technical specifications Seat Leon 5D 2012 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Leon 5D, Model: Seat Leon 5D 2012Pages: 289, PDF Size: 3.81 MB

Page 240 of 289

239

Emergencies

WARNING

● Make sure that the jack* remains stable. If the surface is slippery or

soft, the jack* could slip or sink, respectively, with the resultant risk of

injury.

● Only raise the vehicle with the jack* supplied by the manufacturer.

Other vehicles could slip, with the consequent risk of injury.

● Only mount the jack* on the support points designed for this purpose

on the strut, and always align the jack correctly. If you do not, the jack*

could slip as it does not have an adequate grip on the vehicle: risk of in-

jury!

● The height of the parked vehicle can change as a result of variations

in temperature and loading.

CAUTION

The vehicle must not be raised on the crossbar. Only place the jack* on the

points designed for this purpose on the strut. Otherwise, the vehicle may be

damaged.

Removing and fitting a wheel

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Taking off the wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

– Take off the wheel ⇒

. Putting on the spare wheel

When fitting tyres with a compulsory rotation direction, observe

the instructions in

⇒ page 239.

– Mount the wheel.

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

– Carefully lower the vehicle using the jack*.

– Tighten the wheel bolts in diagonal pairs using the wheel

brace.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

CAUTION

When removing/fitting the wheel, the rim may hit and damage the brake

disc. For this reason, please take care and get a second person to assist

you.

Tyres with compulsory direction of rotation

A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always observe the direction of rotation in-

dicated when mounting the wheel. This is important so that these tyres can

give maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, exceptionally, it is necessary to mount the spare wheel* in the opposite

direction of rotation, please drive carefully, as in this case the tyre does not

have optimum conditions of use. This is particularly important when driving

on wet roads.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 242 of 289

241

Emergencies

– Take out the temporary spare wheel.

Chains

For technical reasons, snow chains must not be used on the temporary

spare wheel.

If you have a puncture on one of the front wheels when using snow chains,

fit the temporary spare wheel in place of one of the rear wheels. Fit the snow

chains on the rear wheel that you have removed and replace the punctured

front wheel with this wheel.

WARNING

● After fitting the temporary spare wheel, check the tyre pressures as

soon as possible. Failure to do so may cause an accident. The tyre pres-

sures are listed on the inside of the fuel tank flap.

● Do not drive at over 80 km/h (50 mph) when the temporary spare

wheel is fitted on the vehicle: risk of accident!

● Avoid heavy acceleration, hard braking and fast cornering: risk of ac-

cident!

● Never use more than one temporary spare wheel at the same time,

risk of accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Jump starting

Jump leads

The jump lead must have a sufficient wire cross section.

If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see cable manufactur-

er's instructions). The wire cross section must be at least 25 mm 2

for petrol

engines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the on-board net-

work.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 244 of 289

243

Emergencies

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 209.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

WARNING (Continued)

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 246 of 289

245

Emergencies

Note

● Please observe legal requirements when doing so.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● The tow rope must not be twisted. Otherwise the front towline anchor-

age could be pulled off the vehicle.

Towline anchorage at the front of the vehicle

The front towline anchorage is only mounted if the vehicle

has to be towed.

Fig. 128 Right side of

the front bumper: towline

anchorage screwed in

There is a cover with an opening into which the towline anchorage

is screwed on the right part of the front bumper.

– To remove the bumper cover, just press the upper left side in-

wards. –

Take the towline anchorage out of the vehicle tool kit

⇒ page 232.

– Screw the towline anchorage into the screw connection as far as

it will go ⇒ Fig. 128 and tighten with the wheel brace.

After use, unscrew the towline anchorage and fit the cover back on the

bumper. Put the towline anchorage back in the vehicle tool kit. The towline

anchorage should always be kept in the vehicle.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 248 of 289

247

Emergencies

Tow-starting

As a general rule, tow-starting is not recommended.

– Engage 2nd or 3rd gear before moving off.

– Press the clutch and hold the pedal down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts: press the clutch and put the gear

lever in neutral.

If the engine will not start, it is best to try starting it using the battery of an-

other vehicle ⇒ page 241 before attempting to tow start. You should only try

to tow-start the engine if jump starting is not successful. Tow-starting is an

attempt to start the engine via the movement of the wheels.

When tow-starting a vehicle with a petrol engine, do not tow it more than a

short distance, otherwise sunburnt fuel can enter the catalytic converter and

cause damage.

WARNING

The risk of accidents is high when tow-starting, as the towed vehicle can

easily be driven into the towing vehicle.

CAUTION

Do not tow vehicles for more than 50 m. Risk of damage to the catalytic con-

verter. Towing vehicles with a manual gearbox

Towing is relatively straightforward.

Please observe the relevant instructions ⇒ page 244.

The vehicle can be towed using a tow bar or tow rope in the normal way,

with all four wheels on the road; it can also be towed with either the front or

rear wheels lifted off the road. The maximum towing speed is 50 km/h (30

mph).

Towing a vehicle equipped with automatic gearbox

Certain restrictions must be observed when towing your ve-

hicle. Please observe the relevant instructions ⇒ page 244.

The vehicle can be towed with a tow bar or tow rope in the normal way, with

all four wheels on the ground. When doing so, please note the following

points:

● Make sure the selector lever is in the N position.

● The vehicle must not be towed faster than 50 km/h (30 mph).

● The vehicle must not be towed further than 50 km (30 miles). Reason:

when the engine is not running, the gearbox oil pump does not work and

the gearbox is not adequately lubricated for higher speeds or longer distan-

ces.

If the vehicle has to be towed with a breakdown truck, it must only be sus-

pended at the front wheels. Reason: the drive shafts are located on the front

wheels. If the car is towed with the rear wheels lifted off the road (I.e. travel-

ling backwards), the drive shafts also turn backwards. The planetary gears

in the automatic gearbox then turn at such high speeds that the gearbox

will be severely damaged in a short time.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 250 of 289

249

Fuses and bulbs

Fuses and bulbs Electrical fuses

Changing fuses

A blown fuse can be identified by the blown metal strip.

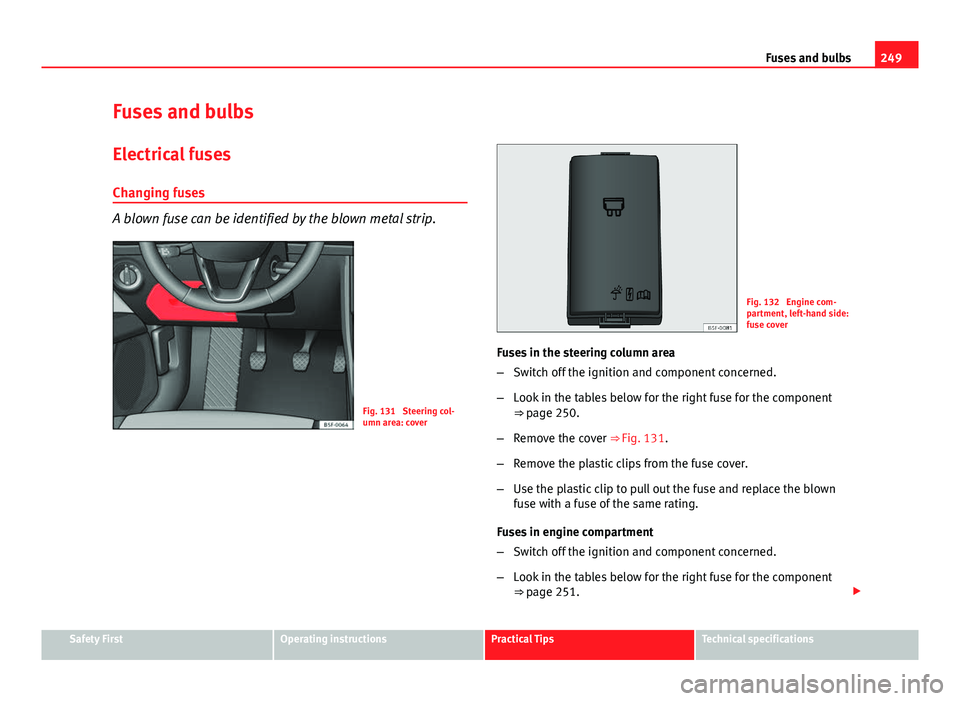

Fig. 131 Steering col-

umn area: cover

Fig. 132 Engine com-

partment, left-hand side:

fuse cover

Fuses in the steering column area

– Switch off the ignition and component concerned.

– Look in the tables below for the right fuse for the component

⇒ page 250.

– Remove the cover ⇒ Fig. 131.

– Remove the plastic clips from the fuse cover.

– Use the plastic clip to pull out the fuse and replace the blown

fuse with a fuse of the same rating.

Fuses in engine compartment

– Switch off the ignition and component concerned.

– Look in the tables below for the right fuse for the component

⇒ page 251.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 252 of 289

251

Fuses and bulbs

No.Electrical consumerAmpsF29Vacant-F30Vacant-F31Left lights40F32Parking aid control unit7,5F33Airbag5

F34Reverse switch, clima sensor, electrochromic

mirror7,5

F35Diagnosis, headlight control unit, headlight ad-

juster10

F36Front camera10F37Vacant-F38Vacant-F39Right door30F4012V socket20F41Steering column20F42Central locking40F43Interior light30F44Vacant-F45Vacant-F47Rear window wiper15F49Starter motor; clutch sensor5F51Vacant-F53Heated rear window30

The electric windows and electric seats* are protected by circuit breakers.

These switch on again automatically after a few seconds when the overload

(caused for example by frozen windows) has been corrected.

Note

Please note that the above list, while correct at the time of printing, is sub-

ject to alterations.

Fuses on left side of engine compartment

No.Electrical consumerAmpsF1Vacant-F2ESC control unit40F3Engine control unit (diesel/petrol)15/30F4Engine sensors5/10F5Engine sensors7,5/10F6Brake light sensor5F7Engine power supply5/10F8Lambda probe10F9Engine5/10/20F10Fuel pump control unit15/20F11PTC40F12PTC40F13Automatic gearbox control unit15/30F15Horn15F16Fuel pump control unit20F17Engine control unit7,5F18Terminal 30 (positive reference)5F19Front windscreen washer30F20Alarm horn10F22Engine control unit5F23Starter motor30

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 254 of 289

253

Fuses and bulbs

LED rear lightTypeReverse lightsP21W LLThe remaining functions work with LEDs

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● When changing bulbs, please take care not to injure yourself on sharp

edges, in particular on the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. Other-

wise, a short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

● Take good care to avoid damaging any components.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also that of all other road users.

● Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, they will be deposited

on the reflector and will impair its surface.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 256 of 289

255

Fuses and bulbs

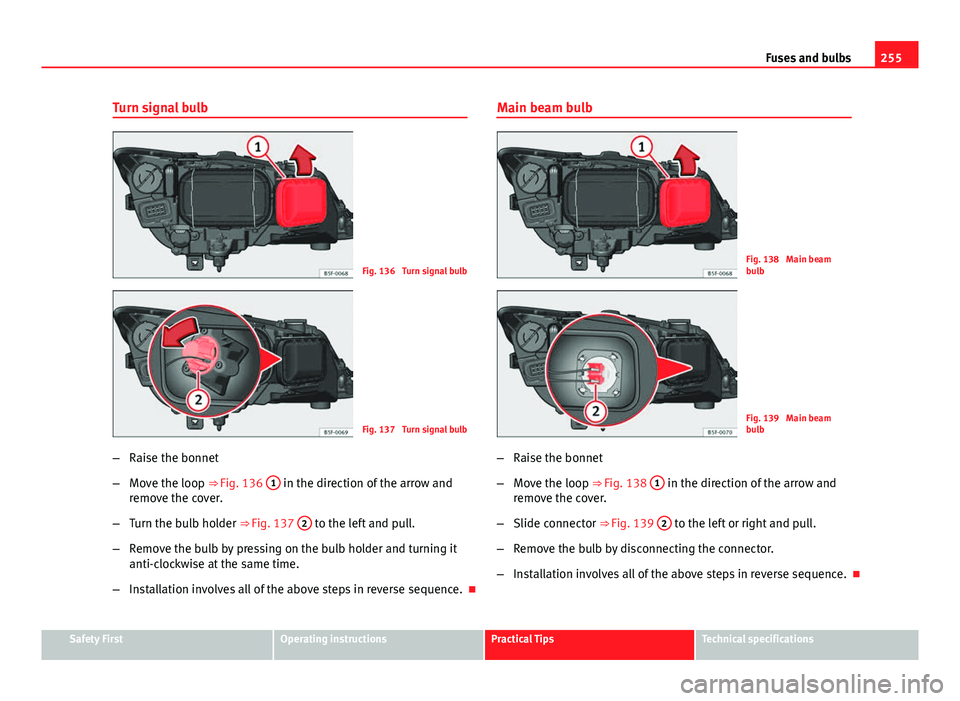

Turn signal bulb

Fig. 136 Turn signal bulb

Fig. 137 Turn signal bulb

– Raise the bonnet

– Move the loop ⇒ Fig. 136 1

in the direction of the arrow and

remove the cover.

– Turn the bulb holder ⇒ Fig. 137 2

to the left and pull.

– Remove the bulb by pressing on the bulb holder and turning it

anti-clockwise at the same time.

– Installation involves all of the above steps in reverse sequence. Main beam bulb

Fig. 138 Main beam

bulb

Fig. 139 Main beam

bulb

– Raise the bonnet

– Move the loop ⇒ Fig. 138 1

in the direction of the arrow and

remove the cover.

– Slide connector ⇒ Fig. 139 2

to the left or right and pull.

– Remove the bulb by disconnecting the connector.

– Installation involves all of the above steps in reverse sequence.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 258 of 289

257

Fuses and bulbs

Remove the bulb holder

Fig. 142 Front fog light

– Remove connector ⇒ Fig. 142 A

from the bulb.

– Turn bulb holder ⇒ Fig. 142 B

to the left and pull.

– Remove the bulb by pressing on the bulb holder and turning it

anti-clockwise at the same time.

– Installation involves all of the above steps in reverse sequence.

– Check that the bulb works properly. Changing tail light bulbs (on side panel)

Overview of tail lights

Rear lights on the side panel

Turn signalPY21W NA LLSide light and brake lightP21W LL

Safety FirstOperating instructionsPractical TipsTechnical specifications