SKODA 120 LSE 1980 Workshop Manual

Manufacturer: SKODA, Model Year: 1980, Model line: 120 LSE, Model: SKODA 120 LSE 1980Pages: 238, PDF Size: 47.09 MB

Page 211 of 238

rill

,ili

I lzz

eslo+ ol doc eql uMop MaJcs

Puo esDeJo

qllM

ll IcDd 'doc

.to1ocl.tqnl iellnDts

eql

llo /v\ercs

s6ultDog dun4

rolDn1

lo uollDcllqnl

'PaDDruDP ll

'l! MoueJ puo pDeq

lloq eq]

rapun 6u1.r 6u1;oes

aql oslD eulrrDx3 '6u1.r

6u;1oas Meu D esn

'pe6otuop es!lvrraqlo lo pelrols!p s!

1! ,l 'uo!lcos

rDlncr!c lo s!

lMoq aql

roPun 6u;.r 6u11oes eql

'uo!lDz!l!qDls sl! reuo la^el llo eql

Iceqcer

puo eu16ua aq1 dols uaql'e6o1oa;

lol 6u;1unou

retl!l l!o eql

6u!lceq3 el!q/v un: eu16ua eql

lol 'lloq

eqt uelq6lt puo

au16ua aql uo JDlloc

6uglunotu aql uo

lMoq palquassD

eql acDld

6u1.rds q11m

elogd

lsnrqt eq]

prDMol spls s!ql qllM

luausle eql u.rn1 '(e1ou

u61aro1 to slueuele

Jotlll euos

lo osDc aql

s!

qc!qlvr) e1o1d eql u!

lDas uouoq

lDuotltppD uD

qllM psp!^o.rd s1

lueuala rellll aql

ll : eto

N

'Du1ua1so; rellll I!o aq1 6u;rnp

roam a^lsDrqD o1

lcelqns s1 6u1.r 6u;1oes

,{rp

V

'lloq oqr 6ur11o1su1a.r eroloq

l!o u!

pDeq

1oq

eql ropun 6ug.r 6ulgoes eq1 d;p o1

1a6ro; lou oC

'luaulple retl!l Mou aq] puD prDMlno

6ugco; e1old

lsnJgl-eql q11r*

6u1.rds aql

l! uo

peddd;gs

6u1noq

rauD lloq eLll

llDlsuler puD

lMoq eql

uDelc

' 'lmoq

oql ulorl

6ugrds sl! tlllM .req1e6o1

uMDlpqllM eq uDc l! puD pesDelel

s!

lueuele

roll!, eql 'pe^ouer

lloq aql

qllnn 'l/v\oq

eqr

Ioano ryrg puD

lloq e:luec eq] a^oueg 'eu16

-ua eql

lo apls

puoq-1q61r

oql uo

lMoq lDclrp

-ug1Ac D ul pallDlsu!

s!

lueuola rell!+

l!o aql

lueualS jall!J

l!o lo lD/t^euau

'lro eql 1o i(1tp1ng1 ecuoqua o1

dn

l! rrlJoM

o] aui!]

Uoqs D rol unJ eu16ua oql

]al

'au16ue ploc D urorl po

aq] 6u1u1orp erole€l

6n16 u1o.16 10 -

Z/C'SL '613 '(g';

.raldoqC oes enbrol

6u!uelq6!t sl!

.ro1) u1

li 6ulrvre.rcs

uaqrrr

6n1d aq1 6u1ua1q611

-.rano r(q pDolr{} eql

dlJls o} ou

In}aJDc eB 'euo

r.lrou D qtlMl!

eco;dal'e6o1oe; u!

llnseJ o1 i;e111

s! qc!qM

e6outop

;o su61s Auo

srvroqs 6n1d u1o.tp

duns ;go aql

lo 6u1.r

6u;1oes eql

ll :

e

1o N

'l! Iceqcar puo 'ez!llqDls

la^al l!o oql

1a; 'slorvrllo

er{t IID o}u!

se}Dr}euad

11o eql_ll!r

(a1nu1u D ,lorl lnoqo) stull

lroqs o .ro1 eu16ua

eql unu 'llo

qserl qurlt

eu!6ua aql

ll!l 'rell!l

l!o aql

puo

6npd ugolp druns

llo eql

pellDlsuler

6u;noq JaUV '(pa11anor1

sarleruol!l Jo Jeqrrnu

eql uo Dulpuedep) ouo /l^ou D qllM

lueuele

Joll!l aql ecolda: rolpuD

lmoq sl! uDelc

PUD

roll!l llo eql oslD

a^ouleu 'lno

/v\oll llo eql

lel

puo duns

l!o oql

uo.r1 6n1d

u!Dip eql e^oueu

e6uoq9 119

6nta

alog 6u1111J

t!O puo

>1c11sd!C

ltO -

L/0'91 '6lJ

'punolD

lo^al uo

pecold

oq plnoqs lDc aql 'le^al

llo aql

6urlceqc ueq6 'sllDM

aug6ue oql uorl uMop

Mol+ o] aull l!o oql

e^tgr '6utllll

JaUD Jo unr D

te1lo Alalogpauu! le^el t!o eql

lceqc lou oC

'asl'vtlcolclluD

11 6u11o1o.r

Aq 6n1d eql pa^oure: 6u1noq

lal1o

ro^oc poeq

lepu1;[c eq] ul aloq aql q6notql

l!o oqt

dn do1 'lq6leq

ulnulxDtx puD unullu!tu

s11 6u1>1.rotu seu!l eql ueomleq

1sn! eq

Plnoqs

qc!qM le^el lto eql

lcsqc o1

4c;1sd;p eql asn

le^o't l!O 6u;1ceqg

PuD ll9 dn'6u;ddo1

sfluossSccv sll cNv

lNleN3 8'9t

leqsDM usorcspu!/v eql

olu!

ISolcvle

rolDlpor eql

olu! ouolodg

X3ClUl

'6'a'(o1>1o^olsoqcazC u!) SfZSSUJIINV

Page 212 of 238

I-

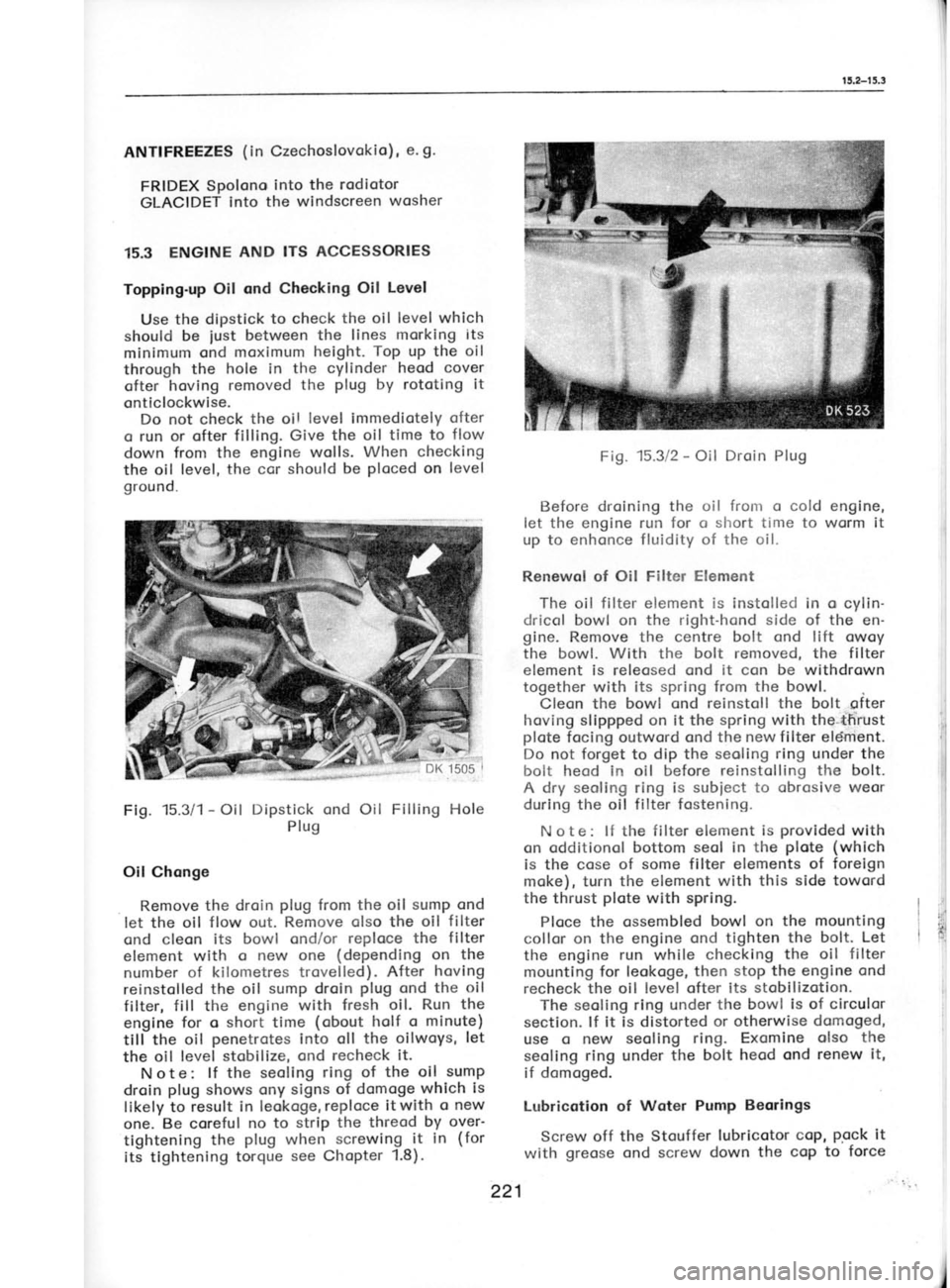

.'t Fig.

15.3/3 -

Oil Filter

oil f ilter bowl

witlr f ilter

element

centre-boll oil pressure

switclr pressure

oir. When driving often

on dusty roods,

ihe cleoning intervols

should

be shortened by

holf. For oir cleoner mointenonce in tropicol

re'

gions refer to

ChoPter 16.2.

Air Cleoner -

winter oPerotion

Remove the rubber

cop from

the cover exten-

sion orm ond

use it to stop the mouth of

the

orm. Fit o guide extension into

the cleored hole

in the ornr ond

insert the

corrugoted poper hose

(included in the

cor equipment) into

the

ex-

iension ond

the holder on the

intoke ond

ex-

houst monifold.

Give the

hose the required shope by

bending

it slowly ond corefully. Above

oll, ploce

it into

the holcier so thot

there is

o suff icient distonce

(wide enough to

insert o

finger) between it

crnd the exhot-tst monifold.

Tightening of

cYlinder heod bolts

The cylinder heod

bolts should be tightened

in the running-in period before

the gosket gets

settled ond then

ofter every replocement of the

gosket, i.e., ofter

obout 1,000

kilometres' For

itre tightening procedure,

s9e

Chopter

-2'16'

Check'ilg of vilve

cleoronce ofter

every tighten'

ing of tlie

cylinder heod

is o

routine procedure

which must not be omitted.

Volve Cleoronce

For checking procedures

ond odiusting volues,

refer to ChoPter 2.13.

Alternotor V'belt

Tensioning

Loosen the

nuts of the bolts

in the olternotor

f longe (fostening

it to

the engine ond

the strut)

ond'of itre

bottJ holding down

the strut on

the

olternotor, ond

swing

oside (tip)

the olternotor'

Adiust the

belt so

thot it gives

woy 10- to

15 mm midwoy between the

belt pulleys

when

depressed lightly (ot

if o- weight of obout

2 kg were opplieal with

the

finger ot this point'

LoCk the

olternotor in

this position

by tighten-

ing properlY

oll the nuts.

Belt dimensions: 9x9.5x1,0O0 mm.

To Cleon the

Distributor

The contoct breoker points, the

cover, ond

the rotor orm

of the distributor must never

be

greosy or dirty. Scrope off

ony burns on the

distributor cover.

lf you hove

cleoned the

distributor with

oetrol, do

not ref it the cover till ofter

the petrol

hos comPletelY evoPoroted.

222

oll

the greose

into the beorings. Tighten

the

cop thoioughly so

thot it connot be worked

loose by vibrotion.

Air Cleoner -

cleoning ond

replocing of

filter

element

Unclosp the cover

fostening clips

and lift

owoy the lid. Depress the

cross broce in

the

1ock6t, rotote

it

slightly to disengoge it, ond

withdrow the filter

element. Wipe

cleon the

inside of the

iocket, cleon

the filter

element or

reploce it with o new

one, ond reclose the oir

cleoner proceeding

in reverse order.

Shoke ond

top the filtet element to

rid it of

clirt porticles, oncl

blow it off ond through with

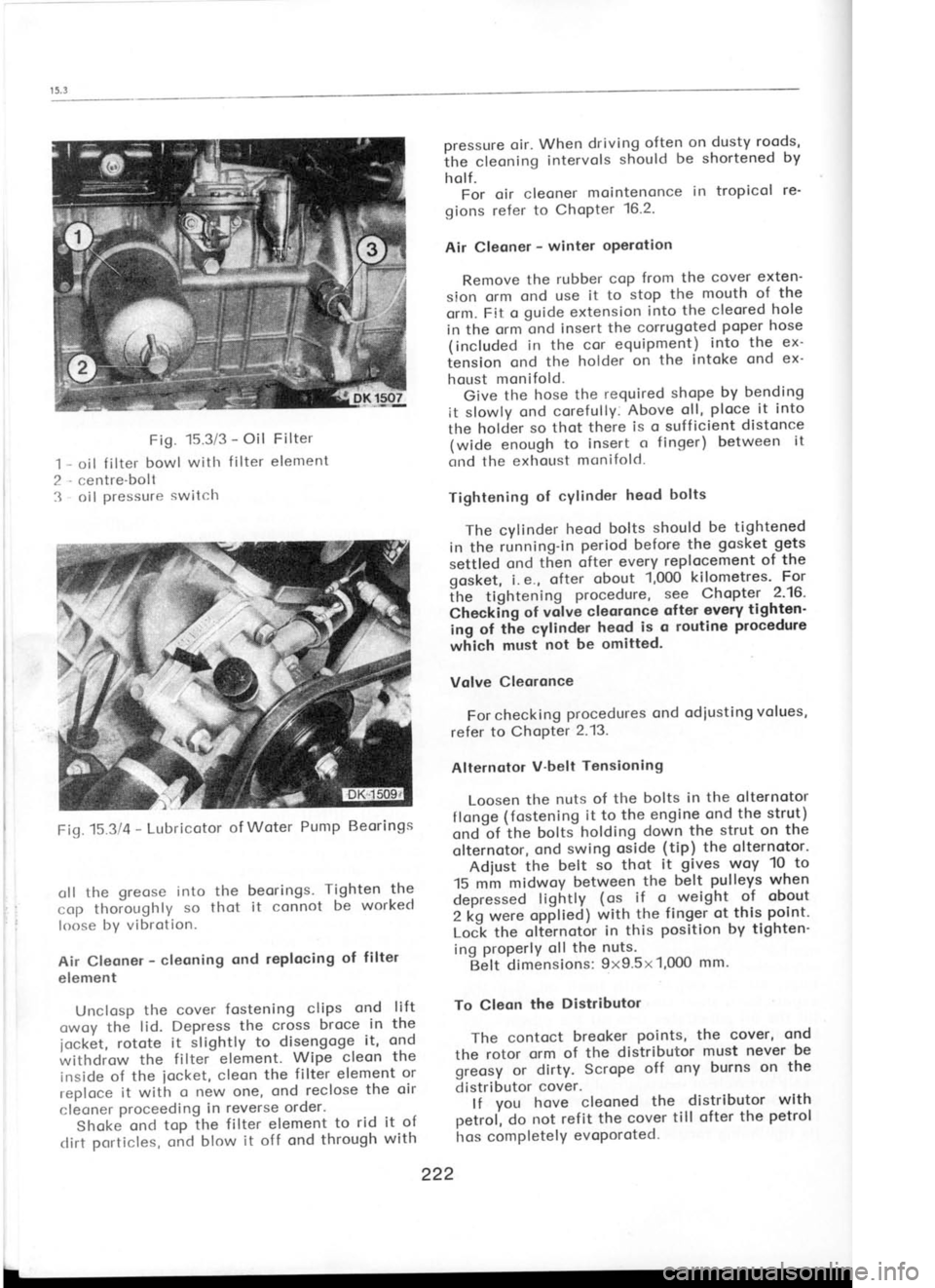

Fiq.15314

-

Lubricotor of

Woter Pump Beorings

Page 213 of 238

ezz

'lloq Aellnd lleq uoqs{uDr3 eql

}o Poaq aq} ol

pe!lddD JeuuDds D esn 'au!6ue

eql 6u;urn1 .ro1

'11oq 6uldruopc

otll 6u1ua1q6g1 Iq uo;11sod slql u! rolnqlrl

:slp aql ajncss 'eu16ue

eql ol elqDc oq] uorl

leno-1rods eql Aq pelllruapl

s! ocuD^po

les eLll

o1 6ulpuodsorroc lolnqlrls!p aqt

lo uotltsod

aq1

'l1mo1s ]! urnler

puD

as!rvrlcolc lotnqllls!p

aql

alDlou 'Icolq

aql qllm

l;enllcnpuoc pelceuuoc

pod au16ue Jaqlouo ro

lcolq :epu11{c eq}

uor}

uut g

ol

t to acuDlslP

D

]D elqoc eql

lo pue

eql

plorl puo (11oc

uo11;u6; tuo.r; pDel 't'g)

re,roc

rolnqlrls!p oql

'o lno alqDc

erluec eql

llnd 't

'uo!l!u

-6! otll uo qcllMs puD

lelcoiq sl! u! rolnqlrlslp

er{l 6u1p1oq lloq 6uldtuolc agt

uesoo-l 'z

'ecuDApD par;nbal aql

lo enlDn oql ol

le^oc

roe6 6u;tu1l aql uo >1.rou 6u1u1l sq] ol e1;soddo

los s! Ae11nd

lleq UoqsluDrc aql uo

)rDr! Dultull

eql loql os

(11oqs1uo.rc) eu;6ua eqt urni '!

:sp!o tnorlllM ernpaco.rd

6u;lsnlpy (oslulod 6ug1oc1.rqn1

rolnqtrlsrC -

llt'gL '6tJ

sllog uMop-ploH rolourollv -

9i0'SL '6ll

uolloledg Jalull"^. lo] esoH

PUD

sd;13 6uluetsDJ ra^oC rauDelC rlv -

9/0'91 '6ll

oZToS

oZ Tot sl

ozl puo

1 ozl vclo)$

1 901 PUD S

901 VAO)S

(1loqs1uorc uo parnsoeu)

senlon Eulues clsDg

ecuDApV uog11u61 clsDg

;o lueulsnlpy

'slcoluoc eql lo Duluedo eql

]o lceLlc rDl

-n6uo :o1 g'g;

.raldoqC eas 'rvra:csdoc

uMop-plotl

aq1 Buluesool JelrD Japloq

]cDluoc aq1

6u1nor-u

Aq do6 oql lsnlpD puo 's1u1od

ralDarq lcDtuoc

aql ueeMleq do6

lcerloo eql

ro' g'g1-

.to1doq3

ol Jelou 'ruDc

llot{s lo}nqlr}slp

eq}

}o }l!l

lln}

eql o] eu16ua eql urnl pLrD 'turD

.ro1ol eq1 'Iro

-ssecau l! 'puD

ia^os Jolnqlllslp eql e^ouou

dogr 1u;o6 ra{Dorg

lcoluoC Du;lsnlPY

'(sttO golcedg -

Z'9L.ra1doq3 o1

reler)

6u;loeq 6u11oc;.rqn1-114s oql

ol uo

11o 1u1od-

-rnod rvrog

1o;ceds o d1.rp

puo

6ulsnoLl lolnq!rl

-s!p aql

to tuolloq

eql uorl

lloq aql

e^otuer

'uollcedsug ec!^Jas o .to

tlode.r o 6u1rvto1;o3

'(tuo11oq rolnqlrls!p eq] u! oloq orlt

q6no.rq1 tno ivrol,

lllrvr l!o snld.rns)

ap;d :e1oa:q

tcDtuoc eql

ut eloq eql q6no.rql pallddo

l!o lo

sdo.rp engl ol rnol qllr*

6u!snoq rolnq!rls!p oql

u! loJluoc 6u1tu11

;o6n;;lluac eq] elDc!rqn-l

'esoal6 LgZ tu!]D!C

qllm ro ('cte 'V

xDulleu lleqS) alo141 u61ero1

1o

sesoare -

z'gL.re1doq3 ees

-

esDor6 qrtr*

Petac

-lrqnl oq oslD uoc 'uoc

eql'6uo1o 6ugp;1s

r1a1

eq1 6u1pn1cug 's1u1od

asoqf '1u!l

loJluoc ulnncon

aql lo u1d eq1

puo

alpulds rolor aql (dorp

euo) 11o q11r*

A16u;.tods

loog 'Plotl

lllM ]lal aql

so 'ruDc

aq] aplsu!

llsl aql

Puo tuDc

aq1 6uo1o

6u;p;1s llel er{l

uo

llo qcnu

os dgtp puo 'r.u.ro

JoloJ eql PUD Je^oc

Jolnqlllslp

eq] a^oueu

rouqlrlslo oql elDclrqn'l ol

Page 214 of 238

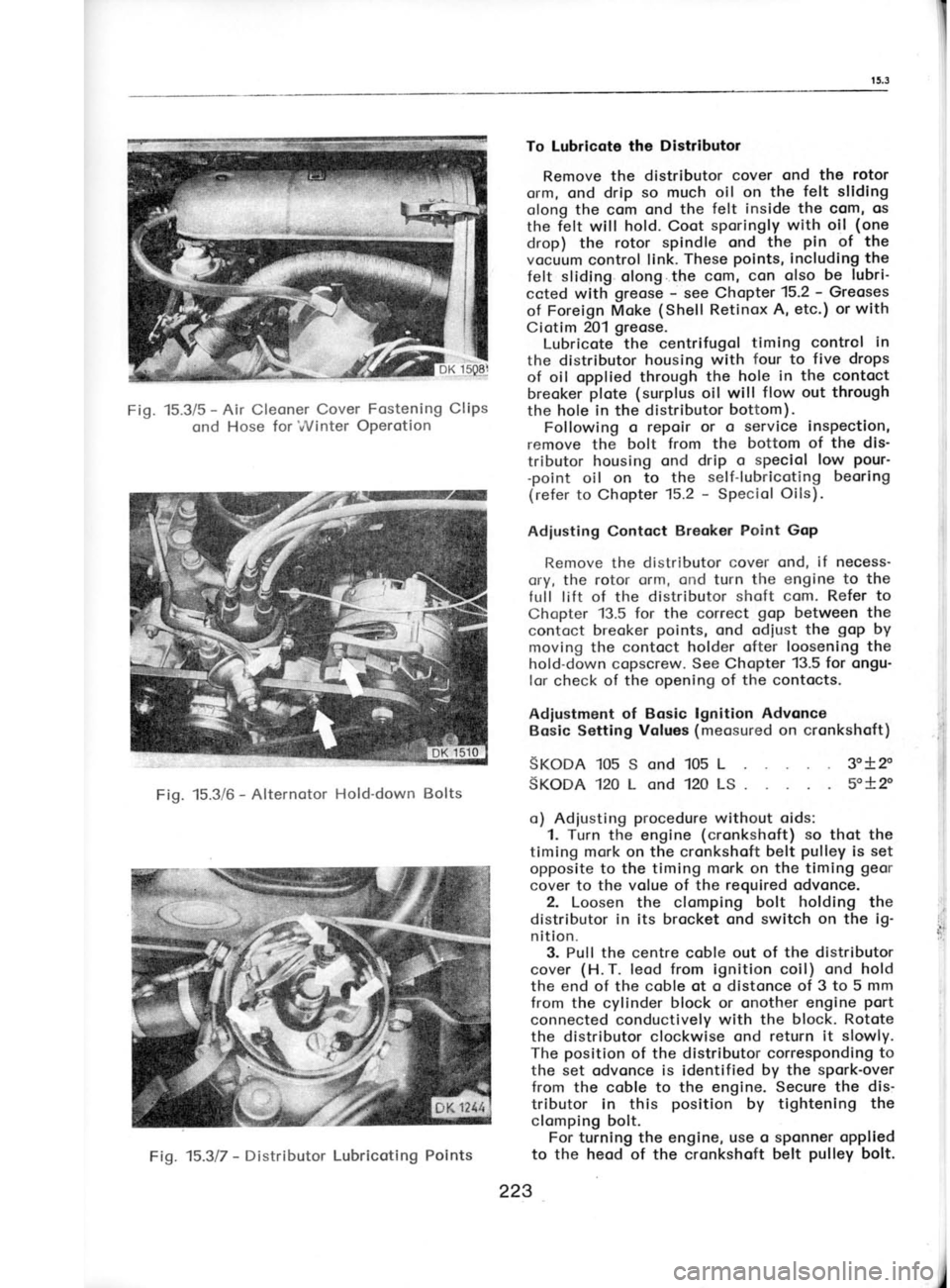

Fig.

15.3/8 -

Distributor Adiusting Elements

1 -

contoct holder, 2 -

rotor orm, 3- com,

4 -

distributor brocket, 5 -

distributor brocket

clomping bolt

Alwoys turn the engine clockwise to eliminote ony ploy

in the distributor drive geor

ond to

ovoid loosening of the bolt. To relieve the

com-

pression resistonce, it

is recommended to bock

off the sporking plugs.

b) Stroboscopic method:

When using this method, the volues of the

bosic ignition timing ond

the odvonce con-

trolled by the centrifugol timing control (for

its

diogrom refer to Chopter 13.5) should be odded

upwhile multiplying bytwo

the odded upvolues

occording to the diogrom. Any effect of the

vocuum control must be

eliminoted by discorr-

necting the respective hose (connecting

the

distributor vocuum unit with the corburettor).

The meosuring procedure

is indicoted by the

diognostic equipment itself.

To Adiust ldling Speed

Use the oir-correction screw (speed

cor-

rection screw). The speed decreoses when ro-

toting the screw clockwise ond increoses when

rototing it onticlockwise.

Adiust the idling speed in occordonce with

the tochometer ond within the limits specified

in the following porogroph "To

Adiust ldle

Run". The engine must be wormed-up

before

storting the odjusting procedure (see

olso the

following porogrophs) ond its ignition must be

in perfect

condition (distributor

contoct-breoker

points, sporking plug

electrodes, ond ignition

odvonce).

N o t e : For the bosic position

of the odiusting

screw refer to Chopter 2.19 - "Mointenonce

ond

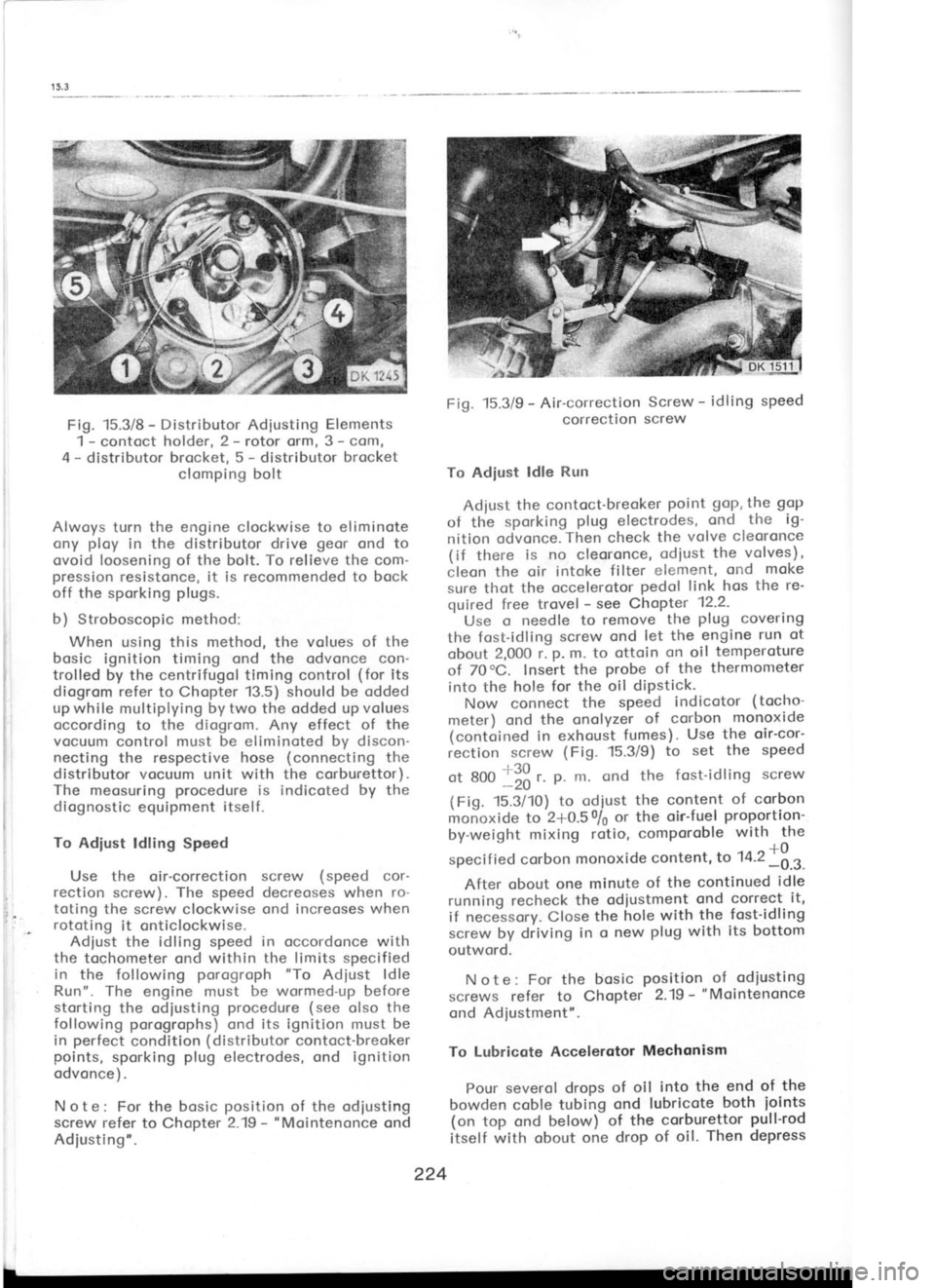

Adiusting". Fig.

15.3/9 -

Air-correction Screw -

idling speed

correction screw

To Adiust ldle

Run

Acljust the contoct-breoker point

gop,

the gop

of the sporking plug

electrodes, ond

the ig-

nition odvonce. Then check

the

volve cleoronce

(if there is no cleoronce, odiust

the

volves),

cleon the oir intoke filter

element, ond moke

sure thot the occelerotor pedol link hos

the re'

quired free trovel -

see Chopter 12.2-

Use o needle to remove the plug

covering

the fost-idling screw

ond let the engine run ot

obout 2,000 r. p.

m. to ottoin on oil temperoture

of 70oC. Insert the probe

of the thermonreter

into the hole for the oil diPstick'

Now connect the

speed indicotor (tocho-

meter) ond the onolyzer of

corbon

.monoxide

(contoined in exhoust fumes). Use

the oir'cor-

iection screw (Fig.

15.3/9) to set the

speed

-r-?n

at 800 l;; t.

p. ni. cnd the fost-idling screw

(Fiq. 15.3/10) to odiust the

content of corbon

moioxide to 2*0.50/s or the oir-fuel proportion-

by-weight mixing rotio,

comporoble with

the

specif ied corbon monoxide content, to

1+.2 +$.t.

After about one minute of

the continued idle

running recheck the odiustment ond

correct it,

if necelsory. Close the hole

with the

fost-idling

screw by driving in o

new plug with

its bottom

outword.

Note: For the bosic position of

odiusting

screws refer to Chopter 2.19 - "Mointenonce

ond Adjustment".

To Lubricote Accelerotor Mechonism

Pour severol drops of oil into

the end of the

bowden coble tubing ond lubricote both

ioints

(on top ond below)- of the corburettor pull-rod

itself with obout one drop of oil. Then

depress

224

Page 215 of 238

![SKODA 120 LSE 1980 Workshop Manual 9ZZ

aqt lo lDeM

oql qll/v

AllDnPDlD sesosJceP ttlsluD

-qceu lnomorq] eql

to lo;d

A.rossaceu eql

luarulsn!PY

llaM l!o e^eols

aql ul

lle eql

uo

]carlp lro eql .rnod

-to 6u1

-.roaq (1 SKODA 120 LSE 1980 Workshop Manual 9ZZ

aqt lo lDeM

oql qll/v

AllDnPDlD sesosJceP ttlsluD

-qceu lnomorq] eql

to lo;d

A.rossaceu eql

luarulsn!PY

llaM l!o e^eols

aql ul

lle eql

uo

]carlp lro eql .rnod

-to 6u1

-.roaq (1](/img/3/57425/w960_57425-214.png)

9ZZ

aqt lo lDeM

oql qll/v

AllDnPDlD sesosJceP ttlsluD

-qceu lnomorq] eql

to lo;d

A.rossaceu eql

luarulsn!PY

'llaM l!o e^eols

aql ul

lle' eql

uo

]carlp lro eql .rnod

-to '6u1

-.roaq (1nomo:ql) esoalar qclnlc

eql

lo e^eels

osDeler eql

]o lle/v l!o eqt olu! uMoP

Moll

lilM

ilo eql

qc!qM

uoJl re^el esDslal qclnlc

eql

+o

ssecer eJluec eql olul po

1o sdorp

ZL ol

OL Jnod

',rapu1lAc esDolar Llolnlc eql ]o Ja^oc el!lolDq

aql lor*o

U!l puD

6u1.rds eq1 lomo 6u1r*s uaql

'sloes rDor eql pulqeq

luaulroduroc a6o66n1

eqt

ur pJDoq

Joolt eql

,o Ja^oc

sJluec eq] a^oujeu

uollDc!rqnl

HCrnlC t'S!

reurDrls rolleinqrDC -

0L/t'gl '6!l

zrsL yo

uaarcs qllM

lMoq a6pnps -

7

.rana; 6u1tu1.rd dund -

;

uls tuDqcolA

rotoreleocv ,o uorlDclrqnl

-

6/t'gL '6!l dLun6

1111 lonJ -

LLlt'gt '6tJ

'u o !l!

-sod pelcol sl! ul aulotl slcrl3

]l lirl sprorvrdtt

ra^al aql 11nd uaql '.rarra1

6uttuud aq1 6utlonlco

Iq lenl gllrrr

dund eq1 er,u1.rd 'Arossecau

;;

'a>;ol aqt +o tnu aql

6u1ualq6r1

{q uorllsod ut lMoq aq}

arnoes 'lMoq

eql otru!

lDas eql LlllM

]l llDlsLreJ puo

1o.r1ad u! uearos

eql qsDM 'lDes

puD ueercs aql 6u1pn1cu!

lMoq

aql ADMD 1l!l puD

lMoq aql

to Luolloq aql

]D

(puoq lanoc) a>1oA aqt

lo 1nu eql

'ro {cDB

lmog a6pnlg

dun4

lanl uDelC

ol

'sseceJ anllcadsa.r

aqt olu! ig6nus s1l

l! loql os Mercs

6n1d eq1

]o plo

aq] qllM

l! llDlsuler puD

loas uo-paddtls

aql qllM

Marcs 6n1d aql uo

11 acu;d

uaql 'llo

ll Molq

puo

;ol1ed u!

ll llrMS 'tau1ol1s

aq1 {omo

llll 'lalur

lanl eLll

lD /v\arcs 6n1d

aqr e^oueu

,teulorls ,ollernqloc uoalc ol

'6ugqn1 uepMoq

eq] olu! requn'

lro aql

Ar.roc po.r-;1nd

aq1

1a1

01 soru!1

lDle^os ;opad lolo.relacsD

aql AlMols

6n1d ctlsold D

ql!M

Pasolc

sl 1l ol ssecco -

rnrrarcs 6ur1p;-1so1 -

0llt'91 '6!l

Page 216 of 238

friction focing. lnodequote

ploy

results irr o too

short free trovel of the clutch pedol

ond on

olmost immediote clutch disengogement. Access

to the releose

cylinder con be goined

os de-

scribed in the previous porogroph

on clutch

lubricotion. Hold the rod protruding from

the

relose cylinder ond force

from it corefully the

releose lever, ogoinst which it is restingi

the

lever con be relieved by disengoging the ten-

sion (pull-off

) springs.

ln service, the forcing-off

must be ot leost

2 mm. Adiust it to 4

to 5 mm by odiusting the

length of the rod. After hoving

loosened the nut

on the rod

of the releose cylinder, rotote

the

releose finger to obtoin the correct rod

length.

Then retighten the nut, thus locking the releose

f inger in its position

on the rod.

lf the ploy

is correctly od justed,

the f ree

trovel of the

clutch pedol

pod should ronge

from 40 to 50 mm. lt should not be ollowed to

drop below '!0

to 15 mm. lf the described od-

justing procedure foils to bring the required

result, it is necessory to odjust the clutch

mech-

onism in occordonce with

informotion con

toined in Chopter 3.2.

Bleeding the Glutch Hydroulic System

The movement of the clutch pedol

is trons-

mitted hydroulicolly to the clutch releose cylin-

der. The couses ond symptoms of penetrotion

of oir into the hydroulic

system (similor

to the

broke hydroulic system) ore described in detoil

in the section deoling with brokes. The pro-

cedure of bleeding the clutch is the some os

wherr bleeding the brokes -

see Chopter 15.8.

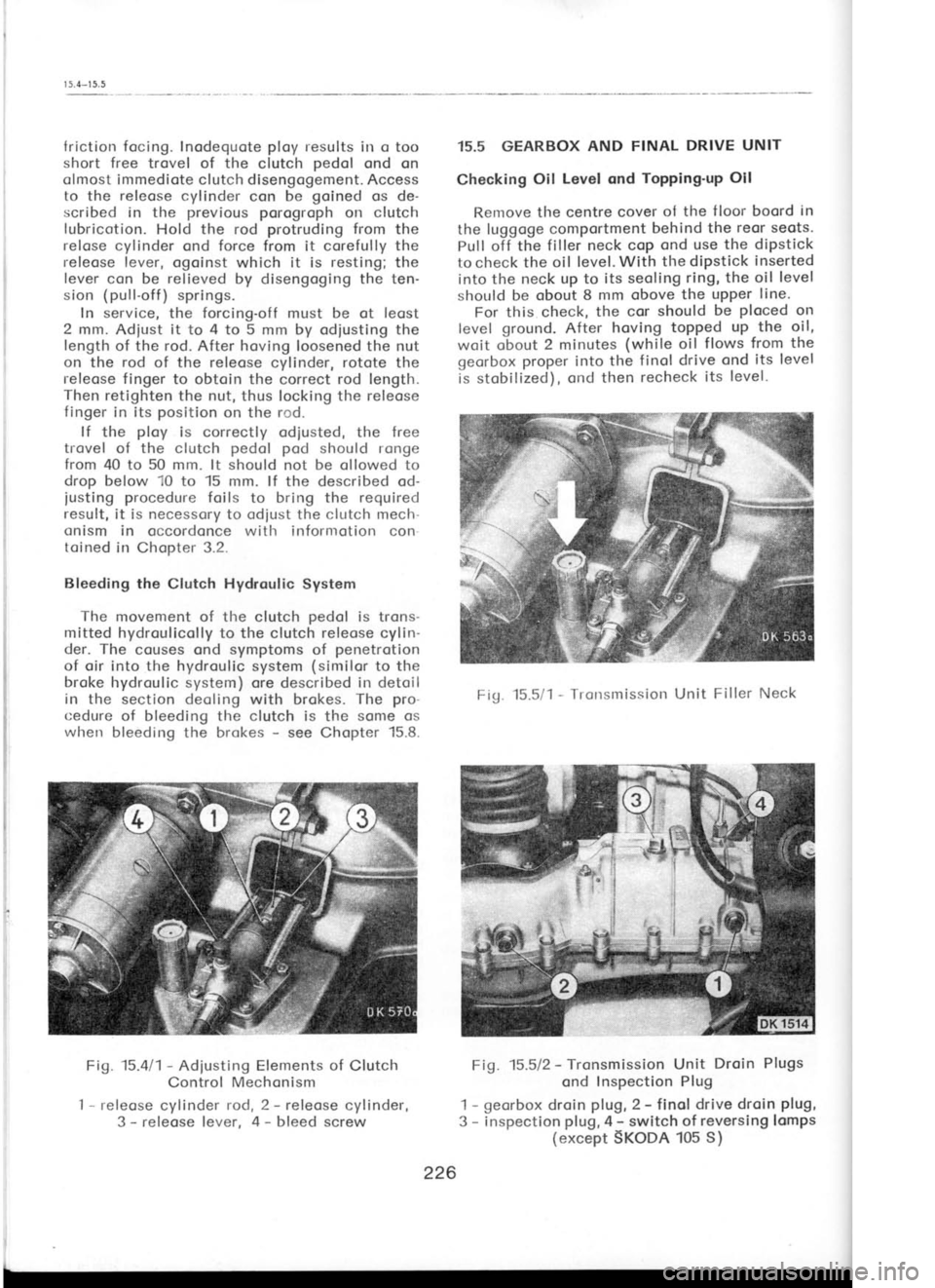

Fig. 15.411-

Adiusting Elements of

Clutch

Control Mechonism

I -

releose cylinder rod, 2 -

releose cylinder,

3 -

releose lever, 4 -

bleed screw 15.5 GEARBOX

AND FINAL DRIVE UNIT

Checking Oil

Level ond Topping'up

Oil

Renrove the centre cover ol the

f loor boord in

the luggoge comportment behind the

reor seots.

Pull off the filler neck cop ond use

the dipstick

to check the oil level. With the diPstick inserted

into the neck up to its seoling ring, the oil level

should be obout 8 mm obove the upper line'

For this check, the cor

should be ploced

on

level ground.

After hoving topped up the oil,

woit obout 2 minutes (while

oil flows from the

georbox proper

into the finol drive ond its level

is stobilized), ond then recheck

its level-

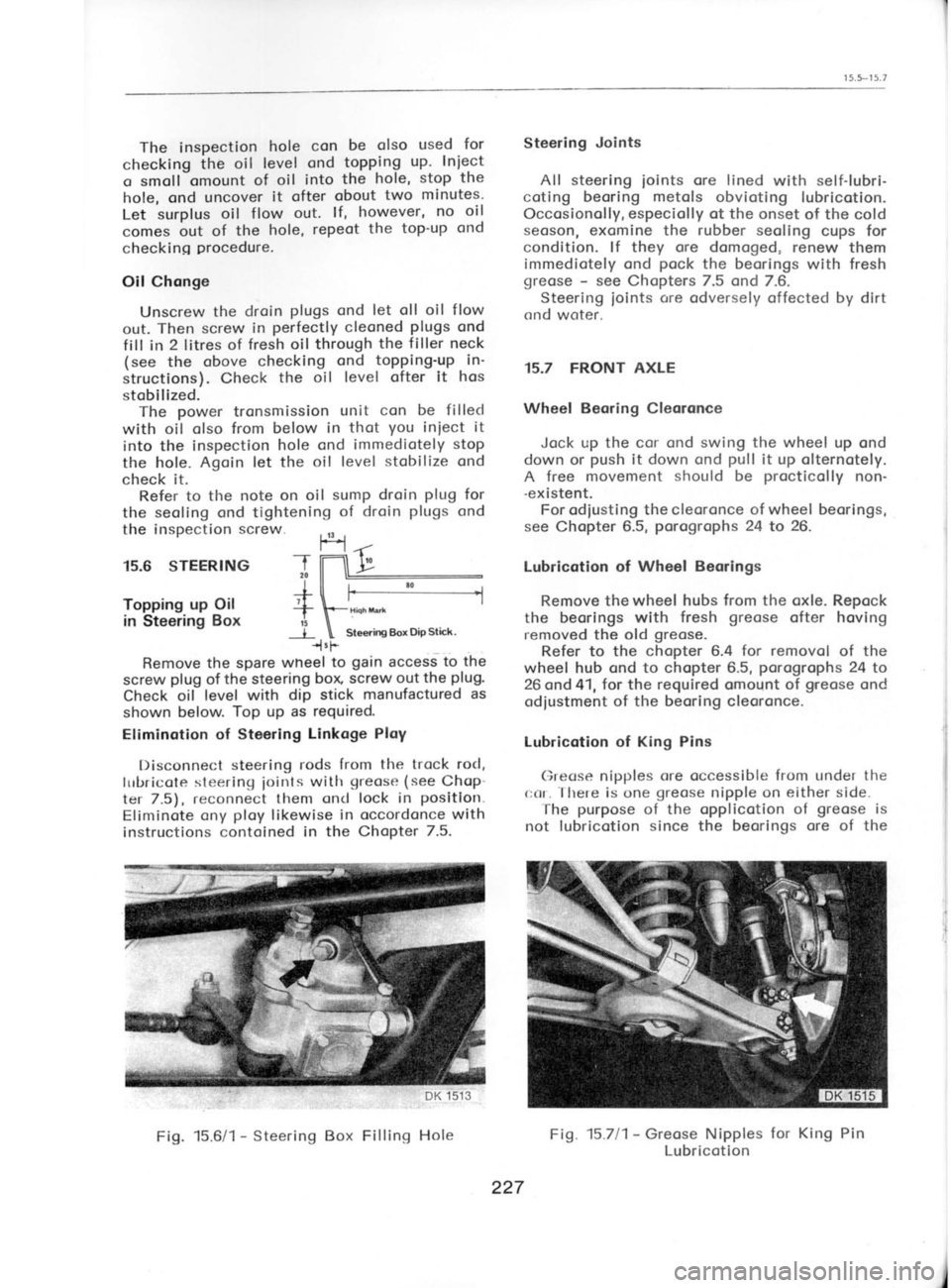

Fig. 15.5/1 -

Tronsmission Unit Filler Neck

Fig. 15.512 -

Tronsmission Unit Droin

Plugs

ond Inspection Plug

1 -

georbox droin plug,

2 -

finol drive droin plug,

3 -

inspection plug,

4 -

switch of reversing lcmps

(except SKoDA 105 S)

ffi

;rt'i,*

tiiffi

ii.! i;

br'ill

226

Page 217 of 238

LZZ

uo!lDc!Jqnl

u!d 6u!) rol sslddtN osDere -

LILgL '6lJ

aql lo eJD s6urrDeq aql

ecu!s uo!lDstrqnl

lou

sr osDer6

lo uollDc!lddo eql

;o asod:nd

eq1

'eprs reql!e uo e1dd1u asoe:6 euo sr

eratl

l- rD:)

aql repun lrroJ] olq!ssoccD eJD selddru ilsno.rt)

su16 6u1; lo uollDcllqn'l

'ecuDJoalc 6u1:oaq eql

lo truaulsnlpo

puo asoer6

lo lunoruD pallnbe;

eql Jol'LVpuogZ

o1 77 sqdolBorod 'g'g

reldoqc ol puD qnq

leoqM

eql lo lD^oruer rol

t'g .raldoqc eqt ol Jeleu

'asoar6 plo eql po^ouar

6u1noq rouo osoe.r6 qsa.r1 qlll

s6ulrDeq eq]

1codey 'elxD

eql urorl

sqnq

leaqM aql

enouau

s6ulroeg leeq/v to uollDclrqn'l

'gZ ol g7

sqdorDorod 'g'g

.ra1doq3 ees

's6u1loeq leeqrl'rto eouoloelc aql 6u;lsnJpo.ro3

luals!xe-

-uou I;locglcord aq plnoqs

luaus^our eer]

V

'I1e1oure1;o dn 1r ;1nd puo

uMop

1g qsnd

ro uMop

puo dn

leeqM eq1 6ulrvrs

puD

loc eql dn >1co1-

ecuDJDelC 6u;roeg laaq1

31XV INOUJ I'91

'JAID/!| put)

frlp Aq

palralto

Alasranpo erD slulol 6u1rae1g

'g'l puD g'2 sleldoqC oss -

asoar6

qsorl q]!M s6ug.roaq eq1

lcod puo

l;a1o1pauru1

ueql Meuar 'pe6ouop

a:o iaql ,l 'uo!l!puoc

:o; sdnc 6ug;oas Jeqqnl eq] eu!uJDxe 'uosDes

ploc eql

lo lesuo eql

lD l1;orcedsa'i11ouo1soccg

'uo!lDc!rqnl 6u;1o1nqo slDleru 6u;.roaq 6u11oc

-!rqnl-,les r.l]!rvt peurl

a.ro s1u1o! 6u1leels

11yalog

6u1111J xog 6ut:aelg -

L/g'gL '6!J

'g'7 raldoqc oql u! peu!oluoc suo!]cnrlsu!

ql!ivr ecuoproccD ut es!rrtsl!l Aold Iuo eloultu!l:l

r:ol1gsod u! lcol puD

ruaql

lceuuoJar '(g'l

lat

doqC aes) asoa.rti rll!M sluto! 6u1.raals oloo!Jqnl

'J)oJ IoDJI eql

uor1 spo-r 6ultaels

lceuuocs!(l

An14 a6o4u;1 6u;ree1g

lo uollDultullf

'paltnbel se dn do1 '/l^oleq

umoqs

se pojnlcelnueuJ

lclls dlp

qrlinr,

la^al llo lceqS

'6n1d aq1 lno Melos

l(oq outlaels eql

lo 6n;d

nne:cs

aql ol lsocce uteb ol

leeu/vl eleds

eq] a^otuou

-T-- 9t

+ J_ I

t

t-J

I e!l .MoJcs

uollcadsul aq]

s6n1d ulorp io 6u1ua1q6ll

puD

6u11oes aq1

xog 6upealg

ur

llO dn butddol

9NrU33rS 9'9t

puD

ro] 6n1d ugorp dr.uns

;go uo

elou aql ol raleu

l! Iceqc

puD ez!ltqDls

le^31 lro eLll

141 u1o6y 'eloq

aqt

dots Ilalo!peuu.r! puD

eloq uoglcadsul eqt olu!

it tcalu! noA

1oq1 u! Molaq

uorl oslD

llo qllM

pell!i oq uoc

llun uolss!ulsuD.r1

.rervrod

eq1

'pez!llqDls

sor{ 1! JaIJD

le^el lro eql

)caqc '(suol1cnr1s

-u! dn-6ugddol puo

6u;1caqo e^oqD

aql ees)

lceu rell!l aql

q6norql

l!o qserl

'o sarl!l

z u!

ll!l

puo s6n1d peuDelc

lllca;led u! Mercs

ueql 'lno

Moll l!o llo lol puo

s6nld ulorp eq]

Marcsun

e6uoqS 1;9

'ajnPasolcl Du!)caqc

puo dn-do1 aql

loeda: 'aloq

eql ,o lno seuoc

i1o ou 'larennoq

';;

'lno

Moll 11o snldlns

1a-1

'selnulu o/v\l lnoqD JeuD

ll Jenocun

PUD 'eloq

sLll dols 'eloq

aql olu!

llo lo lunoulD-

llDuls D

1c'elul 'dn

6ulddol puD

le^el l!o eql

6u!lceqc

Jol pesn oslD

aq uoc eloq

uo;lcadsu; eq1

e19t

yo

t'l-

I EtJ St sluloft

6u;raa15

Page 218 of 238

I 5.7*

1

5.8

sell-lubricoting type

but the greose is intended

to rid the beorings of ony moisture which moy

get to them post

the seols in certoin circum-

stonces. Apply the greose

gun

till the lubricont

seeps post

the upper rubber cuP.

Front Wheel Toe-in

For meosuring

ond odiusting the toe-in, see

Chopter 6.1.

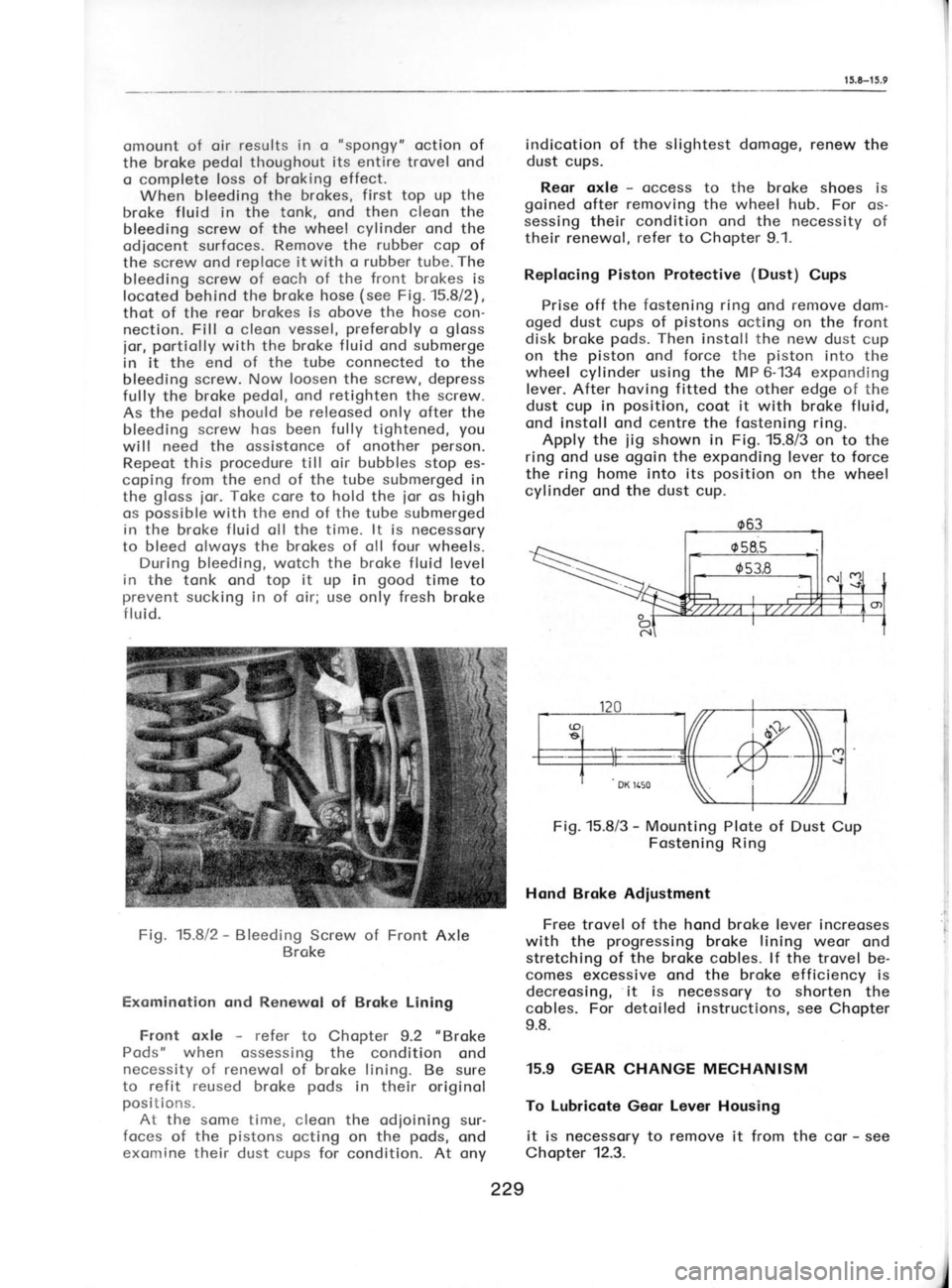

Fliminqtion of

King Pin PloY

Remove the coter pin

of the king pin

nut ond

rotote the nut to the next cotter pin

hole pos-

ition. lf the ploy

is not elinrinoted ond no

friction sets in with the nut in this position,

continue rototing it

until this condition is

ochieved -

see Chopter 6.5, porogroph 21. Lock

the nut in the f irrol position

with the cotter pin

Fig. 15.712 -

King Pin Hold-down

cnd Adjusting Ntit

Note: irr the list

of servicing (mointenonce)

iobs,

I,he porogroph on "Checking

Front ond Reor

Wlreel Brokes" includes

o) inspection of the broke-shoe lining ond its

replocement, if necessory

b) in the cose of the front broke, the cleoning

ond inspection of the protective (dust) cups

of pistons octing on the broke pods (shoes),

in the cose of the reor broke, the inspection

of the wheel cylinder dust cups (boots),

ond

in both coses the replocement of domoged

ports.

i5.8 BRAKE SYSTEM

Broke Fluid Tonlk -

filling

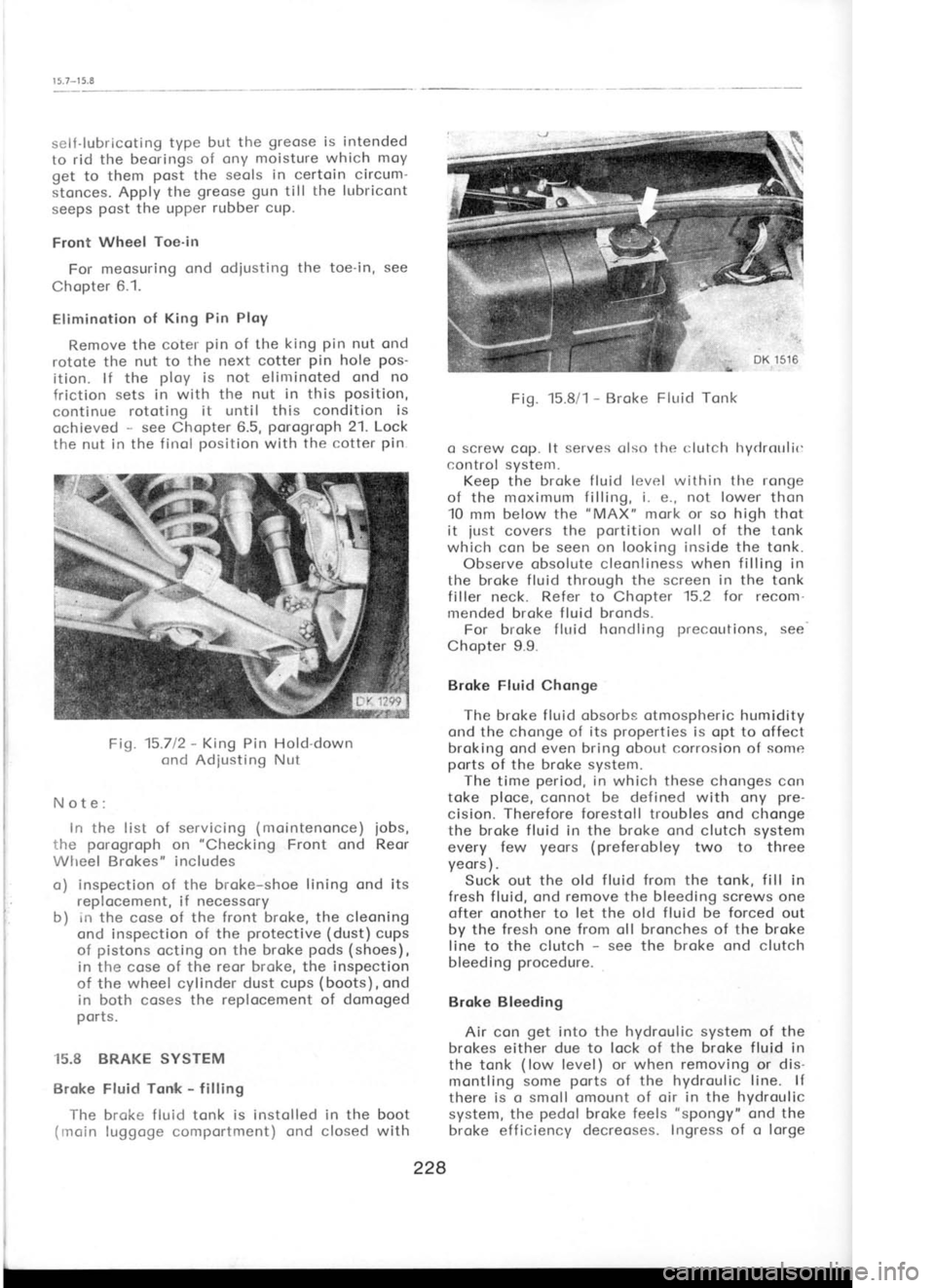

The brake f luid tonk is instolled in the boot

{inoin luggcrge comportment)

cnd closed with Fig.

15.8/1 -

Broke Fluid Tonk

o screw cop. lt serves

olso the r:lutclr lryrlrotrlic

control systenr. Keep the brqke fluid level withirr tlre ronge

of the moximum filling, i.

e., not lower

thon

10 mm below the "MAX"

mork or so high thot

it just

covers the pcrtition

woll of the tonk

which con be seen on looking inside the tonk.

Observe obsolute cleonliness when filling

in

the broke fluid through the screen in the tonk

filler neck. Refer to

Chopter 15.2 for recon'r.

mended broke fluid bronds. For broke fluid hondlinq precoutions, see

Chopter 9.9.

Brqke Fluid Chonge

The broke f luid obsorbs otmospheric humidity

ond the chcnge of its properties

is opt to offect

broking ond even bring obout corrosion of some

ports of the broke system.

The time period,

in which these chonges

con

toke ploce,

connot be defined with ony pre-

cision. Therefore forestoll troubles ond chonge

the broke fluid in the broke ond clutch system

every few yeors (preferobley

two to three

yeors ) .

Suck out the old f

luid from

the tonk, fill in

fresh fluid, ond remove the bleeding screws

one

ofter onother to let the old fluid be forced out

by the fresh

one from oll bronches of the broke

line to the clutch -

see the broke ond clutch

bleeding procedure.

Broke Bleeding Air con get

into the hydroulic system

of the

brokes either due to lock

of the broke fluid in

the tonk (low

level) or when removing

or dis-

montling some ports

of the hydroulic line. lf

there is o smoll omount of oir in the hydroulic

system, the pedol broke feels "spongy"

ond the

broke efficiency decreoses. Ingress of o lorge

228

Page 219 of 238

6ZZ

't'zl reldDr{c

ees -

JDc eql uoJl l! e^oueJ ol AJDSSocau s!

l!

6ulsnop relel rDee

elDclrqn-l oI

WSINVHC3W :IoNVHC UV39 6'9t

'8'6

:a1doq3 ees 'suollcnJlsu!

pallDlep rol 'selqDO

erll ueyor.ls ol A.rossecau sr

11 '6ugsoercep

sr icuelcl;le eIDJq aql puD

ellssecxa seuoc

-eq le^Drl eql

ll 'salqDc

elDrq aql lo 6u1qc1er1s

puD roeM 6u1u11 elorq 6u1ssa.r6o:d eq] qllM

sesD€Jcu! re^el alDrq puDq

eql

lo la^DJl eeJJ

luaulsn!py elorg

puDH

6u1g 6u1ua1so3

dn3 1sn6 +o elold 6u11uno61

-

t/8'gl'6tJ

'dnc lsnp eql

puD

repulllc

leeqM eql uo

uogllsod sll olul auoq 6u1.r eql

acJol otr lene1 6ulpuodxa aq1 u1o6o asn puo

6u1.r

eq] ol uo

t/8'91 '69

ut uMoqs 6tl

aqr ilddy

'6ug: 6ulualsDl eql erluec puD

llDlsu! puD

rp!nll e)DJq qllM

ll looc 'uorlgsod

u1 dnc

lsnp

aq] Jo a6pa :aq1o eql

pallll

6u;noq reUV 'ra^el

6urpuodxa tel-g dU1; eql 6ulsn .rapu1lic

leeqM

aql otrur uolsrd eql acrol puo

uolsgd eql uo

dnc lsnp Meu

eql

llDlsul uaql 'spod

e)Drq )srp

luorl aq]

uo 6u11co suolsld

;o sdnc

lsnp pa6o

-uop e^ouer puD

6ur.r 6ugualsDl eLll

]jo aslrd

sdn3 (1sn6)

en;1celord uolsld 6ugcoldeg

'1-'6 :a1doq3 ol Jelei 'lDMauer

r!oql

;o Allssacau

eql puD

uorl!puoc r!sql 6ugsses

-so ro3 'qnq

leeqM eqt 6u!^oLuer reUD

pau;oD

s! sooqs elDJq eql o1 sseccD -

elxD lDeu

'sdnc lsnp

eql rvreusr 'a6ou.rop

lselqDr;s eql

Jo uo!lDc!pu! Auo

lV 'uo!]!puoc

.ro; sdnc lsnp Jleq] eurmDXa

puo 'spod

aq] uo 6u11co suolsld

aq+

'o sa3D+

-rns 6uturolpo eqf uDelc 'auJrl

aulos eql ]V

'sr:orlrsod

1ou16;.to rtaql u! spod

alDrq pesner

ltler 01

erns eB '6u1u1g

elo:q lo 1Dltneuar

;o Alrssecau

puo uolllpuoo eql 6u rssasso ueLlM

,, spDd

elDJ€,, 7'6 reldoqC ol Jelar -

alxD luot j

6u;u;1 e{DJg lo lD/v\eueu puo

uollDulruoxf

ETDJB

elxv luorl Jo Mercs

6utpealg -Zlg'gL '6lJ

'p!n tl

e)Drq qsarl

lluo asn :JrD

;o u; 6ur>1cns

luenard

ol aur!l poo6

u; dn

]r dol

puD

luDl eqt ul

le^al prnll

a)Drq eqt qcloM '6u1pea1q

6u1.rn6

'slseqM rnoj llo ]o sa)orq

eq1 siorvr;o peelq

ol

fuosseceu sl

1l 'eull

eql llo prnll

a>lorq eq] u!

pe6.rer,uqns aqnl oq]

lo pus

aql qllM

e;qgssod so

q6rq so.rol aql ploq

ol aJoo alol'.rol sso;6 eql

u1 paD.reuqns

eqn] oql

lo pue

eqt uo.rl 6u1doc

-sa dols selqqnq rlo

llll e:npecord

stql

loedag

'uosrad JeqlouD jo

acuols!ssD eql peeu

ll!M

nol 'paue1q611

{11n; uaeq soq Mercs 6u;peelq

eql raUD A;uo pasoaler

eq plnoqs

lopad aql sV

'Mercs aqt uetq6psr puD 'lopad

alorq aq1 A11n;

sserdep 'MeJcs

eq] uesool MoN 'MeJcs

6ulpaepq

eql o1 pelcauuoc

eqnl aql

]o Pua aql

l! ul

o6rauqns puD p!nll

eloJq aql qlrm I11otl.tod '.tol

ssol6 o Alqora;a.rd 'lesse^

uDalc D ll!J 'uotlcau

-uoc asoq aql e^oqD s! se)orq roer 3ql

]o loql

'(Zlg'gt '613

oes) esoq alDrq eql pulqeq

pelocol

sr selorq luor+ eq]

,o qcoe

]o MeJcs

Burpaalq

eLlI'aqnl raqqnr D ql!M

11 acoldar

puo

Marcs eql

;o doc reqqnr

oql aloueu 'secolJns

luacolpo

aql puD

.rapulli{c

leeqM sql

lo Melcs

6u;pealq

eql uDelc ueql puo'IuD]

3qt u! ptnll

eIDJq

aq1 dn do1

1sr;; 'selorq

aql 6ulpaalq ueqM

'lcella 6ur>1o.rq lo ssol

elelduoc o

puD le^Drl arlue s1g

1noq6noq1 ;opad eloiq eql

jo uorloD

,,A6uods,, D u! stlnse't

JtD

lo lunouD

6'S1-8'gl

Page 220 of 238

r

5.9-15. r

2

Dismontle the housing, remove

old greose,

cleon the individuol ports,

opply fresh greose,

ond reossemble the housing. Sook the felt rings

on the links (pull-rods)

in engine oil.

15.10 WHEELS AND TYRES, SNOW

CHAINS

Tyre Inflotion, Boloncing

ond lnterchonge

of Wheels

The procedures ore outlined in

Chopters 10.1

through 10.3. Snow

choins ond their use ore

deolt with in Chopter 10.6.

Wheel Toe-in -

see Chopter 16.1.

Shock Absorbers -

see Chopter 8.3 "Shock

Absorbers ".

15.11 ELECTRTCAL EQUTPMENT

Checking electrolyte level ond topping up --

see Chopter 13.2.

Sporking plugs -

electrode gop

odiustment,

etc. -

see Chopter 13.7.

Stqrter motor -

exqminqtion ond renewol of

brushes, etc. -

see Chopters 13.11 through 13.14.

lgnition timing, odiustment of contoct breoker

point gop, distributor lubricotion -

see Chop-

ter 15.3.

15.12 BODYWORK -

UNDERBODY

Woshing ond Mointenonce

The visible ports

of the body qre

f inislred in

o hord synthetic boking vornish, the remoining

ports in synthetic vornish.

The underbody is sproy-cooted

with o plostic

compound -

for detoiled informotion, see Chop-

ter '14.9.

Follow the

usuol procedures

when

woshing, cleoning ond polishing

the cor, ond

observe the specific instructions for

the use of

woshing ond cleoning preporotions,

issued by

their monufocturers.

All lights with the exception

of heodlomps

hove cosings of plostic

moteriols qnd

they

should be cleoned onlywith woteror shompoos.

When hosing down the corr

cover the voltoge

regulotor of the olternotor ond

the ignition coil

to protect

them ogoinst sploshing with woter,

ond do not

sproy woter direct on

the door lock

ond the lid covering the fuel

tonk filler neck.

Woshing ond Core of Underbody

Mechonisms

The underbody mechonisms

ore protected

with o synthetic vornish which stonds

well the

usuol woshing procedures.

Protect oll rubberports

ogoinst direct contoct with speciol chemi-

col solvLnts or limit the durotion of this

contoct

to o minimum before

o complete woshing off of

the solvents with woter (by

hosing down, etc.)'

Keep the oil cooler, if fitted on

the cor, in

cleon'condition. Hose

it down when woshing

the cor, ond if dirt still

sticks to the cooling

surfoces, use some of the detergents.

Bodywork Lubricotion

Routine mointenonce includes the

lubricotion

of door hinges ond limiters, hinges

ond releose

mechonismi of the engine bonnet ond boot lid,

the releose mechonism of

the spore wheel,

ond

the leveroge of windscreen wipers. Lubricotion

of inner dolor mechonisms is

included in

speciol

mqintenonce. Lubricote oll occessible mechcnisms

with

high-quolity greoses which

do not

dry, do not

oxldize, ond protect

the mechonisms ogoinst

corrosion for o long time. Oil is

not suitoble due

to its short-time efJect. Any greose con

be used

to lubricqte the

door limiters ond

the front

seot

slide roils.

Lubricotion of SporeWheel Corrier

Bearings-

Remove the spore wheel,

cleon the hinges, ond

opply oil on iheit

upper sides. In oddition, rub

in greose of ony brond.

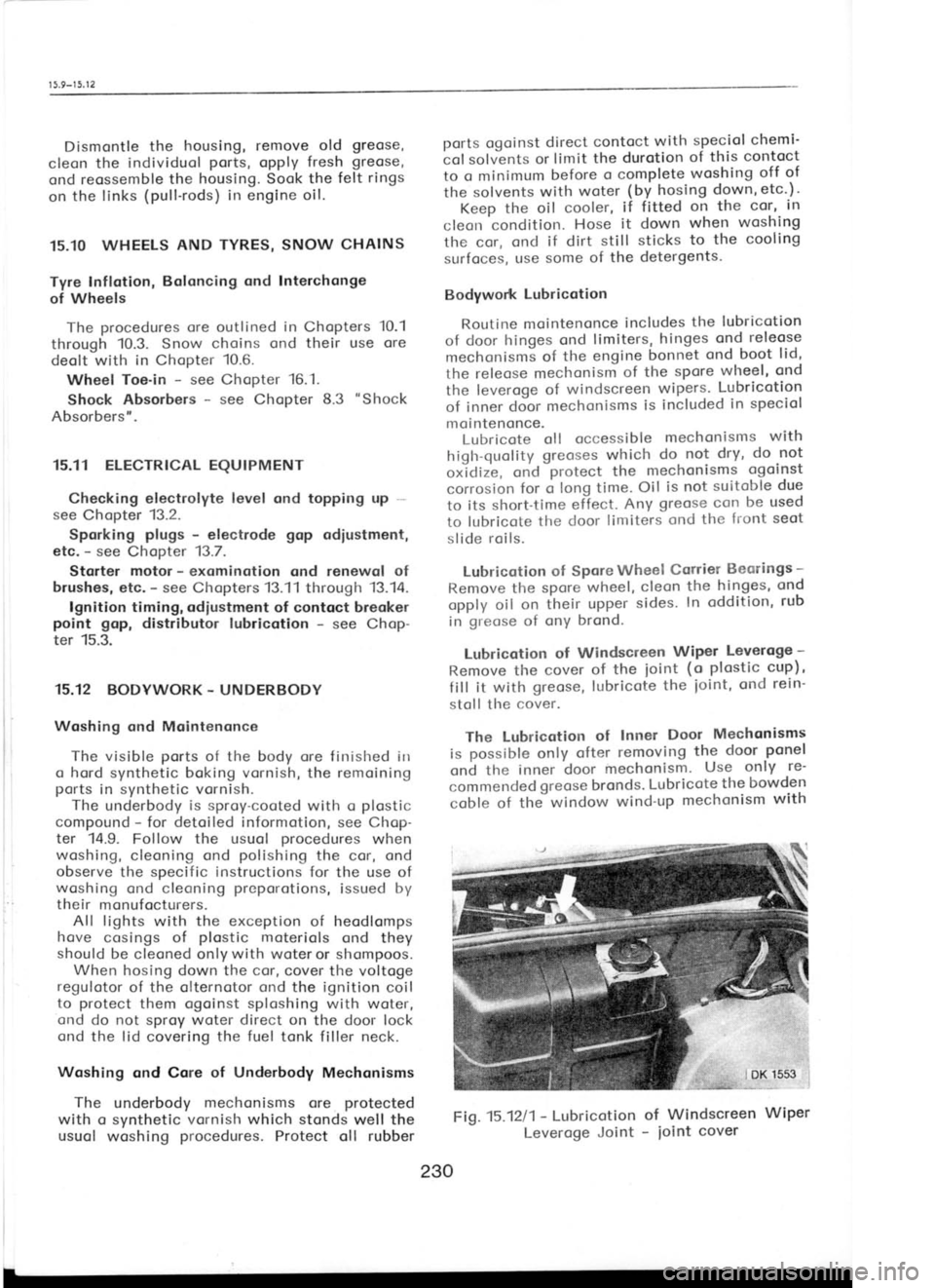

Lubricotion of Windscreen Wiper

Leveroge -

Remove the cover of the

ioint (o

plostic cup),

f ill it with greose, lubricote the

ioint, ond

rein-

stoll tlre cover.

The Lubricotion of

Inner Door Mechonisms

is possible only

ofter removing the

door ponel

ond the inner 'door

mechonism. Use

only re-

commended greose brcnds.

Lubricote

the bowden

coble of thJwindow wind-up mechonism

with

Fig.15.1211- Lubricotion

of Windscreen Wiper

Leveroge Joint -

ioint cover

230