Seat Ibiza 5D 2006 Owner's manual

Manufacturer: SEAT, Model Year: 2006, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2006Pages: 268, PDF Size: 8.14 MB

Page 201 of 268

If and when199

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

The vehicle may also carry:

Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver blade is reversible.

Jack. Before placing the jack in its housing, make sure it is fully retracted.

Then press the handle against the side of the jack.

Wire hook

Box spanner for wheel bolts

Towing eye

WARNING

•

The jack provided with the car is only used with this model. It should

never be used for heavier vehicles or other loads.

•

Never start the car when it is raised. Risk of accident!

•

When work is being carried out unde rneath the vehicle, it must be

secured using suitable frames.Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Compact temporary spare wheel*

If provided as part of the vehicle's equipment, the compact

temporary spare wheel is only intended for temporary use

over short distances.The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut. How to use the compact temporary spare wheel

Should you ever have a punctured tyre, the compact temporary spare wheel

is only intended for temporary use until you can reach a workshop. The

standard-size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the compact temporary

spare wheel. This spare wheel has been specially designed for your vehicle,

thus, it cannot be changed with the spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim.

Snow chains

For technical reasons, snow chains must not

be used on the compact tempo-

rary spare wheel.

If you should have a puncture on one of the front wheels when using snow

chains, fit the compact temporary spare in place of one of the rear wheels.

You can then attach the snow chains to the wheel taken from the rear and use

this wheel to replace the punctured front wheel.

WARNING

•

The tyre pressures must be checked and corrected as soon as possible.

•

Do not drive faster than 80 km/h. High er speeds can cause an accident.

•

Avoid heavy acceleration, hard braking and fast cornering, risk of acci-

dent.

•

Never use two or more compact spare tyres at the same time, risk of

accident.

•

No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

A1A2A3A4A5

ibiza_angles_0706_DEF Seite 199 Freitag, 1. September 2006 1:18 13

Page 202 of 268

If and when

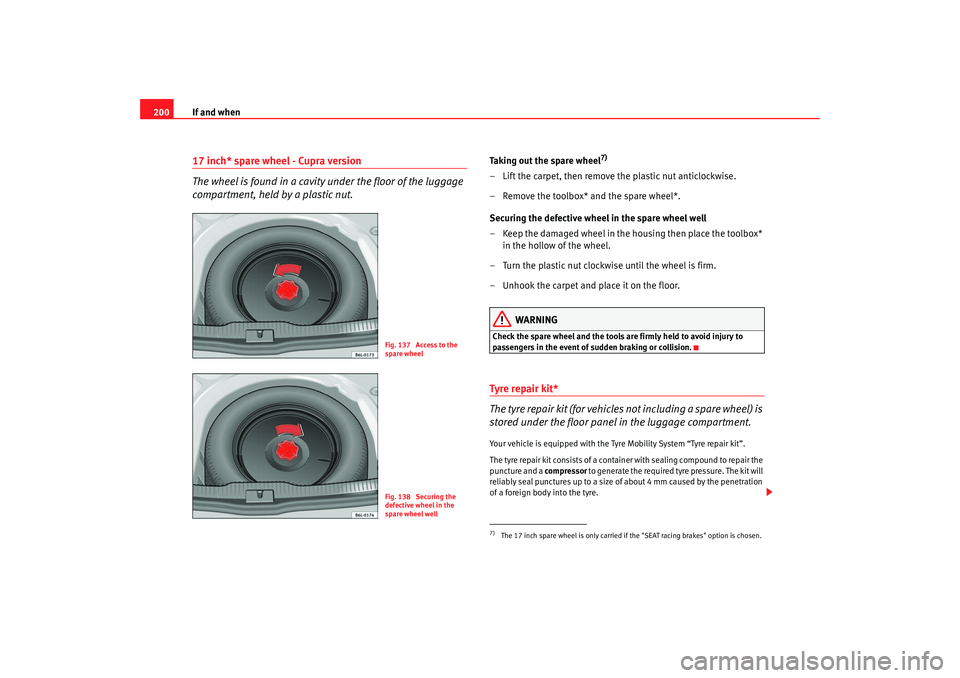

20017 inch* spare wheel - Cupra version

The wheel is found in a cavity under the floor of the luggage

compartment, held by a plastic nut.

Taking out the spare wheel

7)

– Lift the carpet, then remove the plastic nut anticlockwise.

– Remove the toolbox* and the spare wheel*.

Securing the defective wheel in the spare wheel well

– Keep the damaged wheel in the housing then place the toolbox*

in the hollow of the wheel.

– Turn the plastic nut clockwise until the wheel is firm.

– Unhook the carpet and place it on the floor.

WARNING

Check the spare wheel and the tools are firmly held to avoid injury to

passengers in the event of sudden braking or collision.Tyre repair ki t*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a container with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Fig. 137 Access to the

spare wheelFig. 138 Securing the

defective wheel in the

spare wheel well

7)The 17 inch spare wheel is only carried if the "SEAT racing brakes" option is chosen.

ibiza_angles_0706_DEF Seite 200 Freitag, 1. September 2006 1:18 13

Page 203 of 268

If and when201

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

–Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

–Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap see also ⇒page 202.

–Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly i n d i a go na l s e q u e n ce wi t h t h e b ox

spanner.

–Replace the hub cap.

ibiza_angles_0706_DEF Seite 201 Freitag, 1. September 2006 1:18 13

Page 204 of 268

If and when

202After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as

possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

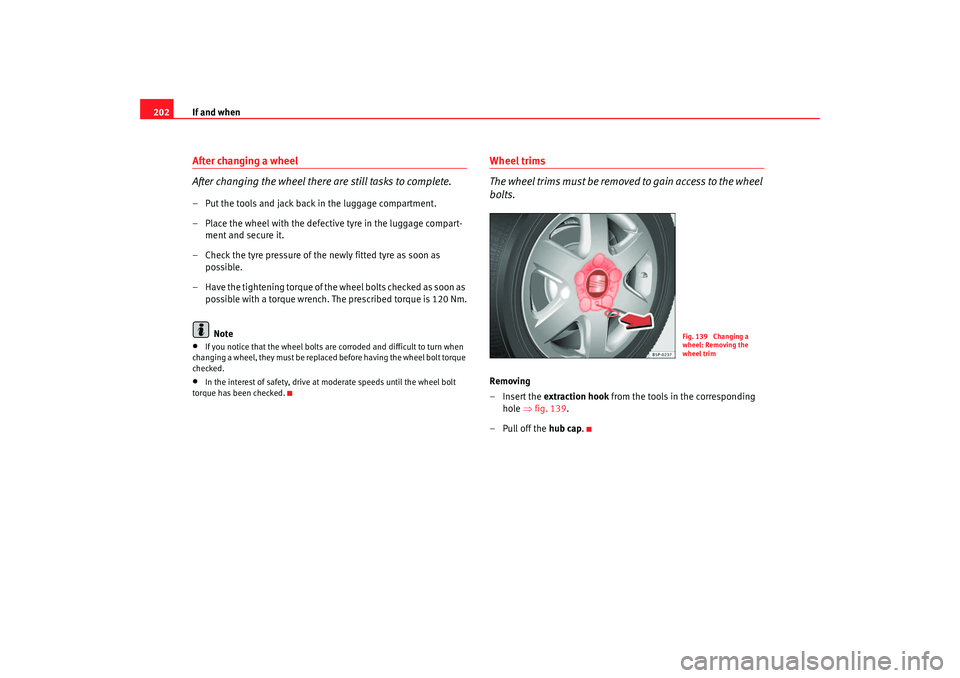

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

– Insert the extraction hook from the tools in the corresponding

hole ⇒fig. 139.

–Pull off the hub cap.

Fig. 139 Changing a

wheel: Removing the

wheel trim

ibiza_angles_0706_DEF Seite 202 Freitag, 1. September 2006 1:18 13

Page 205 of 268

If and when203

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

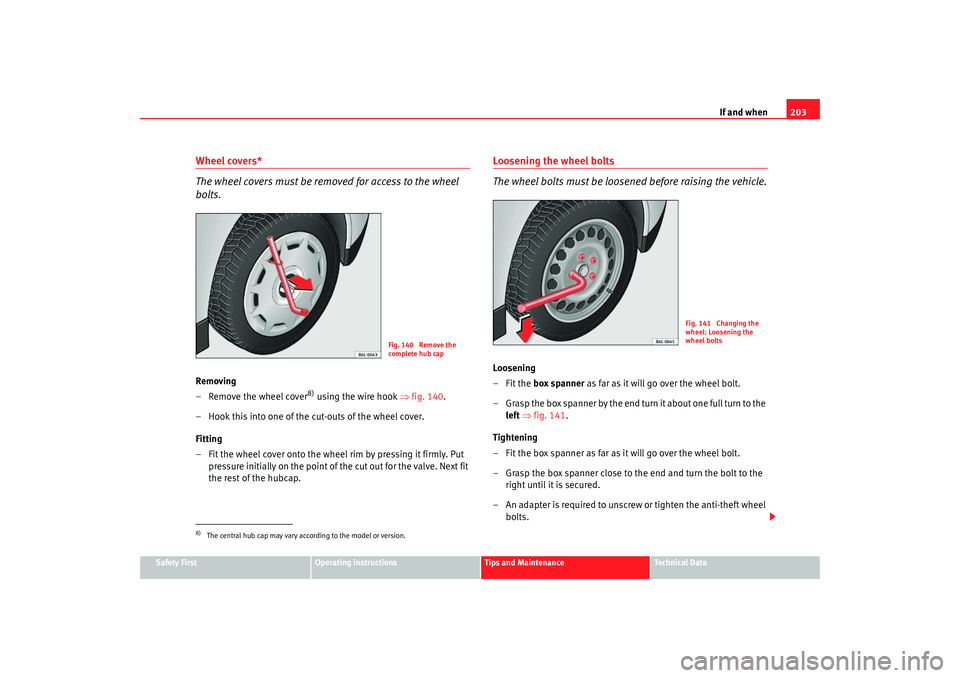

Wheel covers*

The wheel covers must be removed for access to the wheel

bolts.Removing

– Remove the wheel cover

8) using the wire hook ⇒fig. 140.

– Hook this into one of the cut-outs of the wheel cover.

Fitting

– Fit the wheel cover onto the wheel rim by pressing it firmly. Put pressure initially on the point of the cut out for the valve. Next fit

the rest of the hubcap.

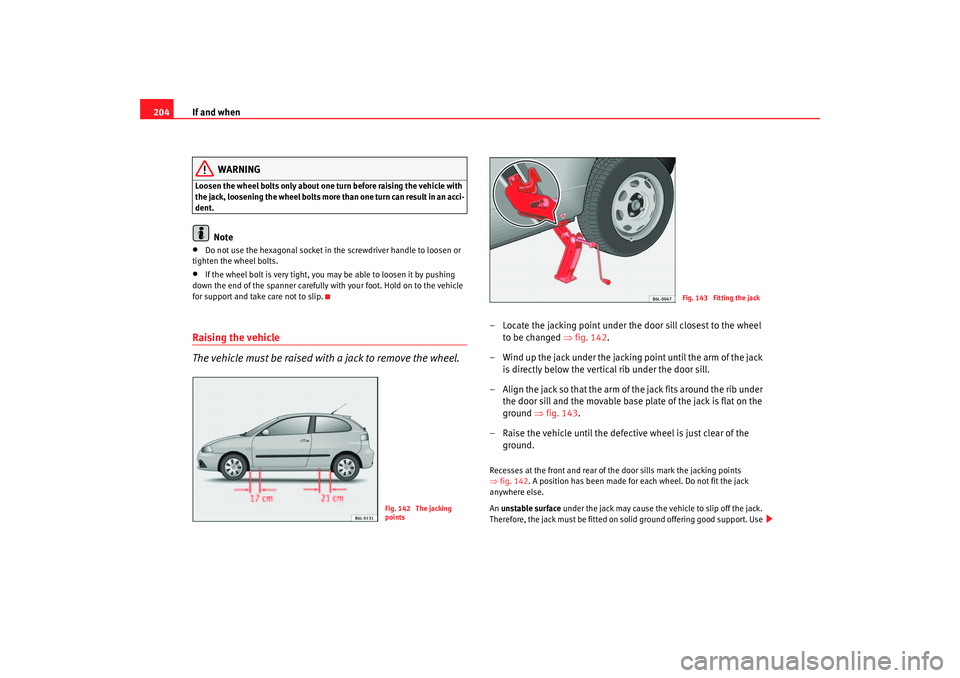

Loosening the wheel bolts

The wheel bolts must be loosened before raising the vehicle.Loosening

–Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner by the end turn it about one full turn to the left ⇒ fig. 141 .

Tightening

– Fit the box spanner as far as it will go over the wheel bolt.

– Grasp the box spanner close to the end and turn the bolt to the right until it is secured.

– An adapter is required to unscrew or tighten the anti-theft wheel bolts.

8)The central hub cap may vary according to the model or version.

Fig. 140 Remove the

complete hub cap

Fig. 141 Changing the

wheel: Loosening the

wheel bolts

ibiza_angles_0706_DEF Seite 203 Freitag, 1. September 2006 1:18 13

Page 206 of 268

If and when

204

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

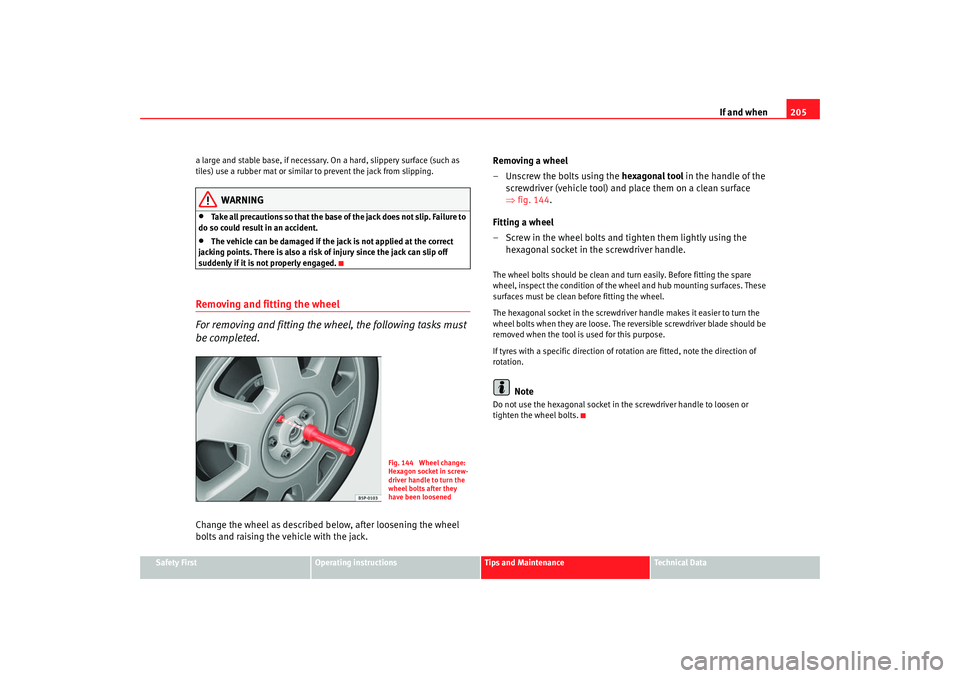

Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

– Locate the jacking point under the door sill closest to the wheel to be changed ⇒fig. 142.

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 143.

– Raise the vehicle until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒fig. 142. A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 142 The jacking

points

Fig. 143 Fitting the jack

ibiza_angles_0706_DEF Seite 204 Freitag, 1. September 2006 1:18 13

Page 207 of 268

If and when205

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

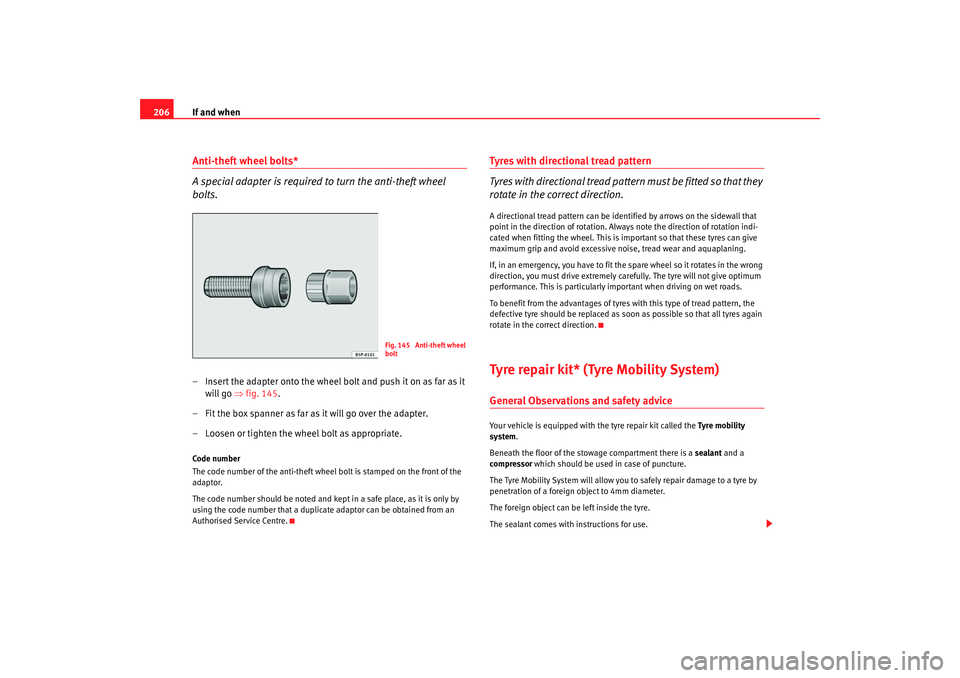

Removing and fitting the wheel

For removing and fitting the wheel, the following tasks must

be completed.Change the wheel as described below, after loosening the wheel

bolts and raising the vehicle with the jack. Removing a wheel

– Unscrew the bolts using the

hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 144.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the wheel and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdriver blade should be

removed when the tool is used for this purpose.

If tyres with a specific direction of ro tation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 144 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

ibiza_angles_0706_DEF Seite 205 Freitag, 1. September 2006 1:18 13

Page 208 of 268

If and when

206Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒fig. 145 .

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Code number

The code number of the anti-theft wheel bolt is stamped on the front of the

adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fi tted s o tha t they

rotate in the correct direction.A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely care fully. The tyre will not give optimum

performance. This is particularly im portant when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.Tyre repair kit* (Tyre Mobility System)General Observations and safety adviceYour vehicle is equipped with the tyre repair kit called the Tyre mobility

system.

Beneath the floor of the stowage compartment there is a sealant and a

compressor which should be used in case of puncture.

The Tyre Mobility System will allow you to safely repair damage to a tyre by

penetration of a foreign object to 4mm diameter.

The foreign object can be left inside the tyre.

The sealant comes with instructions for use.

Fig. 145 Anti-theft wheel

bolt

ibiza_angles_0706_DEF Seite 206 Freitag, 1. September 2006 1:18 13

Page 209 of 268

If and when207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

There is also a guide to using the compressor.

WARNING

•

The sealant should not be used if th

e tyre has been damaged as a result

of going flat.

•

Follow the instructions for your safety and use on the compressor and

the sealant packaging.

•

Do not drive at more than 80 km/h, avoid accelerating or braking hard

or taking curves at high speed.

•

A tyre that has been repaired with sealant should only be used provi-

sionally, and for a short time. Therefore, your car should be taken carefully

to the nearest specialised workshop.For the sake of the environment

If you want to dispose of the sealant bottle, go to a company that treats waste

products.

Note

Seek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible.

–Apply the handbrake firmly. – Engage the first gear

, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– All passengers must leave the vehicle. They should wait in a safe

area (for instance behind the roadside crash barrier).

– Check whether the puncture can be mended using the Tyre Mobility System “General observations and safety advice.”

– Unscrew cap from the valve of the affected wheel.

– Take the tyre repair kit from the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take the utmost caution when repairing a flat tyre on a gradient.

Note

Please observe legal requirements when doing so.

ibiza_angles_0706_DEF Seite 207 Freitag, 1. September 2006 1:18 13

Page 210 of 268

If and when

208Repairing the puncture

To repair the puncture, once the preliminary tasks are done,

follow these steps.Apply the sealant

– The instructions for using the sealant correctly are on the pack-

aging

Inflate the tyres.

– Remove the compressor and hose.

– Tighten the fastening nut onto the tyre valve.

– Connect the compressor power supply to the 12 Volt socket.

– Connect the compressor and chec k the tyre pressure with the

pressure gauge.

Finish the repair

– Remove the compressor hose from the valve.

– Check the cap on the tyre valve.

– Disconnect the compressor from the vehicle mains.

– Put the tools back in the luggage compartment.

NoteThe compressor should not operate more than 6 minutes.

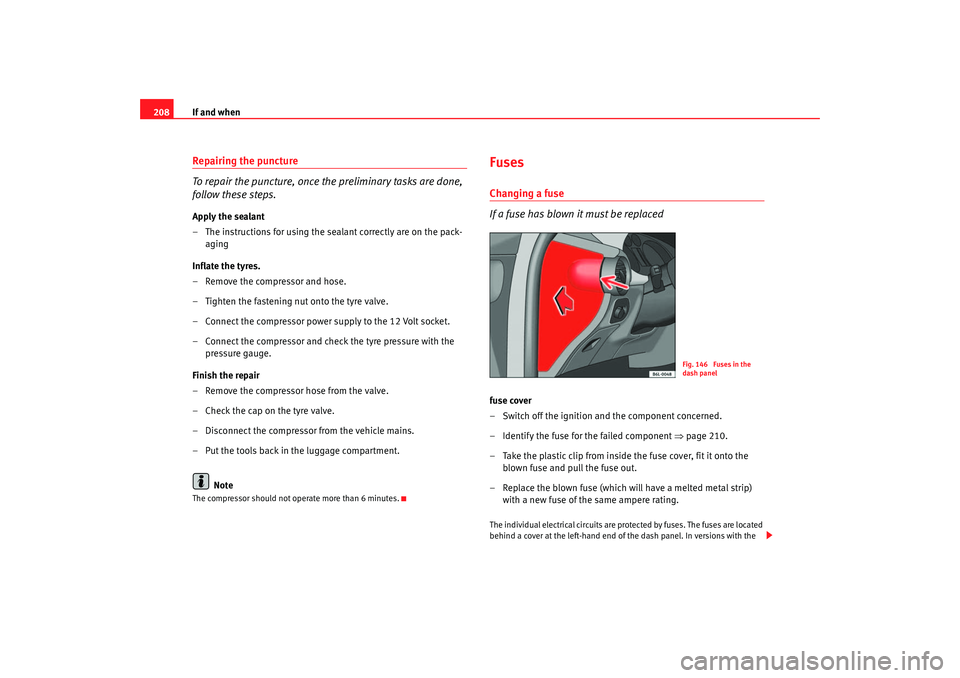

FusesChanging a fuse

If a fuse has blown it must be replacedfuse cover

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 210.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.The individual electrical circuits are protected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel. In versions with the

Fig. 146 Fuses in the

dash panel

ibiza_angles_0706_DEF Seite 208 Freitag, 1. September 2006 1:18 13