ignition Seat Toledo 2013 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 193 of 258

191

Checking and refilling levels

CAUTION

● Never mix the windscreen washing water with anti-freeze used for the

cooling system or other additives.

● If the vehicle is equipped with a headlight washer system, only mix a de-

tergent that does not damage polycarbonates with the water.

Note

On topping up the fluid, do not move the filter on the container opening, as

this could contaminate the fluid pipes and, therefore, lead to a windscreen

washer malfunction.

Battery Introduction

Warning symbols on the battery

SymbolMeaning

Always wear safety glasses!

Battery acid is extremely corrosive. Always wear gloves and

hearing protection!

Keep open flames, sparks, uncovered lights and lit cigarettes

away when working on the battery!

A highly explosive mixture of gases is released when the bat-

tery is under charge!

Keep children away from the battery!

Incorrect handling of the vehicle battery could lead to damage. We therefore

recommend all work on the vehicle battery be performed by an authorised

SEAT dealer.

Always be aware of the danger of injury and scalding as well as the risk of

accident or fire when working on the battery and the electrical system.

Therefore, always observe the warnings and follow all general safety pre-

cautions.

WARNING

● Battery acid is very corrosive, therefore, the battery must be handled

with the utmost care. Wear protective gloves and protect your eyes and

skin when handling batteries. The corrosive fumes in the air irritate and

inflame the respiratory tract and cause conjunctivitis. It corrodes tooth

enamel and causes deep, difficult-to-heal wounds when in contact with

the skin. Repeated contact with diluted acids causes skin disease (in-

flammation, ulcers and fissures). When in contact with water, acids dilute

and develop a great deal of heat.

● Do not tilt the battery, as acid could leak out of the vapour vents. Pro-

tect your eyes with glasses or a protective helmet! Risk of blindness! If

acid should splash into the eyes, rinse the affected eye immediately for

several minutes using clean water. Then seek medical care immediately.

● Neutralize any acid splashes on the skin or clothing with soap solu-

tion as quickly as possible and rinse off with plenty of water. If acid is

swallowed by mistake, consult a doctor immediately.

● Keep children away from the battery.

● Hydrogen is released and a highly explosive mixture of gases is gen-

erated when the battery is under charge. Sparks when disconnecting or

releasing cable terminals with the ignition switched on could also cause

an explosion.

● A short circuit is produced if the battery terminals are bridged, e.g.

using metal objects, cables, etc. Possible consequences of a short cir-

cuit: melting of lead plates, battery explosion and fire, splashing acid.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 194 of 258

192Checking and refilling levels

WARNING (Continued)

● The following is forbidden while working on the battery: fire and open

flames, smoking and activities that could produce sparks. Avoid causing

sparks when handling cables or electrical apparatus. Risk of injury in the

event of large sparks.

● Before working on the electrical system, you must switch off the en-

gine, the ignition and all electrical components and disconnect the cable

from the negative terminal (-) of the battery. To change a bulb, simply

switch off the corresponding light.

● Never charge a frozen or thawed out battery. Risk of explosion and

acid burns! Replace a frozen battery.

● Never use the jump leads on batteries in which the electrolyte level is

too low. Risk of explosion and acid burns.

● Never use a damaged battery. Risk of explosion! Replace a damaged

battery immediately.

CAUTION

● Never disconnect the battery when the ignition is switched on, as the

electrical system (electronic components) of the vehicle could be damaged.

When disconnecting the battery from the vehicle electrical system, discon-

nect its negative terminal (-) first. Only then may the positive terminal (+) be

disconnected.

● When connecting the battery, connect the positive terminal (+) first. On-

ly then may the negative terminal (-) be connected. The battery cables must

never be connected to the wrong battery terminals. Risk of burning the elec-

trical installation.

● Make sure the battery acid does not come into contact with the body-

work. Risk of paintwork damage.

● Do not expose the battery to direct sunlight to protect it from ultraviolet

radiation. ●

If the vehicle is not used for 3 or 4 weeks, the battery could run flat. This

is because some components use electricity even in standby mode (e.g.

control units). Prevent the battery from running flat by disconnecting its

negative terminal or leave it charging at a low current.

● If you frequently use the vehicle for short trips, the battery may not fully

charge and could run flat.

For the sake of the environment

A flat battery is particularly harmful waste for the environment. It must

therefore be disposed of according to current local law.

Note

Replace a battery once it is older than 5 years.

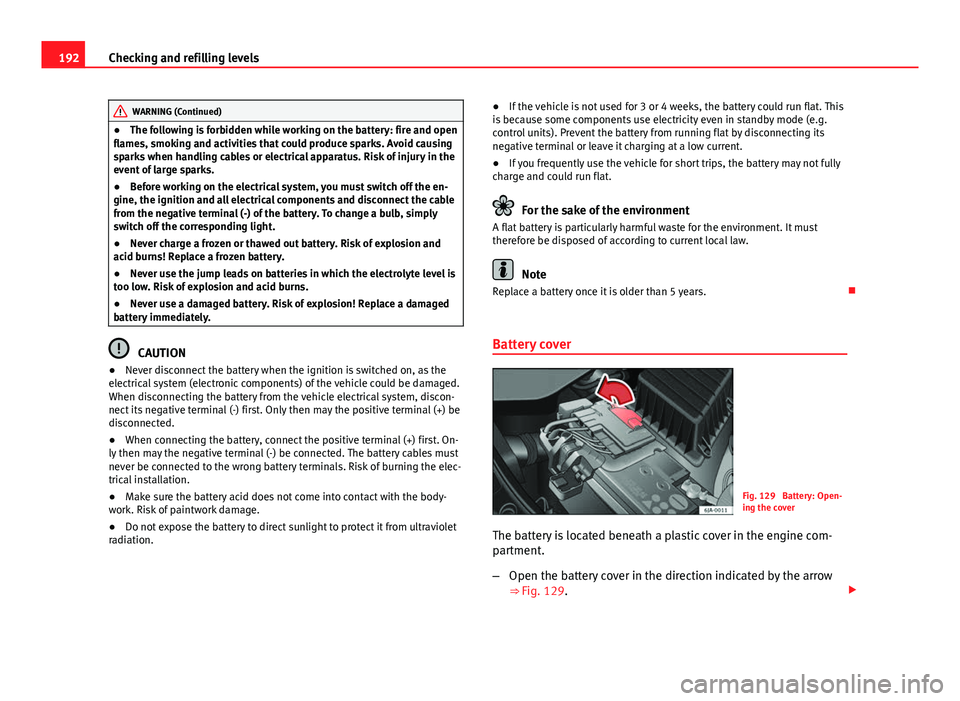

Battery cover

Fig. 129 Battery: Open-

ing the cover

The battery is located beneath a plastic cover in the engine com-

partment.

– Open the battery cover in the direction indicated by the arrow

⇒ Fig. 129.

Page 195 of 258

193

Checking and refilling levels

– The positive terminal (+) of the battery is connected in reverse

order.

Checking battery acid level

Fig. 130 Battery: Acid

level indicator

We recommend you have the acid level regularly checked at an official tech-

nical service, particularly in the following cases.

● At high outside temperatures.

● On long daily trips.

● Whenever the vehicle is loaded ⇒ page 193, Charging the battery.

In vehicles equipped with a battery with colour indicator, the so-called mag-

ic eye ⇒ Fig. 130 changes colour to indicate the acid level.

Air bubbles can influence the colour of the indicator. Therefore, carefully

knock the indicator before checking the acid level.

● Black – the acid level is correct.

● Colourless or light yellow – acid level too low, battery must be changed.

Note

● The battery acid level is also regularly checked during servicing at au-

thorised SEAT dealers.

● The acid level on “AGM” vehicle batteries cannot be checked for techni-

cal reasons.

● Vehicles equipped with the “START-STOP” system include a battery con-

trol unit to control the battery level for repeat engine starting.

Winter service

At low temperatures the battery provides only a fraction of the starting pow-

er it has at normal temperatures.

A flat battery can also freeze at temperatures slightly below 0 °C (32 °F).

We therefore recommend you have the battery checked and, if necessary,

charged at an official SEAT technical service before the start of winter.

Charging the battery

A fully-charged battery is essential for reliable starting.

– Switch off the ignition and all electrical equipment.

– For “fast-charging” only: disconnect both battery connection ca-

bles (first the “negative” terminal and then the “positive”).

– Connect the charger cables to the battery terminals (red = “pos-

itive”, black = “negative”).

– Plug in the battery charger and switch on.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 197 of 258

195

Checking and refilling levels

Note

Despite any measures taken by the control unit, the battery could drain. e.g.

with the engine is switched off, the key is turned in the ignition for a long

period or the side lights or parking lights are switched on. The switching off

of certain electrical components does not impair driving comfort and the

driver will often not even realise.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 203 of 258

201

Wheels and tyres

Removing

– Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 134.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure *

Fig. 135 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 76 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 197.

● Switch the ignition on.

● Hold the

⇒ Fig. 135 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 210 of 258

208Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 207 and the spare wheel

⇒ page 207 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 200 or the wheel bolt covers

⇒ page 200.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 209.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 210.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.

Page 215 of 258

213

Self-help

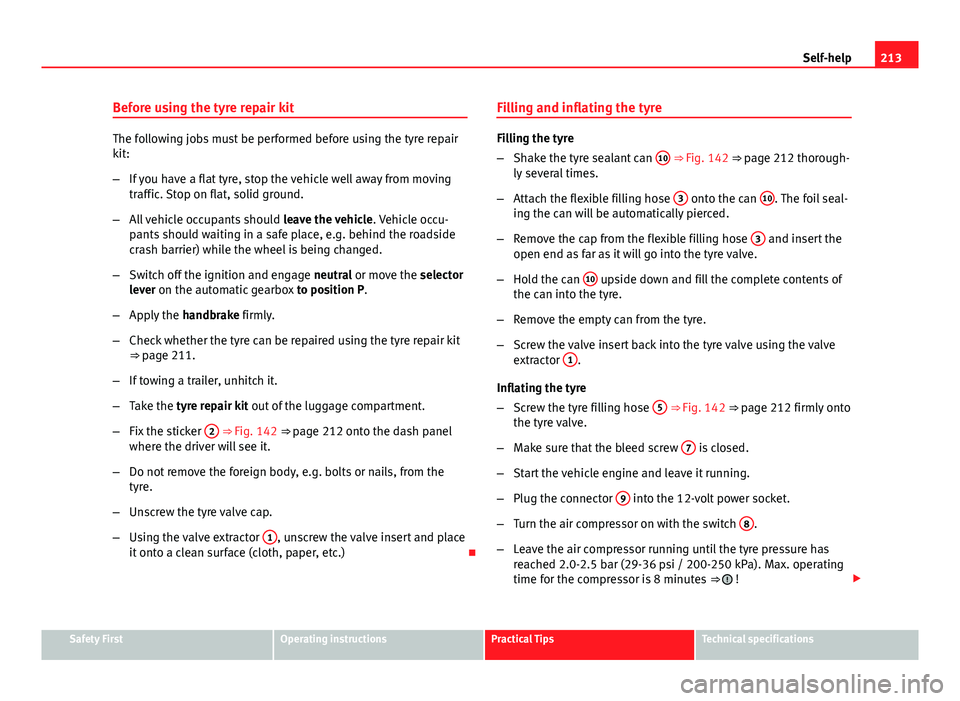

Before using the tyre repair kit

The following jobs must be performed before using the tyre repair

kit:

– If you have a flat tyre, stop the vehicle well away from moving

traffic. Stop on flat, solid ground.

– All vehicle occupants should leave the vehicle. Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– Check whether the tyre can be repaired using the tyre repair kit

⇒ page 211.

– If towing a trailer, unhitch it.

– Take the tyre repair kit out of the luggage compartment.

– Fix the sticker 2

⇒ Fig. 142 ⇒

page 212 onto the dash panel

where the driver will see it.

– Do not remove the foreign body, e.g. bolts or nails, from the

tyre.

– Unscrew the tyre valve cap.

– Using the valve extractor 1

, unscrew the valve insert and place

it onto a clean surface (cloth, paper, etc.) Filling and inflating the tyre

Filling the tyre

–

Shake the tyre sealant can 10

⇒ Fig. 142 ⇒ page 212 thorough-

ly several times.

– Attach the flexible filling hose 3

onto the can 10. The foil seal-

ing the can will be automatically pierced.

– Remove the cap from the flexible filling hose 3

and insert the

open end as far as it will go into the tyre valve.

– Hold the can 10

upside down and fill the complete contents of

the can into the tyre.

– Remove the empty can from the tyre.

– Screw the valve insert back into the tyre valve using the valve

extractor 1

.

Inflating the tyre

– Screw the tyre filling hose 5

⇒ Fig. 142 ⇒ page 212 firmly onto

the tyre valve.

– Make sure that the bleed screw 7

is closed.

– Start the vehicle engine and leave it running.

– Plug the connector 9

into the 12-volt power socket.

– Turn the air compressor on with the switch 8

.

– Leave the air compressor running until the tyre pressure has

reached 2.0-2.5 bar (29-36 psi / 200-250 kPa). Max. operating

time for the compressor is 8 minutes ⇒

!

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 219 of 258

217

Self-help

road. If the vehicle is towed with the rear wheels lifted off the road

the automatic gearbox will be damaged!

It is easier and safer to tow a vehicle with a towbar. A towrope

should only be used if you do not have a towbar.

Follow the instructions below when towing a vehicle:

Notes for the driver of the towing vehicle

– Engage the clutch very gently when starting to move or on vehi-

cles with automatic gearbox press the accelerator carefully.

– On vehicles with manual gearbox, the towrope must be taut be-

fore driving off.

The maximum towing speed is 50 km/h (31 mph).

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the steering wheel

lock is not engaged and the turn signals, horn and windscreen

wipers and washers can be used.

– Put the gear lever in neutral or move the selector lever to posi-

tion N (automatic gearbox).

The brake servo and power steering only work when the engine is

running. Considerably more effort is required on the brake pedal

and steering wheel when the engine is switched off.

Ensure the towrope remains taut at all times when towing.

CAUTION

● Do not tow-start the engine. Risk of engine damage! In vehicles with a

catalytic converter, unburnt fuel could reach the catalytic converter and

catch fire in it. This could damage and destroy the catalytic converter. Use

the battery from another vehicle for help in starting the engine ⇒ page 215,

Starting the engine.

● If, due to a fault, there is no oil in the gearbox, the car may only be tow-

ed with the driven wheels lifted clear of the road and transported on a spe-

cial vehicle transporter or trailer.

● If normal towing is not possible or if the vehicle is to be towed for further

than 50 km (31 miles), the vehicle must be transported on a special vehicle

transporter or trailer.

● The towrope should be slightly elastic to reduce the loading on both ve-

hicles during towing. It is advisable to use a towrope made of synthetic fibre

or similar material only.

● Do not pull too hard with the towing vehicle and always take care to

avoid jerking the towrope. When towing on a loose surface there is always a

risk of overloading and damaging the anchorage points.

● Attach the towrope or towbar only to the towline anchorages or to the

removable towing bracket ⇒ page 164, or ⇒ page 218.

Note

● We recommend you use the towrope or towbar available in the SEAT

Original Accessories programme from authorised SEAT dealers.

● Towing a vehicle requires some experience. Both drivers should be fa-

miliar with the technique required for towing. Inexperienced drivers should

not attempt to tow away another vehicle or to have their vehicle towed.

● Note the legal regulations concerning towing, particularly those regard-

ing the signalling of the towed and towing vehicle.

● The towrope must not be twisted, as under certain circumstances this

could unscrew the front towline anchorage.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 221 of 258

219

Fuses and bulbs

Fuses and bulbs Fuses

Introduction

Due to the constant update of vehicles, fuse assignments depending on

equipment and the use of the same fuse for various electrical components,

at the time of printing this manual it is not possible to provide an up-to-date

summary of the electrical components fuse positions. For detailed informa-

tion about the fuse positions, please consult a Technical Service.

In general, a fuse can be assigned to various electrical components. Like-

wise, an electrical component can be protected by several fuses.

Only replace fuses when the cause of the problem has been solved. If a

newly inserted fuse blows after a short time, you must have the electrical

system checked by a specialised workshop as soon as possible.

Additional information and warnings:

● Working in the engine compartment ⇒ page 182

WARNING

The high voltages in the electrical system can give serious electrical

shocks, causing burns and even death!

● Never touch the electrical wiring of the ignition system.

● Take care not to cause short circuits in the electrical system.

WARNING

Using unsuitable fuses, repairing fuses or bridging a current circuit with-

out fuses can cause a fire and serious injury.

● Never use a fuse with a higher value. Only replace fuses with a fuse of

the same amperage (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple or similar.

CAUTION

● To avoid damage to the vehicles electric system, before replacing a fuse

turn off the ignition, the lights and all electrical elements and remove the

keys from the ignition.

● If you replace a fuse with higher-rating fuse, you could cause damage to

another part of the electrical system.

● Protect the fuse boxes when open to avoid the entry of dust or humidity.

Dirt and humidity inside fuse boxes can cause damage to the electrical sys-

tem.

Note

● One single consumer could have more than one fuse.

● Several consumers could run over one single fuse.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 223 of 258

221

Fuses and bulbs

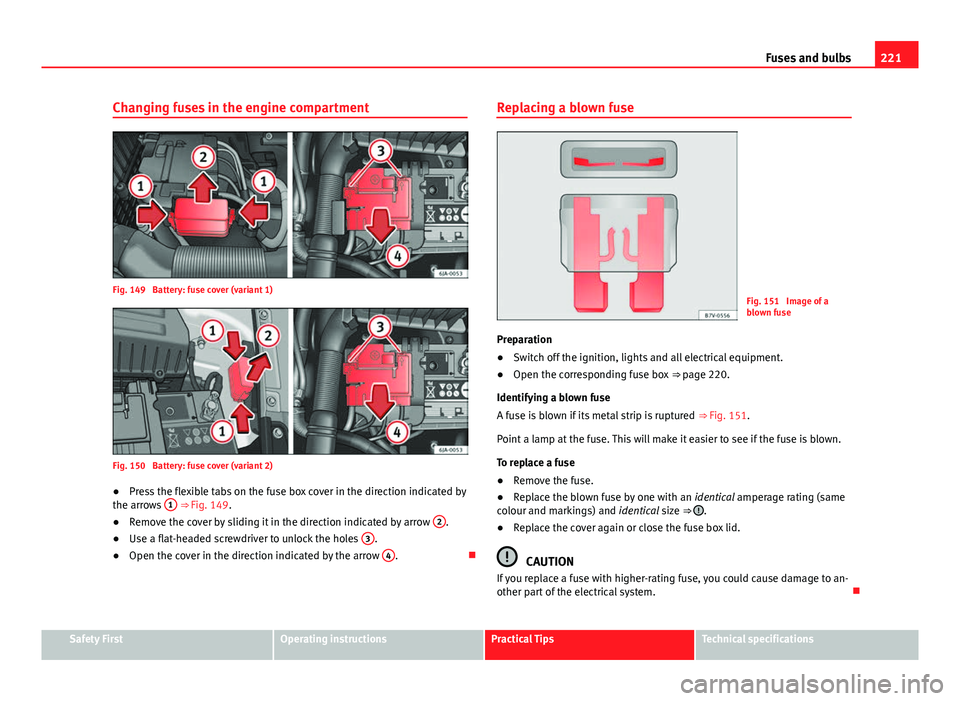

Changing fuses in the engine compartment

Fig. 149 Battery: fuse cover (variant 1)

Fig. 150 Battery: fuse cover (variant 2)

● Press the flexible tabs on the fuse box cover in the direction indicated by

the arrows 1

⇒ Fig. 149.

● Remove the cover by sliding it in the direction indicated by arrow 2.

● Use a flat-headed screwdriver to unlock the holes 3.

● Open the cover in the direction indicated by the arrow 4.Replacing a blown fuse

Fig. 151 Image of a

blown fuse

Preparation

● Switch off the ignition, lights and all electrical equipment.

● Open the corresponding fuse box

⇒ page 220.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured ⇒ Fig. 151.

Point a lamp at the fuse. This will make it easier to see if the fuse is blown.

To replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an identical amperage rating (same

colour and markings) and identical size ⇒

.

● Replace the cover again or close the fuse box lid.

CAUTION

If you replace a fuse with higher-rating fuse, you could cause damage to an-

other part of the electrical system.

Safety FirstOperating instructionsPractical TipsTechnical specifications