light Seat Ibiza 5D 2007 Manual Online

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2007Pages: 272, PDF Size: 8.32 MB

Page 191 of 272

Checking and refilling levels189

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

The coolant additive G 12+ (dyed purple) may be mixed with G 12 (dyed red)

and also with G 11.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartment, always observe the safety

warnings ⇒ page 180.

•

When the engine is warm or hot, the cooling system is pressurised! Do

not unscrew the cap on the expansion t ank when the engine is hot. This is

a burn injury risk.Caution

•

When mixed with other additives the colour of G 12 will change to brown.

If this occurs you should have the coolant changed immediately. Failure to do

so will result in engine damage!

•

If a lot of coolant has been lost, wait for the engine to cool down before

putting in cold coolant. This avoids damaging the engine. Large coolant

losses are an indication of leaks in the cooling system. See a specialised

workshop immediately and have the c ooling system checked. Otherwise,

there is a risk of engine damage.

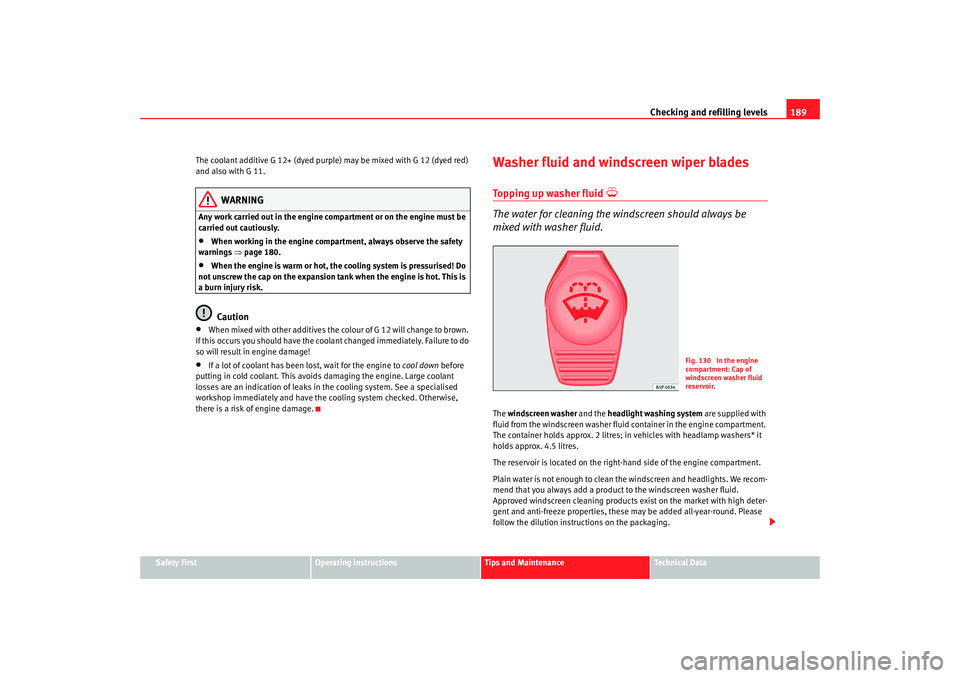

Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer fluid container in the engine compartment.

The container holds approx. 2 litres; in vehicles with headlamp washers* it

holds approx. 4.5 litres.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean th e windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

Fig. 130 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

IBI_ANG_0707 Seite 189 Montag, 6. August 2007 3:59 15

Page 194 of 272

Checking and refilling levels

192

WARNING

Do not drive unless you have good visibility through all windows!•

Clean the windscreen wiper blades and all windows regularly.

•

The wiper blades should be changed once or twice a year.Caution

•

A damaged or dirty window wiper could scratch the rear window.

•

Never use fuel, nail varnish remover, paint thinner or similar products to

clean the window.

•

Never move the windscreen wiper by hand. This could cause damage.

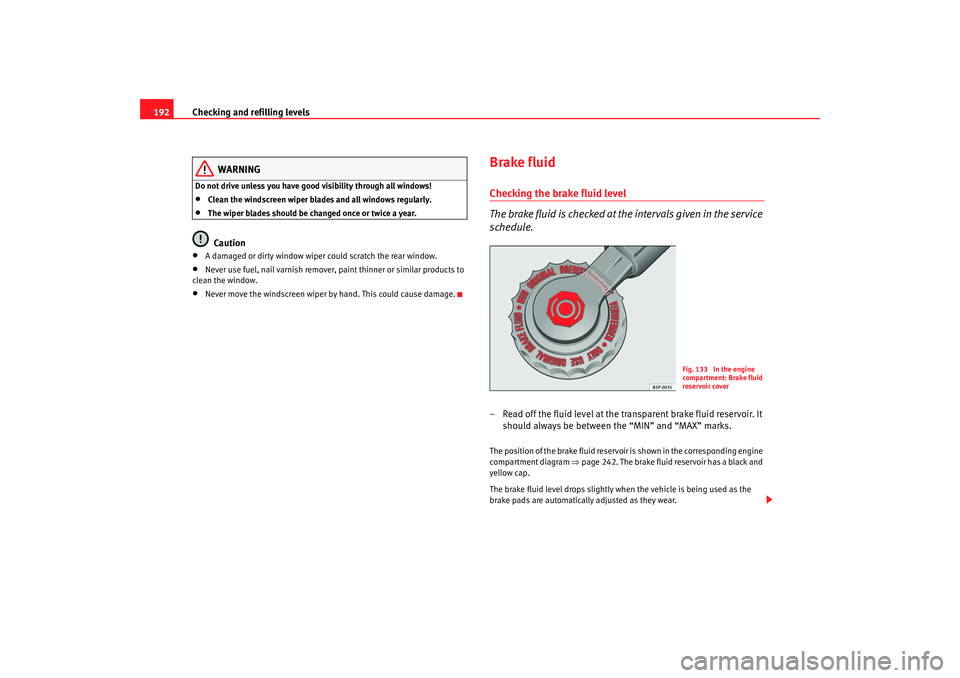

Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment diagram ⇒page 242. The brake fluid reservoir has a black and

yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

Fig. 133 In the engine

compartment: Brake fluid

reservoir cover

IBI_ANG_0707 Seite 192 Montag, 6. August 2007 3:59 15

Page 196 of 272

Checking and refilling levels

194BatteryWarnings on handling the battery

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when working on the battery and the electrical

system:•

Wear eye protection. Protect your ey es, skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoki ng are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic charge. Never short the battery terminals. High-energy sparks can cause

injury.

•

A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

•

Keep children away from acid and batteries.

•

Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bu lb is changed, you need only switch

off the light.

•

Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alar m will otherwise be triggered.

•

When disconnecting the battery from the vehicle electrical system,

disconnect first the negative ca ble and then the positive cable.

•

Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.

•

Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0

°C.

•

Ensure that the vent hose is always connected to the battery.

•

Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•

Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the elec trical system or electronic compo-

nents.

•

Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protec-

tive gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

WARNING (continued)

IBI_ANG_0707 Seite 194 Montag, 6. August 2007 3:59 15

Page 199 of 272

Checking and refilling levels197

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Checking tyre pressure

The correct tyre pressure can be seen on the sticker on the

inside of the tank flap.1. Read the required tyre inflation pressure from the sticker. The

values refer to Summer tyres. For Winter tyres, you must add 0.2

bar to the values given on the sticker.

2. The tyre pressures should only be checked when the tyres are cold. The slightly raised pressures of warm tyres must not be

reduced.

3. Adjust the tyre pressure to the load you are carrying.Tyre pressure

The correct tyre pressure is especially important at high speeds. The pressure

should therefore be checked at least once a month and before starting a

journey.

WARNING

A tyre can easily burst if the pressure is too low, causing an accident!•

At continuously high speeds, a tyre with insufficient pressure flexes

more. In this way it becomes too hot, and this can cause tread separation

and tyre blow-out. Always observe the recommended tyre pressures.

•

If the tyre pressure is too low or too high, the tyres will wear prema-

turely and the vehicle will not handle well. Risk of accident!For the sake of the environment

Under-inflated tyres will increase fuel consumption.

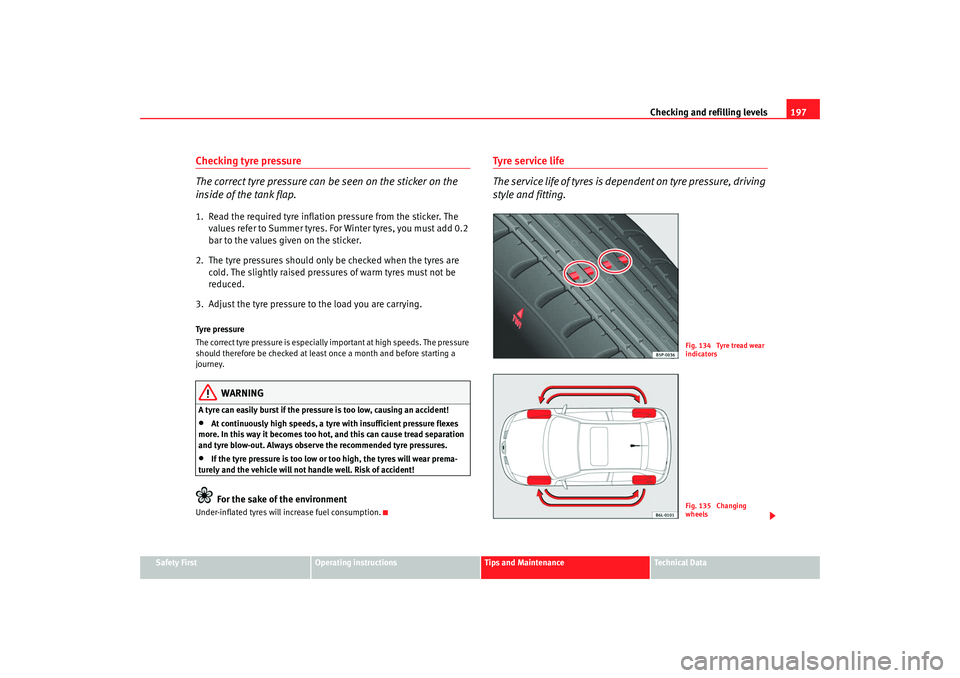

Tyre service life

The service life of tyres is dependent on tyre pressure, driving

style and fitting.

Fig. 134 Tyre tread wear

indicatorsFig. 135 Changing

wheels

IBI_ANG_0707 Seite 197 Montag, 6. August 2007 3:59 15

Page 207 of 272

If and when205

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Taking out the spare wheel

7)

– Lift the carpet, then remove the plastic nut anticlockwise.

– Take out the tool box* and remove the spare wheel*.

Securing the defective wheel in the spare wheel well

– Put the defective wheel into its housing, and then put the tool

box* into the hollow in the wheel.

– Turn the plastic nut clockwise until the defective wheel is well secured.

– Unhook the carpet and place it on the floor.

WARNING

Check the spare wheel and the tools ar e firmly held to avoid injury to

passengers in the event of sudden braking or collision.Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel) is

stored under the floor panel in the luggage compartment.Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a contai ner with sealing compound to repair the

puncture and a compressor to generate the required tyre pressure. The kit will

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear , or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

7)The 17 inch spare wheel is only carried if the "SEAT racing brakes" option is chosen.

IBI_ANG_0707 Seite 205 Montag, 6. August 2007 3:59 15

Page 208 of 272

If and when

206

WARNING

Put the hazard warning lights on and pl ace the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Pull off the hub cap see also ⇒page 207.

–Slacken the wheel bolts.

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly i n d ia go na l s e q u e n ce wi t h t h e b ox

spanner.

–Replace the hub cap.

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart- ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque is 120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

In the interest of safety, drive at moderate speeds until the wheel bolt

torque has been checked.

IBI_ANG_0707 Seite 206 Montag, 6. August 2007 3:59 15

Page 212 of 272

If and when

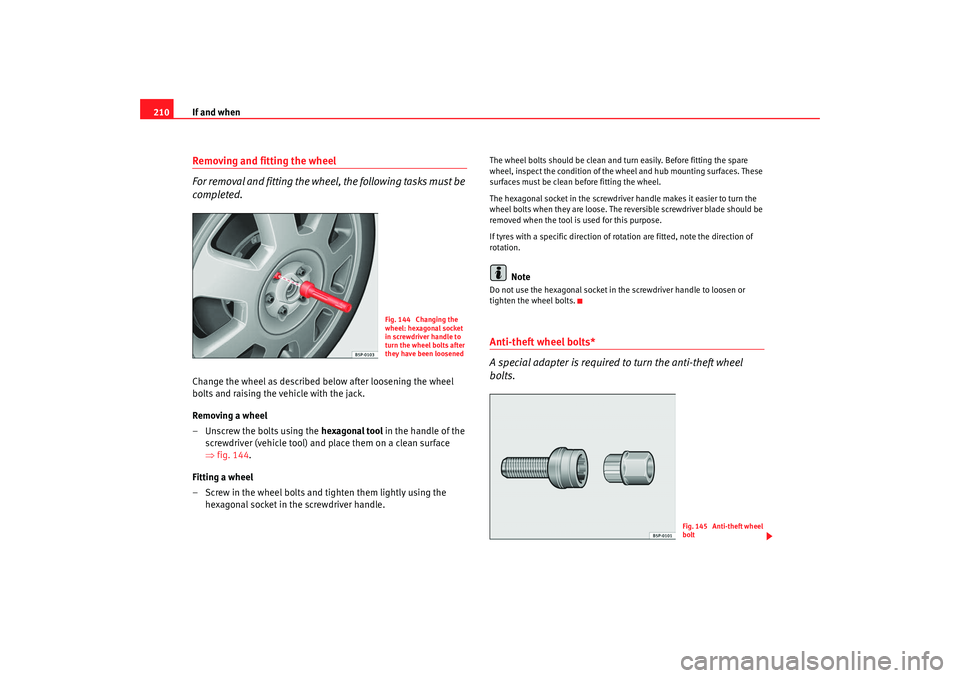

210Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must be

completed.Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack.

Removing a wheel

– Unscrew the bolts using the hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 144.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the whe el and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdrive r blade should be

removed when the tool is used for this purpose.

If tyres with a specific di rection of rotation are fitt ed, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 144 Changing the

wheel: hexagonal socket

in screwdriver handle to

turn the wheel bolts after

they have been loosened

Fig. 145 Anti-theft wheel

bolt

IBI_ANG_0707 Seite 210 Montag, 6. August 2007 3:59 15

Page 214 of 272

If and when

212

NoteSeek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

Certain steps must be taken before repairing a tyre.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible.

–Apply the handbrake firmly.

– Engage the first gear, of put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility System “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and pl ace the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take special care if you have to repair a tyre on a gradient.

Note

Please observe legal requirements when doing so.Tyre repair

The following sections describe the procedures for repairing

a tyre.Using the sealing compound

– The instructions on the container give detailed information on how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt socket.

– Turn on compressor and monitor the pressure shown on the pres- sure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

IBI_ANG_0707 Seite 212 Montag, 6. August 2007 3:59 15

Page 217 of 272

If and when215

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

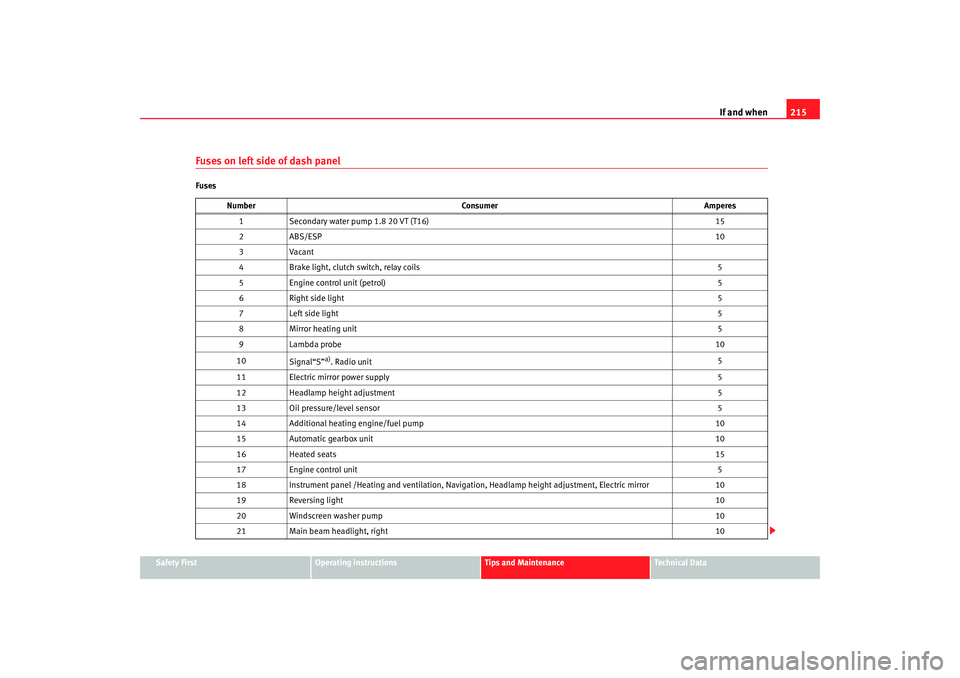

Fuses on left side of dash panelFuses

Number Consumer Amperes

1 Secondary water pump 1.8 20 VT (T16) 15

2A BS/E S P 10

3 Vacant

4 Brake light, clutch switch, relay coils 5

5 Engine control unit (petrol) 5

6 Right side light 5

7 Left side light 5

8 Mirror heating unit 5

9 Lambda probe 10

10 Signal“S”

a). Radio unit 5

11 Electric mirror power supply 5

12 Headlamp height adjustment 5

13 Oil pressure/level sensor 5

14 Additional heating engine/fuel pump 10

15 Automatic gearbox unit 10

16 Heated seats 15

17 Engine control unit 5

18 Instrument panel /Heating and ventilation, Navigation, Headlamp height adjustment, Electric mirror 10

19 Reversing light 10

20 Windscreen washer pump 10

21 Main beam headlight, right 10

IBI_ANG_0707 Seite 215 Montag, 6. August 2007 3:59 15

Page 218 of 272

If and when

216

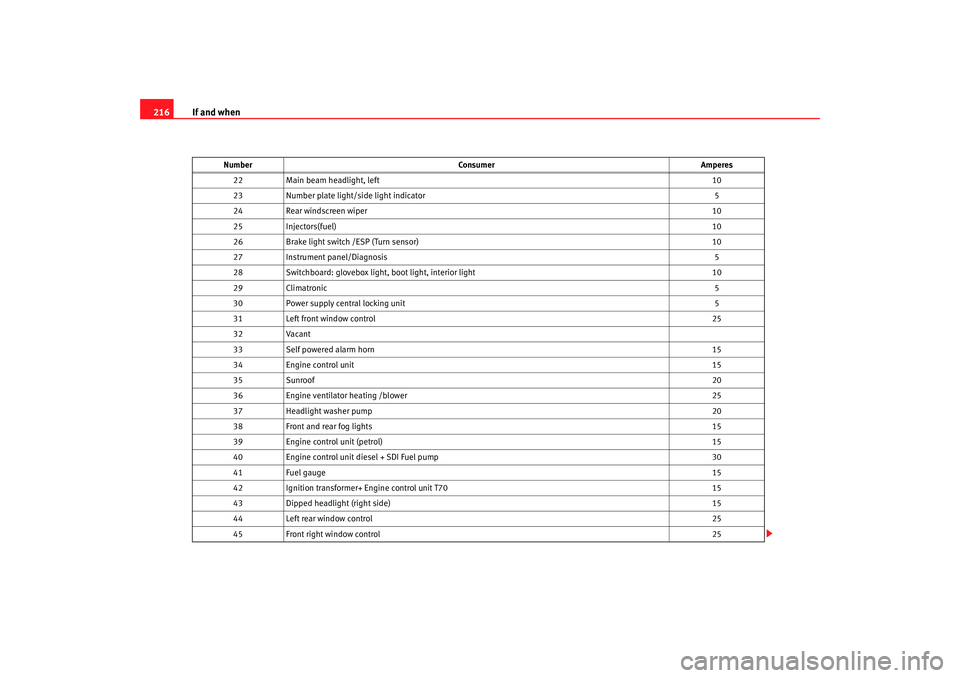

22 Main beam headlight, left 10

23 Number plate light/si de light indicator 5

24 Rear windscreen wiper 10

25 Injectors(fuel) 10

26 Brake light switch /ESP (Turn sensor) 10

27 Instrument panel/Diagnosis 5

28 Switchboard: glovebox light, boot light, interior light 10

29 Climatronic 5

30 Power supply central locking unit 5

31 Left front window control 25

32 Vacant

33 Self powered alarm horn 15

34 Engine control unit 15

35 Sunroof 20

36 Engine ventilator heating /blower 25

37 Headlight washer pump 20

38 Front and rear fog lights 15

39 Engine control unit (petrol) 15

40 Engine control unit diesel + SDI Fuel pump 30

41 Fuel gauge 15

42 Ignition transformer+ Engine control unit T70 15

43 Dipped headlight (right side) 15

44 Left rear window control 25

45 Front right window control 25

Number

Consumer Amperes

IBI_ANG_0707 Seite 216 Montag, 6. August 2007 3:59 15