove the

bulb holder

You can access the bulb holder for the inner tail lights via the in-

side of the tailgate. –

Check which of the bulbs is defective.

– Insert the screwdriver into the opening in the cover ⇒ fig. 230

1

and detach the cover 2.

– Press on the tabs A

⇒ fig. 231 in the direction of the arrows

and remove the bulb holder by pulling in the direction of the ar-

row B

.

– Change the bulbs ⇒ page 281 ⇒ page 282.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 232 Position of the

bulbs in the bulb holder.

Example: Tail lights on

the tailgate

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 285 of 319

283

If and when

Position of the bulbs

Pos.

⇒ fig. 232Bulb function

AReverse lightsP21W LLBRear fog lightH21W

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Fit the cover back in the interior trim so that it engages.

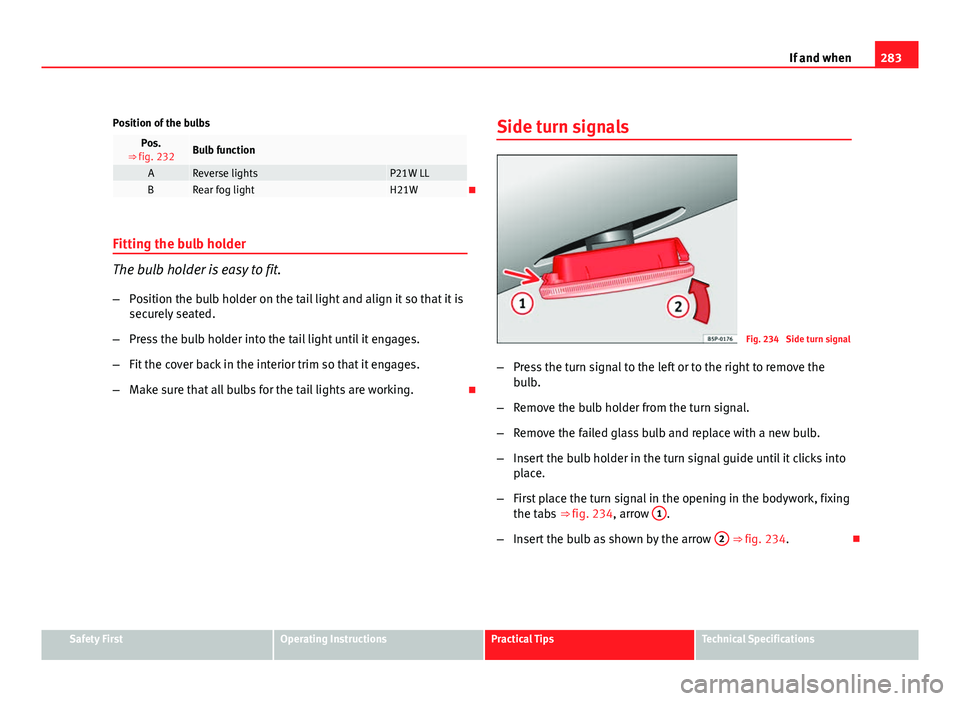

– Make sure that all bulbs for the tail lights are working. Side turn signals

Fig. 234 Side turn signal

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ fig. 234, arrow 1

.

– Insert the bulb as shown by the arrow 2

⇒ fig. 234.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 287 of 319

285

If and when

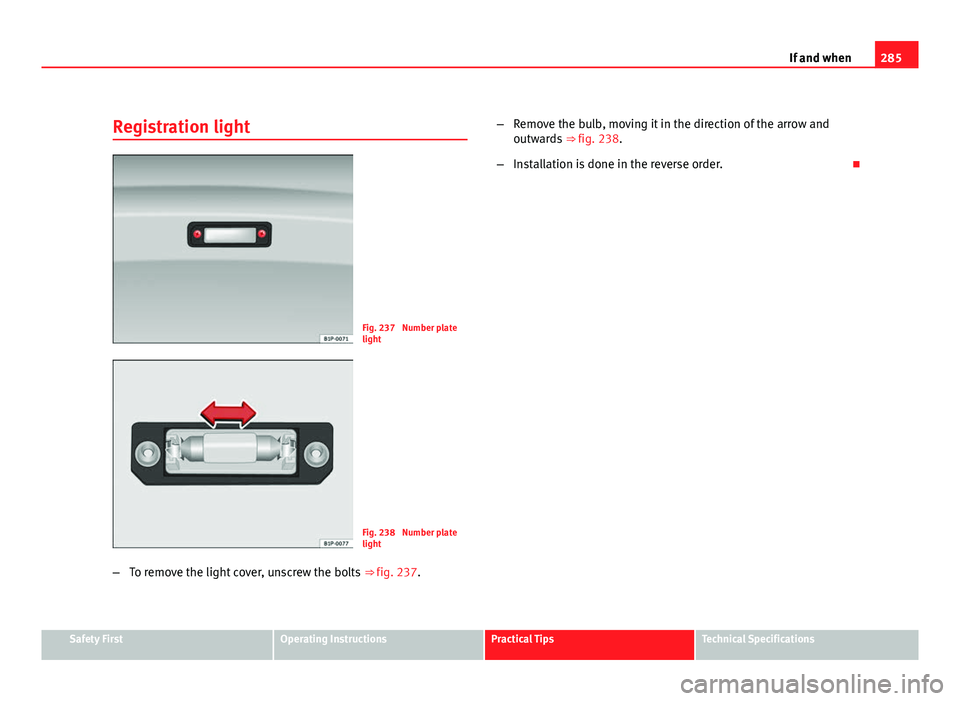

Registration light

Fig. 237 Number plate

light

Fig. 238 Number plate

light

– To remove the light cover, unscrew the bolts ⇒ fig. 237.–

Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 238.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 289 of 319

287

If and when

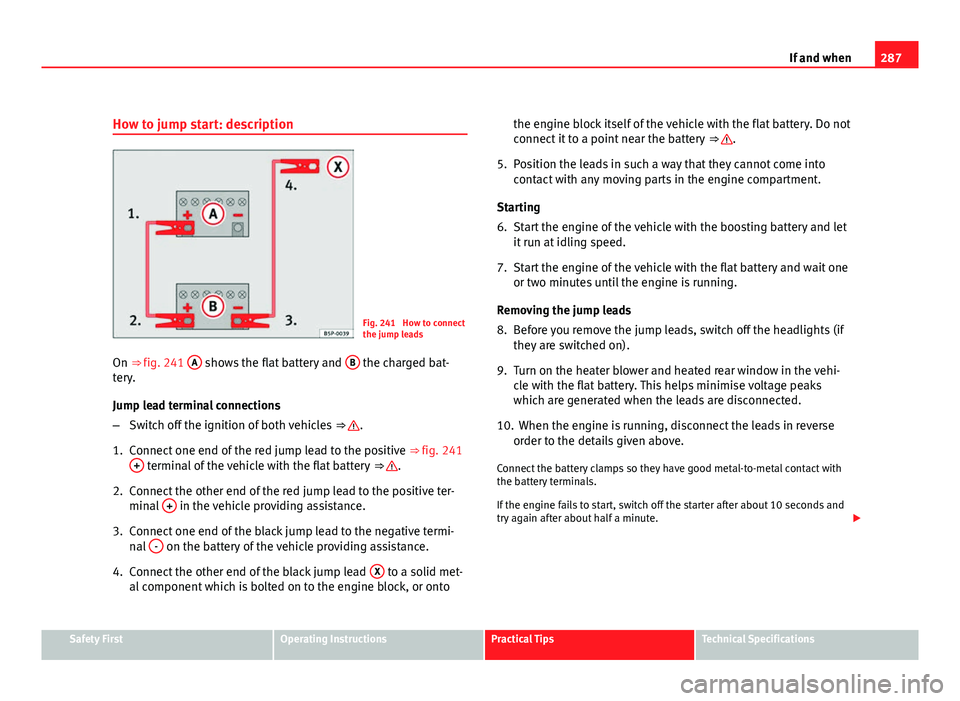

How to jump start: description

Fig. 241 How to connect

the jump leads

On ⇒ fig. 241 A

shows the flat battery and B the charged bat-

tery.

Jump lead terminal connections

– Switch off the ignition of both vehicles ⇒

.

1. Connect one end of the red jump lead to the positive ⇒ fig. 241

+

terminal of the vehicle with the flat battery ⇒ .

2. Connect the other end of the red jump lead to the positive ter- minal +

in the vehicle providing assistance.

3. Connect one end of the black jump lead to the negative termi- nal -

on the battery of the vehicle providing assistance.

4. Connect the other end of the black jump lead X

to a solid met-

al component which is bolted on to the engine block, or onto the engine block itself of the vehicle with the flat battery. Do not

connect it to a point near the battery

⇒

.

5. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

6. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

7. Start the engine of the vehicle with the flat battery and wait one or two minutes until the engine is running.

Removing the jump leads

8. Before you remove the jump leads, switch off the headlights (if they are switched on).

9. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

10. When the engine is running, disconnect the leads in reverse order to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 291 of 319

289

If and when

Towing and tow-starting

Tow-starting

The use of jump leads is preferable to tow-starting.

We recommend that you do not tow-start your vehicle. Jump-start-

ing is preferable ⇒ page 286.

However, if your vehicle has to be tow-started:

– Engage the 2nd or the 3rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the

gear lever into neutral. This helps to prevent driving into the

towing vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it. General notes

Please observe the following points if you use a tow-rope:

Notes for the driver of the towing vehicle

–

Drive slowly at first until the tow-rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto-

matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not

working in the vehicle you are towing. Brake sooner than nor-

mal and pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.

Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 293 of 319

291

If and when

Rear towing eye

There is a towing eye at the rear on the right below the rear bumper.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 294 of 319

292Description of specifications

Technical Specifications

Description of specifications

Important information

Important

The information in the vehicle documentation always has

precedence. All technical specifications provided in this manual are valid for the stand-

ard model in Spain. The vehicle data card included in the Maintenance Pro-

gramme or the vehicle registration documents shows which engine is instal-

led in the vehicle.

The figures may be different depending on if additional equipment is fitted,

for different models, for special vehicles and for other countries.

Abbreviations used in the Technical Specifications section

Abbrevia- tionMeaning

kWKilowatt, engine power measurement.

PSPferdestärke (horsepower), formerly used to denote engine

power.

rpmRevolutions per minute - engine speed.NmNewton metres, unit of engine torque.l/100 kmFuel consumption in litres per 100 km.g/kmCarbon dioxide emissions in grams per km travelled.CO2Carbon dioxide

Abbrevia-

tionMeaning

CNCetane number, indication of the diesel combustion power.

RONResearch octane number, indication of the knock resistance

of petrol.

Page 295 of 319

293

Description of specifications

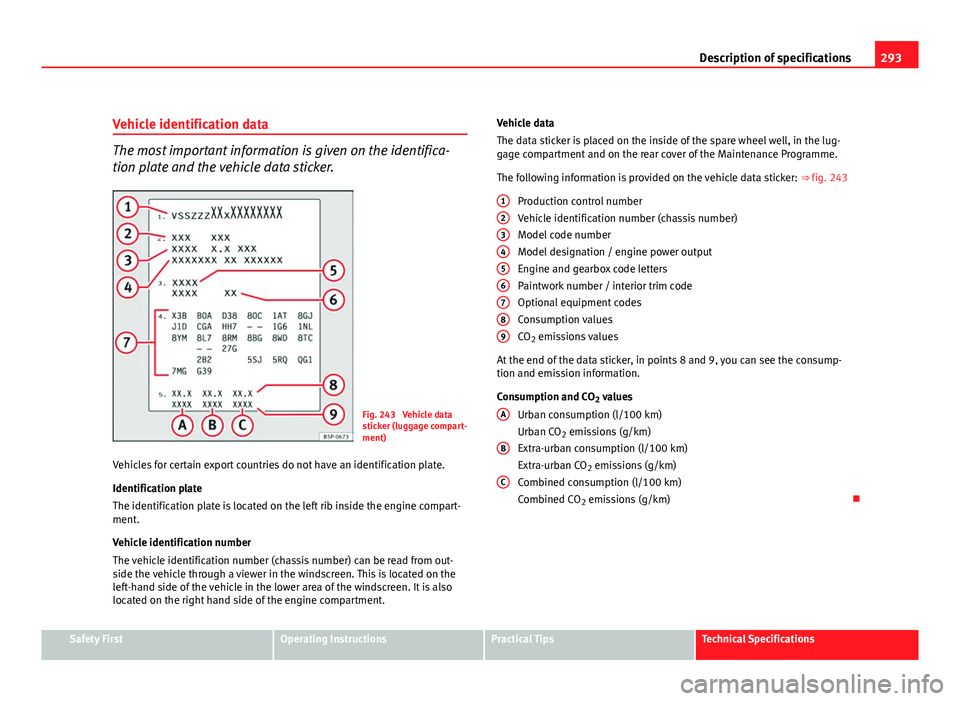

Vehicle identification data

The most important information is given on the identifica-

tion plate and the vehicle data sticker.

Fig. 243 Vehicle data

sticker (luggage compart-

ment)

Vehicles for certain export countries do not have an identification plate.

Identification plate

The identification plate is located on the left rib inside the engine compart-

ment.

Vehicle identification number

The vehicle identification number (chassis number) can be read from out-

side the vehicle through a viewer in the windscreen. This is located on the

left-hand side of the vehicle in the lower area of the windscreen. It is also

located on the right hand side of the engine compartment. Vehicle data

The data sticker is placed on the inside of the spare wheel well, in the lug-

gage compartment and on the rear cover of the Maintenance Programme.

The following information is provided on the vehicle data sticker:

⇒ fig. 243

Production control number

Vehicle identification number (chassis number)

Model code number

Model designation / engine power output

Engine and gearbox code letters

Paintwork number / interior trim code

Optional equipment codes

Consumption values

CO 2 emissions values

At the end of the data sticker, in points 8 and 9, you can see the consump-

tion and emission information.

Consumption and CO 2 values

Urban consumption (l/100 km)

Urban CO 2 emissions (g/km)

Extra-urban consumption (l/100 km)

Extra-urban CO 2 emissions (g/km)

Combined consumption (l/100 km)

Combined CO 2 emissions (g/km)

123456789

A

B

C

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 297 of 319

295

Description of specifications

Drawbar load

The maximum permitted drawbar load on the ball joint of the towing bracket

must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow approach-

ing the maximum drawbar load. The response of the trailer on the road will

be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar load.

WARNING

● For safety reasons, do not exceed the 80 km/h limit. This is also valid

in countries where higher speeds are permitted.

● Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Wheels

Tyre pressure, snow chains, wheel bolts

Tyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced. ⇒

Snow chains

Snow chains may be fitted only to the front wheels. Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the

tightening torque of the wheel

bolts should be checked as soon as possible with a torque wrench ⇒

.

The tightening torque for steel and alloy wheels is 120 Nm.

WARNING

● Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low,

there is an increased danger of accidents, particularly at high speeds.

● If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.

Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications