Seat Ibiza 2020 Directive 2014/53/EU Bluetooth

Manufacturer: SEAT, Model Year: 2020, Model line: Ibiza, Model: Seat Ibiza 2020Pages: 406, PDF Size: 9.22 MB

Page 21 of 406

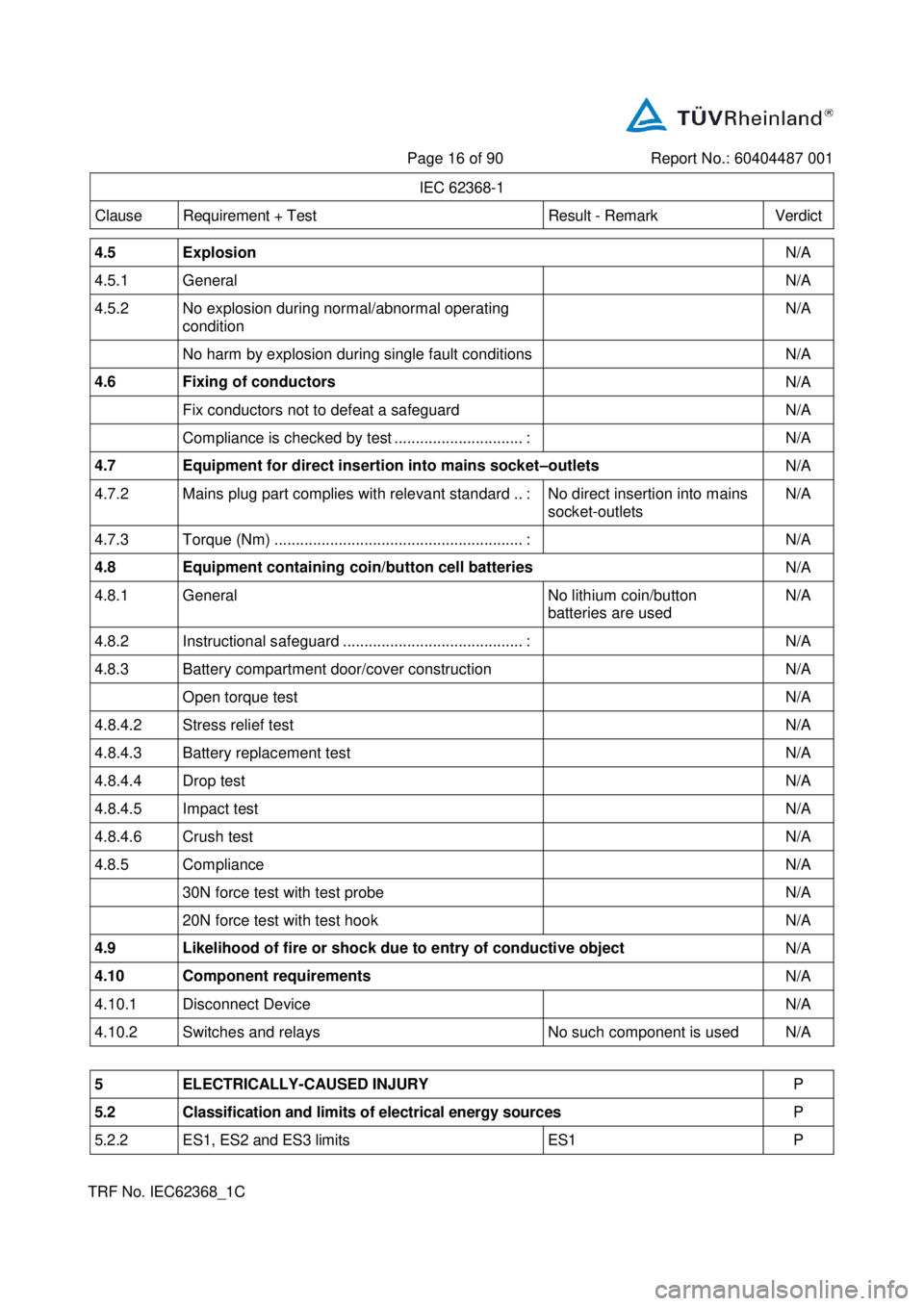

Page 16 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

4.5 Explosion

N/A

4.5.1 General N/A

4.5.2 No explosion during normal/abnormal operating

condition N/A

No harm by explosion during single fault conditions N/A

4.6 Fixing of conductors

N/A

Fix conductors not to defeat a safeguard N/A

Compliance is checked by test .............................. : N/A

4.7 Equipment for direct insertion into mains socket – outlets

N/A

4.7.2 Mains plug part complies with relevant standard .. : No direct insertion into m ains

socket - outlets N/A

4.7.3 Torque (Nm) ................................ .......................... : N/A

4.8 Equipment containing coin/button cell batteries

N/A

4.8.1 General No lithium coin/button

batteries are used N/A

4.8.2 Instructional safeguard ................................ .......... : N/A

4.8.3 Battery compartment door/cover construction N/A

Open torque test N/A

4.8.4.2 Stress relief test N/A

4.8.4.3 Battery replacement test N/A

4.8.4.4 Drop test N/A

4.8.4.5 Impact test N/A

4.8.4.6 Crush test N/A

4.8.5 Compliance N/A

30N force test with test probe N/A

20N force test w ith test hook N/A

4.9 Likelihood of fire or shock due to entry of conductive object

N/A

4.10 Component requirements

N/A

4.10.1 Disconnect Device N/A

4.10.2 Switches and relays No such component is used N/A

5 ELECTRICALLY - CAUSED INJURY

P

5.2 Classi fication and limits of electrical energy sources

P

5.2.2 ES1, ES2 and ES3 limits ES1 P

Page 22 of 406

Page 17 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.2.2.2 Steady - state voltage and current limits .................... : (See appended table 5.2) P

5.2.2.3 Capacitance limits ................................ ..................... : N/A

5.2.2.4 Single pulse limits ................................ ..................... : No such single pulse wi th the

e quipment N/A

5.2.2.5 Limits for repetitive pulses ................................ ........ : No such repetitive pulses with

the e quipment N/A

5.2.2.6 Ringing signals No Ringing signals N/A

5.2.2.7 Audio signals P

5.3 Protection against electrical energy sources

N/A

5.3.1 General R equirements for accessible parts to

ordinary, instructed and skilled persons Only ES1 N/A

5.3.1 a) Accessible ES1/ES2 derived from ES2/ES3 circuits N/A

5.3.1 b) Skilled persons not unintentional contact ES3 bare

conductors N/A

5.3.2.1 Accessibility to electrical energy sources and

safeguards N/A

Accessibility to outdoor equipment bare parts N/A

5.3.2.2 Contact requirements N/A

Test with test probe from Annex V -

5.3.2.2 a) Air gap – electric strength test potential (V) ............. : N/A

5.3.2.2 b) Air gap – distance (mm) ................................ ........... : N/A

5.3.2.3 Compliance N/A

5.3.2.4 Terminals for connecting stripped wire N/A

5.4 Insulation materials and requirements

N/A

5.4.1.2 Properties of insulating material N/A

5.4.1.3 Material is non - hygroscopic N/A

5.4.1.4 M aximum operating temperature for insulating

materials ................................ ................................ .... : N/A

5.4.1.5 Pollution degrees ................................ ...................... : N/A

5.4.1.5.2 Test for pollution degree 1 environment and for an

insulating compound N/A

5.4.1.5.3 Thermal cycling test N/A

5.4.1.6 Insulation in transformers w ith varying dimensions N/A

5.4.1.7 Insulation in circuits generating starting pulses N/A

5.4.1.8 Determination of working voltage ............................. : N/A

Page 23 of 406

Page 18 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.1.9 Insulating surfaces N/A

5.4.1.10 Thermoplastic parts on which conductive metallic

parts are directly mou nted N/A

5.4.1.10.2 Vicat test ................................ ................................ .... : N/A

5.4.1.10.3 Ball pressure test ................................ ...................... : N/A

5.4.2 Clearances N/A

5.4.2.1 General requirements N/A

Clearances in circuits connected to AC Mains,

Alternative method N/A

5.4.2.2 Procedure 1 for determining clearance N/A

Temporary overvoltage ................................ ............ :

5.4.2.3 Procedure 2 for determining clearance N/A

5.4.2.3.2.2 a.c. mains transient voltage ................................ ...... :

5.4.2.3.2.3 d.c. mains transient voltage ................................ ..... :

5.4.2.3.2.4 External circuit transient voltage ............................... :

5.4.2.3.2.5 Transien t voltage determined by measurement ...... :

5.4.2.4 Determining the adequacy of a clearance using an

electric strength test ................................ ................. : N/A

5.4.2.5 Multiplication factors for clearances and test voltages

................................ ................................ ................... : N/A

5.4.2.6 Clearance measurement ................................ .......... : N/A

5.4.3 Creepage distances N/A

5.4.3.1 General N/A

5.4.3.3 Material group ................................ ........................... :

5.4.3.4 Creepage distances measurement .......................... : N/A

5.4.4 Solid insulation N/A

5.4.4.1 General requirements N/A

5.4.4.2 Minimum distance through insulation ...................... : N/A

5.4.4.3 Insulating comp ound forming solid insulation N/A

5.4.4.4 Solid insulation in semiconductor devices N/A

5.4.4.5 Insulating compound forming cemented joints N/A

5.4.4.6 Thin sheet material N/A

5.4.4.6.1 General requirements N/A

5.4.4.6.2 Separable thin sheet ma terial N/A

Page 24 of 406

Page 19 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Number of layers (pcs) ................................ ............ : N/A

5.4.4.6.3 Non - separable thin sheet material N/A

Number of layers (pcs) ................................ ......... : N/A

5.4.4.6.4 Standard test procedure for non - separable thin

sheet material ................................ ........................ : N/A

5.4.4.6.5 Mandrel test N/A

5.4.4.7 Solid i n sulation in wound components N/A

5.4.4.9 Solid insulation at frequencies >30 kHz, E

P , K

R , d ,

V

PW (V) ................................ ................................ ... : N/A

Alternative by electric strength test, tested voltage

(V), K

R ................................ ................................ .... : N/A

5.4.5 Antenna terminal insulation No a ntenna terminal N/A

5.4.5.1 General N/A

5.4.5.2 Voltage surge test N/A

5.4.5.3

Insulation resistance (M ) ................................ ..... : N/A

Electric strength test ................................ ................. : N/A

5.4.6 Insulation of internal wire as part of supplementary

safeguard N/A

5.4.7 Tests for semiconductor components and for

cemented joints N/A

5.4.8 Humidity conditioning N/A

Relative humidity (%), temperature (°C), duration

(h) ................................ ................................ .......... :

5.4.9 Electric strength test Class III equipment N/A

5.4.9.1 Test procedure for type test of solid insulation ....... : N/A

5.4.9.2 Test procedure for routine te st N/A

5.4.10 Safeguards against transient voltages from external

circuits N/A

5.4.10.1 Parts and circuits separated from external circuits N/A

5.4.10.2 Test methods N/A

5.4.10.2.1 General N/A

5.4.10.2.2 Impulse test ................................ ........................... : N/A

5.4.10.2.3 Steady - sta te test ................................ .................... : N/A

5.4.10.3 Verification for insulation breakdown for impulse

test ................................ ................................ ......... : N/A

5.4.11 Separation between external circuits and earth N/A

Page 25 of 406

Page 20 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.4.11.1 Exceptions to separation between external circuits

and earth N/A

5.4.11.2 Requirements N/A

SP Ds bridge separation between external circuit

and earth N/A

Rated operating voltage U

op (V) ............................. :

Nominal voltage U

peak (V) ................................ ....... :

Max increase due to variation U

sp ........................ :

Max increase due to ageing U

sa ......................... :

5.4.11.3 Test method and compliance ................................ : N/A

5.4.12 Insulating liquid N/A

5.4.12.1 General requirements N/A

5.4.12.2 Electric strength of an insulating liquid .................. : N/A

5.4.12.3 Compatibility of an insulating liquid ....................... : N/A

5.4.12.4 Container for insulating liquid ................................ : N/A

5.5 Components as saf eguards

N/A

5.5.1 General N/A

5.5.2 Capacitors and RC units No such component N/A

5.5.2.1 General requirement N/A

5.5.2.2 Safeguards against capacitor discharge after

disconnection of a connector ................................ . : N/A

5.5.3 Transformers No transformers N/A

5.5.4 Optocouplers No o ptocouplers N/A

5.5.5 Relays No Relays N/A

5.5.6 Resistors No Resistors N/A

5.5.7 SPDs No SPDs N/A

5.5.8 Insulation between the mains and an external

circuit consisting of a coaxial cable ....................... : N/A

5.5.9 Safeguards for socket - outlets in outdoor equipment N/A

RCD rated residual operating current (mA) ........... :

5.6 Protective conductor

N/A

5.6.2 Requirement for protective conductors N/A

5.6 Protective conductor

N/A

5.6.2 Requirement for protective conductors N/A

Page 26 of 406

Page 21 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.6.2.1 General require ments N/A

5.6.2.2 Colour of insulation N/A

5.6.3 Requirement for protective earthing conductors N/A

Protective earthing conductor size (mm 2

) .............. :

Protective earthing conductor serving as a

reinforced safeguard N/A

Protective earthing conductor serving as a double

safeguard N/A

5.6.4 Requirements for protective bonding conductors N/A

5.6.4.1 Protective bonding conductors N/A

Protective bonding conductor size (mm 2

). .............. :

5.6.4.2 Protective current rating (A) ................................ .... : N/A

5.6.5 Terminals for pr otective conductors N/A

5.6.5.1 Terminal size for connecting protective earthing

conductors (mm) ................................ .................... : N/A

Terminal size for connecting protective bonding

conductors (mm) ................................ ....................... : N/A

5.6.5.2 Corrosion N/A

5.6.6 Resistance of the protective bonding system N /A

5.6.6.1 Requirements N/A

5.6.6.2 Test Method ................................ ........................... : N/A

5.6.6.3

R esistance ( ) or voltage drop .............................. : N/A

5.6.7 Reliable connection of a protective earthing

conductor N/A

5.6.8 Functional earthing N/A

Conductor size (mm 2

) ................................ ............. : N/A

Class II with functi onal earthing marking .............. : N/A

Appliance inlet cl & cr (mm) ................................ ... : N/A

5.7 Prospective touch voltage, touch current and protective conductor current

N/A

5.7.2 Measuring devices and networks N/A

5.7.2.1 Measurement of touch current N/A

5.7.2.2 Measurement of voltage N/A

5.7.3 Equipment set - up, supply connections and earth

connections N/A

5.7.4 Unearthed accessible parts ................................ ... : N/A

Page 27 of 406

Page 22 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

5.7.5 Earthed accessible conductive parts ..................... : N/A

5.7.6 Requirements when touch current exceeds ES2

limits N/A

Protective c onductor current (mA) ......................... : N/A

Instructional Safeguard ................................ .......... : N/A

5.7.7 Prospective touch voltage and touch current

associated with external circuits N/A

5.7.7.1 Touch current from coaxial cables N/A

5.7.7.2 Prospective touch voltage and touch current

ass ociated with paired conductor cables N/A

5.7.8 Summation of touch currents from external circuits N/A

a) Equipment connected to earthed external

circuits, current (mA) ................................ ............. : N/A

b) Equipment connected to unearthed external

circuits, current (mA) ................................ ............. : N/A

5.8 Backfeed safeguard in battery backed up supplies

N/ A

Mains terminal ES ................................ ..................... : No battery backed up supplies N/ A

Air gap (mm) ................................ .............................. : N/ A

6 ELECTRICALLY - CAUSED FIRE

P

6.2 Classification of PS and PIS

P

6.2.2 Power source circuit classifications .......................... : (See appended table 6.2.2) P

6.2.3 Classification of potential ignition sources P

6.2.3.1 Arcing PIS ................................ ................................ : Open circuit voltage does not

exceed 50 V N/A

6.2.3.2 Resistive PIS ................................ ............................ : (See appended table 6.2.3.2) P

6.3 Safeguards against fire under normal operatin g and abnormal operating

conditions P

6.3.1 No ignition and attainable temperature value less

than 90 % defined by ISO 871 or less than 300 C

for unknown materials ................................ ........... : No ignition and no such

temperature attained within

the equipment P

Combustible materi als outside fire enclosure .......... : Min. HB P

6.4 Safeguards against fire under single fault conditions

P

6.4.1 Safeguard method Control fire spread P

6.4.2 Reduction of the likelihood of ignition under single

fault conditions in PS1 circuits N/A

Page 28 of 406

Page 23 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

6.4.3 Redu ction of the likelihood of ignition under single

fault conditions in PS2 and PS3 circuits N/A

6.4.3.1 Supplementary safeguards N/A

6.4.3.2 Single Fault Conditions ................................ .......... : N/A

Special conditions for temperature limited by fuse N/A

6.4.4 Control of fire spread in PS1 circuits P

6.4.5 Control of fire spread in PS2 circuits P

6.4.5.2 Supplementary safeguards For conductor and devices are

mounted on printed board

made of Min. V - 1.

Other components in PS2 are

mounted on printed board

made of Min. V - 1 and PVC

wire used .

Not ignite during single fault

condition . P

6.4.6 Control of fire spread in PS3 circuits Provided Metallic enclosure P

6.4.7 Separation of combustible materials from a PIS P

6.4.7.2 Separation by distance N/A

6.4.7.3 Separation by a f ire barrier P

6.4.8 Fire enclosures and fire barriers P

6.4.8.2 Fire enclosure and fire barrier material properties P

6.4.8.2.1 Requirements for a fire barrier V - 0 class material or metal,

Printed board made of V - 0 P

6.4.8.2.2 Requirem ents for a fire enclosure Metallic enclosure provided P

6.4.8.3 Constructional requirements for a fire enclosure

and a fire barrier P

6.4.8.3.1 Fire enclosure and fire barrier openings P

6.4.8.3.2 Fire barrier dimensions P

6.4.8.3.3 Top openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings dimensions (mm) ................................ ... : N/A

6.4.8.3.4 Bottom openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Open ings dimensions (mm) ................................ ... : N/A

Flammability tests for the bottom of a fire enclosure N/A

Page 29 of 406

Page 24 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

Instructional Safeguard ................................ ............. : N/A

6.4.8.3.5 Side openings and properties E quipment for building - in ,

e valuation shall be considered

in the end product N/A

Openings di mensions (mm) ................................ ... : N/A

6.4.8.3.6 Integrity of a fire enclosure, condition met: a), b) or

c) ................................ ................................ ............ : Not such fire enclosure N/A

6.4.8.4 Separation of a PIS from a fire enclosure and a fire

barrier distance (mm) or flammability rating .......... : Not such fire enclosure P

6.4.9 Flammability of insulating liquid ............................... : N/A

6.5 Internal and external wiring

P

6.5.1 General requirements P

6.5.2 Requirements for interconnection to building wiring

................................ ................................ ............... : No such interconnection to

building wiring N/A

6.5.3 Internal wiring size (m m 2

) for socket - outlets .......... : N/A

6.6 Safeguards against fire due to the connection to additional equipment

P

7 INJURY CAUSED BY HAZARDOUS SUBSTANCES

N/A

7.2 Reduction of exposure to hazardous substances

N/A

7.3 Ozone exposure

N/A

7.4 Use of personal s afeguards or personal protective equipment (PPE)

N/A

Personal safeguards and instructions ................... :

7.5 Use of instructional safeguards and instructions

N/A

Instructional safeguard (ISO 7010) ........................ :

7.6 Batteries and their protection circuits

N/A

8 MECHA NICALLY - CAUSED INJURY

P

8.2 Mechanical energy source classifications

P

8.3 Safeguards against mechanical energy sources

P

8.4 Safeguards against parts with sharp edges and corners

P

8.4.1 Safeguards All edges and corners are

rounded or smoothed P

Ins tructional Safeguard ................................ ............. : MS1 N/A

8.4.2 Sharp edges or corners P

8.5 Safeguards against moving parts

N/A

Page 30 of 406

Page 25 of 90 Report No. : 60404487 001

IEC 62368 - 1

Clause Requirement + Test Result - Remark Verdict

TR F No. IEC62368_1 C

8.5.1 Fingers, jewellery, clothing, hair, etc., contact with

MS2 or MS3 parts N/A

MS2 or MS3 part required to be accessible for the

function of t he equipment N/A

Moving MS3 parts only accessible to skilled person N/A

8.5.2 Instructional safeguard ................................ .............. : N/A

8.5.4 Special categories of equipment containing moving

parts N/A

8.5.4.1 General N/A

8.5.4.2 Equipment containing work cells with MS3 p arts N/A

8.5.4.2.1 Protection of persons in the work cell N/A

8.5.4.2.2 Access protection override N/A

8.5.4.2.2.1 Override system

N/A

8.5.4.2.2.2 Visual indicator

N/A

8.5.4.2.3 Emergency stop system

N/A

Maximum stopping distance from the poin t of

activation (m) ................................ ............................. : N/A

Space between end point and nearest fixed

mechanical part (mm) ................................ ............... : N/A

8.5.4.2.4 Endurance requirements N/A

Mechanical system subjected to 100 000 cycles of

operation N/A

- Mechanical function check and visual inspection N/A

- Cable assembly ................................ ...................... : N/A

8.5.4.3 Equipment having electromechanical device for

destruction of media N/A

8.5.4.3.1 Equipment safeguards N/A

8.5.4.3.2 Instructional safeguards against moving parts ........ : N/A

8.5.4.3.3 Disconnection from the supply N/A

8.5.4.3.4 Cut type and test force (N) ................................ ........ : N/A

8.5.4.3.5 Compliance N/A

8.5.5 High pressure lamps No High pressure lamps N/A

Explosion test ................................ ............................ : N/A

8.5.5.3 Glass particles dimensions (mm) ............................. : N/A

8.6 Stability of equipment

N/A