SKODA 120 LSE 1980 Repair Manual

Manufacturer: SKODA, Model Year: 1980, Model line: 120 LSE, Model: SKODA 120 LSE 1980Pages: 238, PDF Size: 47.09 MB

Page 51 of 238

t9

:r,uorODtp 6urnno;

-lol eql qllrvt

acuoploccD ur 6ulpaacold epLllvr

palsnlpo eq uoJ .rapug;lc retllouD

lo sa^lD^

qloq

lo eouoJoelc

aql'sa1oura1;o .rapul;Ac euo,o

srrlJo JalcoJ aAlD^ eql

]o lueure^ouJ eql uaqnn

'pasolc eAlD^

aql qllr*

e3uorDalc eq1

lsnlpy 'ulJD

re)oor eql

puD e^lD^ eql

lo spuDl eql

uearv\laq

Peuosu!

e6no6 Jeleal

D esn acuoJDelc e^loA aql 6u11caqc

ro3'Arosseceu sD sJe)cor e^lo^ oql

lo u!d

llDq eql alDlor 'e3uDrDelc

e^lo^ aql

lsnlpo o1

Luru 0z'0 S1 OZL DPOIS

ruru 0z'0 urLu

EL'0 -l

ozl puo

901 DpoIS

e^lD^ lsnoqx:l e^lo^ elolul

:elqol 6uqrnr'o11o1 eql ol 6ulp.rocco

au16ua ploc

D uo ecuDroelc e^lD^

aq1

1snlpy

ecuDloalc onlDn ec!AJes

ulDrlC puD

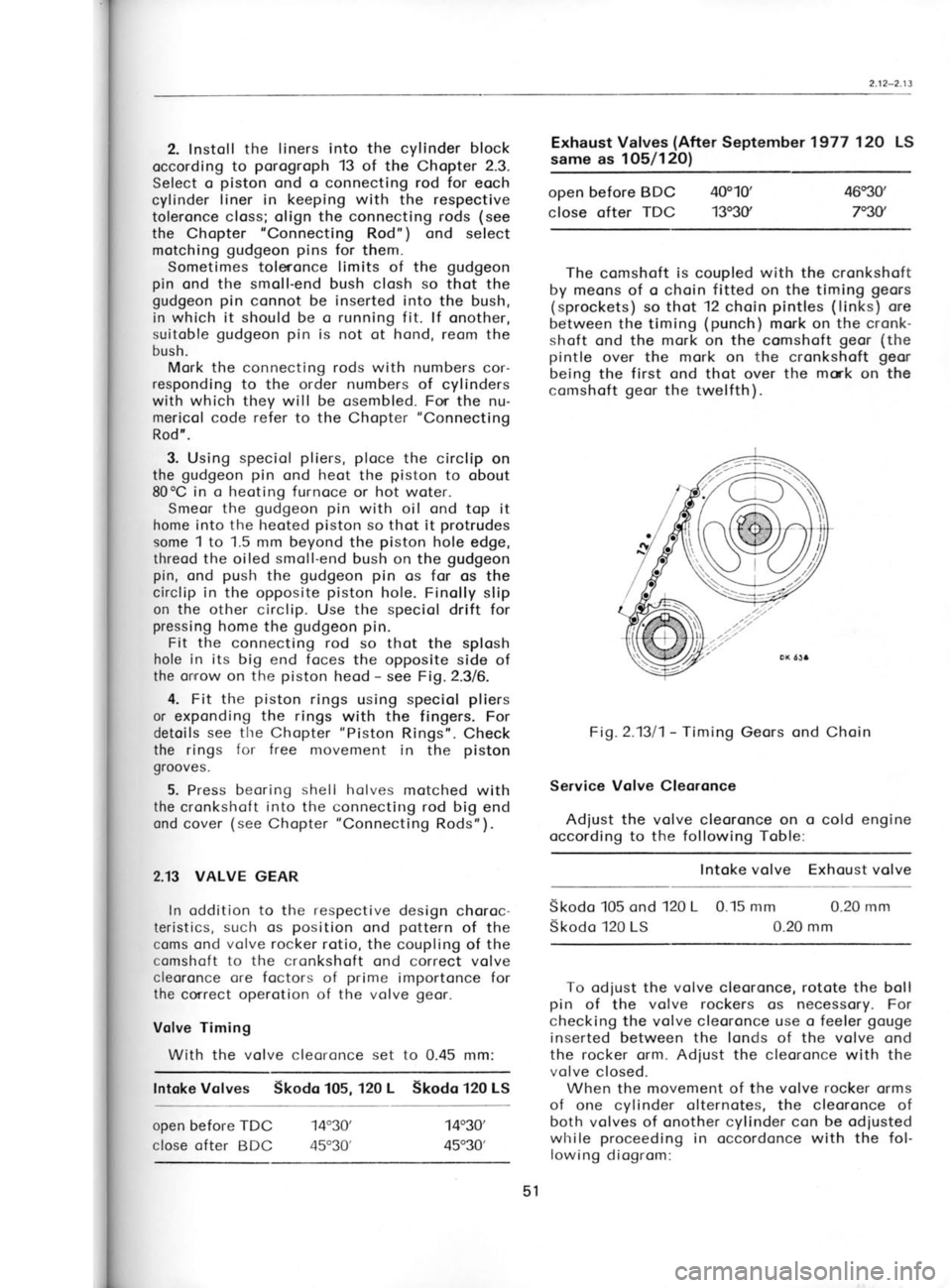

sroee 6urtu11 -LltL'Z'61)

or{r u o

r rD u e

q

},";(J -il",f

L::t i"1"'

i J,i? Tfr :;

.roe6 goqsluD.rc

eql uo

lrDlu aql

rano a;]ugd

aq1) .roe6

lloqsuoc aql

uo

lrDrx eql

puo

UDqs

-),luorc aql uo

1:ou (qcund)

6urrurl eqt uaeMloq

ero (s1u11)

segtuld urDqc

zL lDr{} os

(slelcotds)

sroa6 6u1ru!l eql uo pelllt

uroqc o

1o suoeu

lq

UoqsluDrc aqr

qllr,t paldnoc

sr

llDqsruDc eql s't

ozt DPoIs

1ozt '90t

Dpols se^lDn elDlul

:r.ur.u gt'0

ol

les e3uoroelc e^lo^ eql

qUM

6u1tu;1 en1o1

'.roa6 an;on aLtl Jo uorlolado

loellog aql

Jol ecuDuodut ar-uud

Jo sJo]ool

aro ocuoJDelc

eAIDA lceJJoc puo

lloqsluolc eLl] ol

lJoqsuoc

eql lo 6urqdnoc eql 'orlDJ

Jelool a^lD^ puo

surDc

eql lo u:eltod

puD

uotlrsod so qcns 'sorlsrJel

-JDJDqc u6rsap enrlcadsar eql ol uollrppo ul

uv39 fnlv^ tL'z

'(,,rpoU 6u11ceuuo3,, .re1doq3 aes) ranoc puo

pua 61q po.r

6uglcauuoc aql olur

llDr.ls>luoro eql

ql!r',t peLlclouJ se^loq

;1eqs 6ur.roaq

sseJd 's

^

'seAooJD

uols1d aql u!

luaua^our eaJl ro] s6u1r eql

lceqC ',,s6u1g

uols!d,, raldoq3 aLl] eas sllolep

.ro1 's.ra6u1l

sql qllm

s6ulr aq1 6urpuodxa ro

sre11d ;olcads 6u1sn s6ug.r uolsrd

aql

llj 't

'Slt'Z'6lJ eas -

poeq uolsrd sql uo /v\or,rD eql

lo spls algsoddo

eql seco' pua

6rq slr ut aloq

qsolds aqt

lDrll os

por

6ullcauuoc eql

l!l

'u1d uoe6pn6 aql auoq 6ursserd

iol lilJp logceds aql

asn 'dr1c-r1c

reqlo eql uo

d11s lgloug3 'a1oq

uols1d ellsoddo aq] ul

drlcrrc

aql sD JD] sD u1d uoe6pn6

"qr qsnd puo 'urd

uoe6pn6 aql uo qsnq pua-llDr.us pel!o

aLll poerql

'a6pe aloq uolsgd eql puoAeq

uu g'L

ol

L suJos

sepn:1o.rd 1 lorll os uolsgd

pelDeq

eq] otu! euoq

1l dDl

puo

llo qltru

utd uoa6pn6 eLl] roeus

'JalDM loq Jo acDurn]

6u11oaq p

u!

Co08

lnoqo o1

uolsrd aql

loeLl puo

u;d uoa6pn6 eql

uo d1;cr1c aql ecold 'slegld

;orceds 6urs6 'g

'.pou

6u11ceuuo3,, .ra1doq3 eql ol JeleJ epoc lDc!Jer.ll

-nu aql roJ 'pelquesD

eq 1ilrt Aaqt

qsrqM qllM

srapul;lc lo si€qunu ropro aql o1 Dugpuodsar

-roc sJequlnu qllM

spol 6urlcauuoc eql >lrou\

'qsnq

eql uroer 'puoq

lo lou s!

urd

uoa6pn6 a;qoilns

'reqlouo 11 '11;

6uluunr D

aq plnoqs

l! qcrqrlt

ut

'qsnq eql olur pauasu!

eq

louuoc u1d uoe6pn6

eql ]oql os

qsDlc qsnq pus-llous

aql puo

u1d

uoa6pn6 oql

io sl!uI!l eouD.rolol saur!leuoS

-uraq] ro; surd uoa6pn6 6urqclour

lcelos puD

(,,pou

6u11cauuo3,, :a1doq3 eql

ees) spo.r 6ullcauuoc

eql u6!lo :ssolc acuoJalol

anllcadse.r aql ql!M

6u1daa1 ur

reu!l rapu;;lc

qcDo ro' po.r

6ullcauuoc o puo

uo1sld D

lceles

'g'7 .reldoqC eLll

1o g; qdoroo.rod

o1 oulp.rocco

lcolq ropu;;Ic eq1

olul sreu!l aqt

llolsul 'Z

,0t.Et

'OtoiL ,0t"9t

,0eoDL

ccl8

rello

esolc

361 arolaq

uedo

flt"l

,0eo9? ,0Cr0L

,0Lo0?ccf

JeuD ssolc

369 a:o;aq

uado

{0/Zt lSO! se eures

ST OZ I LL61 requaldes reUV)

sa^len

lsneqxl

s c\lut

utr

r9r! x0

!

1r;6gem <

puo '1q6

jo esoql

otxDS at

eq1 1o i1

eLll lo sJ

9]!M su

u(

lDnp!^!pr

' (suo1s;d

puo (suc

' (sleleur

'uJsluDr.ls

eqt rol I

-do lce.r.r

'pasn aq

spor 6ug1

ocuDJaloi

se!lqrues

aq1 ;o t

eql lo sr

pell!l eq

uDc ssDli

lonbe ;o

SCr

ol alq!ssl qcntu sD

-!luop! or.

eql eP!^(

'polquros{

-u11lc en;

Et z-zl'z

Page 52 of 238

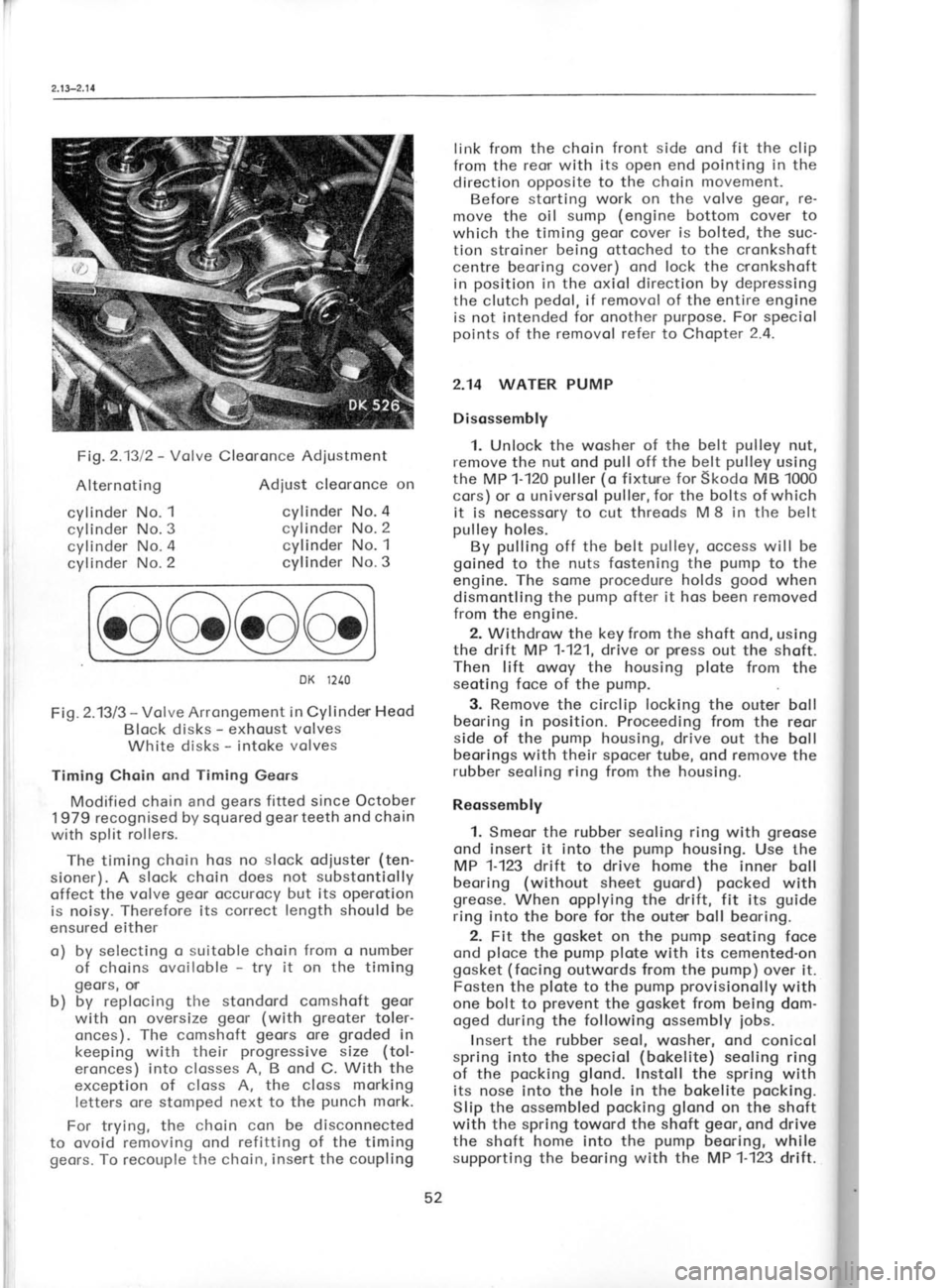

Alternoting

cylinder No. 1

cylinder No.3

cylinder No.4

cylinder No. 2 Adjust cleoronce

on

cylinder No.4

cylinder No.2

cylinder No. 1

cylinder No.3

Fi1.2.1312

-

Volve Cleoronce Adjustment link from the choin

front side ond fit the clip

from the reor with its open end pointing in

the

direction opposite to the choin movement.

Before storting work on the volve geor,

re-

move the oil sump (engine

bottom cover to

which the timing geor

cover is bolted, the suc-

tion stroiner being ottoched to the cronkshoft

centre beoring cover) ond lock

the cronkshoft

in position

in the oxiol direction by depressing

the clutch pedol,

if removol of the entire engine

is not intended for onother purpose.

For speciol

points of the removol refer to

Chopter 2.4.

2.14 WATER PUMP

Disossembly 1. Unlock the wosher of the belt pulley

nut,

remove the nut ond pull

off the belt pulley

using

the MP 1-120 puller (o

fixturre for

Skodo MB 1000

cors) or o universol puller,

for the bolts of which

it is necessory to

cut threods M 8 in the belt

pulley holes.

By pulling

off the belt pulley,

occess will be

goined to the nuts fostening the pump

to the

engine. The some procedure

holds good

when

dismontling the pump

ofter it hos been removed

from the engine.

2. Withdrow the keyfrom

the shoft ond, using

the drift MP 1-121, drive

or press

out the shoft.

Then lift owoy the

housing plote

from the

seoting foce of the pump.

3. Remove the circlip locking the outer boll

beoring in position.

Proceeding from the reor

side of the pump

housing, drive out the boll

beorings with their spocer tube, ond remove

the

rubber seoling rring

from the housing.

Reossembly 1. Smeor the rubber seoling ring with greose

ond insert it into the pump

housing.

Use the

MP 1-123 drift to drive home the inner boll

beoring (without

sheet guord) pocked

with

greose. When opplying the drift,

fit its guide

ring into the bore for the

oute,r boll beoring.

2. Fit the gosket

on the pump

seoting foce

ond ploce

the pump plote

with its cemented-on

gosket (focing outwords from the pump)

over it.

Fosten the plote

to the pump provisionolly

with

one bolt to prevent

the gosket

from being dom-

oged during the following ossembly

iobs.

Insert the rubber seol,

wosher, ond conicol

spring into the speciol (bokelite)

seoling ring

of the pocking glond.

Instoll the spring

with

its nose

into the hole in

the bokelite pocking.

Slip the ossembled pocking glond

on the shoft

with the spring toword the shoft geor,

ond drive

the shoft home into the pump

beoring, while

supporting the beoring with the MP 1-123 drift. Fig.2

4. Fit t

shoft ond

stolling th

in positior

it with gre

sheet guor

5. Top

t

lieve the r

@@@@

DK 1240

Fig.2.1313 -

Volve Arrongement in Cylinderr Heod

Block disks -

exhoust volves

White disks -

intoke volves

Timing Choin ond Timing

Geors

Modified chain and gears

fitted since October

1979 recognised by

squared gearteeth

and chain

with split rollers.

The timing choin hos no slock odiuster (ten-

sioner). A slock choin does not substontiolly

offect the volve geor

occurocy but its operotion

is noisy. Therefore

its correct length should

be

ensured either

o) by selecting o suitoble choin from o number

of choins ovoiloble -

try it on the timing

geors, o1r

b) by replocing the stondord comshoft geor

with on oversize geor

(with greoter

toler-

onces). The comshoft geors

ore groded

in

keeping with their progressive

size (tol-

eronces) into closses A, B ond C. With the

exception of

closs A, the closs morking

letters ore stomped next

to the punch

mork.

For trying, the choin con be disconnected

to ovoid removing ond refitting of the timing

geors. To recouple the choin, insert the coupling Fig.2.1t

52

Page 53 of 238

![SKODA 120 LSE 1980 Repair Manual t9

U!JC IZL-L dtA

6ugsp sDut.roeg sutoH 6u1nt.r6 -ilvLZ6lJ

IIIJQ ZZL-L dIN

6u1sn s6ulmag dun4

1n6r 6utnr:6 -tIVLZ6lJ s6ulroeq

pallolsur 1sn! aqt

lo sserls

aql o^sll

-el o] uollcaJlp SKODA 120 LSE 1980 Repair Manual t9

U!JC IZL-L dtA

6ugsp sDut.roeg sutoH 6u1nt.r6 -ilvLZ6lJ

IIIJQ ZZL-L dIN

6u1sn s6ulmag dun4

1n6r 6utnr:6 -tIVLZ6lJ s6ulroeq

pallolsur 1sn! aqt

lo sserls

aql o^sll

-el o] uollcaJlp](/img/3/57425/w960_57425-52.png)

t9

U!JC IZL-L dtA

6ugsp sDut.roeg sutoH 6u1nt.r6 -ilvL'Z'6lJ

IIIJQ ZZL-L dIN

6u1sn s6ulmag dun4

1n6r 6utnr:6 -tIVL'Z'6lJ 's6ulroeq

pallolsur 1sn! aqt

lo sserls

aql o^sll

-el o] uollcaJlp

lDlxD slr ut

uoqs eq1 do1 'g

'ap!slno (eco.r 11oq) p.ron6

leaqs

sl.! q]lrvr

aluoq 6u1.rrooq eql a,^116 'asDar6

qtlm l!

pe4cod 6u1noq .ra1;o dr1c.r1c

sqt ql!tr,'

uo;1;sod u1

6ulroeq eql Icol '6ur:oaq

llDq retno aql 6u!llols

-u! ro] CZL-L d4 llrp aql

uro6o esn puD

Uoqs

aq] uo eqnl .recods Euuoaq

llDq sqr

rll 't

1}!J(l LZL.L dIA

6u1s6 UoqS dLund

1n6 6urn1.16 -ZlvL'Z'6tJ

Mern lDuo!1cag -

dun6

'll'ru pup

io plD

eql qltM

uo11lsod ut

l! lcol

lleq eql aruoq

do1 'Aonrr^el

s]! u!JeqsoM

eql

puo 'Ae11nd

Ia1 aq1

1;1 'rluP

tzl

ellqrvr'6t

3A!JP Pur

uDqs aql

'6u11cod

q11m 6u1

6u11 6ug1

loc!uoc I

'sq(

-uop 6u1

qtrM Allo

'1r reno (

uo-Pelue

eco; 6u1

'6u1.ro

epgn6 s1

qllM Pe

llDq Jaul

aql asn asoarb q

eql s^ou iloq eql

JosJ eql

llDq relr

eql uIoJ

'lloqs at

6ugsn'pt

peAotxoJ

uaqM p(

eql ol (

aq lllM I

ltaq eql

qc!qM lc

0001Bl/\ 6u1sn Ae

'1nu Ia;1

'i''

gogceds

eugDue i

6ugsse.rc

]lDt{sIul uDqslur

-cns eql

ol Je^oi

-a: 'toof

'lu3

aql ut 6

dglc eq1

Page 54 of 238

6.

Complete the pump

ossembly by fitting

the

Stouffer lubricotor filled with

the recommended

greose.

2.15 ROCKER SHAFT AND ROCKERS

Assembly (on

Skodo 105 engine)

1. Instoll the lock ring, ploin

wosher, ond

spring wosher on the ro6ker shoft

with both

ends plugged.

Smeor the shoft with oil, fit the

rocker (with

its orm with the thrust foce de-

flected toword the next ossembled ports),

the

shim, the rocker support, ond the other

orm

def lected toword the support, i. e. the complete

rocker unit of cylinder

No. 1.

2. Then slip the spring,

the rocker, the sup-

port, the shim,

ond the next rocker, i.e.

the

complete rocker unit of cylinder

No.2, on the

shoft.

3. Threod on the spring ond, using the mirror

orrongement of the ossembled

rocker units,

instoll the rocker

units of the remoining

two

cylinders. Use o lock ring supplemented

with

o ploin

ond o spring wosher

to lock the os-

sembled ports

in position.

The rocker support of the cylinder No.4 must

be provided

with on oil hole

to provide

for the

supply of oil to the rocker shoft.

4. Compress

the springs

by holding down the

rocker orms ond lubricote

oll loterol contoct

surfoces with oil.

Assembly (on Skodo 120 L

ond 120 LS engines)

The rocker shoft is provided

with two od-

ditionol rocker supports fitted from

the outside

of the rocker units (the

shoft is longer), re-

plocing woshers obutting

on the lock rings.

For

the rest, the ossembly is identiccl

with the pro-

cedure described in porogrophs

1 to 4 obove.

NJote: Rocker orms

on the Skodo 120 LS en-

gine ore shorter (18.5

mm) thon those on the

Skodo -120

L ond Skodo 105 engines,

in order

to obtoin o higher rotio.

Disossembly

Remove the lock ring from the shoft

end ond

strike off the

entire volve nocker geor

from

the

shoft.

2.16 CYLINDER HEAD, VALVES

AND

SPRINGS

The cylinder heod is o costing of speciol grey

cost iron. The volve seots ond guides

ore cost

ond mochined directlv in tlre heod. The volves ore of different

diometers, the intoke volves

being lorger. Outer (exhoust)

ports

ore single,

oll remoinlng ore doubled, i.e. bifurcoted

ond

bronching to two volves in odioining

cylinders.

The centre exhoust port

bronches to the cyl.

inders No.2 ond 3, the neighbouring

intoke port

to the cylinders No. 1 ond 2, ond No. 3 ond 4.

The cylinder heod con be hondled

in the cor os

o unit. Of the individuol

iobs, only

the reploce-

ment of volve springs,

cotters, ond cylinder

heod bolts con be corried out with the engine

in. position in the cor. For oll the remoining

iobs, the

cylinder heod hos to be removed

from

the cor.

To remove

the volve springs,

screw out

the

sporking plugs ond, using o tommy

bor with

o curved end (steel

bor of obout 5 mm dio-

meter), broce

the volve to prevent

it from

sliding down into the combustion

chomber.

To Remove

Cylinder Heod from Engine

1. Let

the engine cool down before removing

the cylinder heod to preclude

worping of its

beoring surfoce.

2. Droin

the coolont into o cleon vessel (see

Chopter 15.13), detoch oll ports

connecting the

cylinder heod to the vehicle,

ond remove

oll

ports which ore likely

to obstruct the removol.

3. Remove the oir cleoner,

lift owoy

the

cylinder heod cover, ond remove

the nuts ond

bolts holding down

the cylinder heod (on

en-

gines of Skodo 120 L

ond 120 LS cors, two

bolts olso hold down

the end rocker

shoft sup-

ports) reversing the order of the numbers

in-

dicoted in Fig. 2.1611.

By pulling

the exhoust

monifold, disengoge the

cylinder heod ond lift

it owoy.

To Refit Cylinder

Heod on Engine

. 1.

Locote the cylinder heod gosket

on o per-

fectly cleon surfoce of the cylinder

block (cleon

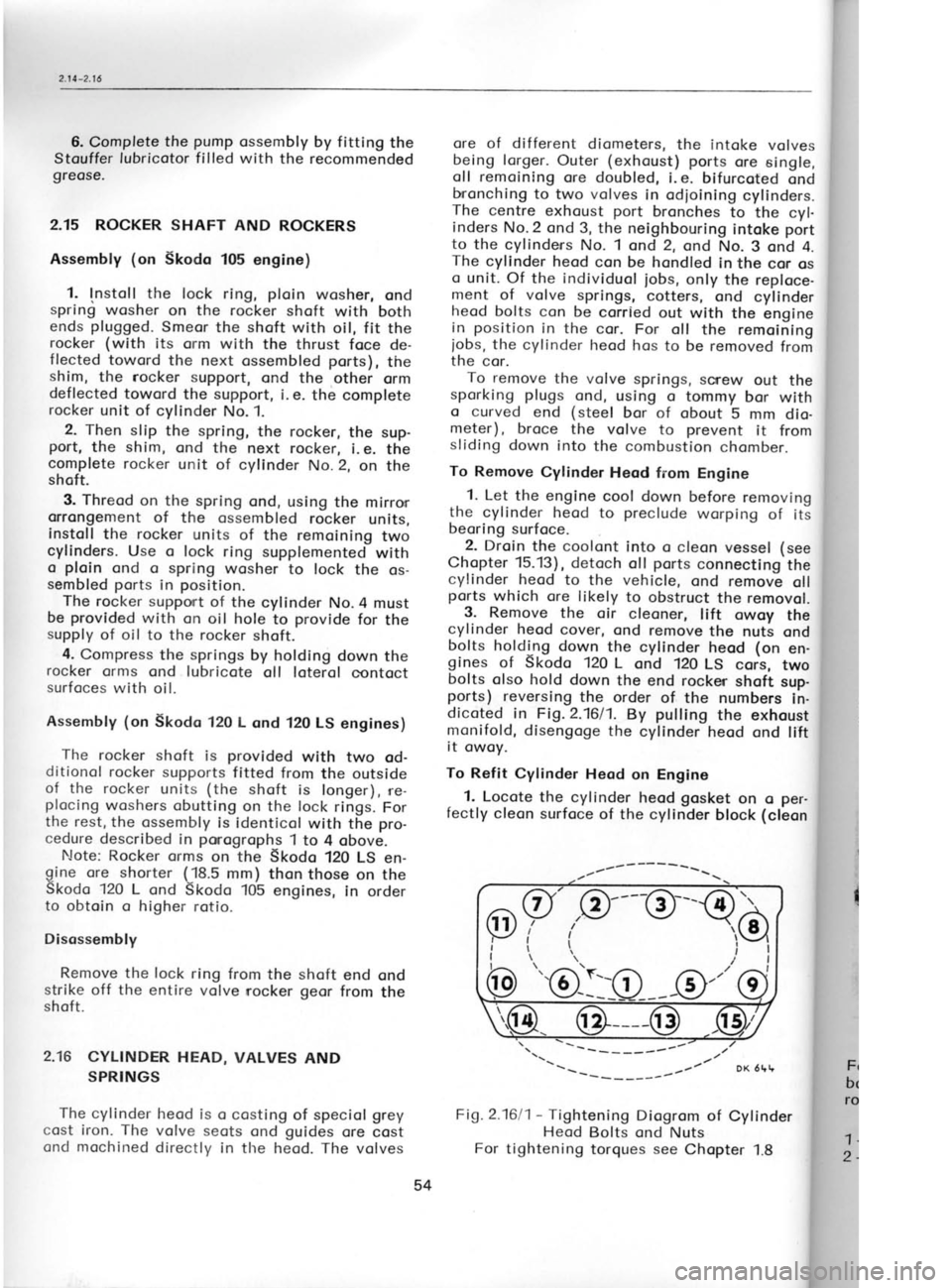

Fi1.2.1611- Tightening Diogrom of Cylinder

Heod Bolts ond Nuts

For tightening torques see Chopter

1.8 the

cylinc

the oilwo,

structed c

Releose

once odjur

heod. lf nr

the rocker

2. Swin<

down the

porogroph

opply the

liminory o

the sequ€

(Fig. 2.16/

shoft suppr

3. Adjus

ter 2.13,

re

cleoner, rer

tighten oll

Cylinder Hr

Disossem

heod on o r

o support i

it does

not

o iob from

t

An exomple

1. Remove

the cosing

control, end

geor ofter

supports.

Fig.2Je

For holding

c

bolt M 8 scrt

rocker-shoft st

1 -

MP 1-113

v,

2 -

MP 1-114

v

Itl

I

I

/\.

-

( 3 r--{ 4)

\-/

\II

l

/

,/

t___v'

?,3

"'@-:lO

54

Page 55 of 238

![SKODA 120 LSE 1980 Repair Manual 99

Zt qdDr6DrDd

tZ .ra1doq3 ees -

sulqs puD

sJeLlsDM q]!M

s11oq 6u1sn sJe)cor qllm

elelduoc

Uorls Jelcor

eq] uMop

lloq puo1.roddns

eql ul eloq aql

otru! srrelue q16ue1

lloq er!lu SKODA 120 LSE 1980 Repair Manual 99

Zt qdDr6DrDd

tZ .ra1doq3 ees -

sulqs puD

sJeLlsDM q]!M

s11oq 6u1sn sJe)cor qllm

elelduoc

Uorls Jelcor

eq] uMop

lloq puo1.roddns

eql ul eloq aql

otru! srrelue q16ue1

lloq er!lu](/img/3/57425/w960_57425-54.png)

99

'Zt qdDr6DrDd

't'Z .ra1doq3 ees -

sulqs puD

sJeLlsDM q]!M

s11oq 6u1sn sJe)cor qllm

elelduoc

Uorls Jelcor

eq] uMop

lloq puo'1.roddns

eql ul eloq aql

otru! srrelue q16ue1

lloq er!luo

eLl]

llll i11q611s

l:oddns oql atolor '({lddns

lto rol oloq

pelllrp

D

qlgm {lqoralerd)

}.roddns sq+ ut oloq aq} otul

reqsDM L1llrtt

lloq eql

uesul 'l.roddns

UDqs-Je)cor

eq+ ol 11o 6u;pae1 Aorrrrllo eql

]o 1u;od eql u1

pDeq repullio eqt uo

1a1so6 aqt ecold'g

'so^lDn eq1 uado o]

suels a^iD^

eql uo 6u11;.r1s rtq 6u11co1 lceJroc .ro1 sa1o1d

6u1ugo1er 6u1.rds aql

lcsqc puo

e1o;d yoddns

orll ulorl pDeq

repu!1Ac eql enourei 's6ur.rds

11o

peull 6ugnog 'o^lDn

aql uo peppeq

Altcarroc

a^Dq selloq relloo

eqt JeqleqM 6u;1ceqc

ol!qM

{1gn;aroc 6ugrds eqt esDaleU'a1o1d 6u1ugo1ar

qcoe u! se^lDq Jralloc a^lD^ oMl

1nd puo

s6ul.rds

aq] sselduoc 'rana1

eq1 6u1s1-l 'lloq

oql uo re^ol

',LL-L dl^ eLll uMop Mercs

puD

sa^lD^ eql re^o

sepld 6u1u1o1ar Jlaq] qllM s6u1.rds dtts 'l

'sburrdg an;en a;6urS Sl OZ I LL6l o3urS.

'alDld

lroddns SLL-L d6 aqt uo seAlDA

popl] qllrlt pDaq

rapugl{c eqt ecold '1sa1

eDoloel oq} rsUV 't

'(sqdo.r6o.rod

Jequnl aql eas s.rlode: puo '6u11se1 'u;-6u;pu1rD

,ro;) e6o>1oal rol loeqo puD pDaq

.rapu1;Ac eqt

u! uoql lllar 'slDos

ug-puno.r6 rlsr.ll qtlM

sa^lo^

eql 6utqclD14 'i1q6no.roq1

(s1rod eql qllM) pDaq

lapullAc aq1 puD

so^lo^ eLll uoalc:6u!ltrtlor

lcerJoo Jol

uraql

lJDur .ro .rap.ro

gou16!Jo

Jloql ul

eplsD uaq] 1nd puo

uelll oAouJaJ 'sanlD^

all] u!-

-punol6 6u1noq reUV 'lDos

oql ql!M

poaq

a^lD^

eqt u!-pu!16 puo

(punodtuoc)

alsod 6u1pu;"16

qtlm lDos o^lD^ aq]

]DoC 'sapln6

lca.uoc ,rgaq1

u! uaq] llDlsul ol

arns aq 'se^lo^

pesn 6u9111;e"r

uaqM 'ap1n6

e^lD^ aql u! e^lo^ eqt

llDlsul 'Z

's:edo.rcs puDq Jo 'lprp

puoq D u; 6u1dtuo1c .!ol

luDqs D

q]!M

edAl

lsrp

aql lo {1qo.ra1a.rd 'seqsnJq

a.rgan 6u1sn .ro (:a.rn1

-cDlnuDru roLll

lo suo!lcnrlsul

luaugl.red aql 6u!

-nrasqo) s1ue6o

lDc!rueqo q11m

sllsodep uoqrDc

eloueu 'dol

uo sJaqruDtlc uorlsnqtuoc

aql qllln

Utg;Z '6r3

ees) Uoddns eql olu!

poaq

repur;[c

pe:roder puD peuoe;c

Al1ce;red eq] ocDld 'l

spto]luDl l puo pDoH

repu;149

;o rtlquressoay

.sapgn6 r!aLl] ul uaql 6u!lll;e.r

uaqan dn uaql xlru ol lou sD os

[!eq]

)rrotr.t Jo

-rep.ro 1ou16!Jo J!eql

u!

aplsD se^lD^ eql

lnd

'e1o1d 6u1u1o1e.r 6u1rds

eql uoJl so^lDrl Jslloc 3^lD^

Llloq MDrpql!nn

'6u;.rds e^lD^ oql sserduoc ol l! esn

puo'1.roddns

UDqs-relcor aql

uMop plaq

Ilsnolne.rd q3!qM

lloq 3ql uo ra^al

tLL-L dy\l aql uMop Marcs 't

'6u;.rds aql 6ulsoalai rauo sriequDLl3

uo!lsnq

-r.uoc oql olu! uMop 6ulpggs tuor+

uaql

luenerd

puo sellD^ eql

l:oddns sJeq[lDLlo uo!]snquoc

eql otul 6u1pn.r1o.rd suo;1ca!o.rd sll 'tLL-L

dlA

alogd Ouryoddns sql uo pDaq

oql ecDld 'Z rane; 6u1p!l e^lo^

VLL-Ldtl1-Z

a1o;d 6ugl.roddns enlon

SLL-L d4 -

L

pDoq aLll tuorl

tuLu gg

er.uos 6u1pn.r1od puo

lloddns UDqs-JalcoJ

eql rol aloq eql u! uMop peMerss g

l l iloq

ILo;;;xno aql esn 'Je^al

eql ur*op 6u;ploq roJ

s6u1.rdg a^lDn 6uttrtleg -

elgL'Z'6lJ

'sl.roddns

Uot.1s-Jelcor eq}

pelloqun

6ug,roq ra11o

roe6

JalcoJ e^lDA aJrlua aql ionro

1111 puD 'loJluoo

arnlorcdual c!lolsoLUraLll aql

lo 6u1soc

aqt

'sp1o;1uoru elDlut puD

lsnoqxe eql e^oueu'l

'llgL'Z '6ll ul uMoqs sr alduoxe uy

'rsquroqc uollsnquoc eq]

+o epls aqtr

uor; qo!

o

6u1op uoqM slloq pnls

aLll uo

lseJ lou seop

l!

tDql os

poeq

eql ecold o1 qclqM

u1 poddns

o

oIDu ol elqDs!^pD s! ll 'q3ueq

lroM D uo

posq

:apu;1Ac oql elquessDor puD

alqurassDsrC

A;quressoslC pDeH

repu;;,tg

'slulo! peua)cDls ;1o uelqDrl

puo 's1.rod

pelcauuooslp llD tcauuoceJ 'JouDelc

rD eql 'Jenoc

pDeq repull{c aql

l!}er 'tL'Z

Jel

-do,{C lad so eouDrDalc a^lD^ aq} }snlpv .g

'uog11sod ur lcol puo

s1:oddns

UDqs

-raloor pauolcols eq1 ua1q61lau'(L/91'Z'6lJ)

uollDJlsnll! eql u! pelDclpur

acuanbas eql

sl:osqo 6ulualq6!l

lDurl sD

llelvr sD fuou1ur;

-erd eql ro1 'enbrot

6utuetq6!] llnl aql llddo

uaql 'I11q6!l

ruaql ua1q6r1 puo

(62 qdorDorod

'g'7 raldoq3 eas) slnu puo

slloq eqt uMop

MeJcs 'spolqsnd

aq] olu! sre)oor aql 6u!ms 'z

'sl:oddns UDqs-ralcor aql

1o 6u1ue1sol

eql uesool os;o 'i.rosseoeu

,l 'pDeq

aql uo Jeloo: srll

llDlsur puo

(lueLulsnlpo acuo

-roolc anlon :o1) surd

1;oq ral3ol

aq] esDeled

'lcolq repu;1Ic aql lo llDM rDer eql uo

pelcnlls

-qo lou s! sJalcor

eql ol

;to 6urpaa; [onn;go eql

loql aJns elDu.r

puo

(11ar* so pDeq

repu!;lc aqr uoagc) >1co1

-:ed o uo l

8'L

rel,

repur;{3

rr9 Io

]l!l PUD p0

lsnoqxe or

-u! sJequn

-dns goqs

o/!,\l 'sJDc

-ue uo) po

PUD Slnu

(

eql ^DMo 'lDAOIUoJ el

llD e^ouroJ

eq1 6urlcer

ees) lesser

s11 1o 6u1r

6urnouer e

ou

'JaqrrDq

LuoJ, +! lr

-D!P tutlr

I

q11r,r roq /

aql lno M

LuoJ' PaAOU

6ulugoue.r

aul6ue eqt

rapullAc p

-ecolder eq

so Joc orll

't puD t'o

pod e>;o1u1

-1Ac aqt ol

'srepul;[c I

puo pepcJ 'e16ugs em

ss^lD^ elo

Page 56 of 238

The rocker-shqft

support hos o poper

seol

preventing leokoge of the oil fed from the cyl-

inder block to the rockers vio the support. lf

o reody-mode seol (gosket

) is not ovoiloble,

moke it yourself

using poper

0.1 mm thick.

A thicker seol

is unpermissible os it

would

couse c distortion of the rocker shoft. The hole

in the seol

must coincide with the oil hole

of

the rocker.

Apply the seol

ond ref it the

exhoust ond in-

toke monifolds. For detoils see

Chopter 2.3.

porogroph 30.

6. Reinstoll the thernrostotic temoeroture

control cosing with its gosket

ond do not forget

to put

spring woshers under the nuts.

Note: When reossembling

the cylinder heqd

of on engine removed

from the cor, it is odvis-

oble to proceed

with the

iobs os

per

porogroph

5 ond 6 with the cylinder heod refitted

on the

engine to focilitote

the tosk.

lf the cylinder heod gosket

hos been reploced

with o new one, invite the customer to bring in

the cor ofter

trqvelling 500

to 1,000 kilometres

for o retightening of the cylinder heod ond

odiusting of the volve cleoronce. 3. To ensure o leokproof

cond ition of the

volves, grind

them in

with their seots

in the

cylinder heod.

Volve GuideS The volve guides

ore formed directly by the

cylinder heod motericl. lf reconditioning

is

necessqry, rebore the guide

hole ond press-fit

o bush.

Volve guide bushes ore not ovoiloble os

sporre ports. They

con be mode

individuolly oc-

cording to the following drowing. The

required

moteriol is grey

cost iron of 200

N/mmz (2O

kpl

mm2) tensile strength, in

Czechoslovokio cost

iron to specificotions of theCzechoslovokSton-

dord CSN 422421.

Hoving press-fitted

the bush, correct ony

shrinkoge of the inside diometer ond, to motch

the new guides, rrecondition

the volve seots

ond grind-in

the volves.

DK 1+J6 Fig.2.16l

To Recon

These

volves fo

groph 3),

new volvt

Use o

conicol sr

with its r

1. Che

necessory

volves. F

shonk of,

eter, ond

will result

ing in ocr

seot widtl

Check 1

occordinq

Coot the"s

volve in tl

troces of

centre of t

2. Coot 1

volve with

of oil with

volve into

seot ond

1

severof tin

onother po

round the I

volve ond

grinding-in

the volve

c

grey. Use

down the v

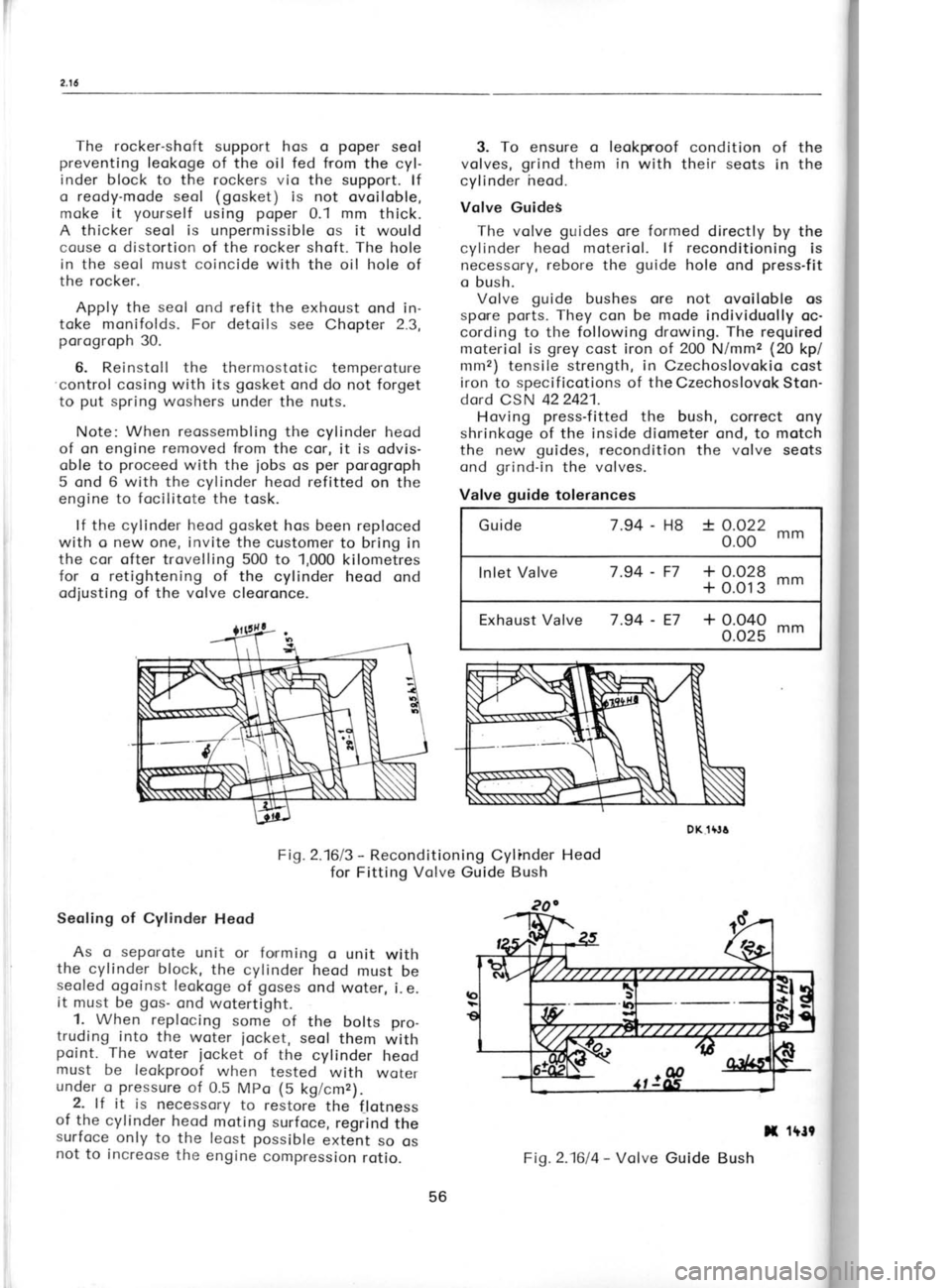

Fi1.2.1613

-

Reconditioning Cylinder Heod

for Fitting Volve Guide Bush

Seoling of

Cylinder Heod

As o seporote unit or forming

o unit with

the cylinder block,

the cylinder heod

must be

seoled ogoinst leokoge

of goses

ond woter, i.e.

it must be gos-

ond wotertight.

1. When replocing

some of the bolts pro-

truding into the woter

iocket, seol

them

with

point. The woter

iocket of the

cylinder

heod

must be leckproof

when tested with woter

under c pressure

of 0.5 Mpo (5

kg/cm2).

2. lf it is necessory

to restore the flotness

of t-he cylinder heod

moting surfoce,

,egiind

the

surfcce only to the leost possible

exte-nt so os

not to increose

the engine

compression rotio.Valve

guide

tolerances

Guide 7.94 -

HB +

O.O22

o.oo mm

lnlet Valve 7.94 -

F7

t 9 9?q .n-

+ 0.013

0.025

56 Fi1.2.1614

-

Volve Guide Bush x

1Tr9

Page 57 of 238

![SKODA 120 LSE 1980 Repair Manual L9

Irrol uMop-ssard

-

t

eca1d pua Jaqqnr -

7 1-roddns

-

L

.r;y pessetdruo3

qlt/t^ lssl e6o1oa1

e^lon -

UgLz6lJ

suoglo:adg ;o acuenbes -

rallnC 6ut11ty11 o

6u1s11 ]DaS e^lon

6u SKODA 120 LSE 1980 Repair Manual L9

Irrol uMop-ssard

-

t

eca1d pua Jaqqnr -

7 1-roddns

-

L

.r;y pessetdruo3

qlt/t^ lssl e6o1oa1

e^lon -

UgLz6lJ

suoglo:adg ;o acuenbes -

rallnC 6ut11ty11 o

6u1s11 ]DaS e^lon

6u](/img/3/57425/w960_57425-56.png)

L9

Irrol uMop-ssard

-

t

'eca1d pua Jaqqnr -

7 '1-roddns

-

L

.r;y pessetdruo3

qlt/t^ lssl e6o1oa1

e^lon -

UgL'z'6lJ

suoglo:adg ;o acuenbes -

rallnC 6ut11ty11 o

6u1s1'1 ]DaS e^lon

6uruo111puocal -

979;'7'6;1

"fLr,e 'u1-6u1pu;.rD

6u1.rnp e^lo^ aql uMop

6u1p1oq .ro; dnc unncDl rsqqnr o esq 'Ie$

llnp urro,lun

o eq

lsnu lDes oLll

puD

a^lo^ eql

qloq lo seco; 6u11ou eql 'arnpaco.rd

ur-Bugpu1r6

eql lo sllnser sql Jo,

l! lcadsul puo

e^lD^

aql e^oural /!\oN 'acueJalunsrlc

aAIDA eql punot

llD aJnpaco.rd s1q1

loeder puD

uo!l!sod .reqlouo

olu! punor

a^lDA eql a^ou ueql 'sarrJll

loJe^os

orl puo

o1

11 6ugu.rnl Aq u1

1g pu1.r6

puD pes

s11 lsugo6o e^lD^ erll sserd 'ep!n6

s11 o1u1 anlon

eql Uesu! puo

({reue po}ool}

au!} q}tM

lto lo

arnlxlru) punoduoc

6u1pu1.16 eu!] o qllM

a^lD^

eql Io esDllns

lDcluoc oql

ro

lDes aql

lDoc'z

'o^lDA aql lo ocDlrns

lDcluoc aq]

lo s4u3c

eql u! pecnpordel

eq

lsnur lDes aql

lo socoJl

aql 'sIJDru

lcoluoc ulDlqo o1

loes eql u! eAlD^

eql ls!lvr] puo

lugod 6u1>;.rotu

r.ll!M

loes aql

tDoC

'poeq a^lD^ eql uo sIrDtx

loDluoc o1 6ulp.rocco

lDes aql

lo qrpl/v

PUD relerilolp sql

lcaqc

'sreilnc 6ug11gtu .raqlo 6ugsn qlplM

loes

eql ocnpar 'glgL'z'6ll

qrtr,r acuopJocco u1 6ut

-peaco:d 'MoN

'lDes

eq1 6uguap!M u!

llnsor lllM

Bulssalp slql 'lDas

e^lo^ aql sse;p puo 'le1e

"ruolp enlo^ aLltr o1 spuodsaxoc qclqM

lo luotls

aql 'Joqlo

uD uo lellnc el6uo uD

1!l 'sellD^

aq] lo 6u;prn6

lceJJoc D e:nsuo

o1 'l:ossaceu

l! 'sepgnB

s^lD^ eql r!odar puD

IOeqC '!

'e^lo^ anllcadse; sll qllm

u1-punor6 oq louuDc lDos eql

l! ocolJns

lDcluoc

aql Du;uolllpuocel lol Jellnc

6u111tut D

osn

'sepln6 enlon 6u1uolltPuoca; JoUD Jo 'sa^lD^

Meu

6ulUt' ueqM 'ep!rvr

ool erD slDas aql

;1 '(g

qdol6

-orod ees) 1se1 aOolosl

oql

ssod ol

llol sellon

eqr ll i.tosseceu

etuoceq

suo11o:ado esgql

so^lDn u!-Pu!19 puD

slDes e^lDn uolllPuocou ol

uo!ltsod

rounC 6ut1tn -

toes e^lDn

6uttltn -

9l9L'Z'6lJ 6trrl

ll

slDos aA

qclDtu ol

Iuo lce.

-uDls lo/

]sDc DlIl

Ft oa)

z

perlnbe.t

-co [g1on

sD alqDl

11;-sse:d s! 6u1uc

aql Iq I

s I

'e6o1oe1

rol eAlD^

-ued enoq Aotu

t! tlclqM

punoduroc 6u1pug.16 eq1or.ll

lcetlc puD 'polDJla

u! sl.rod aql tuoll oslD

elouel Alq6no:oq1 eql

at{i

,O6

Page 58 of 238

2,15-2.'t8

3. The

leokoge test should

be corried out with

the cylinder heod fully ossembled by pouring

o smoll quontity

of petrol

into the exhoust ond

intoke ports.

The petrol must not leok post

the

moting foce of the volve

in the combustion

chomber. Another method involves pouring

o smoll omount of thin oil into the combustion

chomber ond introducing compressed oir into

the exhoust ond intoke ports

using, for

exomple,

o rubber

cone. No oir bubbles must oppeor

oround the volve heods.

This test con be simplif ied by omitting the

fitting of vclve springs while pressing

the

volves into their seots by hond using o suitoble

Jixture (fork)

for holding down the volves.

Volves The volves

ore forgings of speciol high-tem-

peroture steel with o conicol seoling surfoce

ond ho,rdened stem end. The

volve heods ore

of unequol diometers (lorger

with intoke volves

ond smoller with exhoust volves).

Current reconditioning

of the conicol seoling

surfoce is done by grinding-in

with the respect-

ive seot. lf o mojor repoir is required,

regrind

the seoling surfoce

of the volve heod

on

o grinding

mochine to on ongle of 91 o

+10',

ond then grind

it in with the seot.

When regrinding the conicol surfoce, it is

obsolutely essentiol to keep it in

correct olign-

ment with the volve stem.

Valve Springs

rcs/po1201S

Outer Inner

Free Length 45.85

43.645.20

Wire 3.75 2.5

Diameter 4.OO

Mean Spring 26.75

18.5 26.5

urameter

T

Spring Pres-

sure

I nstal led

length L""En-I

3Omm Length

Length

30mm 29mm

299-358 N108-127N

460N hondle)

ond the short oil pumP,

to the cost oil

sump the 330 mn-r long dipstick ond

the longer

oil pump -

see Chopter 2.18.

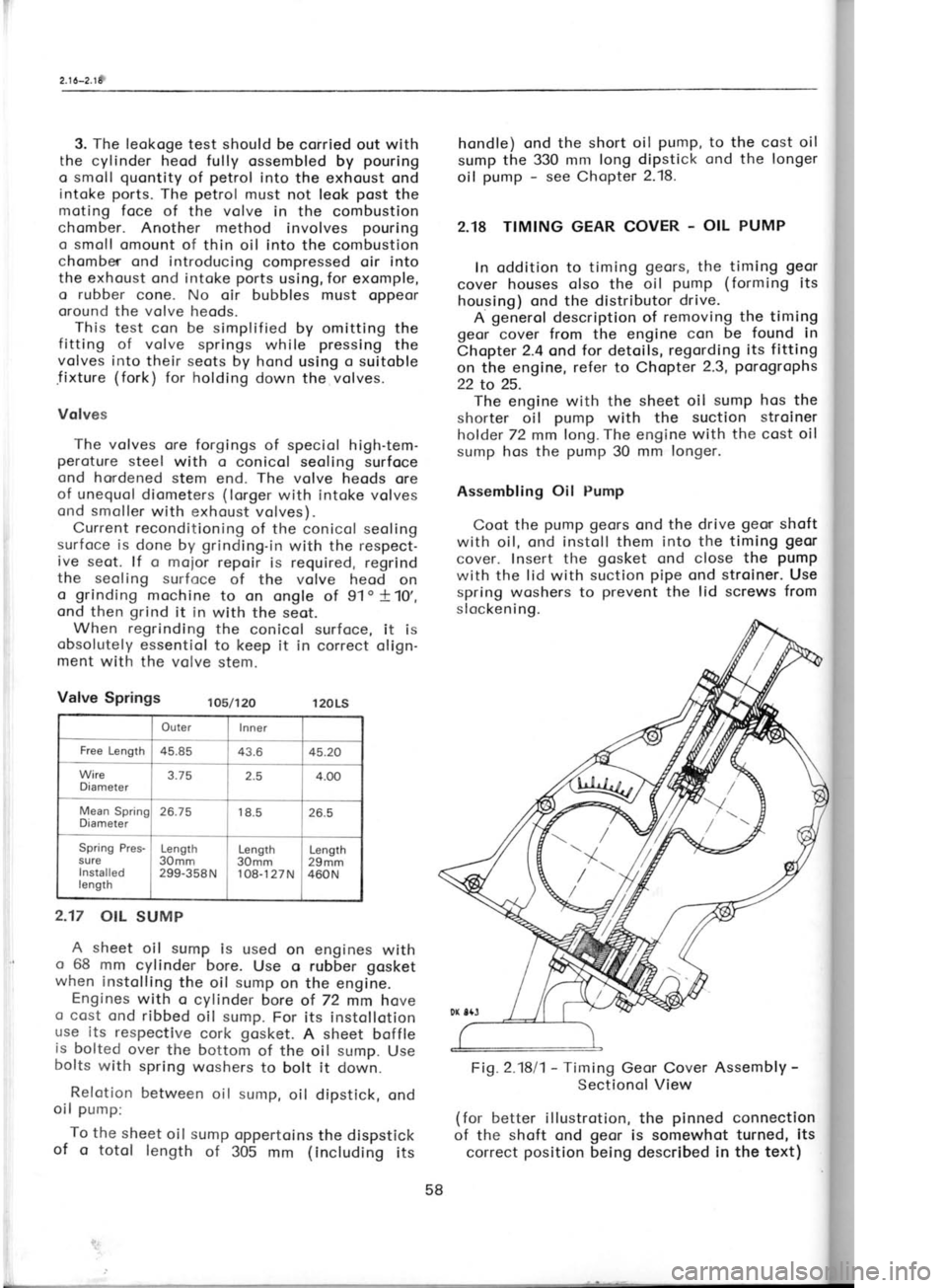

2.18 TIMING GEAR COVER .

OIL PUMP

ln oddition to timing geors,

the timing geor

cover houses olso the oil pump

(f

orm ing its

housing) ond the distributor drive.

A generol

description of removing the timing

geor cover from the engine con be found in

Chopter 2.4

ond for detoils, regording its f

itting

on the engine, refer to

Chopter 2.3,

porogrophs

22 to 25.

The engine with the sheet oil sump hos the

shorter oil pump

with the suction stroiner

holder 72 mm long. The

engine with the

cost oil

sump hos the pump

30 mm longer.

Assembling Oil

Pump

Coot the pump geors

ond the drive geo'r

shoft

with oil, ond instoll them into the timing geor

cover. Insert the gosket

ond close the pump

with the lid with suction pipe

ond stroiner. Use

spring woshers to prevent

the lid screws from

s lcrcken ing.

Fi1.2.1811- Timing

Geor Cover Assembly -

Sectionol View

(for better illustrotion, the pinned

connection

of the shoft ond geor

is somewhot turned, its

correct position

being described in the text)

2.17

OIL SUMP

A sheet oil sump is used on engines with

o 68 mm cylinder bore.

Use o rubber gosket

when instolling the oil sump

on the engine.

Engines with o cylinder bore of 72 mm hove

o cost ond ribbed

oil sump. For its instollotion

use its respective

cork gosket.

A sheet boffle

is bolted

over the bottom of the oil sump.

Use

bolts with spring woshers to bolt it

down.

Relotion between oil sump,

oil dipstick, ond

oil pump:

To the sheet

oil sump oppertoins the dispstick

of o totol length

of 305 mm (including

its For

egi

stroiner v brrocket r

65 mm), 1

(the leng

proximott

The go

provides

geors. lf

gosket is

thicker tl" To prer

obnormol

respectivr

limits spr

Seol F it

the

t ig hte

n in1

thot it pr

edge of tl

Assemblir 1. Thre

brocket, s

pointing r

odio.4c in the pr

bore (pin

the pinne

When c

sure thot

line with

is importr

ignition d

To prev

ing durin

o pilot

m<

Then con

using o sr

2. After

ensure tl'

0.1 mm) I

3. Fit t

into the f

under the

Betwee

driven

I driven

I Axiol

c

I betwee

I and lid

58

Page 59 of 238

![SKODA 120 LSE 1980 Repair Manual 69

Jeuoels Jlo eql rspun

eloll eql qonorql

pelue^

u|DDD sr lequoqc

toolj

eql PUD sesolc

e^lo^ 6ullua^-JlD eql ,seeJ6sp

gL

q6norql I a6Dls

lo lslp elllorqt

eqt

lo 6uruado

aLl] rVe:eqd SKODA 120 LSE 1980 Repair Manual 69

Jeuoels Jlo eql rspun

eloll eql qonorql

pelue^

u|DDD sr lequoqc

toolj

eql PUD sesolc

e^lo^ 6ullua^-JlD eql ,seeJ6sp

gL

q6norql I a6Dls

lo lslp elllorqt

eqt

lo 6uruado

aLl] rVe:eqd](/img/3/57425/w960_57425-58.png)

69

'Jeuoels Jlo eql rspun

eloll eql qonorql

pelue^

u|DDD sr lequoqc

toolj

eql PUD sesolc

e^lo^ 6ullua^-JlD eql ,seeJ6sp

gL

q6norql I a6Dls

lo lslp elllorqt

eqt

lo 6uruado

aLl] rV'e:eqdsotulo eq] olu!

JequtDqc

tool+

at{} uroJl sedocse Jlo puD

enlon 6u11ua^-lD eq}

suedo a6olene; o '1

e6o1s lo lslp aluorql eql

;o 6ursogc

sql JoUV 'JeuDelc

JtD eql lepun ro^oc

aql u! aloq enllcedse.r

aql qOno.rq]

lequDqc

lool' sr.ll

r.uol1

sadocsa JtV 'pautDUD

st la^al

pa1;gceds aql ueqM e^lDA etpeau oq} sasolO

qclqm looll ot{} Aq

1q6req auDs eql

}D paurol

-ulouJ s!

le^al sl!

eJaH 'JequDqc

lDoll eql olul

e^lD^ elpeeu eql puD

JeulDrls

len' aq1

q6norql

sessod renoc

eql qDno.rqt

pallddns

lenJ

Grc;Z puo

L16L'Z 'sOtJ)

requrorlC lDolJ

'se6o1s qloq lo sauoc

Jezrurolo aql

;o s1.rod

lsemorrDu eql uorl

s1a! r1o Iq pa;1ddns

a.lnssard:epun Iq pelDnlco

ur6otqdolp eql lq

palloJluoc JeqUnl puD

pelcolun

{lgocguor.loaur

s! ll uo11;sod qctqM

ut'sael6ap gy

q6norqr

pauedo soq

I e6o1s

lo a^lD^

aluorql oql rellD

6u11o.redo suDls

lt 'unJ

alpr A:orpxno;o urelsis'o

puo 'ualsls

ssod-Aq o '6urpoo;

aul6ua .raq6rq

:o; ualsis urDU eql

lo slsrsuoc

a6o1s srql

{vrc;z '6;1)

lr e6o1g

'pool

eul6ue lln, Jol

aJnlxrul eql

lo 6urqcuua

eLll sD

lleM sD

6u1poo1 aul6ue eqt jo

uod loa.r6 D

puD

'uollDJelecco '6u11p1

Jol ernlxrr! qc;.r

Alalonba

-pD uo

lo Alddns

sq] sernsue e6ols slq_L

1 e6olg

SIUVd 1VNOIICNNJ JO A3NUNS ONV

swSrs^s uouSun8dvc Jo NotrcNnJ

'Aanrns 6urrrtol;o1 eql ul pe111cads

sluaulsnlpo

luaJalllp Iluo

anoq Aaql 'slepour

rDc lDnpt^tpul

aql Jol pasn

o:o sadAl

.rollaJnqJDc e[!DS eq1

'sl!ur !|

pepueuruoceJ eql o1 elqolsnlpo

s!

lueluoc epr

-xouotu uoqroc eql'peads 6ullpt

1y'6urpoog

eu16ua aql ol 6ulp.rocco (unncon)

e.lnsse:drepun

lq llgocrlouolnD pellorluoo

sr

1; e6o1s ';opad

JoloJalecoo eqr lq pellorluoc

s! unr eu16ue

olsDq eql :o1

I e6o1g 'se6ols

oMl Jo 6u11s1suoc

adll lq6noJp-uMop eql

lo s! rollernqroc

eLlI

uo11d!rcsoO lDc!uqceI 'spoeq

MerJS aq] Jepun

sJaqsDM 6u1.rds 6u1sn :anoc loe6

6uru11 eql olul

1a1so6 sll r{l!M

alelduoc

}a)corq eq}

ilJ 't

'UDqs eql puD

.roa6

aql ueeMteq (,utu

l'0

tnoqo) ocuoJDelc

lDrxD urnuJ!u!ur

eql eJnsue

ol lloqs a^lrp oq]

uo

do1 '6u;uu1d

rellv 'Z

'arnlxll elqDllns o 6ursn

Alquesso percdard

snql eql sse.rduoc uaql

'lolcDJq aql olu! palresur

eq ol

lajpuDrrj lol!d D

alDrlr ol

olqosr^pD s!

l! '6u

r111.rp 6urrnp 6u1

-6uoqc uror] uolysod palsnlpo

aq1

luanard o1

'rolnq!rlsrp uo11;u6;

oql jo

luarulsnlpo requnt Auo ro1

luol.rodrur sr

ll 'lols

poeq uor.ls eql

lo s!xD eq]

q]!M

eurl

ug s1 rcaD aql ul saroq eq+

Io slxD eql

lDql erns

aq :aq1e6ol

lloqs puo

roe6 eql 6ulllrrp

ueqg

'uo!]ceuuoc pauurd aql

er'nces ol

1 qoullc puD

(OZxV 'orp

urd) aroq

eq] olul u1d o

Uasul 'selorl

palllrperd eq] ul

UDqs puD

.roe6 eql reqtaBol

lllrp 'lltrp

t 'D!p

D

6u1sn 'puo 'le)cDrq

eql uoJl

spJDMtno 6uglurod

qlaal oql qlgrt

.roe6 uJoM aql uo drls 'le)corq

rolnqrrls!p aql olu!

uDqs eqt

pDerql'L

lelcorg rolnq!rls!6

6u;lquessy

'aroq eq] 1o e6pa

aplsul oql Molaq Luu

Z lnoqD sapnrlord

l! loql

os puD

ra^oc eql aplsul peurnl

u11 6u;ue1q611

sl! rlllM eJoq esol

luort aql

lo loas eql

llj

lDes

:elqol 6ulrvro11o; aq] ul pal11ceds

sl;tu11

aq] ulr,llllvr 1da1 eq

lsnur sacuo:oa1c antlcadse.r

eLl] 'aclnJss

ur dtund eql

lo e6o>goel

lDrlrrouqo

ol enp a:nsse.rd llo lo ssol D apnlcard

o1

'ruru L'0 uoql Jals!rll

lou.radod ruor;

l! aloLu'alqDl!D^o

s!

1a>;so6

eulnue6 ou puD pacolda:

aq ol soq

1r 1g 's.roa6

aql Io eouDrDalc

1o1xo pa:1nbaJ

eql lo; sapl,rold

s.roe6 durnd eql

,o pll

eql repun

1e1so6 aq1

'(A1a1ou1xo:d

-do rur.u gg;

6ugaq

laIOD.rq aql

,o q16ua1

eq1)

laq61q sdtuns

l!o lsoc qllr"r

sau!6ue Jot '(tuttt

gg

euos s! Uod e:luec

sll

u!

PolnsDeul lalsoiq

eql lo t{}6ua1 aq})

roMol

s!

P!l aq}

q}!M reulDrls

uollcns eq] 'duns

po leaqs D

qllM

seul6a ro3

z'o

0L'0 sL'0 9t0'0

8SL'0

Pll

puD

s:oe6 dund ueeMleq

ecuoJDels lolxv

rL0'0

090'0 roa6 uenlrp

puD u!d ueeMls8

6ulroaq sl! puo

lloqs a^!rp

uae/v\la8

U

0

uru.l I tutu

JDSM lecuDJDelcl ecuDlDelc

unulxo141 | 6uguun6

6t'?-9t'z uolrfunSuvc

6L'z (lxeg

e

sl! 'pouJ

uo!lcouu

- Algur

rroJl sM€

esn 'Jau!1

durnd aq

:oe6 6u1t

uDqs .!oer

l!o lsoc e

JauloJls

eql sDq (

sqdo.r6o:r

6utrrtl stl

u! punol

6u;u;1 eq

s11 6u1u:

.roe6 6u1u

dNn,

.rabuol eq llo lsoc e

Page 60 of 238

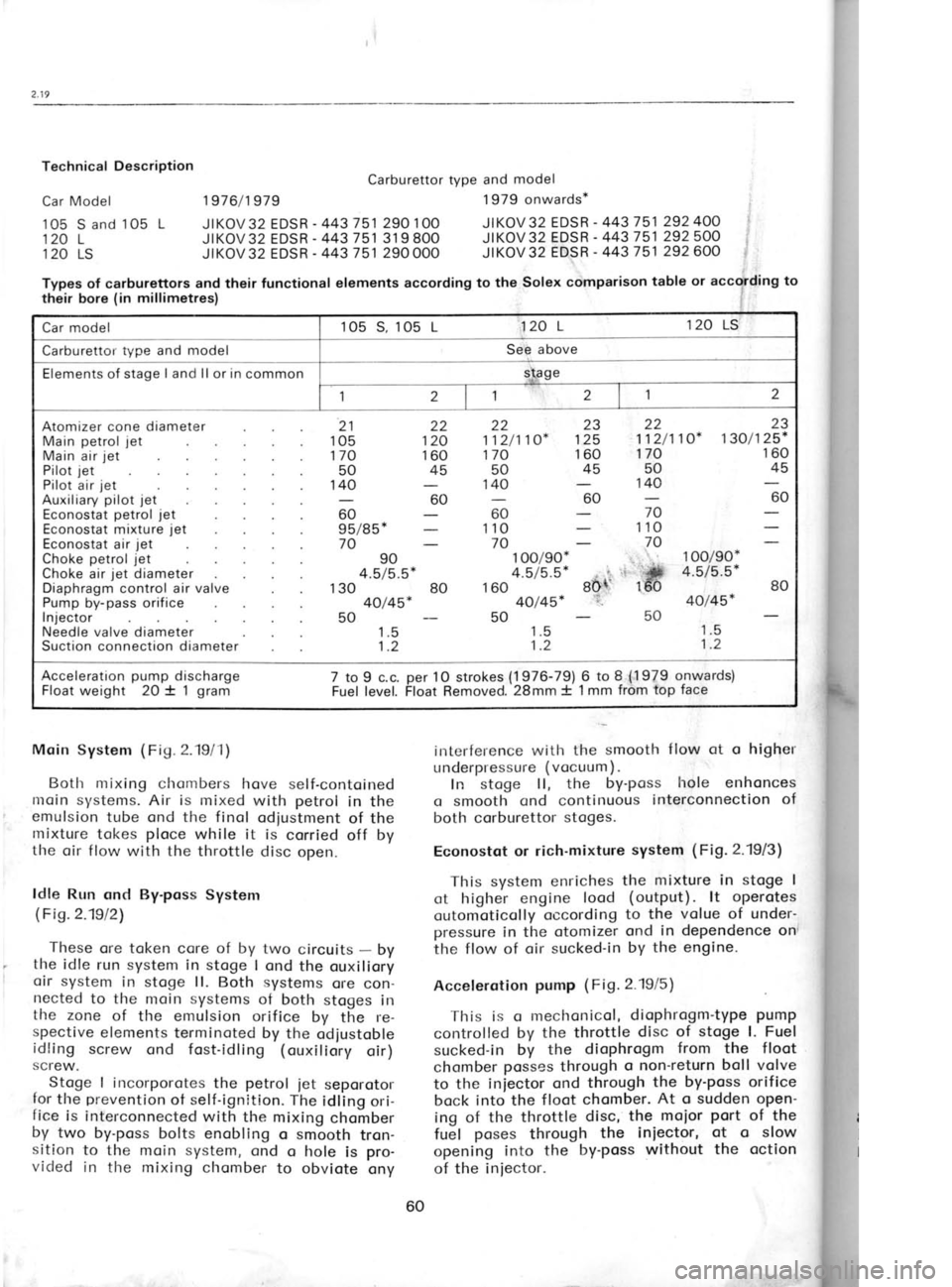

Technical

Description

Car Model 1976/1979 Carburettor type

and model

1979 onwards*

105

120 120 S

and 105 L

L

LS

Types of carburettors and

their functional elements according to

the,polex cdnparison table

or

their bore (in

millimetres) JlKOV32 EDSR

-

443751 290 1

00 JlKOV32 EDSR -

443751 292400

JrKOV32 EDSR -

443751 31 9 800 JlKOV32 EDSR -

443751 292500

J|KOV32 EDSR -

443751290000 J|KOVg2 EnFF -

443751 292600

to

;1

Car model 105S, 1O5L

itZOr- '

l2OLs:

Carburettor type and model Se.B

above

Elements of stage I and ll or in

common

Fge

1 2

1

2

t

2

Atomizer cone diameter

Main petrol jet

Main air jet

Pilot jet

Pilot air jet

Auxiliary pilot jet

Econostat petrol jet

Econostat mixture jet

Econostat air jet

Choke petrol jet

Choke air jet

diameter

Diaphragm control air valve

Pump by-pass orifice

Injector

Needle valve diameter

Suction connection diameter 21

105 170

50

140

60

95/85'70

90

4.5/5.5*

130 40/45*

50 1.5

1.2 22

1 12/1 10*

170 50

140

60

110

70 1 00/90*

4.5/5.5'

160 40/45*

50 22

23

'.112/110*

130/125*

170 50

140

1Orygo*

4.5/5.s*

.80

40/45*

22

120

160 45

1.5

1.2

1,5

1.2 23

125

160 45 160

45

60

Jo

70

1'to

70

50

Jo

*erF

or"fs?

,.w'1'

80

Acceleration pump

discharge

Float weight 2O t 1 gram 7 to 9 c.c.

per

1O strokes (1976-79)

6 to 8.$19f9 onwards)

Fuel level. Float Removed.'28mm t'1mm frEm bp

face

Moin System (Fig.

2.1gl1l

Both mixing chombers hove self-contoined

moin systems. Air is mixed with petrol

in the

emulsion tube ond the finol odiustment

of the

mixture tokes ploce

while it is corried off by

the oir flow with the throttle disc open.

ldle Run ond By-poss System

(Fis.2.19l2l

These ore token core of by two

circuits -

by

the idle run system in stoge I ond the ouxiliory

oir system in stoge ll. Both systems

ore con-

nected to the moin systems

of both stoges in

the zone

of the emulsion orifice

by the re-

spective elements terminoted by the odiustoble

idling screw ond fost-idling (ouxiltory

oir)

screw.

- Stoge

I incorporotes

the petrol

iet seporotor

for the prevention

of self-ignition. The

idling ori-

fice is interconnected with the mixing

chomber

by two by-poss bolts enobling

c smboth tron-

sition to the moin system,

ond o hole is pro-

vided in the mixing chomber to obviote

onyinterference

with the smooth flow ot o hlgtler

underpressure (vocuum).

.

ln stoge ll, the by-poss hole enhonces

o smooth ond continuous intgrconnection

of

both corburettor stoges.

Econostot or rich-mixture syste4

(Fig. 2.19/3)

This system enriches the

mixture in stoge I

ot higher engine lood (output).

lt operotes

outomoticolly occording to the

volue of under',

pressure in the otomizer ond

in dependence onf

the flow of oir sucked-in by

the engine.

Accelerqtion pumP

(Fig. 2.19i5)

This is o mechonicol, diophrogm-type

PumP

controlled by the throttle disc of

stoge

l. Fuel

sucked-in by the diophrogm from the floot

chomber posses

through o non'return boll

volve

to the iniector ond through the

by'poss orifice

bock into the floot chomber. At o sudden open-

ing of the throttle disc,

the moior part

of the

fuel poses

through the

iniector, ot

o slow

opening into the by-poss

without the oction

of the iniector.

60